Study on adsorption of nitrogen oxide in sintering flue gas by modified activated carbon

-

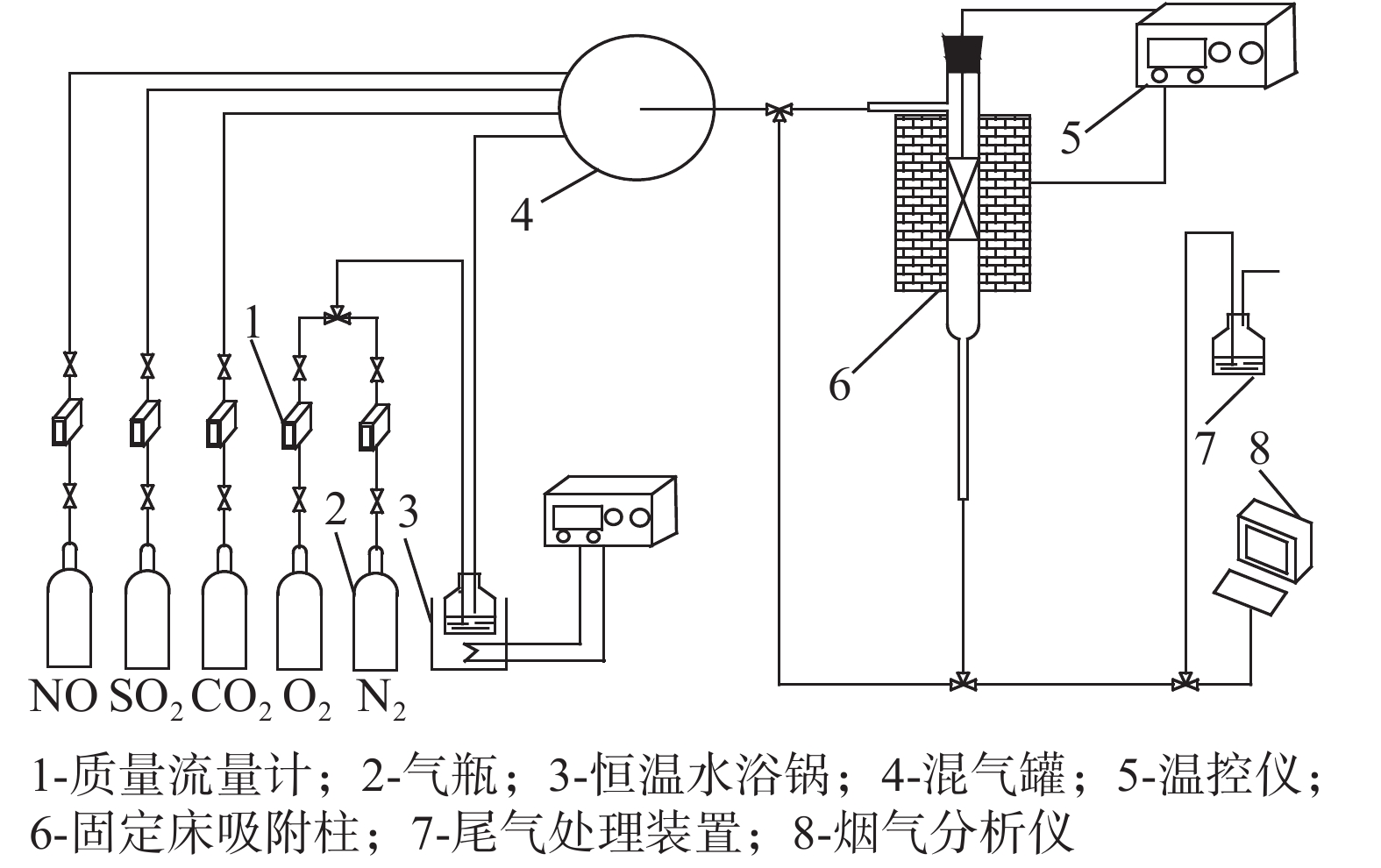

摘要: 以煤质活性炭为原料,制备了碳酸钾(K2CO3)改性活性炭,模拟烧结烟气条件,考察了其在有SO2、CO2和O2条件下的NOx吸附效果。试验表明:0.65 mol/L K2CO3改性活性炭的NOx吸附量最高,120 ℃时NOx吸附量可达15.17 mg/g,较原样提高了20倍以上;随着吸附温度的升高,NOx饱和吸附量有所下降,稳定在13.70~13.97 mg/g;由于SO2吸附后生成稳定硫酸盐难以脱除,影响了活性炭的加热再生效果。该吸附剂适用于移动床吸附处理烧结烟气。Abstract: Potash (K2CO3) modified activated carbon was prepared with coal activated carbon as raw material. Under simulated sintering flue gas conditions, the effect of NOx adsorption under the condition with SO2, CO2 and O2 was investigated. Experimental results show that 0.65 mol/L K2CO3 modified activated carbon have the highest adsorption quantity of NOx. The NOx adsorption capacity can reach 15.17 mg/g and can be improved by more than 20 times. With the increase of adsorption temperature, the desorption quantity of NOx decreases and stabilizes at about 13.70 mg/g to 13.97 mg/g. Since stable sulfate is difficult to remove after SO2 adsorption, which decreases the regeneration effect of activated carbon. The adsorbent is suitable for moving bed adsorption treatment of sintering flue gas.

-

Key words:

- sintering /

- flue gas /

- NOx /

- activated carbon /

- adsorption /

- K2CO3

-

表 1 活性炭比表面积测定结果

Table 1. Measured specific surface area of activated carbon

样品 BET比表面积/(m2·g−1) HH-0.60 906 HH-0.65 892 HH-0.70 897 HH-0.75 904 HH 1108 表 2 活性炭NOx吸附量

Table 2. Capacity of NOx adsorption by activated carbon

样品 NO吸附量/

(mg·g−1)NO2吸附量/

(mg·g−1)NOx吸附量/

(mg·g−1)HH-0.60 5.02 4.12 9.14 HH-0.65 8.40 6.77 15.17 HH-0.70 6.90 6.25 13.15 HH-0.75 7.50 6.52 14.022 HH 0.36 0.26 0.62 表 3 不同温度下活性炭NOx吸附量

Table 3. Capacity of NOx adsorption by activated carbon working at different temperatures

样品 温度/℃ NO吸附量/

(mg·g−1)NO2吸附量/

(mg·g−1)NOx吸附量/

(mg·g−1)HH-0.65 50 8.41 10.00 18.41 HH-0.65 75 6.63 7.33 13.96 HH-0.65 100 7.50 6.47 13.97 HH-0.65 120 7.63 6.07 13.70 表 4 改性活性炭再生后NOx吸附量

Table 4. Capacity of NOx adsorption by regenerative modified activated carbon

再生次数 NO吸附量/

(mg·g−1)NO2吸附量/

(mg·g−1)NOx吸附量/

(mg·g−1)0 12.90 11.01 23.91 1 11.62 12.01 23.63 2 8.81 9.68 18.49 3 7.17 8.48 15.65 -

[1] Wang Yusu, Zhang Lei, Chen Jihao, et al. Harm and treatment of nitrogen oxides in the atmosphere[J]. Technology Innovation and Application, 2019,(7):137−138. (王禹苏, 张蕾, 陈吉浩, 等. 大气中氮氧化物的危害及治理[J]. 科技创新与应用, 2019,(7):137−138. doi: 10.3969/j.issn.2095-2945.2019.07.054 [2] Shen Jun. The denitrification technology of flue gas in the cement industry[J]. Jiangsu Building Materials, 2019,(1):14−17. (沈军. 水泥工业烟气中氮氧化物脱除技术[J]. 江苏建材, 2019,(1):14−17. doi: 10.3969/j.issn.1004-5538.2019.01.003 [3] Wang Xurui. Nitrogen oxide hazards and treatment methods[J]. Modern Chemical Research, 2018,(10):116−117. (王旭睿. 氮氧化物危害及处理方法[J]. 当代化工研究, 2018,(10):116−117. doi: 10.3969/j.issn.1672-8114.2018.10.070 [4] Sun Jinyu. Controlling atmosphere pollution by NOx control technique[J]. Energy Conservation, 2004,(5):41−44. (孙锦余. 利用氮氧化物控制技术治理大气污染[J]. 节能, 2004,(5):41−44. doi: 10.3969/j.issn.1004-7948.2004.05.015 [5] Li Yufang. Research on motor vehicle exhaust pollution and countermeasures[J]. Environment & Development, 2020,32(2):39−42. (李玉芳. 机动车尾气污染及防治对策研究[J]. 环境与发展, 2020,32(2):39−42. [6] Li Guoliang. Hazards of nitrogen oxides to the environment and pollution control technology[J]. Shanxi Chemical Industry, 2019,39(5):123−124. (李国亮. 氮氧化物对环境的危害及污染控制技术[J]. 山西化工, 2019,39(5):123−124. [7] Liu Suying. Analysis of the hazards and countermeasures of flue gas pollution in thermal power plants[J]. Course Education Research, 2019,(19):255. (刘素英. 火力发电厂烟气污染的危害及对策探析[J]. 课程教育研究, 2019,(19):255. [8] Wang Xiaoman, Zhang Chenghao, Quan Fangfang. Harmness of NOx and its catalytic reduction control method[J]. Shanghai Energy Conservation, 2019,(4):259−261. (王小曼, 张晟昊, 权芳芳. 氮氧化物的危害及其催化还原控制方法[J]. 上海节能, 2019,(4):259−261. [9] Yang Yanlong. Emissions reduction of NOx in coal-fired power plant and simple analysis of SCR flue gas denitration technology[J]. Energy Environmental Protection, 2017,31(2):31−35. (杨延龙. 火电厂氮氧化物减排及 SCR 烟气脱硝技术浅析[J]. 能源环境保护, 2017,31(2):31−35. doi: 10.3969/j.issn.1006-8759.2017.02.010 [10] Fan Gaixiao. Talking about the purification technologies of nitrogen oxides in vehicle exhaust gas[J]. Internal Combustion Engine & Parts, 2019,(13):258−259. (樊改肖. 浅谈机动车尾气中氮氧化物减排技术的发展[J]. 内燃机与配件, 2019,(13):258−259. doi: 10.3969/j.issn.1674-957X.2019.13.125 [11] Wang Jichao, Yan Yali. Overtview of nitrous cxides treatment[J]. Industrial Technology Innovation, 2015,(3):375−379. (王纪超, 闫亚丽. 含氮氧化物废气治理方法概述[J]. 工业技术创新, 2015,(3):375−379. [12] Liu Qian, Zhou Zhenzhen. Progress in activated-synthesis of Si-based oxynitrides materials at low temperatures[J]. Journal of Inorganic Materials, 2018,33(2):129−137. (刘茜, 周真真. 低温活化合成含硅氮氧化物材料研究进展[J]. 无机材料学报, 2018,33(2):129−137. doi: 10.15541/jim20170401 [13] Li Wusheng. Discusses the marine diesel exhaust treatment system based on SCR technology[J]. China Plant Engineering, 2019,(13):65−66. (李武胜. 试论基于SCR技术的船舶柴油机尾气处理系统[J]. 中国设备工程, 2019,(13):65−66. doi: 10.3969/j.issn.1671-0711.2019.13.030 [14] Yu Xiaolong, Wu Xiaomin, Chen Ziyi, et al. Oxygen vacancy defect engineering in Mn-doped CeO2 nanostructures for nitrogen oxides emission abatement[J]. Molecular Catalysis, 2019,476:110512. doi: 10.1016/j.mcat.2019.110512 [15] Hu Hebing, Wang Muye, Wu Yongmin, et al. Pollution of nitrogen oxides and its treating method[J]. Environmental Protection Science, 2006,32(4):5−9. (胡和兵, 王牧野, 吴勇民, 等. 氮氧化物的污染与治理方法[J]. 环境保护科学, 2006,32(4):5−9. doi: 10.3969/j.issn.1004-6216.2006.04.003 [16] He Zhiqiao, Wang Jiade, Chen Jianmeng. Research progress of biological methods controlling and eliminating nitrogen oxides air pollution[J]. Techniques and Equipment for Environmental Pollution Control, 2002,3(9):59−62. (何志桥, 王家德, 陈建孟. 生物法处理 NOx 废气的研究进展[J]. 环境污染治理技术与设备, 2002,3(9):59−62. [17] Cheng Canhua. Discussion on application of integrated desulfurization and denitrification technology in power plant[J]. Scientific and Technological Innovation, 2019,(22):185−186. (程灿华. 电厂脱硫脱硝一体化工艺应用探讨[J]. 科学技术创新, 2019,(22):185−186. doi: 10.3969/j.issn.1673-1328.2019.22.115 [18] Yi Honghong, Ning Ping, Chen Yaxiong. Treatment technology of nitrogen oxide waste gas[J]. Environmental Science Trends, 1998,(4):17−20. (易红宏, 宁平, 陈亚雄. 氮氧化物废气的治理技术[J]. 环境科学动态, 1998,(4):17−20. [19] Su Qingfa, Liu Yamin, Chen Jie, et al. Research advance in non-thermal plasma induced selective catalytic reduction NOx with low hydrocarbon compounds[J]. Chemical Industry and Engineering Progress, 2009,(8):1449−1457. (苏清发, 刘亚敏, 陈杰, 等. 低温等离子体诱导低碳烃选择性催化还原 NOx 研究进展[J]. 化工进展, 2009,(8):1449−1457. doi: 10.3321/j.issn:1000-6613.2009.08.032 [20] Yang Guoqing, Cao Yisong, Shao Zhuxia, et al. Lye synergy dielectric barrier discharge on removing NOx of exhaust[J]. High Voltage Engineering, 2018,44(12):4013−4019. (杨国清, 曹一崧, 邵朱夏, 等. 碱液协同介质阻挡放电处理含氮氧化物废气[J]. 高电压技术, 2018,44(12):4013−4019. [21] He Zhi, He Keqiao, Li Lei, et al. Research and application of recycling high concentration nitrogen oxide flue gas[J]. Sichuan Metallurgy, 2019,41(06):32−35. (何志, 何珂桥, 李磊, 等. 高浓度氮氧化物烟气资源化研究及应用[J]. 四川冶金, 2019,41(06):32−35. doi: 10.3969/j.issn.1001-5108.2019.06.009 [22] Lourenço M A O, Ferreira P, Gomes J R B. Flue gas adsorption on periodic mesoporous phenylene-silica: a DFT approach[J]. Physical Chemistry Chemical Physics, 2018,20(24):16686−16694. doi: 10.1039/C8CP02589D [23] Liu Zhisong, Yu Feng, Ma Cunhua, et al. A critical review of recent progress and perspective in practical denitration application[J]. Catalysts, 2019,9(9):771. doi: 10.3390/catal9090771 [24] Zhu Yiyan. Research progress of nitrogen oxide treatment technology[J]. Guangxi Journal of Light Industry, 2015,31(6):100−101, 103. (朱奕谚. 氮氧化物治理技术的研究进展[J]. 轻工科技, 2015,31(6):100−101, 103. [25] Ma Xiancheng, Li Liqing, Chen Ruofei, et al. Porous carbon materials based on biomass for acetone adsorption: Effect of surface chemistry and porous structure[J]. Applied Surface Science, 2018,459:657−664. doi: 10.1016/j.apsusc.2018.07.170 [26] Zhou Ke, Ma Weiwu, Zeng Zheng, et al. Experimental and DFT study on the adsorption of VOCs on activated carbon/metal oxides composites[J]. Chemical Engineering Journal, 2019,372:1122−1133. doi: 10.1016/j.cej.2019.04.218 [27] Creamer A E, Gao B. Carbon-based adsorbents for postcombustion CO2 capture: a critical review[J]. Environmental Science & Technology, 2016,50(14):7276−7289. [28] Shen Yafeng. Rice husk silica derived nanomaterials for sustainable applications[J]. Renewable and Sustainable Energy Reviews, 2017,80:453−466. doi: 10.1016/j.rser.2017.05.115 [29] Promdee K, Chanvidhwatanakit J, Satitkune S, et al. Characterization of carbon materials and differences from activated carbon particle (ACP) and coal briquettes product (CBP) derived from coconut shell via rotary kiln[J]. Renewable and Sustainable Energy Reviews, 2017,75:1175−1186. doi: 10.1016/j.rser.2016.11.099 [30] Yang Si’e, Lin Jianqing. Review of modification technology of activated carbon and its application[J]. Journal of Anhui Agricultural Sciences, 2014,42(9):2712−2715. (杨四娥, 林建清. 活性炭的改性技术及其应用研究进展[J]. 安徽农业科学, 2014,42(9):2712−2715. doi: 10.3969/j.issn.0517-6611.2014.09.072 [31] Li Chongjiu, Zhao Ran, Peng Mengqi, et al. Study on desulfurization and denitrification by modified activated carbon fibers with visible-light photocatalysis[J]. Journal of Fuel Chemistry and Technology, 2015,43(12):1516−1522. doi: 10.1016/S1872-5813(16)30004-4 [32] Du Yaru, Zhang Xinghui, Yang Jiaojiao. NOx adsorptive performance by impregnated activated carbon fibers[J]. Chinese Journal of Environmental Engineering, 2019,13(7):1694−1702. (都亚茹, 张兴惠, 杨姣姣. 浸渍改性活性碳纤维吸附氮氧化物性能[J]. 环境工程学报, 2019,13(7):1694−1702. doi: 10.12030/j.cjee.201811179 [33] Pang Chengyong, Li Yuping. Study on removing of nitrogen oxides by adsorption in activated carbon[J]. Energy Environmental Protection, 2006,20(6):38−41. (庞成勇, 李玉平. 用活性炭吸附法脱除氮氧化物的研究[J]. 能源环境保护, 2006,20(6):38−41. doi: 10.3969/j.issn.1006-8759.2006.06.012 [34] Li Guoxi, Huang Qizhong, Hou Juan. NO adsorption activity of Pt supported on activated carbon fiber[J]. Chinese Journal of Catalysis, 2003,24(2):107−110. (李国希, 黄启忠, 侯娟. 负载 Pt 活性炭纤维对 NO 的吸附活性[J]. 催化学报, 2003,24(2):107−110. doi: 10.3321/j.issn:0253-9837.2003.02.008 [35] Lee Y W, Choi D K, Park J W. Surface chemical characterization using AES/SAM and TOF-SIMS on KOH-impregnated activated carbon by selective adsorption of NOx[J]. Industrial & Engineering Chemistry Research, 2001,40(15):3337−3345. [36] Illán-Gómez M J, Raymundo-Piñero E, García-García A, et al. Catalytic NOx reduction by carbon supporting metals[J]. Applied Catalysis B, Environmental, 1999,20(4):267−275. doi: 10.1016/S0926-3373(98)00119-2 [37] Sayğılı H, Sayğılı G A. Optimized preparation for bimodal porous carbon from lentil processing waste by microwave-assisted K2CO3 activation: Spectroscopic characterization and dye decolorization activity[J]. Elsevier Ltd, 2019,226:968−976. [38] Chen Yandan, Huang Biao, Huang Mingjie, et al. On the preparation and characterization of activated carbon from mangosteen shell[J]. Journal of the Taiwan Institute of Chemical Engineers, 2011,42(5):837−842. doi: 10.1016/j.jtice.2011.01.007 [39] Deng Hui, Li Guoxue, Yang Hongbing, et al. Preparation of activated carbons from cotton stalk by microwave assisted KOH and K2CO3 activation[J]. Chemical Engineering Journal, 2010,163(3):373−381. doi: 10.1016/j.cej.2010.08.019 [40] Ünveren E E, Monkul B Ö, Sarıoğlan Ş, et al. Solid amine sorbents for CO2 capture by chemical adsorption: a review[J]. Petroleum, 2017,3(1):37−50. doi: 10.1016/j.petlm.2016.11.001 [41] Lee Y W, Choi D K, Park J W. Performance of fixed-bed KOH impregnated activated carbon adsorber for NO and NO2 removal in the presence of oxygen[J]. Carbon, 2002,40(9):1409−1417. doi: 10.1016/S0008-6223(01)00312-8 [42] Lee Y W, Kim H J, Park J W, et al. Adsorption and reaction behavior for the simultaneous adsorption of NO–NO2 and SO2 on activated carbon impregnated with KOH[J]. Carbon, 2003,41(10):1881−1888. doi: 10.1016/S0008-6223(03)00105-2 [43] Dai Shifeng, Ren Deyi, Song Jianfang, et al. Application of XPS in research on occurrence of organic sulfur in vitrain[J]. Journal of China University of Mining, 2002,31(3):225−228. (代世峰, 任德贻, 宋建芳, 等. 应用 XPS 研究镜煤中有机硫的存在形态[J]. 中国矿业大学学报, 2002,31(3):225−228. doi: 10.3321/j.issn:1000-1964.2002.03.002 [44] Cai Chuanchuan, Yang Minghu, Pan Lulu, et al. Study of types and content of sulfur in coal samples of different densities using X-ray photoelectron spectroscopy(XPS)[J]. Coal Prepapation Technology, 2018,(5):56−59. (蔡川川, 杨明虎, 潘露露, 等. 基于XPS技术的不同密度煤样中硫的类型和含量研究[J]. 选煤技术, 2018,(5):56−59. [45] Ge Tao, Cai Chuanchuan. The XPS analysis of different-density-level organic sulfur in coking coal[J]. Journal of Anhui University of Science and Technology, 2015,35(3):14−16, 20. (葛涛, 蔡川川. 不同密度炼焦煤中有机硫的 XPS 研究[J]. 安徽理工大学学报 (自然科学版), 2015,35(3):14−16, 20. [46] Liu Yifeng, Shen Benxian, Pi Zhipeng, et al. Oxidation transferring mechanism of SO2 in FCC flue gas over CeO2 surface[J]. Journal of Chemical Industry and Engineering, 2016,67(12):5015−5023. (刘逸锋, 沈本贤, 皮志鹏, 等. CeO2表面氧化转移FCC烟气中SO2的反应过程[J]. 化工学报, 2016,67(12):5015−5023. [47] Xu Ning, Tao Xiuxiang, Xie Maohua, et al. Study on variation of sulfur chemical forms in microwave desulfurized coal based on XPS[J]. Coal Engineering, 2014,46(12):111−113. (许宁, 陶秀祥, 谢茂华, 等. 基于 XPS的微波脱硫前后煤中硫形态的变化研究[J]. 煤炭工程, 2014,46(12):111−113. doi: 10.11799/ce201412036 [48] Tang Qiang, Zhang Zhigang, Zhu Wenpei, et al. SO2 and NO selective adsorption properties of coal-based activated carbons[J]. Fuel, 2005,84(4):461−465. doi: 10.1016/j.fuel.2004.03.010 -

下载:

下载: