Effect of deformation temperature and cooling rate on microstructure and properties of microalloyed 82B wire rod

-

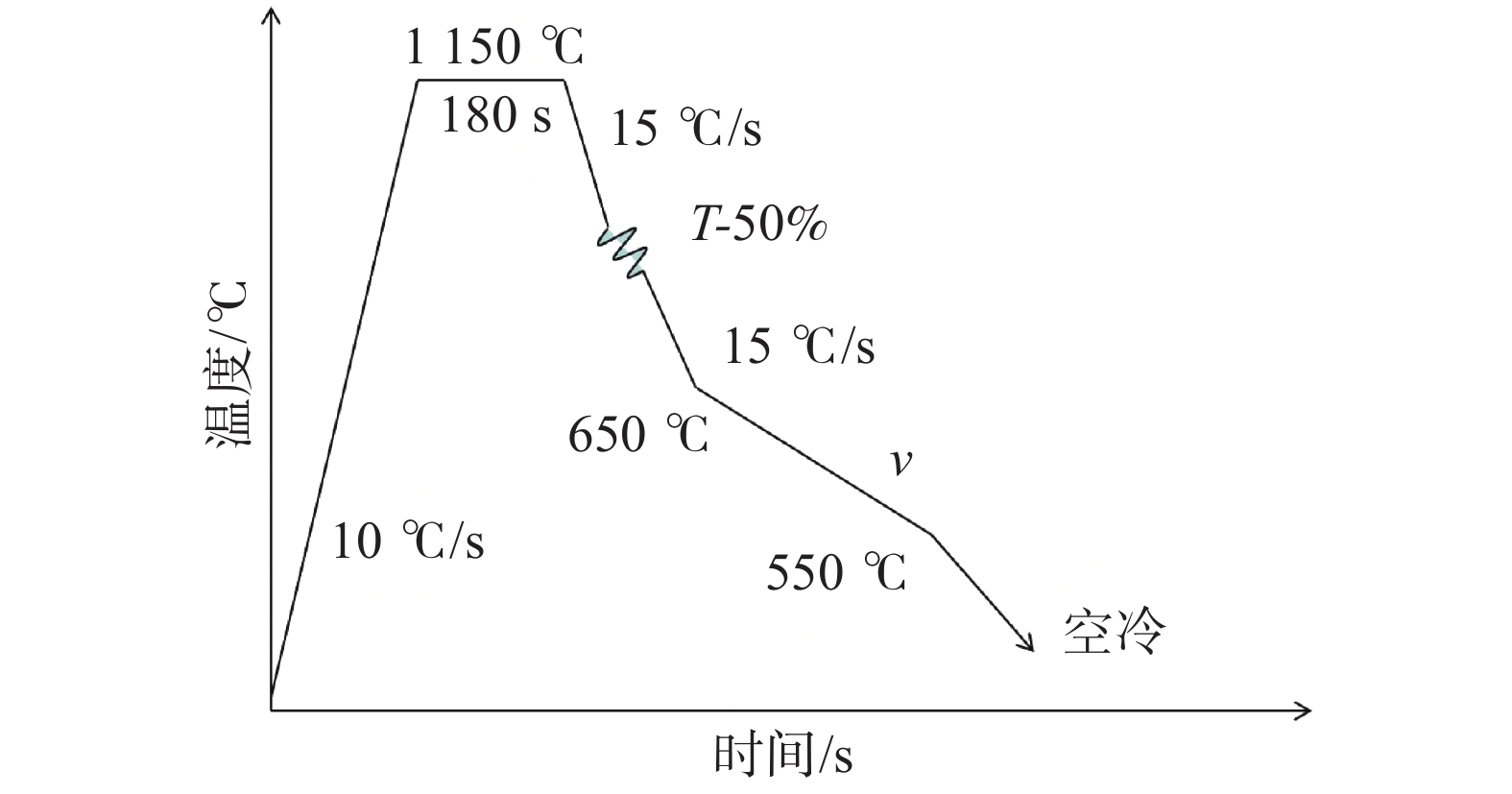

摘要: 利用热模拟仪、金相显微镜、万能试验机等手段对微合金化82B盘条的变形温度及冷却速度进行了研究分析,试验结果表明:较快的冷速会促进钒合金化试样中含钒第二相的析出,提高材料强度的同时降低其塑性,该合金化方式需控制钒含量;钒氮合金化是一种适合82B盘条的强化方式,但材料的钒和氮含量比例关系,以及与冷速的交互作用可显著影响材料的强韧性,需严格控制钢中钒氮配比;铬钒复合微合金化可显著提高82B盘条的强度和韧性,且不受冷速的强烈影响,是理想的微合金化方式,铬钒复合微合金化82B盘条组织均匀,未出现中心元素偏析,适宜终轧温度范围为900~940 ℃。Abstract: The deformation temperature and cooling rate of microalloyed 82B wire rod were studied by means of thermal simulator, metallographic microscope and universal testing machine in this paper. Experiment results show that the rapid cooling rate can promote the precipitation of the second phase containing vanadium in the vanadium alloyed sample, improving the strength of the material and reducing its plasticity, thus the vanadium should be well controlled for this alloying design. V-N alloying was suitable for 82B wire rod, but the ratio of V to N and the interaction with cooling rate could significantly affect the strength and toughness of the material, so it was necessary to control the ratio of V to N in the steel. Cr-V composite microalloying could significantly improve the strength and toughness of 82B wire rod, whichwas not strongly affected by the cooling rate, so it was an ideal microalloying method. The microstructure of 82B wire rod was uniform without element center segregation, and the suitable finishing temperature range was 900 ~ 940 ℃ for experimental steels.

-

Key words:

- 82B wire rod /

- deformation temperature /

- cooling rate /

- microalloying /

- mechanical properties

-

表 1 试验钢的主要化学成分

Table 1. Main chemical compositions of steelis

% 序号 C Mn Si V N Cr 备注 1# 0.80 0.75 0.22 0.0074 0.0025 82B 2# 0.83 0.73 0.26 0.044 0.0028 82B+0.044V 3# 0.82 0.74 0.22 0.079 0.0026 82B+0.079V 4# 0.81 0.74 0.28 0.14 0.0022 82B+0.14V 5# 0.83 0.74 0.26 0.096 0.009 82B+0.096V、0.009N 6# 0.83 0.74 0.26 0.095 0.013 82B+0.095V、0.013N 7# 0.81 0.74 0.24 0.014 0.18 82B+0.18Cr 8# 0.83 0.72 0.20 0.075 0.0037 0.19 82B+0.075V、0.19Cr 表 2 微合金化82B钢热模拟变形断口硬度

Table 2. Surface hardness of thermal simulated deformation fracture of microalloyed 82B steel

变形温度/℃ 硬度(HRC) 测量值 平均值 820 37.2, 37.9, 37.6, 37.3 37.5 840 37.5, 36.9, 38.3, 38.1 37.7 860 37.1, 37.6, 37.1, 38.5 37.6 880 37.1, 37.4, 37.9, 36.8 37.3 900 35.8, 36.9, 37.3, 35.3 36.3 920 35.7, 36.6, 37.2, 36.6 36.5 940 36.9, 36.3, 36.6, 36.9 36.7 -

[1] Hu Bo, Guo Shanli, Zhang Changjing, et al. Optimization of controlled rolling and cooling process for recrystallization of high carbon wire rod SWRH82B[J]. Hot Working Process, 2014,(19):140−142. (胡波, 郭善莉, 张长静, 等. 高碳盘条SWRH82B再结晶型控制轧制与冷却工艺的优化研究[J]. 热加工工艺, 2014,(19):140−142. [2] Wang Bingxi, Ren Yuhui, Guo Dayong, et al. Production process and quality analysis of SWRH82B wire rod[J]. Metal Products, 2009,35(5):49−52. (王秉喜, 任玉辉, 郭大勇, 等. SWRH82B盘条生产工艺及质量分析[J]. 金属制品, 2009,35(5):49−52. doi: 10.3969/j.issn.1003-4226.2009.05.017 [3] Li Zhengsong, Gao Changyi, Liu Lide, et al. Production practice of SWRH82B hot rolled wire rod[J]. Metal Products, 2016,42(3):35−37. (李正嵩, 高长益, 刘立德, 等. SWRH82B热轧线材生产实践[J]. 金属制品, 2016,42(3):35−37. doi: 10.3969/j.issn.1003-4226.2016.03.010 [4] Yang Feng, Liang Yilong, Xiang Song, et al. Effect of heat treatment process on microstructure of SWRS82B wire rod[J]. Heat Treatment Process, 2012,41(18):173−176. (杨峰, 梁益龙, 向嵩, 等. 热处理工艺对SWRS82B盘条显微组织的影响[J]. 热加工工艺, 2012,41(18):173−176. [5] Ma Zhijun, Li Zilin, Sun Haoran, et al. Controlled cooling process and microstructure and properties of SWRH82B wire rod for steel strand[J]. Rolling, 2006,23(2):56−58. (马志军, 李子林, 孙浩然, 等. 钢绞线用SWRH82B盘条的控冷工艺及组织性能[J]. 轧钢, 2006,23(2):56−58. doi: 10.3969/j.issn.1003-9996.2006.02.018 [6] Li Minna, Du Zhongze, Wang Qingjuan, et al. Application of microalloying and controlled cooling in high carbon steel wire rod[J]. Hot Working Process, 2016,(1):6−10. (李敏娜, 杜忠泽, 王庆娟, 等. 微合金化及控制冷却在高碳钢盘条中的应用现状[J]. 热加工工艺, 2016,(1):6−10. [7] Wang Yongwei, Gui Meiwen, Zhou Yong, et al. Effect of V and N microalloying on the properties of 82B high carbon steel[J]. Journal of Material Heat Treatment, 2011,(1):84−88. (王勇围, 桂美文, 周勇, 等. V、N微合金化对高碳钢82B性能的影响[J]. 材料热处理学报, 2011,(1):84−88. [8] Shen Jinlong, Qin Zhiguang, Xia Yanhua, et al. Application of vanadium nitrogen alloy in high carbon steel wswrh82b[J]. Iron Steel Vanadium Titanium, 2009,30(4):21−26. (沈金龙, 覃之光, 夏艳花, 等. 钒氮合金在高碳钢WSWRH82B中的应用[J]. 钢铁钒钛, 2009,30(4):21−26. doi: 10.7513/j.issn.1004-7638.2009.04.005 [9] Li Yueyun, Hu Lei, Wang Lei, et al. Development of high performance prestressed steel strand wire SWRH72BCr-1%[J]. Metal Heat Treatment, 2018,43(9):31−36. (李月云, 胡磊, 王雷, 等. 高性能预应力钢绞线盘条SWRH72BCr-1%的开发[J]. 金属热处理, 2018,43(9):31−36. [10] Hua Wei, Xu Zhen, Song Jinling, et al. Effect of controlled cooling on microstructure and properties of SWRH82B-1V high carbon steel wire rod[J]. Special Steel, 2010,(1):70−72. (华蔚, 徐震, 宋金玲, 等. 控制冷却对SWRH82B-1V高碳钢盘条组织和性能的影响[J]. 特殊钢, 2010,(1):70−72. [11] Fu Jun, Wang Fuming, Chai Guoqiang, et al. Dynamic continuous cooling structure transformation of 82B high carbon steel wire rod[J]. Metal Heat Treatment, 2010,35(8):5−8. (付军, 王福明, 柴国强, 等. 82B高碳钢盘条的动态连续冷却组织转变[J]. 金属热处理, 2010,35(8):5−8. -

下载:

下载: