Simulation on separation of organic impurities in titanium tetrachloride

-

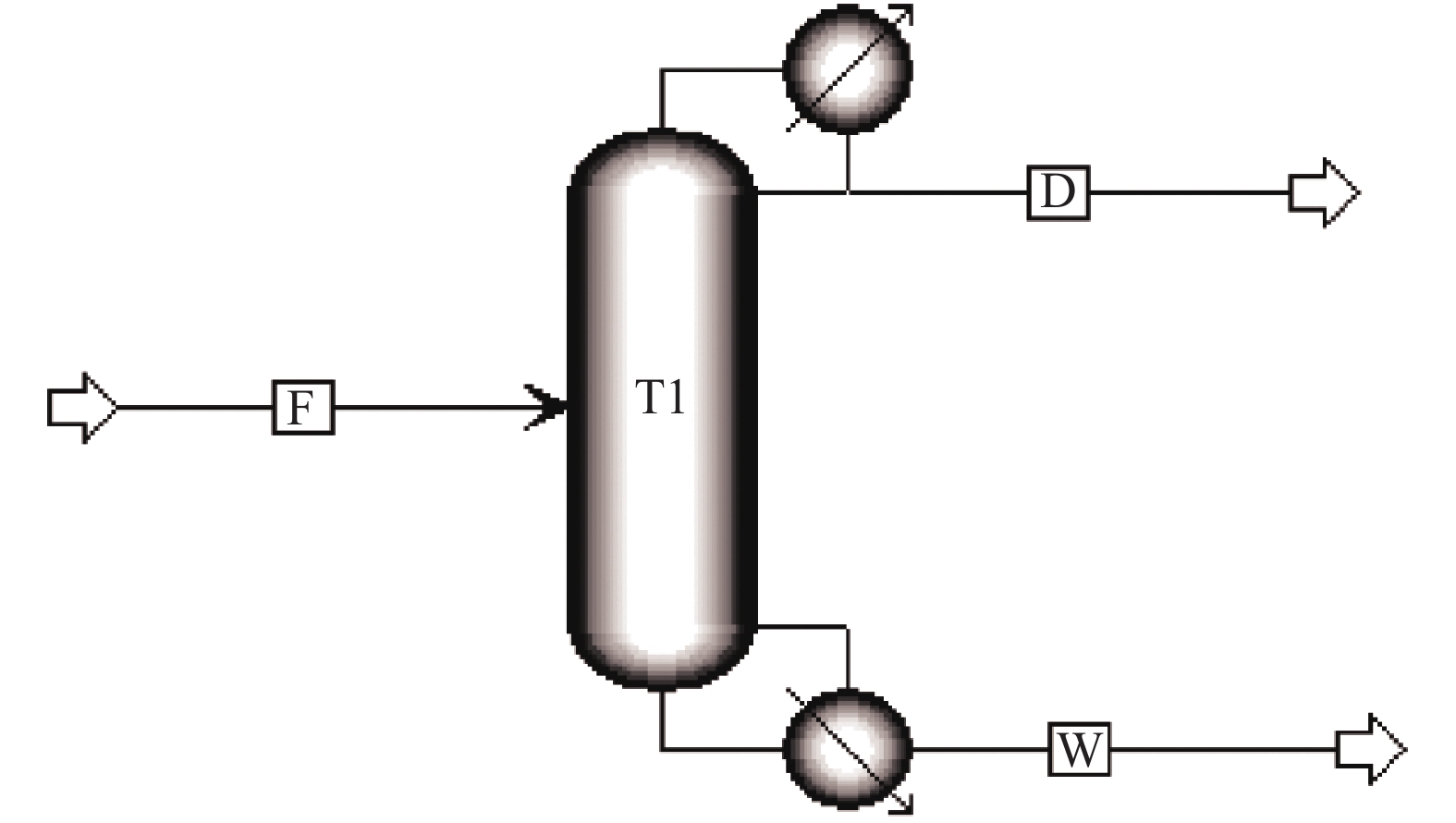

摘要: 针对有机物精制除钒工艺生产的四氯化钛含有机杂质的现状,采用Aspen P1us模拟软件计算了除钒后四氯化钛中有机杂质的精馏分离过程,并结合灵敏度分析方法对精馏塔的设计参数进行了优化。结果表明,精馏塔的最佳设计参数如下:回流比为100,塔板数为68块,进料位置为第24块塔板,塔顶温度为64.38 ℃,塔底温度为155.06 ℃,塔顶馏出量为223 kg/h。此操作条件下,精馏后四氯化钛质量纯度可达99.9967%,收率达到99.0%以上,有机杂质和SiCl4主要汇入塔顶馏出物,其中CCl3COCl的收率大于99.0%,满足分离要求。Abstract: Aiming at separating the organic impurities in titanium tetrachloride after vanadium removal by organics refining, Aspen P1us software was used to simulate the rectification process of TiCl4, and the design parameters of the rectification column were optimized by sensitivity analysis. The optimal design parameters of the rectification column were determined at the reflux ratio of 100, the number of column plate of 68, the feed position on the 24th plate, the top temperature of 64.38 ℃, the bottom temperature of 155.06 ℃, and the distillate rate of 223 kg/h. At the optimum conditions, the purity of titanium tetrachloride after rectification is up to 99.9967%, with the yield ratio more than 99.0%. Organic impurities and SiCl4 mainly flow into the distillate. The yield of CCl3COCl in the distillate is more than 99.0%, which meets the separation requirement.

-

Key words:

- TiCl4 /

- vanadium removal /

- organic impurities /

- rectification separation /

- simulation

-

表 1 有机物精制除钒后四氯化钛的组成

Table 1. Compositions of TiCl4 after vanadium removal by organics refining

名称 分子式 沸点/℃ 质量分数/% 四氯化钛 TiCl4 135.85 98.74 四氯化碳 CCl4 76.64 0.6 三氯乙酰氯 CCl3COCl 118 0.4 光气 COCl2 7.56 0.18 四氯化硅 SiCl4 56.85 0.08 表 2 精馏塔简捷设计结果

Table 2. Shortcut design results of the rectification column

最小

回流比实际

回流比最小理论

板数理论

板数进料

位置再沸器负荷/

kW冷凝器负荷/

kW塔顶温度/

℃塔底温度/

℃塔顶馏出量/

(kg·h−1)63.998 75.805 25.929 48 21.358 1046.61 1037.91 64.62 148.67 224.66 表 3 精馏塔的严格设计参数结果

Table 3. Results of rigorous design parameters for the rectification column

实际回流比 实际板数 进料位置 再沸器负荷/kW 冷凝器负荷/kW 塔顶温度/℃ 塔底温度/℃ 塔顶馏出量/(kg·h−1) 100 68 第24块塔板 1607.36 1586.04 64.38 155.06 223 表 4 精馏塔物流的严格计算结果

Table 4. Rigorous calculation results of material streams for the rectification column

项目 质量流量/(kg·h−1) 温度/℃ 压力/kPa w/% TiCl4 CCl4 CCl3COCl COCl2 SiCl4 进料物流 10000 139.87 124.83 98.74 0.6 0.4 0.18 0.08 塔顶馏出物 223 64.38 116.52 43.64 26.91 17.79 8.07 3.59 塔底产品 9777 155.06 161.60 99.9967 3.48×10−9 3.33×10−3 3.66×10−55 2.91×10−29 -

[1] (宋玉萍. 四氯化钛中的有机杂质分析[D]. 贵阳: 贵州大学, 2008.)Song Yuping. Analysis of organic impurities in titanium tetrachloride[D].Guiyang: Guizhou University, 2008. [2] (邓国珠. 钛冶金[M]. 北京: 冶金工业出版社, 2010.)Deng Guozhu. Titanium metallurgy[M]. Beijing: Metallurgy Industry Press, 2010. [3] (孙兰义. 化工过程模拟实训—Aspen Plus教程(第二版)[M]. 北京: 化学工业出版社, 2017.)Sun Lanyi. Chemical process simulation practice-Aspen Plus tutorial(2nd ed.)[M]. Beijing: Chemical Industry Press, 2017. [4] (陈光进. 化工热力学(第二版)[M]. 北京: 石油工业出版社, 2018.)Chen Guangjin. Chemical engineering thermodynamics(2nd ed.)[M]. Beijing: Petroleum Industry Press, 2018. [5] (中国石化集团上海工程有限公司. 化工工艺设计手册(第五版上册)[M]. 北京: 化学工业出版社, 2018.)Sinopec Group Shanghai Engineering Co., Ltd.. Chemical process design handbook(5th ed., Vol. 1)[M]. Beijing: Chemical Industry Press, 2018. -

下载:

下载: