Study on reduction of panxi titanium ore pellets by coke oven gas

-

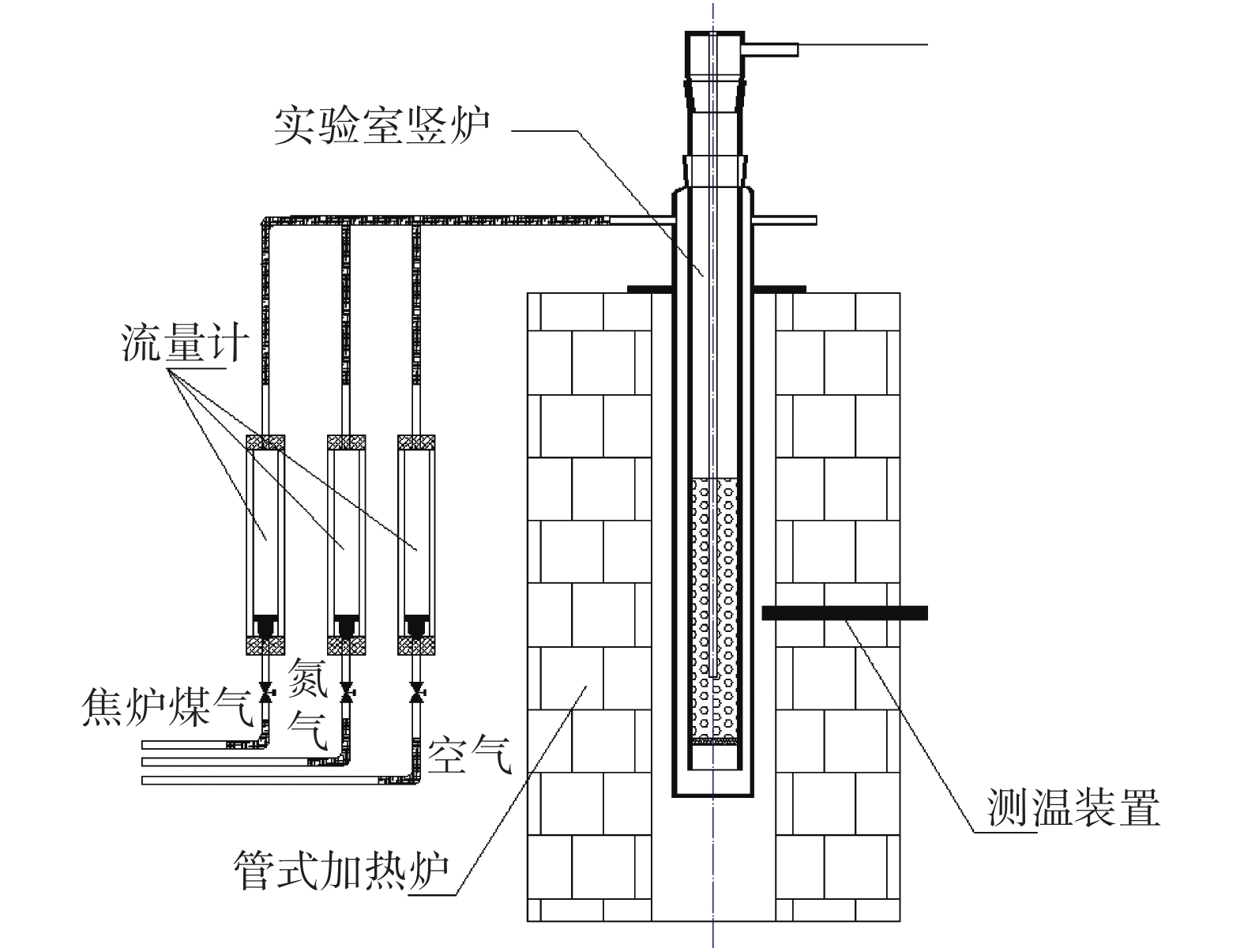

摘要: 针对攀西钛精矿粒度细、直接入炉冶炼钛渣难的问题,提出细粒级钛矿制备钛矿球团,钛矿球团焦炉煤气还原,并与细粒级钛精矿开展对比试验研究。结果表明:钛矿球团通过预焙烧后出现微裂纹和孔洞,有利于气相还原反应的进行,当还原温度在950 ℃时,钛矿球团焦炉煤气还原4 h后,金属化率可达85%以上,还原过程中钛矿球团物相结构发生较大变化,其主要物相由铁板钛矿相变成金属铁相、金红石相和少量钛铁矿相;随着反应进行钛矿球团中金属Fe逐渐显现、呈星点状分布、随之长大,最后连接成片。为攀西细粒级钛精矿冶炼钛渣提供了一定理论支撑。Abstract: Aiming at the problem that Panxi titanium concentrate is difficult to be directly added into furnace due to the fine particle size, the process of reducing the pellets prepared from the titanium ore by coke oven gas was proposed. And the comparative experiments between the pellets and titanium concentrate were also carried out. The results show that micro-cracks and holes appear in the titanium pellets after preroasting, which is favorable for the gas phase reduction reaction. At the reduction temperature of 950 ℃ for 4 h, the metallization rate of titanium ore pellets can reach more than 85%. During the reduction process, the phases of titanium ore pellets change greatly. The main phases change from pseudobrookite to metallic iron, rutile and a small amount of ilmenite. As the reaction progresses, the metallic Fe in the titanium ore pellets gradually appears with scattered distribution, and gradually grows into pieces. It provides theoretical support for smelting titanium slag from Panxi fine grade titanium concentrate.

-

Key words:

- titanium ore pellets /

- coke oven gas /

- reduction /

- metallization rate /

- phase

-

表 1 攀西细粒级钛精矿典型粒度分析

Table 1. Particle size distribution of typical Panxi titanium concentrate

粒径/mm 含量/% >0.25 0 0.25~0.125 10.21 0.125~0.09 15.08 0.09~0.074 9.57 0.074~0.044 36.6 <0.044 28.54 表 2 攀西典型钛精矿化学成分

Table 2. Chemical compositions of typical Panxi titanium concentrate %

TiO2 FeO Fe2O3 SiO2 S CaO MgO MnO 46.76 34.95 6.55 3.98 0.26 0.95 4.86 0.721 表 3 氧化球团粒度分布

Table 3. Size distribution of oxidized pellets

粒径/mm 含量/% <10.5 8 10.5~11.5 21 11.5~12.5 20 12.5~13.5 17 13.5~14.5 14 14.5~15.5 11 >15.5 9 表 4 氧化球团基本指标

Table 4. Basic indexes of oxidized pellets

w/% 抗压强度/N 转鼓指数/% TiO2 TFe FeO S 43.11~46.15 30.40~32.14 0.51~1.60 0.011~0.019 388~833 51.13~82.13 45.86 31.03 0.56 0.013 665 65.98 表 5 攀钢焦炉煤气成分(体积分数)

Table 5. Compositions of coke oven gas from Pangang group (volume fraction)

% CO2 CnHm O2 CO H2 CH4 N2 2.1 2 0.3 8.2 63.5 20.6 3.3 表 6 还原球团扫描电镜能谱分析(质量分数)

Table 6. Chemical compositions of reduced pellets via EDS (mass fraction)

% 序号 O Mg Al Si Ca Ti Fe 1# 1.40 1.32 97.28 2# 1.19 1.03 4.90 92.88 3# 54.40 2.69 0.78 3.57 0.89 31.10 5.75 -

[1] Wen Xiaolian, Guo Mingbin, Ran Dingwei. Current situation, existing problems and countermeasures of titanium resources utilization in Panzhihua region[J]. Metal Mines, 2008,(8):5−10. (文孝廉, 郭明彬, 冉定伟. 攀枝花地区钛资源利用的现状、存在的问题及对策[J]. 金属矿山, 2008,(8):5−10. doi: 10.3321/j.issn:1001-1250.2008.08.002 [2] Xiao Liujun. Resources and mineral magnetic characteristics of vanadium-titanium magnetite in Panzhihua[J]. Metal Mines, 2001,(1):28−30. (肖六均. 攀枝花钒钛磁铁矿资源及矿物磁性特征[J]. 金属矿山, 2001,(1):28−30. doi: 10.3321/j.issn:1001-1250.2001.01.011 [3] (邹建新. 非高炉炼铁技术在攀枝花钒钛磁铁矿综合利用中的发展前景[C]//2010年非髙炉炼铁学术年会暨钒钛磁铁矿综合利用技术研讨会文集. 攀枝花: 中国金属学会, 2010: 260−264.)Zou Jianxin. Development prospect of non-blast furnace ironmaking technology in the comprehensive utilization of vanadium-titanium magnetite in Panzhihua[C]//Proceedings of the 2010 Annual Conference of Smelting Ironmaking in Non-Gao Furnace and Symposium on The Comprehensive Utilization Technology of Vanadium-titanium Magnetite. Panzhihua: Chinese Society of Metals, 2010: 260−264. [4] Hu Junge. Development of gas-based shaft furnace direct reduction technology[C]//Proceedings of the 5th International Congress on the Science and Technology of Ironmaking. 2006: 1292−1296. [5] Wei Guangliang. Preparation of metallizaed pellets from Panzhihua titanium concerntrate by pre-reduction[J]. Iron Steel Vanadium Titanium, 2018,39(3):7−11. (魏光亮. 攀枝花钛精矿预还原制备金属化球团技术研究[J]. 钢铁钒钛, 2018,39(3):7−11. doi: 10.7513/j.issn.1004-7638.2018.03.002 [6] Han Kexi. Experimental study on granulation of fine-grained titanium concertrate[J]. Panzhihua Sci-tech and Information, 2011,(4):52−56. (韩可喜. 细粒级钛精矿造粒试验研究[J]. 攀枝花科技与信息, 2011,(4):52−56. [7] Ye Endong. Study on oxidation modification of Panzhihua titanium concentrate[J]. Inorganic Salt Industry, 2014,(10):26−29. (叶恩东. 攀枝花钛精矿氧化改性研究[J]. 无机盐工业, 2014,(10):26−29. doi: 10.3969/j.issn.1006-4990.2014.10.006 -

下载:

下载: