Preparation of spherical titanium-tantalum alloy powder for additive manufacturing by radio frequency plasma

-

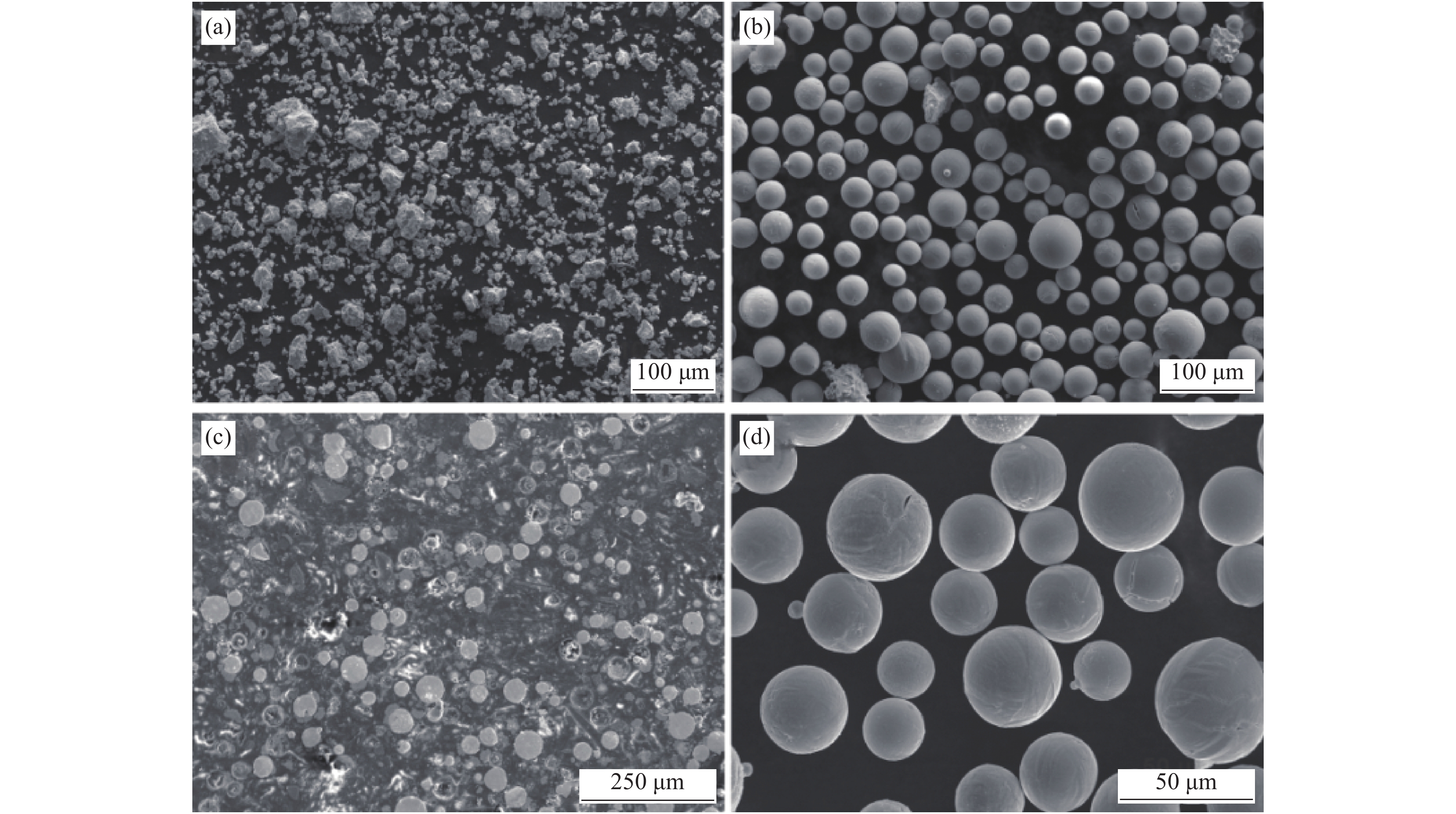

摘要: 采用射频等离子体球化技术对氢化破碎不规则形貌的钛钽合金粉末进行球化处理,研究了送粉速率、载气流量和鞘气中氦气流量等工艺参数对钛钽合金粉末球化率、粉体性能和显微结构的影响,并开展了球化后钛钽合金粉末选区激光熔化成形适用性评价。结果表明:经过射频等离子体球化处理后,粉末截面组织由板条状α″-Ti和胞状β-Ti组成,球化率在98%以上,粒度分布变宽,平均粒径由球化前21.41 μm增大至32.3 μm。粉末球化率受送粉速率、载气流量和鞘气中氦气流量等因素影响,当送粉速率为35 g/min,载气流量为5.5 L/min,鞘气中氦气流量为40 L/min,球化效果最好。与原料粉末相比,球化后粉末的霍尔流速(50 g计)为6.27 s,松装密度由1.38 g/cm3提高至3.11 g/cm3,振实密度由2.54 g/cm3提高至3.48 g/cm3。此外,球化后的钛钽合金粉末具有良好的选区激光熔化适用性,成形后制件致密度大于99%,微观组织为针状α″-Ti和胞状β-Ti,钛、钽元素分布均匀,无未熔融的钽颗粒,显微硬度(HV)达到725。Abstract: The titanium-tantalum alloy powder prepared by hydrogen decrepitation process with irregular morphology was spheroidized by radio frequency (RF) plasma. The effects of feeding rate, carrier gas flow rate and sheath gas (He) flow rate on the spheroidization efficiency, powder characteristics and microstructure were studied. The selective laser melting (SLM) process of the spherical titanium-tantalum alloy powder was also explored. The results show that the cross-sectional microstructure of the powder is lamellar α″-Ti and cellular β-Ti after spheroidization, with the spheroidization efficiency over 98%. The particle size distribution becomes wider and the average particle size increases from 21.41 μm to 32.30 μm. The spheroidization efficiency is influenced by the feeding rate, carrier gas flow rate, sheath gas (He) flow rate. The best spheroidization efficiency can be obtained at 35 g/min of feeding rate, 5.5 L/min of carrier gas flow rate and 40 L/min of sheath gas (He) flow rate, respectively. Compared with the raw powder, the hall velocity of the spherical titanium-tantalum alloy powder reaches 6.27 s/50 g, with the apparent density and tap density increased from 1.38 g/cm3 to 3.11 g/cm3, 2.54 g/cm3 to 3.48 g/cm3, respectively. The spherical titanium-tantalum alloy powder is compatible with the selective laser melting process. The relative density of the formed parts is over 99%, with the microstructure of acicular α″-Ti and cellular β-Ti. No unmelted tantalum particles can be found in the samples and the vickers hardness of the samples reaches 725 HV.

-

表 1 原料钛钽合金粉末化学成分

Table 1. Chemical composition of raw titanium-tantalum alloy powder

% Ti Ta H O C Bal. 28.24 2.84 0.85 0.024 表 2 射频等离子体球化工艺参数

Table 2. Experimental parameters for RF plasma spheroidization

功率/kW 鞘气流量1(Ar)/(L·min−1) 鞘气流量2(He)/(L·min−1) 载气流量(Ar)/(L·min−1) 送粉速率/(g·min−1) 20~40 30~50 20~40 3~7 28~42 表 3 选区激光熔化成形参数

Table 3. SLM process parameters used for this study

编号 激光功率/W 扫描速度/(mm·s−1) 层厚/μm 扫描间距/μm 激光能量密度/(J·mm−3) 1 80 400 30 60 111.11 2 120 400 30 60 166.66 3 160 400 30 60 222.22 4 80 500 30 60 88.88 5 120 500 30 60 133.33 6 160 500 30 60 177.78 7 80 600 30 60 74.00 8 120 600 30 60 111.11 9 160 600 30 60 148.15 表 4 球化后钛钽合金粉末化学成分

Table 4. Chemical composition of titanium-tantalum alloy powder after spheroidization

% Ti Ta H O C Bal. 29.62 2.28 0.8 0.024 表 5 钛钽合金粉末球化前后的粉末特征

Table 5. Particle characteristics of titanium-tantalum alloy powder before and after spheroidization

粉末 流动性(50 g计)/s 松装密度/(g·cm−3) 振实密度/(g·cm−3) 氧含量/% 原料粉末 1.375 2.542 0.85 球化粉末 6.27 3.113 3.478 0.8 -

[1] Niinomi M. Recent metallic materials for biomedical applications[J]. Metallurgical & Materials Transactions A, 2002,33(3):477. [2] Laheurte P, Prima F, Eberhardt A, et al. Mechanical properties of low modulus β titanium alloys designed from the electronic approach[J]. J Mech Behav Biomed Mater, 2010,3(8):565−573. doi: 10.1016/j.jmbbm.2010.07.001 [3] Xu Lijuan, Xiao S L, Tian J, et al. Microstructure, mechanical properties and dry wear resistance of β-type Ti-15Mo-xNb alloys for biomedical applications[J]. Transactions of Nonferrous Metals Society of China, 2013,23(3):692−698. doi: 10.1016/S1003-6326(13)62518-2 [4] Taekyung, Lee, Yoon-Uk, et al. Microstructure tailoring to enhance strength and ductility in Ti–13Nb–13Zr for biomedical applications[J]. Scripta Materialia, 2013,69(11−12):785−788. doi: 10.1016/j.scriptamat.2013.08.028 [5] Pokluda J. Theoretical strength of solids: recent results and applications[J]. Materials Science, 2012,47(5):492−495. [6] Ying L Z, Niinomi M, Akahori T. Effects of Ta content on Young’s modulus and tensile properties of binary Ti–Ta alloys for biomedical applications[J]. Mater Sci Eng A, 2004,371(1/2):283−290. [7] Zhou Y L, Niinomi M, Akahori T, et al. Corrosion resistance and biocompatibility of Ti-Ta alloys for biomedical applications[J]. Materials Science & Engineering A, 2005,398(1−2):28−36. [8] Yang Xuechun, Jiang Wenjun, Cao Ming, et al. Organization and mechanical properties of selected laser melting aluminum alloys[J]. Machine Tools and Hydraulics, 2021,49(1):21−25, 41. (杨雪春, 江文俊, 曹铭, 等. 选区激光熔化铝合金的组织和力学性能[J]. 机床与液压, 2021,49(1):21−25, 41. doi: 10.3969/j.issn.1001-3881.2021.01.005 [9] Sing, Leong S, Yeong, et al. Selective laser melting of titanium alloy with 50 % tantalum: Microstructure and mechanical properties[J]. Journal of Alloys and Compounds: An Interdisciplinary Journal of Materials Science and Solid-state Chemistry and Physics, 2016,660(5):263−265. [10] Egba B, Aema C, Jef A, et al. Remelt processing and microstructure of selective laser melted Ti25Ta-science direct[J]. Journal of Alloys and Compounds, 2020,820(6):363−366. [11] Dz A, Ch B, Yan L A, et al. Improvement on mechanical properties and corrosion resistance of titanium-tantalum alloys in-situ fabricated via selective laser melting[J]. Journal of Alloys and Compounds, 2019,804:288−298. doi: 10.1016/j.jallcom.2019.06.307 [12] Gou Y J, Chen G, Zhao S Y, et al. Titanium-tantalum alloy powder produced by the plasma rotating electrode process (PREP)[J]. Key Engineering Materials, 2018,770:18−22. doi: 10.4028/www.scientific.net/KEM.770.18 [13] Bai L, Fan J, Peng H, et al. RF plasma synthesis of nickel nanopowders via hydrogen reduction of nickel hydroxide/carbonate[J]. Journal of Alloys & Compounds, 2009,481(1−2):563−567. [14] Kumar R, Cheang P, Khor K A. Radio frequency (RF) suspension plasma sprayed ultra-fine hydroxyapatite (HA)/zirconia composite powders[J]. Biomaterials, 2003,24(15):2611−2621. doi: 10.1016/S0142-9612(03)00066-8 [15] A Y Y, A M M H, A T W, et al. Effects of feed rate and particle size on the in-flight melting behavior of granulated powders in induction thermal plasmas[J]. Thin Solid Films, 2008,516(19):6622−6627. doi: 10.1016/j.tsf.2007.11.084 [16] Wang J J, Hao J J, Guo Z M, et al. Preparation of spherical tungsten and titanium powders by RF induction plasma processing[J]. Rare Metals, 2015,34(6):431−435. doi: 10.1007/s12598-014-0293-4 [17] Jiang X L, Boulos M. Induction plasma spheroidization of tungsten and molybdenum powders[J]. Transactions of Nonferrous Metals Society of China, 2006,16(1):13−17. doi: 10.1016/S1003-6326(06)60003-4 [18] Gu Zhongtao, Ye Gaoying, Jin Yuping. Component analysis of spherical titanium powder prepared by radio frequency induction plasma[J]. Intense Laser and Particle Beam, 2012,24(6):1409−1413. (古忠涛, 叶高英, 金玉萍. 射频感应等离子体制备球形钛粉的成分分析[J]. 强激光与粒子束, 2012,24(6):1409−1413. doi: 10.3788/HPLPB20122406.1409 [19] Hou Y B, Zeng K L, Yue-Guang Y U, et al. Plasma spheroidization of tungsten powder[J]. Nonferrous Metals, 2008,(1):41−43. [20] Harbec D, Gitzhofer F, Tagnit-Hamou A. Induction plasma synthesis of nanometric spheroidized glass powder for use in cementitious materials[J]. Powder Technology, 2011,214(3):356−364. doi: 10.1016/j.powtec.2011.08.031 [21] Zhang Ge, Wang Jianhong, Zhang Hao. Study on spheroidization phenomenon of laser melting in selected areas of metal powder[J]. Casting Technology, 2017,38(2):262−265. (张格, 王建宏, 张浩. 金属粉末选区激光熔化球化现象研究[J]. 铸造技术, 2017,38(2):262−265. [22] Leong S S, Edith W F, Yee Y W. Selective laser melting of titanium alloy with 50 % tantalum: Effect of laser process parameters on part quality[J]. International Journal of Refractory Metals and Hard Materials, 2018,77:120−127. doi: 10.1016/j.ijrmhm.2018.08.006 [23] Soro N, Attar H, Brodie E, et al. Evaluation of the mechanical compatibility of additively manufactured porous Ti–25Ta alloy for load-bearing implant applications[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2019,97(3):326−329. -

下载:

下载: