Experimental study on high-efficiency beneficiation of fine-grained olivine pyroxene ilmenite

-

摘要: 针对攀西地区某选厂细粒橄辉岩型钛铁矿粒度细,橄榄石脉石含量高,常规的螺旋选矿机和强磁无法对其进行高效富集的难点,开发了一种重选组合流程—“新型螺旋+悬振锥面选矿”,对其进行预富集后再浮选。相比强磁作业,新工艺所获得的产率能提高8.24%,浮选给矿TiO2品位提高2个百分点,富集作业尾矿TiO2品位下降4个百分点,浮选作业药剂成本大幅降低,每年能增加钛精矿6万t,从而实现此类型钛铁矿的高效回收。Abstract: The recovery efficiency of fine-grained olivine pyroxene ilmenite from a concentration plant in Panxi area is low, which brings about high cost of flotation reagents and low annual output of titanium concentrate. To solve these problems, a kind of gravity concentration process, i.e., the new type “spiral + suspended vibration cone surface mineral processing”, is creatively developed. By using the new technique, the yield increased by 8.24%, the grade of flotation feed TiO2 increased by 2%, and the grade of TiO2 tailings decreased by 4% compared to that of current high-intensity magnetic separation process, the cost of flotation reagents is greatly reduced, and 60, 000 tons of titanium concentrate can be increased every year. In this way, the efficient recovery of this type of ilmenite can be realized.

-

表 1 试样全粒级筛分分析结果

Table 1. Results of full size screening analysis of samples

粒级/mm 产率/% TiO2品位/% TiO2分布率/% −0.20~+0.16 0.18 3.95 0.10 −0.16~+0.125 1.82 6.19 1.60 −0.125~+0.10 5.74 6.25 5.13 −0.10~+0.074 22.05 5.13 16.16 −0.074~+0.045 29.93 6.22 26.59 −0.045~+0.038 15.40 8.10 17.82 −0.038~+0.019 18.63 10.25 27.28 −0.019~+0.010 2.94 6.29 2.64 −0.010 3.32 5.65 2.68 合计 100.00 7.00 100.00 表 2 试样矿物组成及含量

Table 2. Mineral composition and content of samples

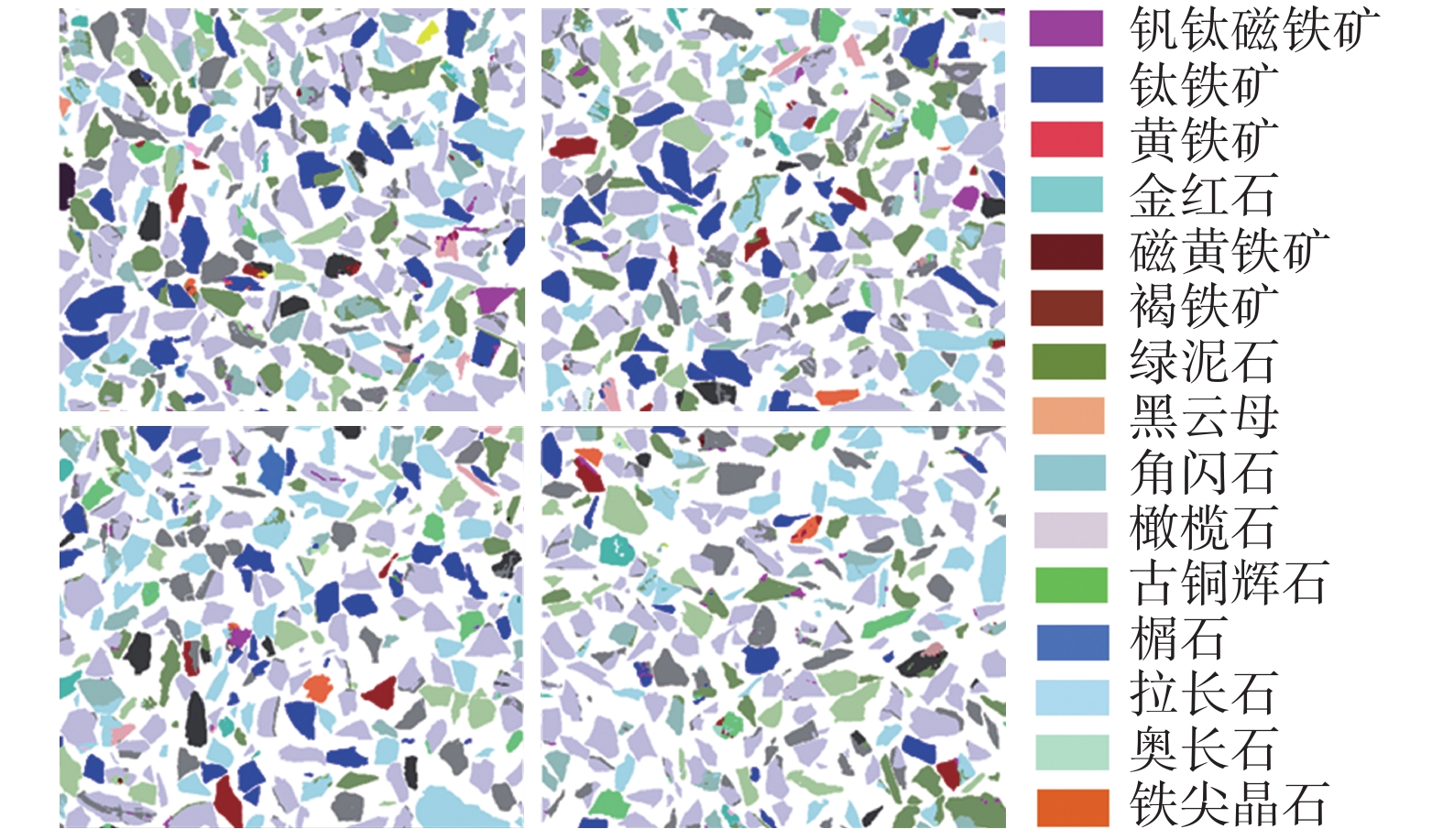

矿物 含量/% 矿物 含量/% 矿物 含量/% 钒钛磁铁矿 2.456 透辉石 0.183 绿泥石 9.153 钛铁矿 13.283 普通辉石 8.578 锆石 0.001 榍石 0.117 古铜辉石 2.113 褐铁矿 0.419 黄铁矿 0.015 角闪石 5.540 水锰矿 0.001 磁黄铁矿 2.117 橄榄石 34.210 铁尖晶石 1.311 镍黄铁矿 0.091 黑电气石 0.117 三水铝石 0.023 黄铜矿 0.168 钙铁榴石 0.036 方解石 0.024 闪锌矿 0.006 钙铝榴石 0.081 白云石 0.001 毒砂 0.002 钙铁橄榄石 0.050 菱铁矿 0.003 石英 0.050 葡萄石 0.767 磷灰石 0.075 长石 12.201 绿帘石 0.116 重晶石 0.002 白云母 0.091 褐帘石 0.009 其他 0.068 黑云母 0.189 蛇纹石 5.712 合计 100.000 金云母 0.425 铁蛇纹石 0.196 表 3 新型螺旋试验结果

Table 3. Test results of the spiral separation process

产品 产率/% TiO2品位/% 回收率/% 精矿1 13.83 17.79 34.48 精矿2 8.52 14.55 17.36 精矿3 6.42 12.49 11.24 综合精矿 28.78 15.65 63.08 尾矿 71.22 3.70 36.92 给矿 100.00 7.10 100.00 表 4 悬振锥面选矿试验结果

Table 4. Test results of suspension vibration cone beneficiation process

产品 产率/% TiO2品位/% 回收率/% 精矿 12.21 13.42 44.29 尾矿2 25.92 3.47 24.28 尾矿1 61.87 1.88 31.44 综合尾矿 87.79 2.35 55.71 给矿 100.00 3.70 100.00 表 5 浮选原料对比结果

Table 5. Comparison results of flotation for raw materials

表 6 开路浮选指标对比结果

Table 6. Comparison results of open-circuit flotation indexes

富集流程 钛精矿指标/% 药剂用量/(g∙t−1) 产率 TiO2品位 捕收剂 硫酸 黄药 生产工艺 3.57 47.00 2500 3800 300 新工艺 4.95 47.00 2 000 3000 300 -

[1] (王向东, 逯福生, 贾翃. 2007年中国钛工业发展报告[J]. 钛工业进展, 2008(2): 2−4.)Wang Xiangdong, Lu Fusheng, Jia Hong. Development report of China titanium industry in 2007[R]. Progress of Titanium Industry, 2008 (2): 2−4. [2] Yu Jiahua, Liu Honggui. Production status and development trend of titanium ores and titanium rich materials at home and abroad[J]. World Nonferrous Metals, 2003,(6):4−8. (余家华, 刘洪贵. 国内外钛矿和富钛料生产现状及发展趋势[J]. 世界有色金属, 2003,(6):4−8. [3] (邱凯. 攀枝花微细粒钛铁尾矿再选新工艺研究[D]. 昆明: 昆明理工大学, 2018.)Qiu Kai. Study on the new process of re-concentration of Panzhihua fine grained ferrotitanium tailings[D]. Kunming: Kunming University of Science and Technology, 2018. [4] Xiao Liangchu, Wang Yong. Difficulties analysis on beneficiation of low grade ilmenite ore from baima panzhihua[J]. Modern Mining, 2016,32(3):58−62. (肖良初, 王勇. 攀枝花白马低品位钛铁矿选别难点分析[J]. 现代矿业, 2016,32(3):58−62. doi: 10.3969/j.issn.1674-6082.2016.03.024 [5] (王勇, 吴雪红. 低品位钛铁矿选钛技术研究[R]. 攀枝花: 攀钢集团矿业有限公司.)Wang Yong, Wu Xuehong. Study on titanium separation technology of low grade ilmenite[R]. Panzhihua. Panzhihua Iron and Steel Group Mining Co., Ltd. [6] Xie Qichun, Wang Hongbin. Countermeasures to existing problems in demonstration line for processing lean ilmenite from baima mine in Panzhihua[J]. Mining and Metallurgical Engineering, 2017,37(6):51−53. (谢琪春,王洪彬. 攀枝花白马矿区低品位钛铁矿回收示范线问题及对策分析[J]. 矿冶工程, 2017,37(6):51−53. doi: 10.3969/j.issn.0253-6099.2017.06.011 -

下载:

下载: