Development of X80M hot-rolled steel plate for LSAW pipe

-

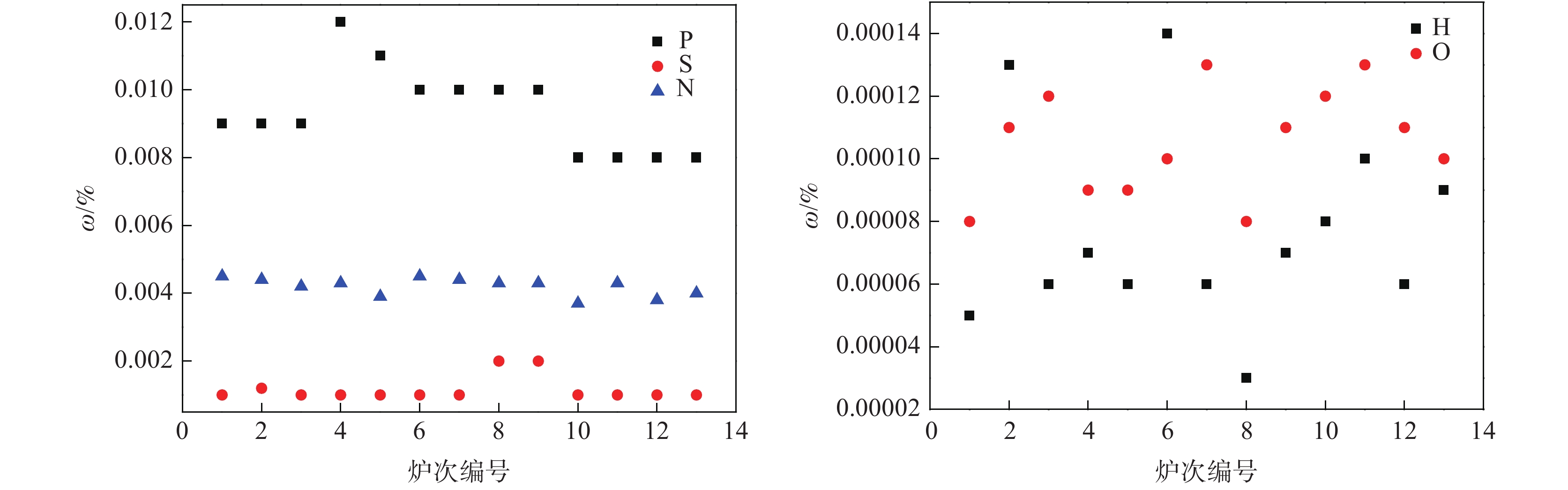

摘要: 为了满足中俄东线450×108 m3/a超大输量及−40 ℃极寒地区服役的国家重大管道工程建设用钢要求,结合南钢自身设备特点,试验开发了具有高强韧性的Φ1422 mm×32.1 mm直缝埋弧焊管用热轧钢板。通过冶金热力学温度控制及保护浇铸手段,得到了成分波动范围窄、低倍组织评级C0.5级的高洁净度铸坯,试验确定了TMCP轧制工艺,钢板力学性能检测富裕量充裕,少量先共析铁素体+针状铁素体+贝氏体+马奥岛的软/硬相复合组织,满足了X80M钢板高强韧性要求,强韧性指标符合管道技术规范要求,实现了中俄东线低温超大输量管道用钢的批量工业生产。Abstract: In order to meet the requirements for annual transportation of 45 billion cubic meters of the China-Russian Eastern Line and the demand for construction of major national pipelines in extremely cold regions at −40 ℃, NISCO has tested and developed Φ1422 mm×32.1 mm straight seam submerged arc welded pipeline steel plates which have high strength and toughness. The high cleanliness casting slabs with narrow composition fluctuation range and low organization rating C0.5 were obtained by metallurgical thermodynamic temperature control and protective casting methods. The industrial test verified the TMCP rolling process. The microstructure is composed of small amount of eutectoid ferrite+acicular ferrite+bainite+M/A island soft/hard phase, which meets the high strength and toughness requirements of X80M steel plate. The strength and toughness performance indicators meet the requirements of pipeline technical specifications and meet mass industrial production of steel for low-temperature and large-volume pipelines.

-

表 1 X80MΦ1422 mm×32.1 mm直缝埋弧焊管用热轧钢板拉伸性能试验要求

Table 1. Requirements for X80M Φ1 422 mm×32.1 mm hot-rolled steel plate for LSAW pipe

钢级 屈服强度/MPa 抗拉强度/MPa 最大屈强比(Rt0.5/Rm) 最小伸长率(Af) /% 最小 最大 最小 最大 X80 555 700 625 765 0.93 按API Spec 5L 注:本要求为钢管拉伸性能要求。根据协商一致原则,由制造商负责对供应的钢板拉伸性能进行调整,但应保证制成钢管的拉伸性能符合直缝埋弧焊钢管技术条件的规定。 表 2 X80MΦ1422 mm×32.1 mm直缝埋弧焊管用热轧钢板夏比冲击试验要求

Table 2. Charpy impact test requirements for X80M Φ1422 mm×32.1 mm hot-rolled steel plate for LSAW pipe

钢级 试验温度/℃ 位置 夏比冲击剪切面积(SA)/% 夏比冲击功/J 单个试样最小值 三个试样最小平均值 单个试样最小值 三个试样最小平均值 X80 −30 板宽1/4横向 70 85 160 210 注:10 mm×10 mm×55 mm试样。 表 3 X80MΦ1 422 mm×32.1 mm直缝埋弧焊管用热轧钢板X80M坯料成分设计

Table 3. Alloying design for X80MΦ1 422 mm×32.1 mm hot-rolled steel plate for LSAW X80M billet

% C Si Mn P S Nb+V+Ti Ca 内控 0.040~0.060 0.20~0.30 1.60~1.70 ≤0.012 ≤0.002 0.055~0.080 0.0005~0.0040 A1t Cr Ni Cu B N H Pcm 内控 0.015~0.050 0.10~0.20 0.15~0.30 0.10~0.20 ≤0.0005 ≤0.0060 ≤0.0002 0.17~0.22 表 4 X80MΦ1 422 mm×32.1 mm直缝埋弧焊管用热轧钢板硬度(HV10)检测结果

Table 4. Hardness (HV10) test results of X80M Φ1 422 mm×32.1 mm hot rolled steel plate for LSAW pipe

试样号 厚度/mm 厚度方向截面硬度(HV10) 近上表单值 心部单值 近下表单值 最大值 试样1 32.1 205 203 216 208 209 207 205 211 206 216 试样2 32.1 234 211 229 216 211 213 212 219 218 234 试样3 32.1 220 215 213 221 212 220 221 219 218 221 试样4 32.1 239 225 229 216 220 214 217 216 211 239 -

[1] Zeng Y P, Zhu P Y, Tong K. Effect of microstructure on the low temperature toughness of high strength pipeline steels[J]. International Journal of Minerals, Metallurgy and Materials, 2014,22(3):254. [2] Shin S Y, Huang B, Lee S, et al. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels[J]. Materials Scuence and Engineering: A, 2007,458(1−2):281. doi: 10.1016/j.msea.2006.12.097 [3] Niu Yanlong, Liu Qingyou, Jia Shujun. Microstructure and impact toughness of X80 grade high strength low alloy pipeline steel[J]. Iron &Steel, 2019,54(2):67. (牛延龙, 刘清友, 贾书君. X80级高强低合金管线钢组织与冲击韧性[J]. 钢铁, 2019,54(2):67. [4] Du Wei, Li Helin, Wang Haitao, et al. Research status of high-performance oil and gas pipelines in China and abroad[J]. Oil & Gas Storage and Transportation, 2016,35(6):577−582. (杜伟, 李鹤林, 王海涛, 等. 国内外高性能油气输送管的研发现状[J]. 油气储运, 2016,35(6):577−582. [5] Zhang Kunfeng, Zhang Xingchang, Gao Zhaoliang, et al. Study on the distribution characteristics of environment and geological hazards along the west-east gas pipeline[J]. Industry and Technology Forum, 2009,8(4):117−128. (张昆锋, 张兴昌, 高照良, 等. 西气东输管道沿线环境及地质灾害分布特征研究[J]. 产业与科技论坛, 2009,8(4):117−128. doi: 10.3969/j.issn.1673-5641.2009.04.043 [6] Wang Xinhua, Li Xiugang, Li Qiang, et al. Control of string shaped non-metallic inclusions of CaO-Al2O3 sysrem in X80 pipeline steel plates[J]. Acta Metall. Sin., 2013,49(5):553−561. (王新华, 李秀刚, 李强, 等. X80管线钢板中条串状CaO-Al2O3系非金属夹杂物的控制[J]. 金属学报, 2013,49(5):553−561. doi: 10.3724/SP.J.1037.2012.00505 [7] Li Pingquan. Failure accidents and typical cases of oil and gas transmission pipeline[J]. Welded Pipe and Tube, 2005,(4):76−84, 92. (李平全. 油气输送管道失效事故及典型案例[J]. 焊管, 2005,(4):76−84, 92. doi: 10.3969/j.issn.1001-3938.2005.04.025 [8] Tong Ke, Xie Xuedong, Li Liang, et al. Failure cause and typical case analysis of bending pipe used in oil and gas transmission[J]. Petroleum Tubular Goods & Instruments, 2016,2(1):46−49. (仝珂, 谢学东, 李亮, 等. 油气输送用弯管失效原因及典型案例分析[J]. 石油管材与仪器, 2016,2(1):46−49. doi: 10.3969/j.issn.1004-9134.2016.01.014 [9] Fang Wei, Zou Bin, Li Weiwei, et al. Separations and their contribution into the impact toughness of pipeline steels of strength class K65 (X80)[J]. Welded Pipe and Tube, 2018,41(2):65. (方伟, 邹斌, 李为卫, 等. K65(X80)管线钢断口分离及其对冲击韧性的影响[J]. 焊管, 2018,41(2):65. -

下载:

下载: