Effect of heat treatment process on microstructure and properties of titanium alloy tubing

-

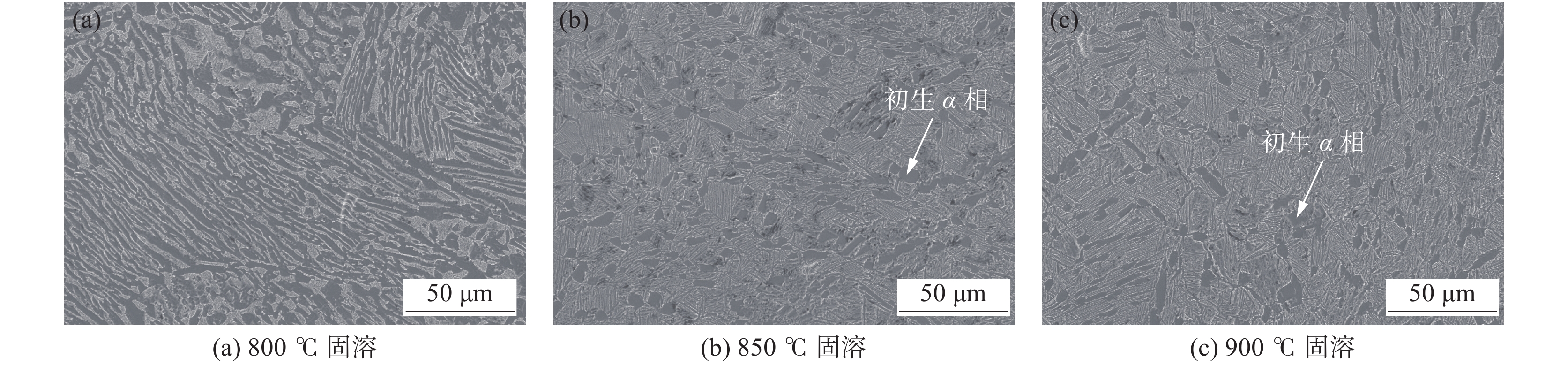

摘要: 通过光学显微镜、扫描电镜、拉伸试验机、冲击试验机等手段研究了不同热处理工艺对钛合金油管组织和性能的影响。结果表明:固溶温度对钛合金油管的晶粒形态和各相占比产生较大的影响。在α+β两相区固溶处理,随着固溶温度的升高,α相的占比下降;在850 ℃固溶1 h水冷+550 ℃时效2 h空冷热处理工艺下获得了双态组织,可实现钛合金油管的高强韧性匹配,综合性能优异,满足SY/T 6896.3标准对110ksi钢级钛合金油管的要求。Abstract: The effect of heat treatment process on the microstructure and properties of titanium alloy oil well tubes was studied by means of optical microscope, scanning electron microscope, tensile testing machine and impact testing machine. The results show that the solid solution temperature has a great influence on the grain morphology and phase proportion of titanium alloy tubing. In the α+β two-phase region, the proportion of α phase decreases with increase of the solution temperature. Bimodal structure of titanium alloy can be obtained at 850 ℃ of solid solution for 1 h followed by water cooling and 550 ℃ aging for 2 h followed by air cooling, which can realize the matching of high strength and toughness of titanium alloy oil well tubes. And it has excellent comprehensive properties, meeting the requirements of SY/T 6896.3 standard for 110ksi steel grade titanium alloy oil well tubes.

-

表 1 钛合金油管的化学成分

Table 1. Chemical compositions of titanium alloy tubing

% Al V Fe C N H O Mo+Zr Ti 5.06 4.05 0.045 0.015 0.01 0.005 0.08 ≥3 Bal 表 2 不同热处理钛合金油管的力学性能

Table 2. Mechanical properties of titanium alloy tubing with different heat treatment parameters

工艺 试样号 屈服强度/MPa 抗拉强度/MPa 延伸率A /% 1 1-1 805 915 12.0 1-2 825 920 10.5 1-3 815 925 11.5 2 2-1 900 1000 15.5 2-2 895 1010 15.0 2-3 915 1035 15.5 3 3-1 930 1040 12.0 3-2 925 1030 12.5 3-3 920 1025 13.5 SY/T 6896.3标准对

110ksi钢级要求758~965 ≥862 ≥12 表 3 不同热处理钛合金油管的夏比冲击值

Table 3. Charpy impact value of titanium alloy tubing with different heat treatment

工艺 取样方向 冲击值(0 ℃)/J 测试值 平均值 1 纵向 36,38,40 38.0 2 纵向 68,69,64 67.0 3 纵向 38,45,43 42.0 注:冲击试样尺寸为10 mm×10 mm×55 mm。SY/T 6896.3标准对110ksi钢级要求:0 ℃纵向冲击值≥41 J。 -

[1] Xing Na, He Libo, Gao Zhenfeng, et al. Development status of Ni-based alloy tube and casing for high acidic corrosive cas fields[J]. Shanghai Metals, 2013,35(4):59−62. (邢娜, 何立波, 高真凤, 等. 高酸性腐蚀油气田用镍基合金油套管开发现状[J]. 上海金属, 2013,35(4):59−62. doi: 10.3969/j.issn.1001-7208.2013.04.015 [2] Ishiguro Y, Miyata Y, Nakahashi T, et al. Enhanced corrosion-resistant stainless steel OCTG of 17Cr for sweet and sour environments[C]//USA 68th NACE Annual Conference, 2013. [3] Zhao Yongqing. Current situation and development trend of titanium alloys[J]. Materials China, 2010,29(5):1−8. (赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010,29(5):1−8. [4] Fu Yanyan, Song Yueqing, Hui Songxiao, et al. Research and application of typical aerospace titanium alloys[J]. Chinese Journal of Rare Metals, 2006,30(6):850−856. (付艳艳, 宋月清, 惠松骁, 等. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006,30(6):850−856. doi: 10.3969/j.issn.0258-7076.2006.06.028 [5] Zhu Zhishou. Recent research and development of titanium alloys for aviation application in China[J]. Journal of Aeronautical Materials, 2014,34(4):44−50. (朱知寿. 我国航空用钛合金技术研究现状及发展[J]. 航空材料学报, 2014,34(4):44−50. doi: 10.11868/j.issn.1005-5053.2014.4.004 [6] He Junli, Mao Xiaonan, Zhang Pengsheng. Effect of cycling temperature on microstructure and mechanical properties of TC4 alloy[J]. Heat Treatment of Metals, 2013,38(2):62−66. (何军利, 毛小南, 张鹏省. 循环热处理温度对TC4 钛合金组织和力学性能的影响[J]. 金属热处理, 2013,38(2):62−66. [7] Gu Xiaohui, Liu Jun, Shi Jihong. Influence of quenching and aging temperature on microstructure and mechanical properties of TC4 titanium alloy[J]. Heat Treatment of Metals, 2011,36(2):29−33. (顾晓辉, 刘君, 石继红. 淬火、时效温度对TC4钛合金组织和力学性能的影响[J]. 金属热处理, 2011,36(2):29−33. [8] Vanderhasten M, Rabet L, Verlinden B. Ti6Al4V deformation map and modelisation of tensile behaviour[J]. Materials and Design, 2008,(29):1090−1098. [9] He Defu, Cao Zhiliang, Zhou Zhijiang, et al. A newly-developed pneumatic process for leak testing of stainless steel tube and titanium alloy tube[J]. Steel Pipe, 2012,41(4):63−67. (何德孚, 曹志樑, 周志江, 等. 不锈钢管和钛管的气动泄漏密实性试验新方法[J]. 钢管, 2012,41(4):63−67. doi: 10.3969/j.issn.1001-2311.2012.04.014 [10] Gonzalez Manuel, Maskos Krystian, Hargrave Robert, et al. Titanium alloy tubing for HPHT applications[C]//U K SPE International. Society of Petroleum Engineers, 2008. [11] Li Liang, Sun Jianke, Meng Xiangjun. Application state and prospects for titanium alloys[J]. Titanium Industry Progress, 2004,21(5):19−24. (李梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前景[J]. 钛工业进展, 2004,21(5):19−24. doi: 10.3969/j.issn.1009-9964.2004.05.005 [12] Kane D R, Craig B, Venkatesh A. Titanium alloys for oil and gas service: a review[C]. NACE International. Proceedings of International Conferce NACE Corrosion, 2009. [13] Wu Xinyuan, Zhang Heng, Xu Xuejun, et al. Application of titanium alloy in oil&gas exploration and development[J]. Petrochemical Industry Application, 2016,35(11):105−108, 113. (吴欣袁, 张恒, 徐学军, 等. 钛合金在石油天然气勘探开发中的应用[J]. 石油化工应用, 2016,35(11):105−108, 113. doi: 10.3969/j.issn.1673-5285.2016.11.026 [14] Shi Xuezhi, Zhou Xiaohu. Status quo of research on properties of titanium alloy OCTG and relevant application evaluation[J]. Steel Pipe, 2015,44(1):10−14. (史雪枝, 周小虎. 钛合金油井管性能研究及应用评价现状[J]. 钢管, 2015,44(1):10−14. doi: 10.3969/j.issn.1001-2311.2015.01.002 [15] Yu Cunye. Development and application on corrosion resistant titamium alloys[J]. Total Corrosion Control, 2002,16(6):6−11. (余存烨. 耐蚀钛合金的发展与应用[J]. 全面腐蚀控制, 2002,16(6):6−11. doi: 10.3969/j.issn.1008-7818.2002.06.004 [16] Lü Xianghong, Shu Ying, Zhao Guoxian, et al. Research and application progress of Ti alloy oil country tubular goods[J]. Rare Metal Materials and Engineering, 2014,43(6):1518−1524. (吕祥鸿, 舒滢, 赵国仙, 等. 钛合金石油管材的研究和应用进展[J]. 稀有金属材料与工程, 2014,43(6):1518−1524. -

下载:

下载: