Inclusion analysis in magnesium free-cutting steel

-

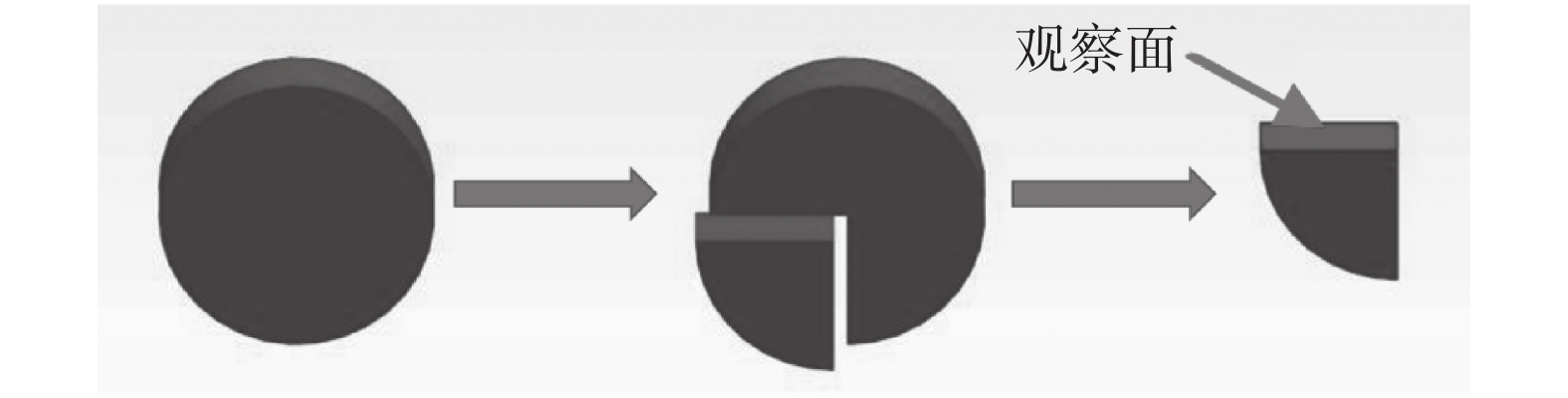

摘要: 为了探究Mg处理对易切削钢中夹杂物的影响,以1144高硫易切削钢为试验钢种,采用金相和能谱仪等手段研究了Mg处理对1144易切削钢中夹杂物的形态、尺寸分布和夹杂物成分的影响。结果表明:在易切削钢铸坯中,Mg处理使得易切削钢铸坯硫化物夹杂由Ⅱ类向Ⅲ类、Ⅰ类转变,分布更为均匀,同时使得复合硫化锰夹杂物比例提升。在轧材中,使得钢中夹杂物球化,并且钢中硫化锰夹杂物的尺寸和分布也得到了较好的改善,同时,Mg处理能够有效提高易切削钢的切削加工性能。Abstract: In order to explore the influence of Mg treatment on inclusions in free-cutting steel, 1144 high-sulfur free-cutting steel was used as experimental steel, and the influence of Mg composite treatment on the shape, size distribution and inclusion composition of free-cutting steel 1144 was studied by means of metallography and energy spectrometer. Experimental results show that in the free-cutting steel slab, due to Mg treatment sulfide inclusion changes from class Ⅱ into class Ⅲ and class Ⅰ, and becomes more uniform distribution, at the same time the amount of composite MnS inclusion increases. During rolling the inclusion becomes spheroidization, and its size and distribution of manganese sulfide inclusions has been improved. It is concluded that Mg treatment can effectively improve the machining performance of studied free cutting steel.

-

Key words:

- free cutting steel /

- MnS /

- inclusion /

- Mg treatment

-

表 1 1144易切削钢试验钢种成分要求

Table 1. 1144 test steel composition requirements for free cutting steel

% C Si Mn P S 内控指标 0.43~0.47 0.18~0.25 1.45~1.52 <0.025 0.24~0.30 目标 0.45 0.22 1.47 0.27 表 2 夹杂物统计数据

Table 2. Statistics of inclusions according to its size

传统工艺 新工艺(Mg处理) 夹杂物平均面积/μm2 夹杂物等效直径/μm 夹杂物密度/(个·mm−2) 夹杂物平均面积/μm−2 夹杂物等效直径/μm 夹杂物密度/(个·mm−2) 中心 13.909 3.873 1169 16.412 4.245 1101 1/4处 16.858 4.091 1211 18.065 4.334 1065 边部 16.431 4.395 864 16.343 4.10 695 表 3 铸坯中夹杂物类型统计

Table 3. Statistics of inclusion types in billets

类型 对比炉 试验炉 个数 比例/% 个数 比例/% 单纯MnS 564 97.2 553 93.9 复合夹杂物 16 2.8 36 6.1 Al-O-MnS复合硫化物 14 2.5 0 0 Mg-Al-O-MnS复合硫化物 2 0.3 10 1.7 Mg-Al-Ca-Si-O-MnS复合硫化物 0 0 26 4.4 表 4 轧材A类夹杂物评级结果

Table 4. Results of grade inclusions of rolled steel

炉次 对比炉次 试验炉次 细系长度/μm 细系评级 粗系长度/μm 粗系评级 细系长度/μm 细系评级 粗系长度/μm 粗系评级 1 2690 5.5 1647 4.0 2110 4.5 1317 2.5 2 2291 5.0 2434 5.0 2682 5.5 890 2.5 3 2206 4.5 1569 4.0 2369 5.0 1167 2.0 4 2108 4.5 1741 4.0 1 999 4.5 1719 4.0 5 2296 5.0 1658 4.0 2537 5.0 1690 4.0 6 2845 5.5 1562 4.0 2431 5.0 1795 4.0 7 3341 6.0 2292 5.0 2606 5.0 1322 2.5 8 2911 5.5 2242 5.0 2766 5.5 1564 4.0 表 5 切削试验参数

Table 5. Parameters of cutting test

进给量f/(mm·r−1) 切削深度aq/mm 转速w/(r·min−1) 0.19 1 180 0.19 1 560 0.09 1 560 0.09 1 1200 -

[1] Yang Wen, Yang Xiaogang, Zhang Lifeng, et al. Review of control of MnS inclusions in steel[J]. Steelmaking, 2013,29(6):71−78. (杨文, 杨小刚, 张立峰, 等. 钢中MnS夹杂物控制综述[J]. 炼钢, 2013,29(6):71−78. doi: 10.3969/j.issn.1002-1043.2013.06.017 [2] Yu Zhe, Liu Chengjun, Min Yi, et al. Experimental study on inclusions control of resulfurized free cutting steel[J]. Iron Steel Vanadium Titanium, 2017,38(3):140−144. (于哲, 刘承军, 闵义, 等. 含硫易切削钢夹杂物控制试验研究[J]. 钢铁钒钛, 2017,38(3):140−144. doi: 10.7513/j.issn.1004-7638.2017.03.025 [3] Li Guozhong,Wang Fuming,Hui Rong,et al. Effects of sulfur addition methods and Ca-Si treatment on the microstructure and properties of 30MnVS[J]. International Journal of Minerals Metallurgy and Materials, 2009,16(6):650−653. [4] Wang Deyong, Xu Zhou, Qu Tianpeng. Effect of Mg addition on inclusions and solidification structure in low carbon microalloy steels[J]. Steelmaking, 2017,(5):12−18. (王德永, 徐周, 屈天鹏. 镁处理对低碳微合金钢中夹杂物和凝固组织的影响[J]. 炼钢, 2017,(5):12−18. [5] Jiang Guanghui, Gu Longjian, Shi Zhe, et al. General situation and trend for free-cutting steel[J]. Sichuan Metallurgy, 2006,28(5):10−14. (蒋光辉, 古隆建, 施哲, 等. 易切削钢现状与发展趋势[J]. 四川冶金, 2006,28(5):10−14. doi: 10.3969/j.issn.1001-5108.2006.05.004 [6] Lv Ming, Wang Bo, Wang Deyong, et al. Control performance of nonmetallic inclusion in molten steel using Mg-treatment[J]. Steelmaking, 2014,30(5):1−4. (吕铭, 王博, 王德永, 等. 镁处理对钢中非金属夹杂物的控制效果[J]. 炼钢, 2014,30(5):1−4. [7] Xiao Guohua, Dong Han, Wang Maoqiu, et al. Effect of Mg/Ca-treatment on morphology of sulfide in non-quenched and tempered steel[J]. Iron & Steel, 2011,46(4):65−69. (肖国华, 董瀚, 王毛球, 等. 镁和镁钙处理对非调质钢中硫化物形态的影响[J]. 钢铁, 2011,46(4):65−69. [8] Tian Xiangsheng, Zhu Longfei, Lin Hao, et al. Effect of trace magnesium treatment on inclusion and microstructure of cast low carbon steel[J]. Journal of Materials ence and Engineering, 2017,3:489−493, 484. (田祥省, 祝龙飞, 林浩, 等. 微镁处理对铸态低碳钢中夹杂物和组织的影响[J]. 材料科学与工程学报, 2017,3:489−493, 484. [9] Guo Zhenhe, Deng Liqin. Effect of Mg and Ca treatment on inclusion and fatigue properties of wheel steel[J]. Baosteel Technology, 2016,(4):16−20. (郭振和, 邓丽琴. 镁钙处理对车轮钢中夹杂物及疲劳性能的影响[J]. 宝钢技术, 2016,(4):16−20. doi: 10.3969/j.issn.1008-0716.2016.01.017 [10] Zhou Yahui, Lin Hao, Tong Lianhai, et al. Effect of magnesium treatment on inclusions and microstructure of low carbon steel[J]. Hot Working Technology, 2016,45(9):31−34. (周亚辉, 林浩, 仝连海, 等. 镁处理对低碳钢中夹杂物和组织的影响[J]. 热加工工艺, 2016,45(9):31−34. [11] Lu Pengyan, Wu Huajie, Yue Feng, et al. Effect of calcium treatment on change behavior of inclusions in sulfur-containing non quenched and tempered steel[J]. Steelmaking, 2015,31(2):30−35. (陆鹏雁, 吴华杰, 岳峰, 等. 钙处理对含硫非调质钢中夹杂物演变行为的影响[J]. 炼钢, 2015,31(2):30−35. [12] Shao Xiaojing, Wang Xinhua, Jiang Min, et al. Effect of heat treatment conditions on shape control of large-sized elongated MnS inclusions in resulfurized free-cutting steels[J]. Isij International, 2011,51(12):1995−2001. doi: 10.2355/isijinternational.51.1995 [13] Jiang Zhouhua, Zhuang Ying, Li Yang, et al. Effect of modification treatment on inclusions in 430 stainless steel by Mg-Al alloys[J]. Journal of Iron and Steel Research(International), 2013,20(5):6−10. doi: 10.1016/S1006-706X(13)60089-8 [14] Wang Xiaohong, Xie Bing, Feng Zhongyu. Present status and development of research on free cutting steel at home and abroad[J]. Special Steel, 2005,(4):26−28. (王小红, 谢兵, 冯仲渝. 国内外易切削钢的现状和研究进展[J]. 特殊钢, 2005,(4):26−28. doi: 10.3969/j.issn.1003-8620.2005.04.008 [15] Wang Yvnan, Bao Yanping, Wang Min, et al. Smelting process and machinability of BN-type free cutting steel[J]. Journal of University of Science & Technology Beijing, 2013,35(7):869−874. (王毓男, 包燕平, 王敏, 等. BN型易切削钢的冶炼工艺及其切削加工性[J]. 北京科技大学学报, 2013,35(7):869−874. -

下载:

下载: