Thermal parameters measurement and application of TA1 industrial pure titanium

-

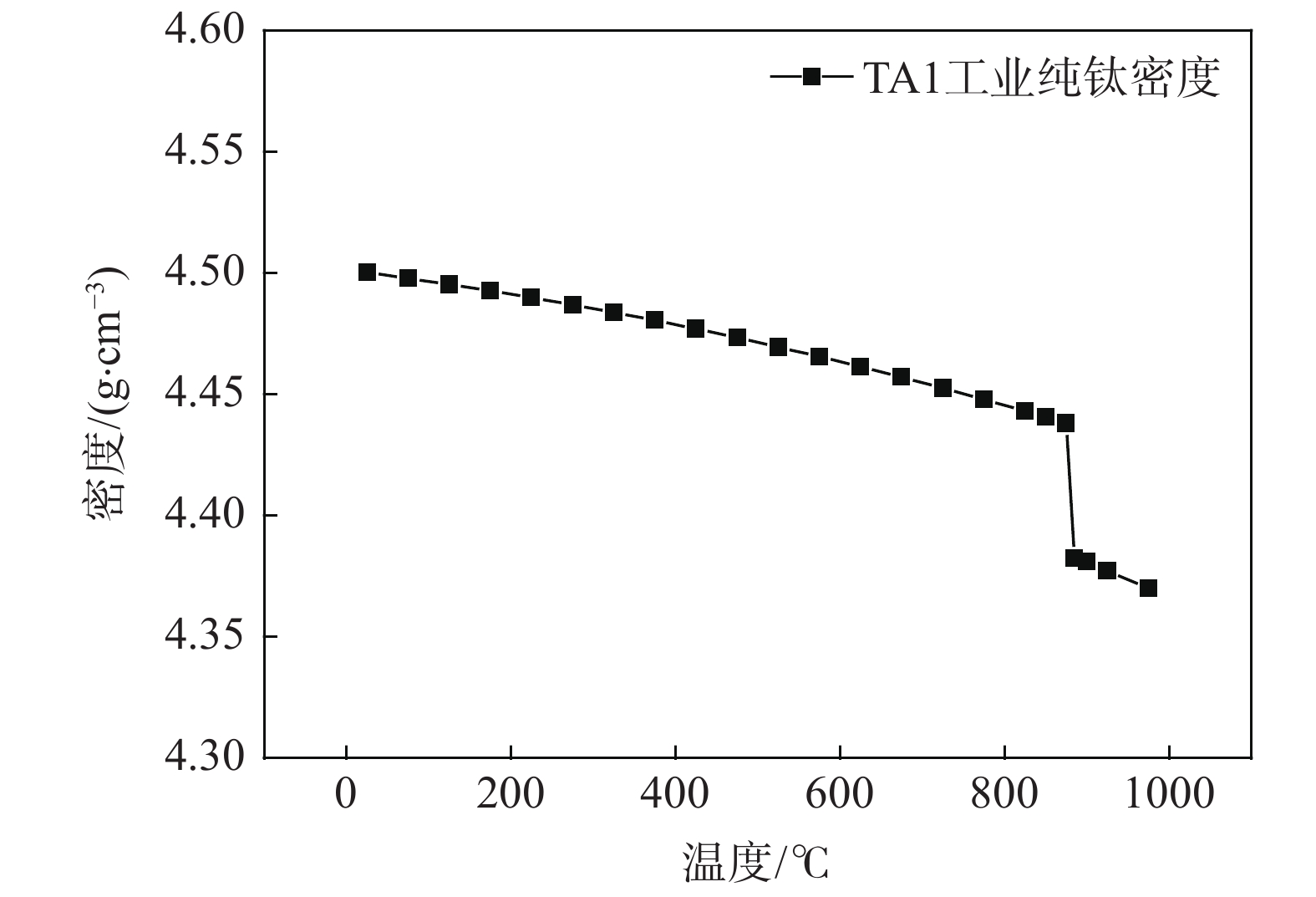

摘要: 为了实现纯钛板坯在钢铁工业加热炉中的加热过程自动化控制,测量了TA1工业纯钛在21.6 ~975 ℃的密度、比热、热扩散系数等参数,计算了导热系数,分析了这些参数的变化规律,得到纯钛的晶格结构转变温度约为885 ℃,并在此基础上开发了TA1钛坯加热自动控制模型,实现了在钢铁工业加热炉中高质量加热钛坯。工业试验结果表明,模型计算温度与钛坯出炉实测温度相差在9 ℃之内,表明该热物性参数及加热控制模型准确、可靠,满足工业化生产的要求。Abstract: To control the heating process of industrial pure titanium slab (TA1) automatically, the parameters such as density, specific heat capacity, thermal diffusivity and thermal conductivity in the range of 21.6~975 ℃ were measured or calculated. The variation trends of the parameters were analyzed, and the phase-transition temperature of the pure titanium was determined at 885 ℃. Based on the obtained experimental results, an automatic combustion control (ACC) model of the heating process of the TA1 slab was developed. Industrial applications show that the difference in the average tapping temperature of the TA1 slab is within 9 ℃ between the calculated temperature by the developed model and the measured temperature. It indicates that the thermal parameters and the ACC model are accurate and reliable, meeting the industrial production requirements.

-

表 1 TA1工业纯钛样品的化学成分

Table 1. Chemical compositions of the TA1 sample

% 编号 H O N Fe C Ti 1# 0.0009 0.096 0.015 0.027 0.012 余 2# 0.0006 0.049 0.011 0.033 0.012 余 表 2 ACC模型计算温度与实测值比较(出炉)

Table 2. Comparison of the calculated temperature by ACC model and the measured temperature

℃ 编号 头部实测 中部实测 尾部实测 实测平均 模型预报均温 预报与实测差 1# 862 858 860 860 854 6 2# 855 853 857 855 846 9 -

[1] (莫为. 钛[M]. 北京: 冶金工业出版社, 2008: 1−5.)Mo Wei. Titanium[M]. Beijing: Metallurgical Industry Press, 2008: 1−5. [2] Wang Xiashu, Li Hongbo, Wang Chao, et al. Control system of double-regenerative slab heating furnace[J]. Metallurgical Industry Automation, 2016,40(1):50−55. (王夏书, 李洪波, 王超, 等. 双蓄热式板坯加热炉控制系统[J]. 冶金自动化, 2016,40(1):50−55. doi: 10.3969/j.issn.1000-7059.2016.01.011 [3] Zhou Jinjun, Shi Deming, Fan Mancang, et al. Optimization of combustion control system for slab reheating furnace[J]. Metallurgical Power, 2018,(9):30−34. (周劲军, 史德明, 范满仓, 等. 板坯加热炉燃烧控制系统优化[J]. 冶金动力, 2018,(9):30−34. [4] Chen Wenyi. Optimization design of automatic combustion control system for the metallurgical industrial furnace[J]. Metallurgical Industry Automation, 2019,43(1):64−68. (陈文仪. 冶金工业加热炉自动燃烧控制系统优化设计[J]. 冶金自动化, 2019,43(1):64−68. [5] Shen Jihai. Application of the combustion control model of the reheating furnace in Meishan 1780 mm hot-rolling mill production line[J]. Metallurgical Industry Automation, 2014,38 (3):33−37. (沈际海. 加热炉燃烧控制模型在梅钢1780中的应用[J]. 冶金自动化, 2014,38 (3):33−37. doi: 10.3969/j.issn.1000-7059.2014.03.007 [6] Liu Shu, Tan Ou, Xu Zhaohui. Research of automatic combustion control system of regenerative heating furnace in hot strip plant[J]. Steel Rolling, 2018,35 (2):65−67. (刘树, 谭欧, 徐朝辉. 热连轧蓄热式加热炉全自动燃烧控制系统研究[J]. 轧钢, 2018,35 (2):65−67. [7] Marino P, Pignotti A, Sois D. Control of pusher furnaces for steel slab reheating using a numerical model[J]. Latin American Applied Research, 2004,(34):249−255. [8] Song Ping. Computer control system design of slab heating furnace in hot rolling plant[J]. Iron and Steel Technology, 2006,(5):21−23. (宋萍. 热轧厂板坯加热炉的计算机控制系统设计[J]. 钢铁技术, 2006,(5):21−23. [9] Peng Lan, Mao Yujun, Li Yourong. Cycle calculation of combustion control system in reheating furnace in Pangang hot strip mill[J]. Journal of North China Electric Power University, 2007,34(2):87−90. (彭岚, 毛玉军, 李友荣. 攀钢热轧加热炉自动燃烧控制系统的周期性计算[J]. 华北电力大学学报, 2007,34(2):87−90. [10] Du Juan. Analysis on the functions of the automatic combustion control(ACC) model of the heating furnace[J]. Sci-Tech Information Development & Economy, 2009,19 (7):145−147. (杜娟. 加热炉自动燃烧控制模型功能浅析[J]. 科技情报开发与经济, 2009,19 (7):145−147. -

下载:

下载: