Effect of ferrite thermal insulation on microstructure and mechanical properties of vanadium microalloyed HRB500 steel rebar

-

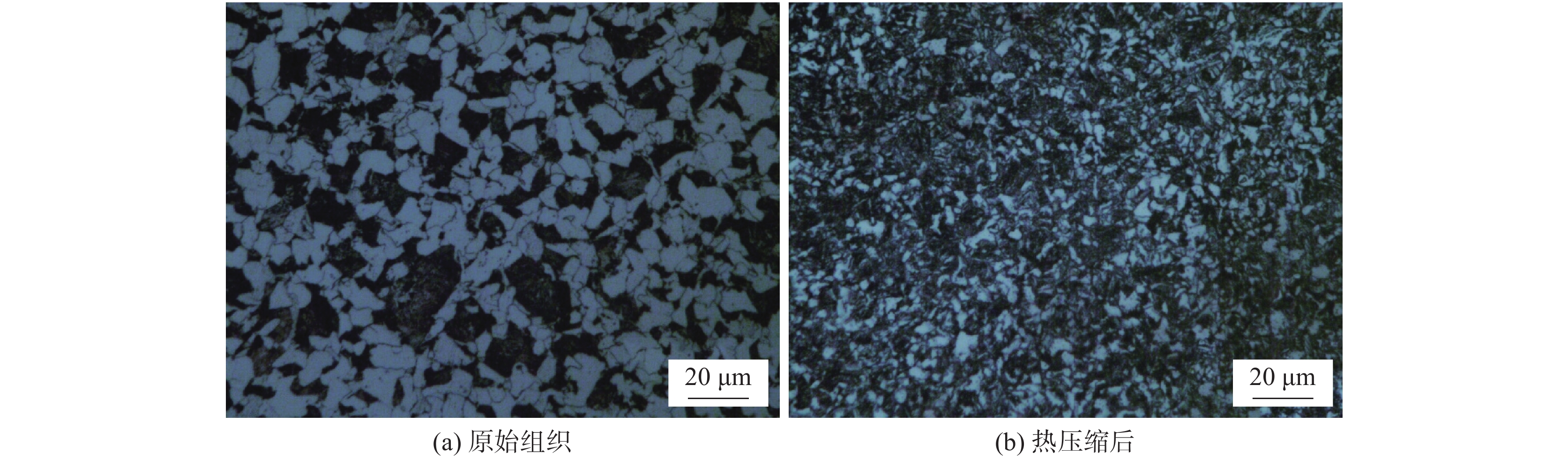

摘要: 通过Gleeble3500对HRB500进行了奥氏体区形变+铁素体区保温的热模拟压缩试验,研究了铁素体区保温工艺对HRB500组织和性能的影响。结果表明,试样加热到980 ℃保温15 min,进行80%压下之后,随着铁素体区保温温度的降低,珠光体组织逐渐碎化,铁素体出现少量针状结构,但硬度未随之发生规律性改变;在保温工艺中,700 ℃×15 min保温时获得了最高硬度(HV)300,较直接冷却试样提高了30,这可归于碳化钒的析出强化,进一步延长保温时间硬度显著降低,可知保温过程中晶粒的粗化抵消了碳化钒的第二相强化效果。由试验数据可以推测,常规热轧生产的HRB500并未充分利用VC的第二相强化,在轧后冷床上进行700 ℃×10~15 min的保温作业,可望实现该钢10 MPa以上的强度增量。Abstract: The thermal simulation compression experiment of austenite deformation and ferrite area insulation was carried out on HRB500 steel rebar by a Gleeble3500 simulator, and the effect of ferrite area insulation technology on microstructure and properties of HRB500 steel rebar was studied. The results show that after the sample was reheated at 980 ℃ × 15 min and then deformed by 80% reduction, as the temperature of the ferrite zone decreases, the pearlite structure gradually breaks down and a small amount of needle-like structure appears in the ferrite, but the hardness changing does not show a clear tendency. During the isothermal holding process, the highest hardness (HV) 300 was obtained after 700 ℃ × 15 min proccess, which was 30 higher than that of the directly cooled sample. This could be attributed to the precipitation strengthening of vanadium carbide, which would decrease when the holding time elongated. The coarsening of the grains counteracts the second phase strengthening effect of vanadium carbide. It can be inferred from the test data that the HRB500 steel rebar produced by conventional hot rolling does not fully take advantage of the second phase strengthening of VC. Insulation at 700 ℃ × 10 ~ 15 min on the workbench after rolling is expected to achieve a strength increment of more than 10 MPa.

-

Key words:

- HRB500 /

- vanadium microalloyed /

- ferrite zone /

- insulation /

- thermal simulation compression experiment

-

表 1 钢的化学成分与轧态硬度(HV)

Table 1. Chemical compositions and hardness of as-hot rolled steel

化学成分/% 平均硬度 C Si Mn S P V 0.20~0.25 0.35~0.80 1.46~1.60 ≤0.04 ≤0.04 0.08~0.02 280 -

[1] (周大伟, 李元廷. V-Nb微合金化HRB500钢筋的试制[C]//第二届宝钢学术年会, 2006: 422−424.)Zhou Dawei, Li Yuanting. Trial production of V-Nb micro-alloyed HRB500 reinforced bar[C]. Baosteel BAC 2006, 2006: 422−424. [2] Lin Bingsong. Analysis on rolling and process improvement of high-strength reinforced HRB500 steel with vanadium microalloying[J]. China High-Teach Enterprises, 2013,(8):37−38. (林炳松. 钒微合金化HRB500高强度钢筋轧制与工艺改进探析[J]. 中国高新技术企业, 2013,(8):37−38. [3] Zhao Liang, Zhang Chaohui, Ju Jiantao, et al. Comparison experiment and research on HRB500 reinforced bars produced by adding V-N alloy and V-Fe alloy[J]. Materials & Heat Treatment, 2007,36(8):35−37. (赵亮, 张朝晖, 巨建涛, 等. 钒铁与钒氮合金生产HRB500钢筋的对比试验研究[J]. 材料热处处理, 2007,36(8):35−37. [4] Yang Caifu, Zhang Yongquan, Liu Shuping. Strengthening mechanism in V-N micro-alloyed reinforcing bar steels[J]. Iron and Steel, 2001,36(5):55−57. (杨才福, 张永权, 柳书平. 钒氮微合金化钢筋的强化机制[J]. 钢铁, 2001,36(5):55−57. doi: 10.3321/j.issn:0449-749X.2001.05.015 [5] OHMORIA, O IK, KAWABATA F, et al. Effect of VN precipitates on formation of grain boundary and intragranular ferrite in a high N-V bearing steel[J]. Journal of the Iron and Steel Institute of Japan, 1998,84(7):797−803. [6] (王芳丽. 微合金化钢筋中V、Nb析出行为研究[D]. 重庆: 重庆大学, 2016.)Wang Fangli. Study on precipitation behaviors of V and Nb in microalloyed steel bars[D]. Chongqing: Chongqing University, 2016. [7] Wang Andong, Wang Junyu, Tian Linmao. Precipitation law of V (C, N) in austenite of vanadium microalloyed steel[J]. Materials for Mechanical Engineering, 2016,40(8):23−26. (王安东, 王骏宇, 田林茂. V (C, N)在含钒微合金钢奥氏体中的析出规律[J]. 机械工程材料, 2016,40(8):23−26. doi: 10.11973/jxgccl201608006 -

下载:

下载: