Preparation of permeable brick for sponge city from vanadium titanium blast furnace slag and lead slag

-

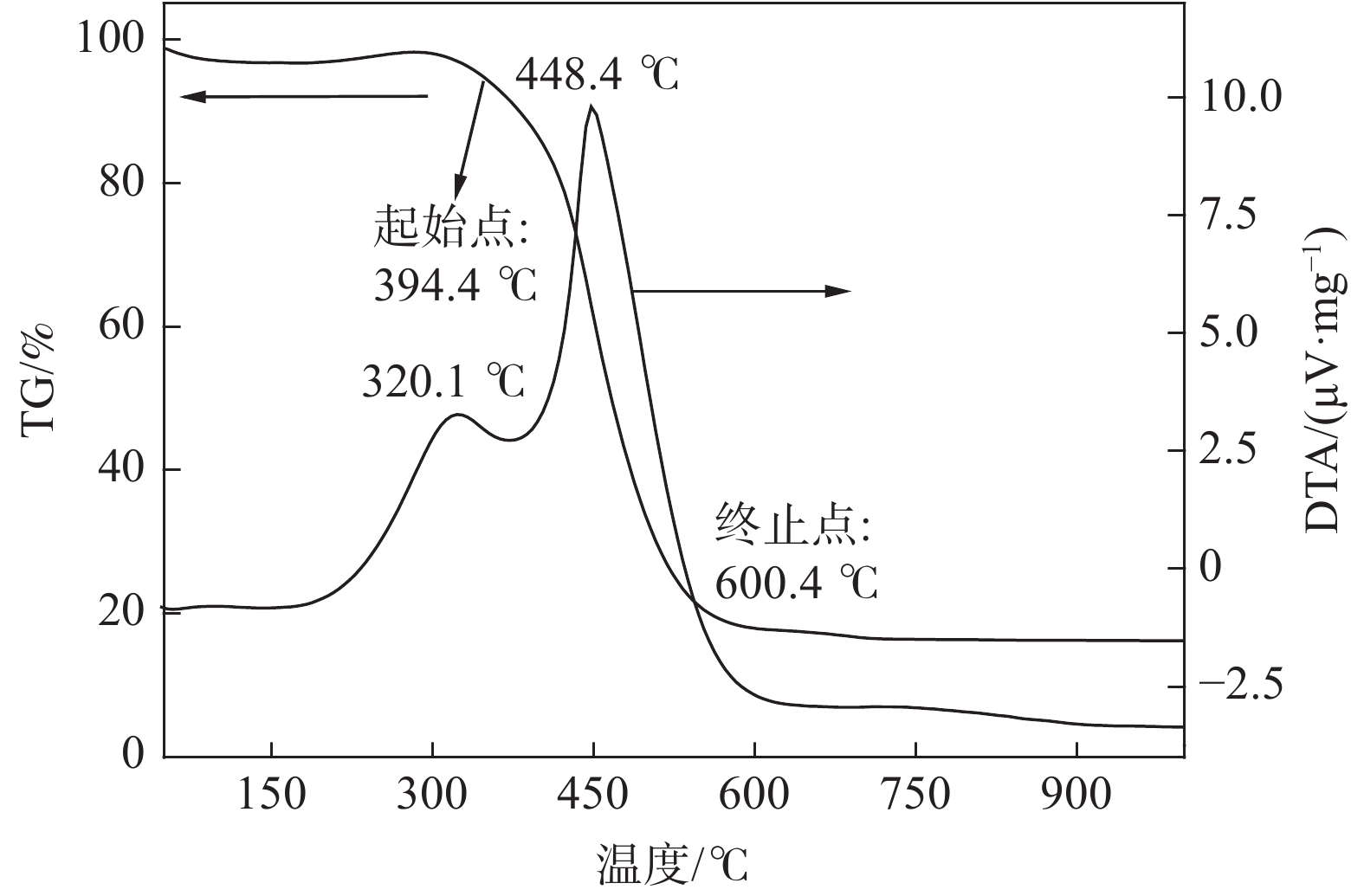

摘要: 以钒钛高炉矿渣和铅渣为主要原料,以锯末为造孔剂,采用压制成型—无压烧结法制备了高抗折强度与高孔隙率的透水砖,研究了配方组成、锯末添加量与烧成温度对样品物理性能的影响,分析了样品的结构、渗透性与环境安全性。结果表明:适当降低钒钛高炉矿渣与烧成温度及提高锯末的添加量可提高样品的气孔率。当钒钛高炉矿渣、铅渣与锯末的添加量(外加)分别为50%、50%与20%时,生坯经1 100 ℃烧成后,透水砖的气孔率、抗折强度与透水系数分别为45.27%、32.94 MPa与1.58~2.02 cm/s。XRD与SEM分析表明,赤铁矿、鳞石英、钙长石与玻璃相相互交织,三维连通的气孔均匀分布,因此透水砖具有较高的强度与优良的透水性能。玻璃相束缚了重金属离子的浸出活性,赋予样品良好的环境安全性。本研究为利用钒钛高炉矿渣与铅渣制备透水砖提供了理论依据。Abstract: Permeable brick with high flexural strength and high porosity were prepared by pressure forming-pressureless sintering respectively using vanadium and titanium blast furnace slag and lead slag as raw materials and sawdust as pore-forming agent. The effects of formula compositions, sawdust addition and sintering temperature on the physical properties of the samples were studied. The structure, permeability and environmental safety of the samples were analyzed. The results show that the porosity of samples could be increased by properly decreasing the amount of blast furnace slag as well as the sintering temperature, and it can be increased by increasing the sawdust addition. When the addition of lead slag, blast furnace slag and sawdust (additional) are 50%, 50% and 20% respectively, the porosity, flexural strength and permeability coefficient of the permeable brick roasted at 1 100 ℃ are respectively 45.27%, 32.94 MPa and 1.58~2.02 cm/s. XRD and SEM analyses show that hematite, quartz and calcareous feldspar intertwine with glass phase, and the pore distribution is uniform in three-dimensional connection, which endow the permeable brick high porosity, good acid and alkali resistance. In addition, the activity of heavy metal ions is bound by glass phase, endowing the permeable brick good environmental safety. This study provides a theoretical basis for the preparation of permeable brick using vanadium titanium blast furnace and lead slag.

-

Key words:

- vanadium titanium blast furnace slag /

- lead slag /

- permeable brick /

- porosity /

- flexural strength /

- microstructure

-

表 1 原料的化学组成

Table 1. Chemical compositions of raw materials

% 原料 SiO2 Al2O3 CaO MgO FeO Na2O ZnO PbO TiO2+V2O5 烧损 矿渣 25.30 18.08 30.01 11.69 1.23 − − − 11.45 2.24 铅渣 20.96 22.24 18.19 3.51 18.21 1.36 3.35 1.09 0.68 10.41 表 2 原料的粒度分布组成

Table 2. Size distribution of raw materials

原料 比例/% −0.17~+0.14 mm −0.14~+0.105 mm −0.105~+0.074 mm −0.074~+0.03 mm −0.03 mm 矿渣 1.39 18.55 35.64 35.59 8.83 铅渣 12.43 24.66 30.70 26.18 6.03 表 3 样品在不同过滤压力下的透水系数

Table 3. Permeability coefficient of the sample under different filtration pressures

过滤压力/MPa 透水系数/(cm·s−1) 0 1.58 0.03 1.61 0.05 1.71 0.07 1.83 0.09 2.01 1.10 2.02 表 4 样品重金属浸出浓度与相关标准要求

Table 4. Leaching concentration of heavy metals in ceramics and relevant standard requirement

mg/L 项目 Cu Pb Cd Cr Zn 测定值 2.34 4.01 0.63 8.96 82.86 标准限值 3.00 5.00 1.00 15.00 100.00 -

[1] Liu Lina, Han Xiuli, Li Zhimin, et al. Study on the mineralogical structure of medium titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2013,34(6):56−59. (刘丽娜, 韩秀丽, 李志民, 等. 中钛型高炉渣矿相结构研究[J]. 钢铁钒钛, 2013,34(6):56−59. [2] (于明珠. 承德市尾矿库安全监管问题与对策研究[D]. 保定: 河北大学, 2014.)Yu Minzhu. Study on safety supervision and management of tailings pond in Chengde[D]. Baoding: Hebei University, 2014. [3] Cui Yaru, Chen Aoli, Hu Ke, et al. Thermodynamic analysis of slag properties and reduction characteristics of high lead slag reduction process[J]. China Nonferrous Metallurgy, 2015,44(4):79−82. (崔雅茹, 陈傲黎, 户可, 等. 高铅渣还原过程渣性能及其还原特性的热力学分析[J]. 中国有色冶金, 2015,44(4):79−82. doi: 10.3969/j.issn.1672-6103.2015.04.021 [4] Ma Shanshan, Zhuang Baoyu, Zhang Xinbo, et al. Analysis of peak flow reduction with green roof and sunken lawn applied in series[J]. China Water & Waste Water, 2014,30(3):101−104. (马姗姗, 庄宝玉, 张新波, 等. 绿色屋顶与下凹式绿地串联对洪峰的削减效应分析[J]. 中国给水排水, 2014,30(3):101−104. [5] Han Jiecai, Hu Luyang, Zhang Yumin, et al. In situ synthesis of hierarchically porous silica ceramics with unidirectionally aligned channel structure[J]. Scripta Materialia, 2010,62:431−434. doi: 10.1016/j.scriptamat.2009.12.019 [6] Lu Junjie. Problems & countermeasures of permeable brick pavement application[J]. China Municipal Engineering, 2018,(2):16−18, 128. (路俊杰. 透水砖路面应用存在的问题及对策[J]. 中国市政工程, 2018,(2):16−18, 128. doi: 10.3969/j.issn.1004-4655.2018.02.005 [7] Li Zhu, Wang Nengjian, Zhao Lin, et al. Study on preparation and perform ances of the high carbon fly ash brick[J]. Concrete, 2018,(3):118−120. (李珠, 王能健, 赵林, 等. 高碳粉煤灰透水砖的制备及性能研究[J]. 混凝土, 2018,(3):118−120. doi: 10.3969/j.issn.1002-3550.2018.03.029 [8] Qiu Fuguo, Wang Juanli, Fu Kunming, et al. Preparation of ecological permeable brick with adsorbable pollutants from water plant sludge[J]. Science and Technology and Engineering, 2018,18(32):253−259. (仇付国, 王娟丽, 付昆明, 等. 水厂污泥制备可吸附污染物的生态透水砖[J]. 科学技术与工程, 2018,18(32):253−259. [9] Zu Bin, Wang Tianrui, Wang Chaojie, et al. Preparation of aeolian sand based sintered permeable materials[J]. New Building Materials, 2019,46(2):150−152. (祖彬, 王天瑞, 王超杰, 等. 风积沙基烧结透水材料的制备[J]. 新型建筑材料, 2019,46(2):150−152. [10] Dealrp, Bernardez L A. Remarks on the short-term chemical stability of primary lead smelting slag[J]. Environmental Earth Sciences, 2017,76(2):89. doi: 10.1007/s12665-017-6396-0 [11] Choi N C, Kim B J, Cho K H, et al. Enhancement of gold recovery during lead fire assay by salt-roasting[J]. Geosystem Engineering, 2014,17(4):226−234. doi: 10.1080/12269328.2014.962709 [12] Wu Jianfeng, Zhang Minglei, Xu Xiaohong, et al. Study on the preparation of porous ceramic filter balls from sintered red mud[J]. Journal of Ceramics, 2007,28(4):276−281. (吴建锋, 张明雷, 徐晓虹, 等. 用烧结法赤泥制备多孔陶瓷滤球的研究[J]. 陶瓷学报, 2007,28(4):276−281. doi: 10.3969/j.issn.1000-2278.2007.04.007 [13] Chen Shibing, Wang Shifeng, Xin Xuliang, et al. Research progress of porous ceramic filter materials[J]. Journal of Shandong Institute of Light Industry, 2009,23(2):17−20. (陈士冰, 王世峰, 辛旭亮, 等. 多孔陶瓷过滤材料的研究进展[J]. 山东轻工业学院学报, 2009,23(2):17−20. [14] Bunzl K, Trautmannsheimer M, Schramel P, et al. Availability of arsenic, copper, lead, thallium, and zinc to various vegetables grown in slag-contaminated soils[J]. Journal of Environmental Quality, 2001,30(3):934−939. doi: 10.2134/jeq2001.303934x -

下载:

下载: