Research on cracking mechanism of girth and weld straightening of grade 800 MPa automobile torsion beam steel

-

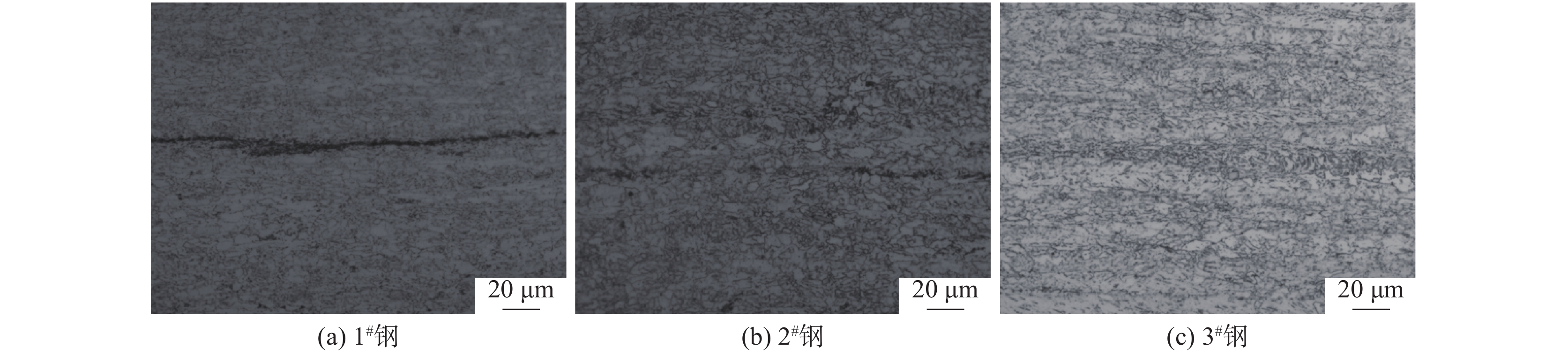

摘要: 利用光镜、扫描电镜、透射电镜、EBSD、Thermo-Calc热力学软件、JMatPro软件研究了Nb-Ti复合微合金化800 MPa级扭力梁用钢热轧板在汽车扭力梁围管和焊缝矫直过程中的开裂原因。对三种不同成分的试验钢的显微组织和纳米析出相的研究结果表明,围管和焊缝矫直开裂的主要原因为:3#钢中添加了Cr、Mo、V元素,使钢的TTT曲线右移,提高了奥氏体的稳定性,使轧后冷却过程中生成了大量的含有高密度位错的板条马氏体和板条铁素体等硬相组织,而等轴铁素体的数量较少,而且晶粒大小不均匀,在力学性能上表现为抗拉强度偏高。由于板条铁素体和板条马氏体含有高密度位错,降低了钢的塑韧性,使其在围管和焊缝矫直过程中容易开裂。Abstract: The cracking mechanism of grade 800 MPa steel for automobile torsion beam during girth and weld straightening were studied by OM, SEM, TEM and EBSD. Thermos-Calc thermodynamic software and J Mat Pro software were used to calculate equilibrium precipitated phase in steel and TTT curves. The microstructure and nano precipitates of experimental steels with different compositions were observed. The results show that the main reasons for cracking of experimental steel during girth and weld straightening are as follows: the addition of Cr, Mo and V elements in the 3# steel makes the TTT curve of the steel shift to the right, improving the stability of austenite and generating a large number of lath martensite and lath ferrite with high density dislocation during cooling after rolling. However, the amount of equiaxed ferrite is less and the grain size is uneven, so the tensile strength is higher. High density dislocation in lath martensite and lath ferrite results in the decrease of plasticity and toughness, and then causing crack in girth and weld during straightening.

-

表 1 化学成分

Table 1. Chemical compositions of used steels

% 编号 C Mn Si Als N Nb Ti Mo V Cr 1# 0.069 1.75 0.09 0.046 0.004 0.05 0.11 0 0 0 2# 0.045 1.50 0.05 0.032 0.004 0.03 0.09 0.17 0 0 3# 0.060 1.56 0.10 0.045 0.003 0.05 0.07 0.03 0.23 0.13 表 2 力学性能

Table 2. Mechanical properties of used steels

编号 抗拉强度/MPa 屈服强度/MPa 断后伸长率A50/% 开裂情况 1 828 767 22 未开裂 2 804 741 23 未开裂 3 838 753 27 开裂 表 3 相变温度计算结果

Table 3. Calculated phase transition temperatures

试样 Fs/℃ Ps/℃ Bs/℃ Ms/℃ $M_{{\rm{f}}} $/℃ 1# 838.4 670.6 618.5 451.2 344.2 2# 854.1 676.2 630.7 463.0 356.9 3# 847.4 688.3 619.1 451.7 344.8 表 4 晶界长度

Table 4. Grain boundary length of three steels

钢种 晶界长度/μm 2~5° 5~15° >15° 1# 410.78 465.98 2010 2# 454.95 586.41 2270 3# 124.65 202.82 1450 -

[1] Zhang Xiaoming Yin Shubiao, Yang Chunlei, et al. Reasons and improvement of K510L steel automobile crossbeam bending crack[J]. Hot Working Technology, 2017,46(5):257−262. (张小明, 阴树标, 杨春雷, 等. 汽车大梁K510L钢折弯裂纹成因及改进[J]. 热加工工艺, 2017,46(5):257−262. [2] Liu Sheniu, Cheng Yonggu, Duan Yun. Analysis of 510L automobile Frames machining crack[J]. Henan Metallougy, 2010,18(6):18−23. (刘社牛, 程永固, 段云. 汽车大梁钢510L加工开裂的原因分析[J]. 河南冶金, 2010,18(6):18−23. doi: 10.3969/j.issn.1006-3129.2010.06.006 [3] Narayanasamy R, Parthasarathi N L, Narayanan C S. Effect of microstructure on void nucleation and coalescence during forming of three different HSLA steel sheets under different stress conditions[J]. Materials & Design, 2009,30(4):1310−1324. [4] Xiao Guangyao, Song Yingjin, Tian Yaqiang, et al. Experimental study on the behavior of compressive strength and peak strain of concrete under high strain rates[J]. Journal of Hebei United University (Natural Science Edition), 2012,34(3):71−74. (肖广耀, 宋进英, 田亚强,等. 硫化物夹杂及成分偏析对610L钢冷弯开裂的影响[J]. 河北联合大学学报(自然科学版), 2012,34(3):71−74. [5] Zhao Peilin, Sun Xinjun, Yong Qilong, et al. Crack analysis of super high strength steel plate during cold stamping process[J]. Heat Treatment of Metals, 2012,37(7):122−126. (赵培林, 孙新军, 雍岐龙, 等. 超高强度热轧钢板冷冲压开裂原因及分析[J]. 金属热处理, 2012,37(7):122−126. [6] Xu Liling. Microscopic analysis on cold bend fracture of BM510L beam steel plate[J]. Physics Examination and Testing, 2005,23(5):53−55. (徐礼玲. BM510L汽车大梁钢板冷弯开裂的显微分析[J]. 物理测试, 2005,23(5):53−55. doi: 10.3969/j.issn.1001-0777.2005.05.019 [7] Song Zhuofei, Feng Yunli, Feng Runming, et al. Study on reason for low impact toughness and cold bending crack of 610L[J]. Hot Working Technology, 2014,43(2):221−222. (宋卓斐, 冯运莉, 冯润明, 等. 610L汽车大梁钢冲击韧性低及冷弯开裂原因研究[J]. 热加工工艺, 2014,43(2):221−222. [8] Sun Feng, Yin Xiaoli, Zhao Da. Rolling process optimization of vanadium microalloyed automobile titanium alloy[J]. Iron Steel Vanadium Titanium, 2020,41(3):59−63. (孙凤, 尹晓丽, 赵达. 钒微合金化汽车钛合金的轧制工艺优化[J]. 钢铁钒钛, 2020,41(3):59−63. doi: 10.7513/j.issn.1004-7638.2020.03.009 [9] Hang Zidi, Feng Yunli, Cui Yan, et al. Mathematical modeling of the recrystallization kinetics of high Ti-microalloyed high strength steel[J]. Iron Steel Vanadium Titanium, 2020,41(1):141−146. (杭子迪, 冯运莉, 崔岩, 等. 高Ti微合金高强钢静态再结晶动力学模型[J]. 钢铁钒钛, 2020,41(1):141−146. [10] Gao B, Chen X, Pan Z, et al. A high-strength heterogeneous structural dual-phase steel[J]. Journal of Materials Science, 2019,54(19):66−72. [11] Yang Yilei, Hui Yajun, Ju Xinhua, et al. Causes and control measures of stamping cracking of 700 MPa grade high strength beam steel[J]. China Metallurgy, 2019,29(6):77−80. (杨一雷, 惠亚军, 鞠新华, 等. 700MPa级高强度大梁钢冲压开裂原因与控制措施[J]. 中国冶金, 2019,29(6):77−80. [12] HuoXiangdong, Mao Xinping, Dong Feng. Effect of coiling temperature on the mechanical properties of Ti-microalloyed high strength steel[J]. Journal of University of Science and Technology Beijing, 2013,35(11):1472−1477. (霍向东, 毛新平, 董锋. 卷取温度对Ti微合金化高强钢力学性能的影响机理[J]. 北京科技大学学报, 2013,35(11):1472−1477. [13] Ghosh A, Ray A, Chakrabarti D, et al. Cleavage initiation in steel: Competition between large grains and large particles[J]. Materials Science and Engineering: A, 2013,561:126−135. doi: 10.1016/j.msea.2012.11.019 [14] Bu F Z, Wang X M, Yang S W, et al. Contribution of interphase precipitation on yield strength in thermomechanically simulated Ti-Nb and Ti-Nb-Mo microalloyed steels[J]. Materials Science & Engineering: A, 2014,(620):22−29. [15] Xu Y, Zhang W, Sun M, et al. The blocking effect of interphase precipitation on dislocations' movement in Ti-bearing micro-alloyed steel[J]. Materials Letters, 2015,(139):177−181. [16] Lv Yong, Peng Jun, Cai Changkun, et al. Rare earth Ce on thermodynamics of titanium containing inclusions in steel and its experimental research[J]. Iron Steel Vanadium Titanium, 2019,40(3):93−98. (吕勇, 彭军, 蔡长焜, 等. 稀土铈对钢中含钛夹杂物析出行为的研究[J]. 钢铁钒钛, 2019,40(3):93−98. [17] Shu Wei, Wang Xuemin, Li Shurui, et al. Influence of second-phase particles containing Ti on microstructure and properties of weld-heat-affected-zone of a microalloy steel[J]. Acta Metallurgica Sinica, 2010,46(8):997−1003. (舒玮, 王学敏, 李书瑞, 等. 含复合第二相粒子对微合金钢焊接热影响区组织和性能的影响[J]. 金属学报, 2010,46(8):997−1003. [18] Jung J, Park J, Kim J, et al. Carbide precipitation kinetics in austenite of a Nb–Ti–V microalloyedsteel[J]. Materials Science and Engineering: A, 2011,528(16-17):5529−5535. doi: 10.1016/j.msea.2011.03.086 [19] Wang Z, Sun X, Yang Z, et al. Carbide precipitation in austenite of a Ti–Mo-containing low-carbon steel during stress relaxation[J]. Materials Science and Engineering: A, 2013,573:84−91. doi: 10.1016/j.msea.2013.02.056 [20] Li Liming, Feng Yunli, Yang Lina. Thermodynamic calculation of Ti-containing second phase in Ti-microalloyed high strength steel[J]. Iron Steel Vanadium Titanium, 2019,40(1):118−122. (李立铭, 冯运莉, 杨丽娜. 钛微合金化高强钢含Ti第二相的热力学计算[J]. 钢铁钒钛, 2019,40(1):118−122. doi: 10.7513/j.issn.1004-7638.2019.01.021 -

下载:

下载: