Effect of vanadium content on microstructure and properties of W6Mo5Cr4Vx high speed steel for bit

-

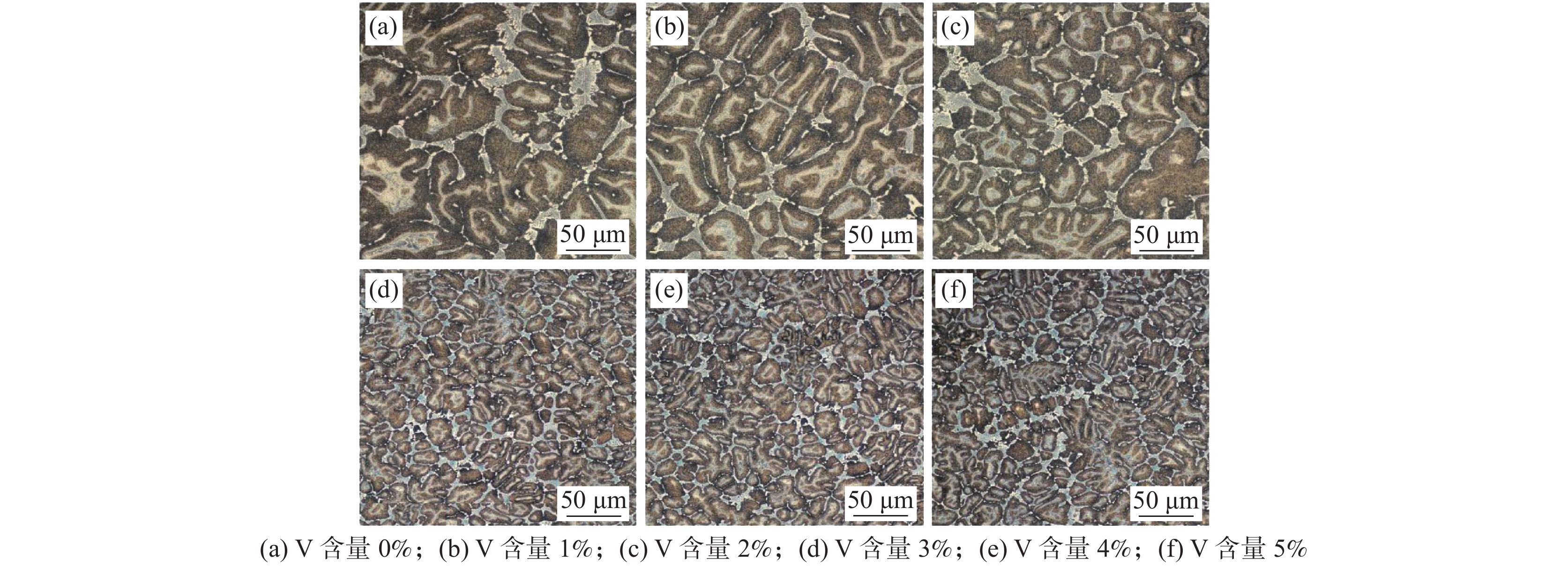

摘要: 在钻头用W6Mo5Cr4Vx高速钢中添加了不同含量的合金元素钒,并进行了显微组织、耐磨损和耐腐蚀性能的测试与分析。结果表明:添加钒有助于提高高速钢的耐磨损和耐腐蚀性能,随钒含量从0增至5%,钢的耐磨损和耐腐蚀性能均先提高后下降。钢中钒含量优选为3%。与不添加钒相比,W6Mo5Cr4Vx(x=3)高速钢的磨损体积减小5.2×10−3 mm3、腐蚀电位正移57 mV。Abstract: In this paper, different content of vanadium was added to W6Mo5Cr4Vx high speed steel for bit, and the microstructure, wear resistance and corrosion resistance were tested and analyzed. The results show that the addition of vanadium can improve the wear resistance and corrosion resistance of high speed steel. With the increase of vanadium content from 0 to 5%, the wear resistance and corrosion resistance of steel increase firstly and then decrease. The optimized vanadium content in experimental steel is 3%. Compared the steel without vanadium addition, the wear volume of W6Mo5Cr4Vx (x=3) high speed steel decreases by 5.2×10−3 mm3, and the corrosion potential shifts positively by 57 mV.

-

Key words:

- high speed steel /

- vanadium content /

- wear resistance /

- corrosion resistance /

- microstructure

-

表 1 W6Mo5Cr4Vx高速钢试样化学成分

Table 1. Chemical compositions of W6Mo5Cr4Vx high speed steel specimens

% 编号 C W Mo Cr V Si Mn 其它元素 Fe 试样1(x=0) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 0 <0.03 <0.035 <0.3 Bal. 试样2(x=1) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 1 <0.03 <0.035 <0.3 Bal. 试样3(x=2) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 2 <0.03 <0.035 <0.3 Bal. 试样4(x=3) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 3 <0.03 <0.035 <0.3 Bal. 试样5(x=4) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 4 <0.03 <0.035 <0.3 Bal. 试样6(x=5) 0.9±0.05 6.0±0.2 5.0±0.2 4.0±0.1 5 <0.03 <0.035 <0.3 Bal. 表 2 W6Mo5Cr4Vx高速钢耐腐蚀性能测试结果

Table 2. Corrosion resistance test results of W6Mo5Cr4Vx high speed steel specimens

试样编号 钢中钒含量/% 腐蚀电位/V 试样1 0 −0.724 试样2 1 −0.711 试样3 2 −0.692 试样4 3 −0.667 试样5 4 −0.672 试样6 5 −0.679 -

[1] Liu Zhiqiang, Cao Huanjun, Zheng Xiping, et al. Research and application of high vanadium high speed steel[J]. Hot Working Technology, 2014,43(16):23−26. (刘志强, 曹环军, 郑喜平, 等. 高钒高速钢的研究与应用[J]. 热加工工艺, 2014,43(16):23−26. [2] Liu Dongdong, Zhang Guoshang, Wei Shizhong, et al. Investigation of wear performance of high vanadium high speed steel[J]. Foundry Technology, 2013,34(2):135−137. (刘冬冬, 张国赏, 魏世忠, 等. 高钒高速钢磨损性能的研究现状[J]. 铸造技术, 2013,34(2):135−137. [3] Wang Qiming, Cheng Guoguang, Huang Yu. Morphology and precipitation mechanism of large carbides in M2 high speed steel[J]. Iron & Steel, 2018,53(1):65−71. (王启明, 成国光, 黄宇. M2高速钢大尺寸碳化物的形貌特征及析出机理[J]. 钢铁, 2018,53(1):65−71. [4] Xue Qi, Yi Cheng, Zhou Yi, et al. Effect of quenching temperature on friction and wear properties of high vanadium high speed steel[J]. Heat Treatment of Metals, 2017,42(11):156−160. (薛屺, 易诚, 周毅, 等. 淬火温度对高钒高速钢摩擦磨损性能的影响[J]. 金属热处理, 2017,42(11):156−160. [5] Kou Guofu, Yan Xianguo, Feng Zhiyang, et al. Research on wear mechanism of W6Mo5Cr4V2 high speed steel taps based on cryogenic and passivation technology[J]. Tool Engineering, 2017,51(3):26−28. (寇国富, 闫献国, 冯志阳, 等. 基于深冷和钝化工艺的W6Mo5Cr4V2高速钢丝锥磨损机理的研究[J]. 工具技术, 2017,51(3):26−28. doi: 10.3969/j.issn.1000-7008.2017.03.006 [6] He Shijian. Effect of heat treatment on microstructure and mechanical properties of high speed steel cutter for machine tool[J]. Hot Working Technology, 2017,46(12):215−217, 221. (何时剑. 热处理对机床用高速钢刀具组织和力学性能的影响[J]. 热加工工艺, 2017,46(12):215−217, 221. [7] He Xing, Li Yanzheng, Lei Xionghui, et al. Effect of heat treatment process on microstructure and properties of CM2 high speed steel[J]. Shanghai Metals, 2019,41(1):66−70. (何星, 李炎铮, 雷雄辉, 等. 热处理工艺对CM2高速钢组织性能的影响[J]. 上海金属, 2019,41(1):66−70. doi: 10.3969/j.issn.1001-7208.2019.01.014 [8] Chen Xiang, Zhang Deqiang, Sun Wenqiang, et al. Effect of scanning speed on deformation and microstructure of thin plate high-speed steel by laser cladding[J]. Surface Technology, 2019,48(9):150−157. (陈翔, 张德强, 孙文强, 等. 扫描速度对激光熔覆薄板高速钢变形与组织的影响[J]. 表面技术, 2019,48(9):150−157. [9] Hou Ximing, Liu Kunfeng, Zeng Xuelan. Influence of heat treatment process on microstructures and mechanical properties of SF9V steel[J]. Foundry Technology, 2015,36(4):913−914, 917. (侯锡铭, 刘坤峰, 曾雪兰. 热处理工艺对SF9V高速钢组织及性能的影响[J]. 铸造技术, 2015,36(4):913−914, 917. [10] Wang Sheng. Parameters optimization of plastic nylon parts formed by high speed steel turning tool[J]. Journal of Plasticity Engineering, 2016,23(2):162−165. (王胜. 特制高速钢车刀成形塑料尼龙时工艺参数的优化[J]. 塑性工程学报, 2016,23(2):162−165. [11] Chi Hongxiao, Xu Huixia, Fang Feng, et al. High temperature mechanical properties of M2 high speed steel[J]. China Metallurgy, 2016,26(1):31−34. (迟宏宵, 徐辉霞, 方峰, 等. M2高速钢的高温力学性能[J]. 中国冶金, 2016,26(1):31−34. [12] Liang Gang, Wang Zhenting. Effect of molybdenum and modification treatment on wear behaviors of high vanadium high speed steel[J]. Journal of Heilongjiang University of Science and Technology, 2014,24(6):599−602. (梁刚, 王振廷. Mo和变质处理对高钒高速钢耐磨性的影响[J]. 黑龙江科技大学学报, 2014,24(6):599−602. -

下载:

下载: