Simulation and experimental study on ultrasonic spray pyrolysis of ultrafine vanadium dioxide powder

-

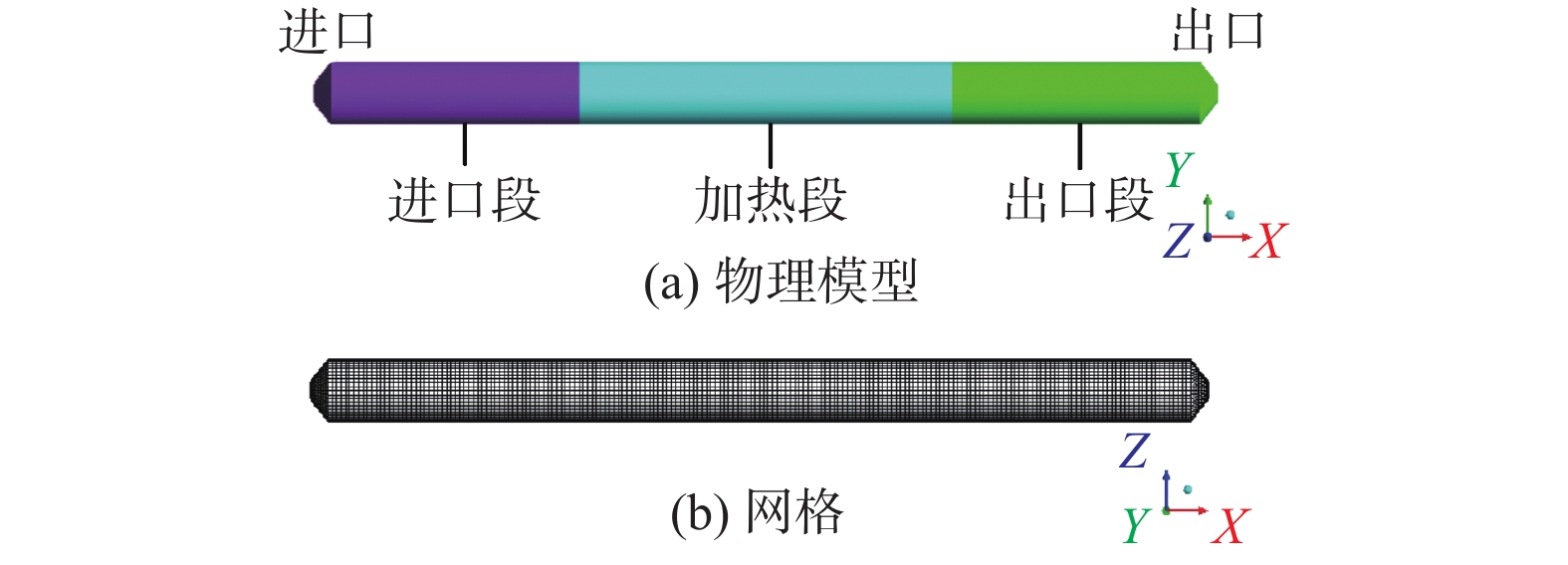

摘要: 针对喷雾热解过程,采用计算流体力学(CFD)方法对其装置进行了设计优化,通过对比分析,对管式炉的进出口段进行保温优化来改善管内温度和速度场分布不均的问题;设计搭建了超声喷雾热解装置,并通过试验考察了不同的前驱体溶液、前驱体浓度、热解温度对于产物粒径和形貌的影响。结果表明:草酸氧钒溶液超声热解后的产物主要为V2O3,而硫酸氧钒及二氯氧钒热解后的产物为蓝黑色VO2颗粒;随着硫酸氧钒前驱体浓度的增加,大颗粒粉体明显增多,颗粒粒径大于100 nm;二氯氧钒热解后的VO2颗粒以二次粒子和一次粒子的形式存在,随着热解温度和前驱体浓度的提高,颗粒分散性明显提高,小粒径颗粒增加,粒径基本在100 nm左右。Abstract: For the spray pyrolysis process, the device was optimized by computational fluid dynamics (CFD) method. Through comparison and analysis, the heat preservation optimization was adopted for the inlet and outlet sections of the tubular furnace to improve the uneven temperature and velocity field distributions. An ultrasonic spray pyrolysis device was designed and set up, and the influences of precursor solution, precursor concentration and pyrolysis temperature on the particle size and morphology of the products were investigated through experiments. The results show that the main products of the ultrasonic pyrolysis of vanadyl oxalate solution are V2O3, while the pyrolysis products of vanadyl sulfate and vanadyl dichloride are blue black VO2 particles. With increase of the concentration of vanadyl sulfate precursor, the amount of large particles increases significantly, and the particle size is more than 100 nm. The VO2 particles obtained via pyrolysis of vanadyl dichloride are the secondary and primary particles. With increase of the pyrolysis temperature and precursor concentration, the dispersion of the particles increases obviously, and the number of small particles increases, and the particle size is about 100 nm.

-

Key words:

- superfine VO2 /

- ultrasonic spray pyrolysis /

- vanadyl oxalate /

- vanadyl sulfate /

- vanadyl dichloride /

- velocity field /

- temperature field /

- CFD

-

表 1 固体硫酸氧钒中主要化学成分

Table 1. The main compositions of solid vanadyl sulfate

% K Na Fe Cr Si Al Ca Mg Mn P 0.0033 <0.002 0.0037 <0.002 <0.002 <0.002 <0.002 <0.002 <0.002 <0.002 表 2 超声喷雾热解法制备VO2粉体的试验参数

Table 2. The experimental parameters for preparation of VO2 powder by ultrasonic spray pyrolysis

试验编号 前驱体溶液 浓度/(mol·L−1) 反应温度/℃ EX1 VOSO4 0.1 750 EX2 VOSO4 0.01 750 EX3 VOC2O4 0.1 380 EX4 VOCl2 0.1 500 EX5 VOCl2 0.1 700 EX6 VOCl2 0.2 700 -

[1] Milosevic O B, Mancic L, Rabanal M E, et al. Aerosol route in processing of nanostructured functional materials[J]. KONA Powder and Particle Journal, 2009,27:84−106. doi: 10.14356/kona.2009010 [2] Patil P S. Versatility of chemical spray pyrolysis technique[J]. Mater. Chem. Phys., 1999,59:185−198. doi: 10.1016/S0254-0584(99)00049-8 [3] Kodas T T, Hampden-Smith M J. Aerosol processing of materials[M]. New York: Wiley-VCH, 1998. [4] Arpagaus C. A novel laboratory-scale spray dryer to produce nano particles[J]. Drying Technol, 2012,30:1113−1121. doi: 10.1080/07373937.2012.686949 [5] Arun M. Principles, classification and selection of dryers[C]//In Handbook of Industrial Drying. Third Edition.CRC Press, 2006. [6] Dosev D, Guo B, Kennedy I M. Photoluminescence of as an indication of crystal structure and particle size in nanoparticles synthesized by flame spray pyrolysis[J]. J. Aerosol Sci., 2006,37:402−412. doi: 10.1016/j.jaerosci.2005.08.009 [7] Zhang Yue, Yan Jiazhen, Huang Wanxia, et al. Study on thermochromic properties of the Mo –doped VO2 thin films on muscovite subtrate[J]. Iron Steel Vanadium Titanium, 2008,29(2):5−8. (张月, 颜家振, 黄婉霞, 等. 云母衬底掺钼二氧化钒薄膜热致相变性能研究[J]. 钢铁钒钛, 2008,29(2):5−8. doi: 10.7513/j.issn.1004-7638.2008.02.002 [8] Pu Hong, Tian Congxue. Preparation of porous TiO2 photocatalyst by hydrothermal crystallizing process[J]. Iron Steel Vanadium Titanium, 2014,35(2):31−34, 55. (蒲洪, 田从学. 水热晶化制备多孔二氧化钛[J]. 钢铁钒钛, 2014,35(2):31−34, 55. doi: 10.7513/j.issn.1004-7638.2014.02.006 [9] Pu Hong. Hydrothermal synthesis of titanium dioxide and its photocatalytic properties evaluation[J]. Iron Steel Vanadium Titanium, 2017,38(3):21−24. (蒲洪. 二氧化钛的水热制备及其催化性能评价[J]. 钢铁钒钛, 2017,38(3):21−24. doi: 10.7513/j.issn.1004-7638.2017.03.003 [10] Lang R J. Ultrasonic atomization of liquids[J]. Journal of the Acoustical Society of America, 1962,34:6−8. doi: 10.1121/1.1909020 [11] Zhang Huafu, Sha Hao, Wu Zhiming, et al. Recent progress on vanadium dioxide thin film at terahertz range[J]. Materials Review, 2019,33(15):2513−2523. (张化福, 沙浩, 吴志明, 等. 太赫兹波段二氧化钒薄膜的研究进展[J]. 材料导报, 2019,33(15):2513−2523. doi: 10.11896/cldb.18060112 [12] Dao Rina, Kong Xinru, Zhang Haifeng, et al. Design of a tunable microwave absorber based on vanadium dioxide[J]. Laser Technology, 2019,43(4):557−562. (道日娜, 孔心茹, 章海锋, 等. 一种基于二氧化钒材料的可调谐吸波器设计[J]. 激光技术, 2019,43(4):557−562. doi: 10.7510/jgjs.issn.1001-3806.2019.04.021 [13] Tang Lu, Huang Wanxia, Wen Hao, et al. Study on thermal insulation properties of nano-VO2 modified plexi glass[J]. Iron Steel Vanadium Titanium, 2019,40(5):55−60. (唐露, 黄婉霞, 文皓, 等. 纳米VO2改性有机玻璃的隔热性能研究[J]. 钢铁钒钛, 2019,40(5):55−60. [14] Mwakikunga B W, Sideras-Haddad E, Maaza M. First synthesis of vanadium dioxide by ultrasonic nebula-spray pyrolysis[J]. Optical Materials, 2007,29(5):481−487. doi: 10.1016/j.optmat.2005.10.007 [15] Bharathi R, Naorem R, Umarji A M. Metal−insulator transition characteristics of vanadium dioxide thin films synthesized by ultrasonic nebulized spray pyrolysis of an aqueous combustion mixture[J]. Journal of Physics D: Applied Physics, 2015,48(30):305103. doi: 10.1088/0022-3727/48/30/305103 -

下载:

下载: