In-situ preparation of VS4 from vanadium-containing leaching solution of vanadium chromium slag

-

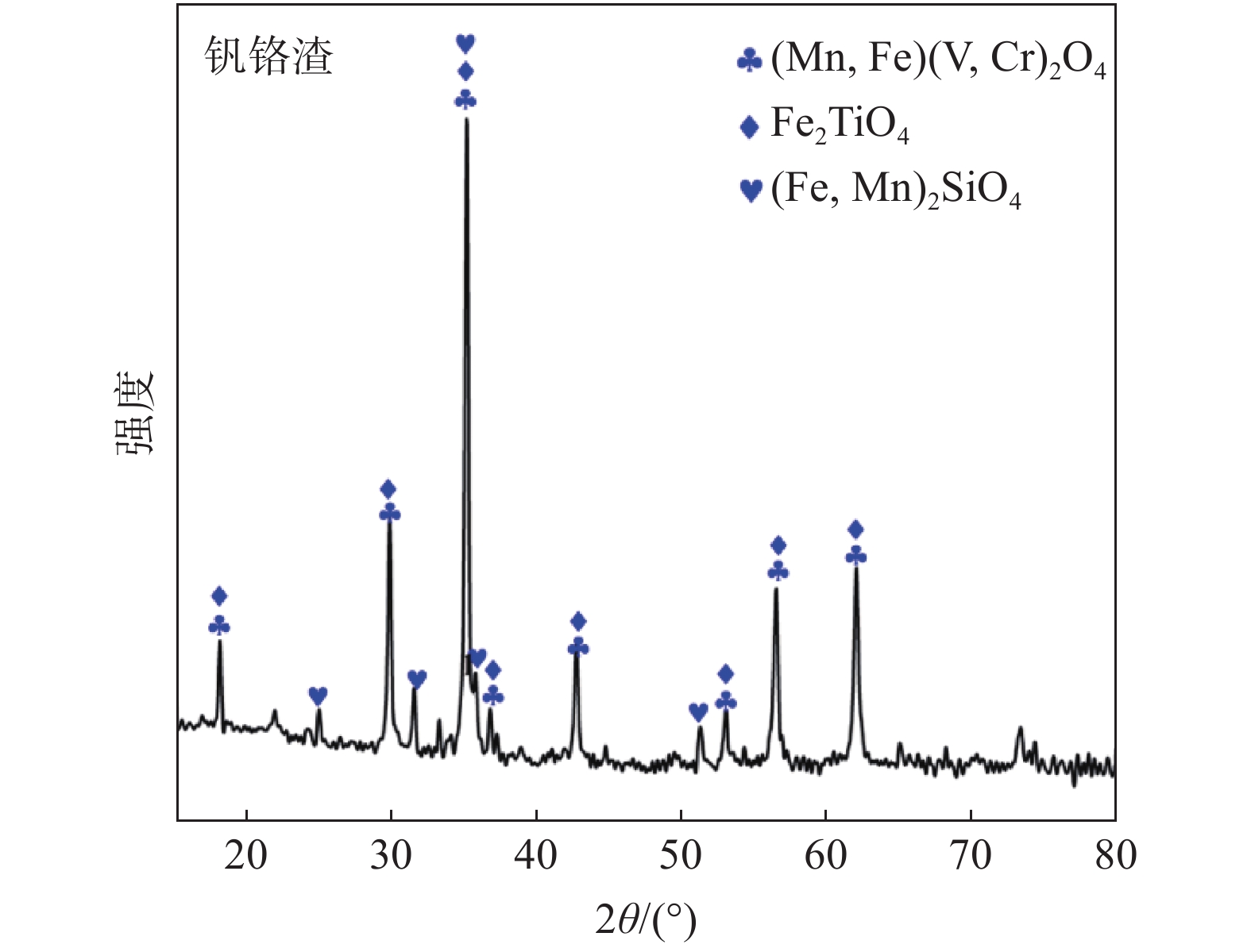

摘要: 目前传统的提钒工艺仍以制备钢铁和化工行业的钒产品为主,为进一步促进钒产品深加工,提出含钒浸出液原位制备高附加值含钒材料VS4的新技术,该产品可用于储能和催化等领域。以钒铬渣为原料,分别以不同焙烧、浸出工艺所得含钒浸出液为钒源,硫代乙酰胺为硫源制备了VS4产品,并对其物相和微观形貌进行表征。结果表明,钒铬渣钠化焙烧水浸工艺和钙化焙烧碳酸钠浸出工艺所得含钒浸出液均可作为含钒母液原位转化VS4,但钠化焙烧水浸工艺由于焙烧过程中生成硅酸钠、铬酸钠等产物导致浸出液中含大量钠、硅、铬等杂质离子,所得VS4产品纯度较低。而钙化焙烧碳酸钠浸出工艺中由于钙盐对钒的选择性钙化效应,浸出过程钒铬分离效率很高,所得VS4产品纯度较高,且与分析纯偏钒酸钠为钒源制备的VS4具有相似的形貌。该工艺不仅实现了钒铬渣的增值利用,更显著缩短了含钒材料VS4的制备流程。Abstract: At present, the traditional vanadium extraction process is still based on the preparation of vanadium products for steel and chemical industries. In order to promote the deep processing of vanadium products, a new technology of in-situ preparation of high value-added material VS4 from vanadium leaching solution was proposed in this paper, which can be used in energy storage and catalysis fields. VS4 was prepared from vanadium chromium slag with different roasting and leaching processes as the vanadium source and thioacetamide as sulfur source. The results show that the leaching solution from sodium roasting-water leaching process and calcification roasting-sodium carbonate leaching process can be used as mother liquor for VS4 generation. However, due to the formation of sodium silicate, sodium chromate and other sodium salts in the sodium roasting process, the corresponding leaching solution contains a large amount of sodium, silicon, chromium and other impurities, resulting in low purity of VS4 products. Due to the selective calcification effect of calcium salt on vanadium, the separation efficiency of vanadium and chromium is very high in the process of calcium roasting and sodium carbonate leaching process. The purity of VS4 product is high, and it has similar morphology with VS4 prepared using sodium metavanadate as the vanadium source. The process not only realizes the value-added utilization of vanadium chromium slag, but also significantly shortens the preparation process of vanadium containing materials.

-

Key words:

- vanadium chromium slag /

- VS4 /

- in-situ preparation /

- purity

-

表 1 钒铬渣主要化学成分

Table 1. Chemical compositions of the vanadium-chromium slag %

FeO V2O3 Cr2O3 SiO2 TiO2 MnO CaO Total 39.21 11.88 9.45 15.73 11.19 7.03 1.67 96.16 -

[1] Moskalyk R R, Alfantazi A M. Processing of vanadium: a review[J]. Minerals Engineering, 2003,16(9):793−805. doi: 10.1016/S0892-6875(03)00213-9 [2] Zhang Yimin, Bao Shenxue, Liu Tao, et al. The technology of extracting vanadium from stone coal in China: Current status and future prospects[J]. Hydrometallurgy, 2011,109(1−2):116−124. doi: 10.1016/j.hydromet.2011.06.002 [3] Peng H. A literature review on leaching and recovery of vanadium[J]. J. Environ. Chem. Eng., 2019,7:103313. doi: 10.1016/j.jece.2019.103313 [4] Rout C S, Khare R, Kashid R V, et al. Metallic few-layer flowerlike VS2 nanosheets as field emitters[J]. Eur. J. Inorg. Chem., 2014:5331−5336. [5] Sun R, Wei Q, Li Q, et al. Vanadium sulfide on reduced graphene oxide layer as a promising anode for sodium ion battery[J]. ACS Appl. Mater. Interfaces, 2015,7:20902−20908. doi: 10.1021/acsami.5b06385 [6] Ulaganathan M, Aravindan V, Yan Q, et al. Recent advancements in all-Vanadium redox flow batteries[J]. Adv. Mater. Interfaces., 2016,3:1500309. doi: 10.1002/admi.201500309 [7] Zhou Y, Liu P, Jiang F, et al. Vanadium sulfide sub-microspheres: A new near-infrared-driven photocatalyst[J]. J. Colloid Interface Sci., 2017,498:442−448. doi: 10.1016/j.jcis.2017.03.081 [8] Liu B, Du H, Wang S N, et al. A novel method to extract vanadium and chromium from vanadium slag using molten NaOH-NaNO3 binary system[J]. AIChE Journal, 2013,59(2):541−552. doi: 10.1002/aic.13819 [9] Wang J. Research on the systhesis and lithium/sodium battery anode electrochemical performance of VS4/rGO hybrid[D]. Wuhan: Central China Normal University, 2018. [10] Mohan P, Yang J, Jena A, et al. VS2/rGO hybrid nanosheets prepared by annealing of VS4/rGO[J]. J. Solid State Chem., 2015,224:82−87. doi: 10.1016/j.jssc.2014.06.031 [11] Wen J, Jiang T, Shapkat Arken. Selective leaching of vanadium from vanadium-chromium slag using sodium bicarbonate solution and subsequent in-situ preparation of flower-like VS2[J]. Hydrometallurgy, 2020,198:105498. doi: 10.1016/j.hydromet.2020.105498 [12] Li M, Xiao L, Liu J J, et al. Effective extraction of vanadium and chromium from high chromium content vanadium slag by sodium roasting and water leaching[J]. Mater. Sci. Forum., 2016,863:144−148. doi: 10.4028/www.scientific.net/MSF.863.144 [13] Wen J, Jiang T, Liu Y J, et al. Extraction behavior of vanadium and chromium by calcification roasting-acid leaching from high chromium vanadium slag: optimization using response surface methodology[J]. Miner. Process. Extr. Metall. Rev., 2018,40:56−66. [14] Wen J, Jiang T, Zheng X, et al. Efficient separation of chromium and vanadium by calcification roasting–sodium carbonate leaching from high chromium vanadium slag and V2O5 preparation[J]. Sep. Purif. Technol., 2020,230:115881. doi: 10.1016/j.seppur.2019.115881 [15] Wen J, Jiang T, Wang J P, et al. An efficient utilization of high chromium vanadium slag: Extraction of vanadium based on manganese carbonate roasting and detoxification processing of chromium-containing tailings[J]. J. Hazard. Mater., 2019,378:120733. doi: 10.1016/j.jhazmat.2019.06.010 [16] Li H Y, Wang C J, Yuan Y H, et al. Magnesiation roasting-acid leaching: A zero-discharge method for vanadium extraction from vanadium slag[J]. Journal of Cleaner Production, 2020,260:121091. doi: 10.1016/j.jclepro.2020.121091 -

下载:

下载: