Experimental study on beneficiation of a weathered V-Ti iron ore from abroad

-

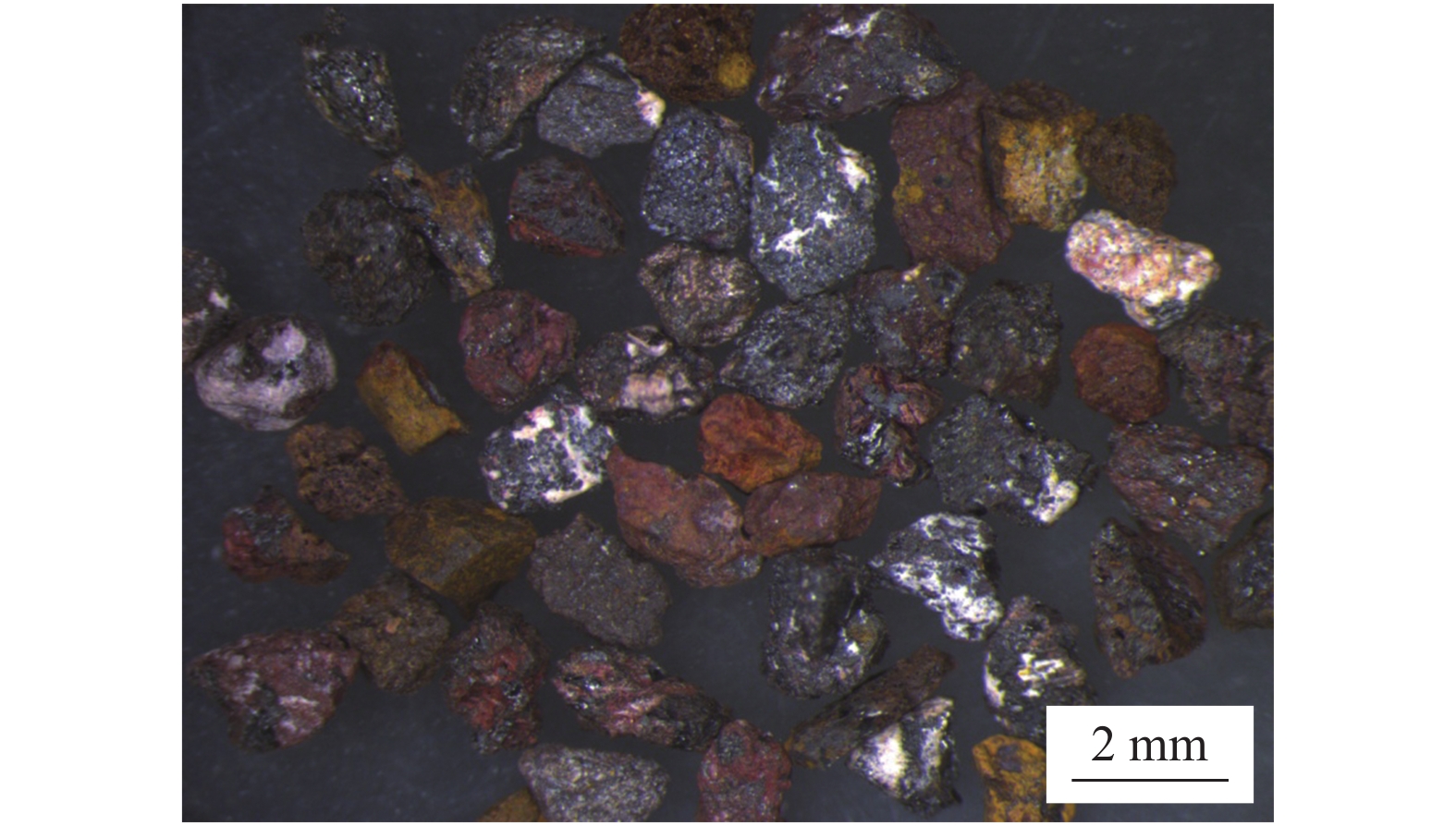

摘要: 针对国外某深度蚀变氧化型钒钛铁矿,铁矿物与钛矿物难以物理选矿实现分离,脉石矿物的比磁化系数、比重与金属矿物差异较大、易磨矿解离的特征,开展了选矿富集钒钛铁试验研究,对比了磁选回收工艺、分级-磁选回收工艺及重选回收工艺,确定磁选回收工艺为最适宜的回收工艺。磁选回收工艺获得了可市售的含钒铁精矿含Fe 60.52%、V2O5 1.03%,回收率分别为Fe 8.12%、V2O5 8.62%,钒钛铁混合精矿Fe 50.03%、V2O5 0.80%、TiO2 16.01%,回收率分别为Fe 78.61%、V2O5 78.45%、TiO2 82.88%的选别指标,混合精矿钒、钛、铁品位较高,可作为冶金进一步获取钒、钛、铁的原料。Abstract: For a severely weathered and oxidized V-Ti iron ore from abroad, Fe minerals and Ti minerals are disseminated closely to each other thus it is difficult to separate by physical beneficiation. Based on the specific magnetization coefficient and specific gravity, gangue minerals are quite different from those of metal minerals and are easy to dissociate by grinding, the study on primary enrichment of V-Ti-Fe was carried out. Recovery of V-Ti-Fe by magnetic separation, classification–magnetic separation and gravity separation were compared. The result shows that the magnetic separation is the most suitable method for the ore. The saleable V-bearing iron concentrate consisting of Fe 60.52%, V2O5 1.03% with the recovery of Fe 8.12%, V2O5 8.62%, and the V-Ti-Fe bulk concentrate consisting of Fe 50.03%, V2O5 0.80%, TiO2 16.01% with the recovery of Fe 78.61%, V2O5 78.45%, TiO2 82.88% were obtained by magnetic separation. The bulk concentrate with high grade of V2O5 and TiO2 could be used as raw materials for extracting vanadium, titanium and iron.

-

表 1 矿石的多元素分析

Table 1. The major element composition of ROM

% Fe V2O5 TiO2 Al2O3 SiO2 P2O5 S K2O Na2O CaO 43.51 0.71 13.26 7.85 10.54 <0.01 0.004 0.002 0.31 0.03 表 2 矿石矿物组成

Table 2. The mineralogical composition of ROM

% 磁铁矿-磁赤铁矿-赤铁矿 钛铁矿-蚀变钛铁矿 褐铁矿 蒙脱石 粘土矿物 白钛石 石英 叶腊石 其它 41.85 15.78 22.97 0.25 16.54 0.22 0.22 0.23 1.94 表 3 −2 mm原矿筛分分析结果

Table 3. The screening analysis result of −2 mm ROM

粒级/mm 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 −2.0~+1.5 6.63 49.36 0.76 13.81 7.43 7.20 6.87 −1.5~+1.0 11.68 50.14 0.78 14.40 13.30 13.01 12.62 −1.0~+0.5 19.90 49.94 0.78 14.37 22.55 22.17 21.45 −0.5~+0.25 13.69 48.92 0.83 14.75 15.21 16.23 15.15 −0.25~+0.10 13.44 48.34 0.75 12.74 14.75 14.40 12.84 −0.1~+0.075 4.11 45.64 0.69 15.99 4.25 4.05 4.92 −0.075~+0.038 8.35 42.91 0.64 17.03 8.14 7.63 10.67 −0.038~+0.02 8.93 40.45 0.68 15.07 8.20 8.68 10.10 −0.02~+0.01 3.26 30.59 0.44 9.48 2.26 2.05 2.32 −0.01~+0.005 1.86 24.75 0.41 6.64 1.05 1.09 0.93 −0.005 8.15 15.45 0.30 3.52 2.86 3.49 2.15 合计 100.00 44.05 0.70 13.33 100.00 100.00 100.00 表 4 磁选粗精矿精选试验结果

Table 4. The test result of magnetic separation concentrate cleaning

精选作业 产品名称 作业产率/% 品位/% 作业回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 高梯度磁选 精矿 82.49 51.14 0.79 16.65 85.40 82.68 86.58 中矿 17.51 41.20 0.78 12.16 14.60 17.32 13.42 混合精矿 100.00 49.40 0.79 15.86 100.00 100.00 100.00 细泥摇床 精矿 35.09 52.35 0.91 19.06 37.19 41.42 42.35 中矿 40.71 50.95 0.80 14.89 41.99 42.25 38.39 尾矿 24.20 42.48 0.52 12.56 20.82 16.33 19.25 混合精矿 100.00 49.39 0.77 15.79 100.00 100.00 100.00 表 5 磁选回收试验结果

Table 5. The test result of magnetic seperation

产品名称 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 含钒铁精矿 5.84 60.52 1.03 9.28 8.12 8.62 4.10 混合精矿 68.40 50.03 0.80 16.01 78.61 78.45 82.88 尾矿 25.76 22.42 0.35 6.68 13.27 12.93 13.02 原矿 100.00 43.53 0.70 13.21 100.00 100.00 100.00 含钒铁精矿+混合精矿 74.24 50.85 0.82 15.48 86.73 87.07 86.98 表 6 原矿擦洗—振动筛筛分试验结果

Table 6. The test result of recovery of V, Ti, Fe by scrubbing screening

产品名称 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 粗粒级粗精矿 50.59 49.29 0.81 14.14 56.05 57.04 53.26 −0.25 mm粒级 49.41 38.30 0.60 12.12 43.95 42.96 46.74 原矿 100.00 43.86 0.71 13.14 100.00 100.00 100.00 表 7 −0.25 mm粒级磁选回收试验结果

Table 7. The test result of −0.25 mm size range recovery by magnetic seperation

产品名称 作业产率/% 品位/% 作业回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 含钒铁精矿 3.65 60.01 0.96 8.64 5.67 5.80 2.61 混合精矿 56.61 48.16 0.76 17.22 70.63 71.19 80.63 尾矿 39.74 23.02 0.35 5.10 23.70 23.01 16.76 −0.25 mm粒级 100.00 38.60 0.60 12.09 100.00 100.00 100.00 表 8 原矿分级–磁选试验结果

Table 8. The test result of classification–magnetic separation

产品名称 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 含钒铁精矿 1.54 60.12 0.98 8.17 2.12 2.15 0.96 混合精矿 77.42 48.68 0.77 15.22 86.34 84.96 89.96 尾矿 21.04 23.93 0.43 5.65 11.53 12.89 9.08 原矿 100.00 43.65 0.70 13.10 100.00 100.00 100.00 含钒铁精矿+混合精矿 78.96 48.90 0.77 15.08 88.46 87.11 90.92 表 9 原矿分级摇床试验结果

Table 9. The test result of classification-shaking process

产品名称 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 摇精1~3 39.40 52.36 0.90 17.08 47.62 51.48 51.01 摇中1~3 25.88 47.12 0.72 13.49 28.15 27.05 26.46 摇床尾矿 34.72 30.23 0.43 2.97 24.23 21.47 22.53 原矿 100.00 43.32 0.69 13.19 100.00 100.00 100.00 摇精+摇中 65.29 50.28 0.80 15.66 75.77 78.53 77.47 表 10 原矿螺旋溜槽试验结果

Table 10. The test result of spiral chute process

产品名称 产率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 精矿 43.48 52.11 0.87 17.12 51.82 54.08 55.93 中矿 23.81 43.54 0.60 12.82 23.71 20.57 22.93 尾矿 32.71 32.70 0.54 8.60 24.47 25.35 21.14 原矿 100.00 43.72 0.70 13.31 100.00 100.00 100.00 精矿+中矿 67.29 49.07 0.78 15.60 75.53 74.65 78.86 表 11 三种工艺回收指标对比结果

Table 11. The comparison result of recovery indexes of three processes

回收工艺 抛废率/% 品位/% 回收率/% Fe V2O5 TiO2 Fe V2O5 TiO2 分级-磁选 21.04 48.90 0.77 15.08 88.46 87.11 90.92 磁选 25.76 50.85 0.82 15.48 86.73 87.07 86.98 螺旋溜槽 32.71 49.07 0.78 15.60 75.53 74.65 78.86 表 12 含钒铁精矿多元素分析

Table 12. The major element composition of V-bearing iron concentrate

% Fe V2O5 TiO2 Al2O3 SiO2 P2O5 S Zn Sn Cu As 60.52 1.03 9.28 2.98 3.412 0.01 0.05 0.08 0.02 0.01 <0.01 表 13 强磁选精矿多元素分析

Table 13. The major element composition of strong magnetic concentrate

% Fe V2O5 TiO2 Al2O3 SiO2 P2O5 S Zn Sn Cu As 50.03 0.80 16.01 8.43 9.87 0.02 0.12 0.05 0.05 0.045 <0.01 -

[1] (郭宇峰.钒钛磁铁矿固态还原强化及综合利用研究[D].长沙: 中南大学, 2007.)Guo Yufeng. Study on solid reduction strengthening and comprehensive utilization of vanadium titanium magnetite[D].Changsha: Central South University, 2007. [2] Chen Yilin, Tang Xiaoling, Li Yanjun, et al. Study on continoua test of suspension magnetization roasting of Jiuquan iron and steel company tailings[J]. Metal Mine, 2020,(5):178−184. (陈毅琳, 唐晓玲, 李艳军, 等. 酒钢尾矿悬浮磁化焙烧扩大连续试验研究[J]. 金属矿山, 2020,(5):178−184. [3] Yang Zhaojun, Wang Fengyu, Luo Rongfei, et al. Magnetic separation and enrichment method of ultrafine vanadium-bearing titanomagnetite in Panxi region[J]. Iron Steel Vanadium Titanium, 2019,40(3):26−29. (杨招君, 王丰雨, 罗荣飞, 等. 攀西超细粒级钒钛磁铁矿磁选富集方法[J]. 钢铁钒钛, 2019,40(3):26−29. [4] (郑析科. 攀西地区钒钛磁铁矿中伴生钴的富集规律[D]. 成都: 成都理工大学, 2019.)Zheng Xike. Enrichment of associated cobalt in vanadium titanomagnetite from Panxi area[D].Chengdu: Chengdu University of Technology, 2019. [5] Li Lixia, Shen Shuaiping, Yuan Zhitao, et al. Loss mechanism of fine-grainedimenite in magnetic separation[J]. China Mining Magazine, 2018,27(11):138−144. (李丽匣, 申帅平, 袁致涛, 等. 微细粒钛铁矿磁选回收率低原因分析[J]. 中国矿业, 2018,27(11):138−144. [6] Wang Hongbin, Li Jin, Zhang Guohua. Study on efficient recovery process of ilmenite from vanadic titanium magnetite in Panxi area[J]. Iron Steel Vanadium Titanium, 2020,41(3):23−29. (王洪彬, 李金, 张国华. 攀西钒钛磁铁矿中钛铁矿高效回收工艺研究[J]. 钢铁钒钛, 2020,41(3):23−29. doi: 10.7513/j.issn.1004-7638.2020.03.003 [7] Li Junhan, Sun Ning, Ma Lan, et al. Study on the mineralogical characteristics of titano-magnetite of V-Ti magnetite ore in Panxi region[J]. Iron Steel Vanadium Titanium, 2018,39(5):98−105. (李俊翰, 孙宁, 马兰, 等. 攀西某钒钛磁铁矿中钛磁铁矿的矿物特征研究[J]. 钢铁钒钛, 2018,39(5):98−105. [8] Gao Yongzhang. Vanadium resources and it's supply and demand situation in China[J]. China Mining Magazine, 2019,28(S2):5−10. (高永璋. 中国钒矿资源及供需形势分析[J]. 中国矿业, 2019,28(S2):5−10. [9] Liu Mudan, Liu Yong, Zhou Jikui, et al. Experimengal research on metallurgical enrichment crude concentrate from benefication of V-Ti-Fe polymetallic ore[J]. Rare Metals and Cemented Carbides, 2019,47(6):15−19. (刘牡丹, 刘勇, 周吉奎, 等. 钒钛铁多金属矿选矿粗精矿冶金富集试验研究[J]. 稀有金属与硬质合金, 2019,47(6):15−19. [10] Liao Qian, Gong Wenyong, Zhang Hua, et al. Experimental study on gravity and magnetic separation proces sfor coastal placer in Mozambique[J]. Mining and Metallurgical Engineering, 2019,39(6):54−56. (廖乾, 龚文勇, 张华, 等. 莫桑比克某海滨砂矿重选—磁选工艺试验研究[J]. 矿冶工程, 2019,39(6):54−56. doi: 10.3969/j.issn.0253-6099.2019.06.013 [11] Wang Xun, Han Yuexin, Li Yanjun, et al. Processing mineralogical genetic characterization ofaforeign refractory iron ore[J]. Metal Mine, 2019,(2):178−182. (王勋, 韩跃新, 李艳军, 等. 国外某难选铁矿石工艺矿物学基因特性研究[J]. 金属矿山, 2019,(2):178−182. [12] Yu Lianxiang, Zhou Jikui, Liu Jun, et al. Study on pricess mineralogy and separation technology of titanium-zirconium rough concentrate with refractory hematite in Malawi[J]. Conservation and Utilization of Mineral Resources, 2019,(6):171−178. (喻连香, 周吉奎, 刘军, 等. 马拉维含难分离赤铁矿的钛锆粗精矿工艺矿物学及分离新技术的研究[J]. 矿山保护与利用, 2019,(6):171−178. [13] Hu Yibo, Ye Guohua, Wang Heng, et al. Market analysis of vanadium and progress on technologies of vanadium extraction from stone coal[J]. Iron Steel Vanadium Titanium, 2019,40(2):31−40. (胡艺博, 叶国华, 王恒, 等. 钒市场分析与石煤提钒工艺进展[J]. 钢铁钒钛, 2019,40(2):31−40. doi: 10.7513/j.issn.1004-7638.2019.02.006 -

下载:

下载: