Analysis of the strength mechanism of lime-base activated titanium gypsum composite cementitious material

-

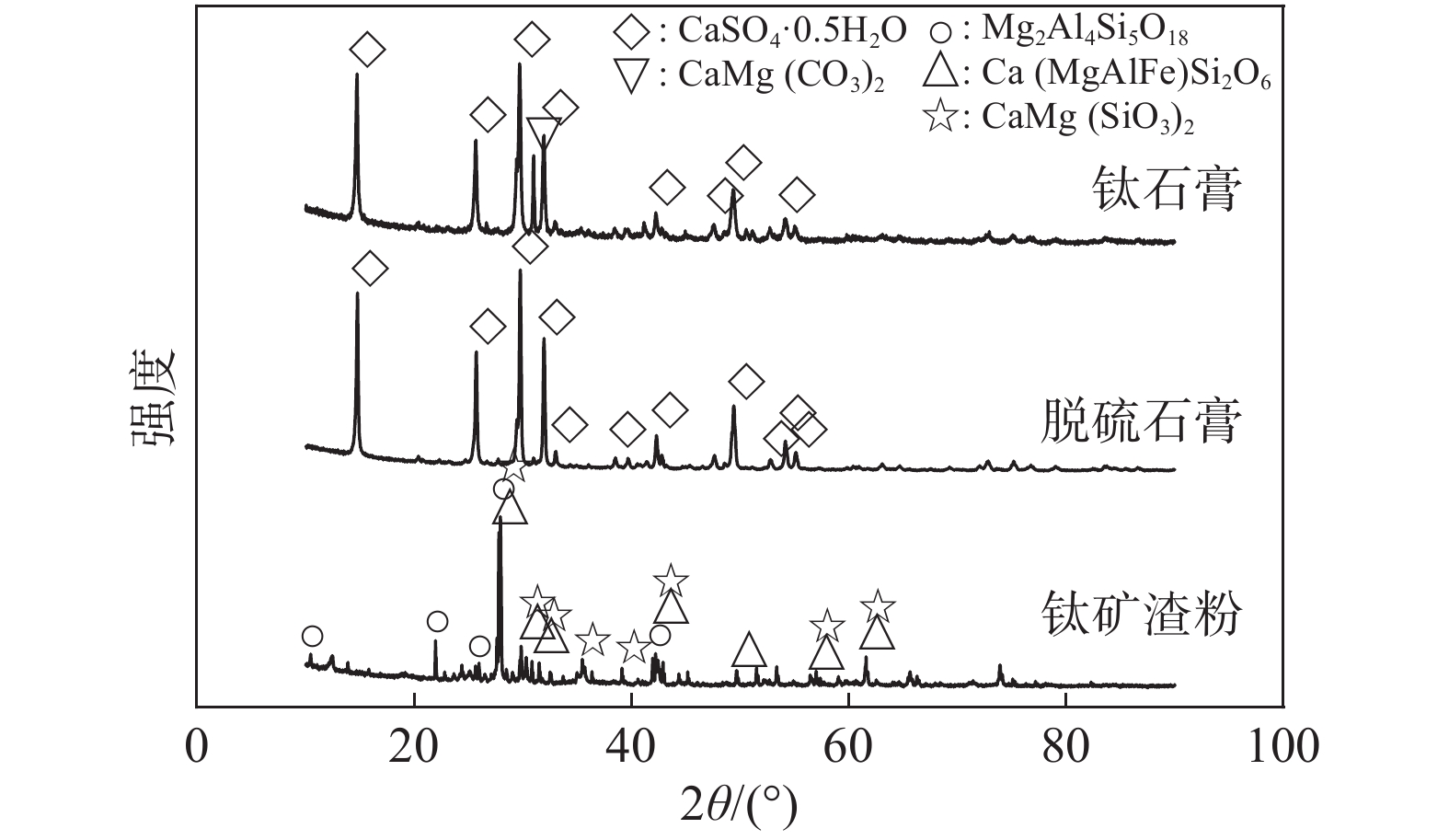

摘要: 以钛石膏、脱硫石膏和钛矿渣三种钛工业固体废弃物为主要原料,石灰作碱性激发剂制作钛石膏复合胶凝材料。采用正交试验,结合XRD、SEM等分析测试方法,对石灰碱激发钛石膏复合胶凝材料强度机理进行分析。结果表明:钛石膏的掺量在42.9%~50.3%,可以制作出强度达到《建筑石膏》(GB/T 9776—2008)2.0强度等级的钛石膏复合胶凝材料。石灰碱激发钛石膏复合胶凝材料的前期强度主要来自钛石膏和脱硫石膏水化产生的二水石膏,后期强度主要来自水泥、石灰和石膏进一步反应产生钙矾石。其水化机理为:第一,CaSO4·0.5H2O水化产生CaSO4·2H2O;第二,水泥中的3CaO·Al2O3与CaSO4·2H2O反应生成钙矾石,石灰与水反应产生Ca(OH)2,结合CaSO4·2H2O和CaO·Al2O3反应产生钙矾石,进一步提升钛石膏复合胶凝材料的强度。Abstract: Titanium gypsum, flue gas desulphurization gypsum and titanium slag are used as main raw materials of titanium industrial solid wastes, and lime is used as an alkaline activator to make titanium gypsum composite cementing materials. Orthogonal experiments, combined with XRD, SEM and other analytical testing methods, are used to analyze the strength mechanism of lime-base activated titanium gypsum composite cementing materials. The experimental results show that the content of titanium gypsum is between 42.9% and 50.3%, which can produce a titanium gypsum composite cementing material with strength of 2.0 in “Building Gypsum” (GB/T 9776—2008). The initial strength contribution of the lime-based titanium gypsum composite cementing material mainly comes from the dihydrate gypsum produced by the hydration of titanium gypsum and flue gas desulphurization gypsum, and the later strength contribution mainly comes from the further reaction of cement, lime and gypsum to produce ettringite. The hydration mechanism is as follows: First, CaSO4·0.5H2O hydrates to produce CaSO4·2H2O; Second, the 3CaO·Al2O3 in the cement reacts with CaSO4·2H2O to produce ettringite, the lime reacts with water to produce Ca(OH)2, and the combination of CaSO4·2H2O and CaO·Al2O3 react to produce ettringite. Therefore, the strength of the titanium gypsum composite cementitious material is further improved.

-

表 1 原材料主要化学组成

Table 1. Main chemical compositions of raw materials

% SiO2 CaO TiO2 Al2O3 MgO SO3 Fe2O3 TFe 钛石膏 1.83 30.66 3.46 0.68 5.21 26.53 17.78 钛矿渣粉 43.82 7.70 3.90 9.40 7.57 0.46 8.79 脱硫石膏 0.58 32.28 0.015 0.34 0.63 41.91 0.35 表 2 正交试验因素及水平

Table 2. Factors and levels of orthogonal experiment

水平 TG FGD(A) TSP(B) 水泥(C) 石灰(D) 1 0.315 0.375(A1) 0.20(B1) 0.09(C1) 0.020(D1) 2 0.394 0.350(A2) 0.17(B2) 0.07(C2) 0.016(D2) 3 0.473 0.325(A3) 0.14(B3) 0.05(C3) 0.012(D3) 4 0.552 0.300(A4) 0.11(B4) 0.03(C4) 0.008(D4) 5 0.631 0.275(A5) 0.08(B5) 0.01(C5) 0.004(D5) 注:表中数值为总质量4 kg前提下,各物料加入量所占质量分数。 表 3 抗折强度正交试验结果

Table 3. Flexural strength results from orthogonal experiments

组号 水/kg TG/% FGD(A) TSP(B) 水泥(C) 石灰(D) 抗折强度/MPa 2 h 7 d 28 d F1 1.19 31.5 A1 B1 C1 D1 1.93 2.44 3.70 F2 1.21 39.4 A2 B2 C2 D2 1.99 2.10 4.18 F3 1.24 47.3 A3 B3 C3 D3 2.27 2.00 3.93 F4 1.27 55.2 A4 B4 C4 D4 2.24 2.05 3.60 F5 1.30 63.1 A5 B5 C5 D5 2.13 2.16 3.60 F6 1.21 39.7 A1 B2 C3 D4 2.24 2.48 4.06 F7 1.24 47.6 A2 B3 C4 D5 2.39 2.29 3.50 F8 1.27 53.5 A3 B4 C5 D1 2.12 2.47 3.72 F9 1.30 51.4 A4 B5 C1 D2 2.08 2.11 3.56 F10 1.19 44.3 A5 B1 C2 D3 1.98 2.01 3.86 F11 1.24 45.9 A1 B3 C5 D2 2.42 2.06 3.47 F12 127 43.8 A2 B4 C1 D3 2.16 2.30 3.67 F13 1.30 51.7 A3 B5 C2 D4 2.30 2.21 3.65 F14 1.19 44.6 A4 B1 C3 D5 2.22 2.00 3.81 F15 1.21 50.5 A5 B2 C4 D1 1.97 1.97 3.62 F16 1.27 44.1 A1 B4 C2 D5 2.26 2.32 4.25 F17 1.30 50.0 A2 B5 C3 D1 2.28 2.70 3.64 F18 1.19 42.9 A3 B1 C4 D2 2.40 2.29 3.53 F19 1.21 50.8 A4 B2 C5 D3 2.02 1.93 3.84 F20 1.24 48.7 A5 B3 C1 D4 1.97 1.90 4.02 F21 1.30 50.3 A1 B5 C4 D3 2.56 2.30 3.69 F22 1.19 43.2 A2 B1 C5 D4 2.30 2.10 3.91 F23 1.21 41.1 A3 B2 C1 D5 2.17 2.21 4.23 F24 1.24 47.0 A4 B3 C2 D1 2.07 2.18 3.29 F25 1.27 54.9 A5 B4 C3 D2 2.21 2.38 3.56 2 h抗折强度极差Rf2 0.150 0.230 0.192 0.250 0.160 7 d抗折强度极差Rf7 0.164 0.266 0.218 0.168 0.244 28 d抗折强度极差Rf28 0.212 0.214 0.358 0.258 0.284 表 4 抗压强度正交试验结果

Table 4. Compressive strength results from orthogonal experiments

组号 水/kg TG/% FGD(A) TSP(B) 水泥(C) 石灰(D) 抗压强度/MPa 2 h 7 d 28 d F1 1.19 31.5 A1 B1 C1 D1 5.50 7.79 16.32 F2 1.21 39.4 A2 B2 C2 D2 5.41 6.86 15.62 F3 1.24 47.3 A3 B3 C3 D3 6.17 8.11 17.65 F4 1.27 55.2 A4 B4 C4 D4 5.89 6.57 16.35 F5 1.30 63.1 A5 B5 C5 D5 5.93 6.04 15.90 F6 1.21 39.7 A1 B2 C3 D4 6.61 6.86 17.42 F7 1.24 47.6 A2 B3 C4 D5 6.53 6.53 17.61 F8 1.27 53.5 A3 B4 C5 D1 6.30 7.32 16.30 F9 1.30 51.4 A4 B5 C1 D2 5.74 6.72 16.12 F10 1.19 44.3 A5 B1 C2 D3 5.15 5.69 14.80 F11 1.24 45.9 A1 B3 C5 D2 6.45 5.69 16.55 F12 127 43.8 A2 B4 C1 D3 5.67 6.46 17.34 F13 1.30 51.7 A3 B5 C2 D4 5.88 5.88 17.34 F14 1.19 44.6 A4 B1 C3 D5 5.34 5.59 17.04 F15 1.21 50.5 A5 B2 C4 D1 5.08 5.39 15.16 F16 1.27 44.1 A1 B4 C2 D5 5.74 6.67 17.92 F17 1.30 50.0 A2 B5 C3 D1 5.75 7.51 16.98 F18 1.19 42.9 A3 B1 C4 D2 5.79 6.27 15.47 F19 1.21 50.8 A4 B2 C5 D3 6.18 5.31 16.38 F20 1.24 48.7 A5 B3 C1 D4 5.42 5.78 16.26 F21 1.30 50.3 A1 B5 C4 D3 6.68 5.86 17.60 F22 1.19 43.2 A2 B1 C5 D4 6.13 5.45 16.03 F23 1.21 41.1 A3 B2 C1 D5 5.66 6.62 16.42 F24 1.24 47.0 A4 B3 C2 D1 5.78 6.14 15.59 F25 1.27 54.9 A5 B4 C3 D2 5.99 7.66 15.75 2 h抗压强度极差Rc2 0.382 0.682 0.488 0.606 0.304 7 d抗压强度极差Rc7 1.272 0.774 0.778 1.184 0.722 28 d抗压强度极差Rc28 0.408 1.584 0.856 0.736 1.076 -

[1] Wei Changhe, Sun Yuzhuang, Gao Xinbao, et al. Study on leaching characteristics of heavy metals in titanium gypsum[J]. Environmental Engineering, 2015,33(5):131−135. (魏长河, 孙玉壮, 高兴保, 等. 钛石膏中重金属元素的浸出特性研究[J]. 环境工程, 2015,33(5):131−135. [2] José Zapata-Carbonella, Carole Bégeota, Nicolas Carrya, et al. Spontaneous ecological recovery of vegetation in a red gypsum landfill: Betula pendula dominates after 10 years of inactivity[J]. Ecological Engineering, 2019,(132):31−40. [3] Yang He, Chen Wei, Liang Hezhi. Study on mechanical properties of FGD -titanium slag powder composite cementitious material[J]. Iron Steel Vanadium Titanium, 2019,40(6):67−72. (杨贺, 陈伟, 梁贺之. 脱硫石膏-钛矿渣粉复合胶凝材料力学性能研究[J]. 钢铁钒钛, 2019,40(6):67−72. [4] Gazquez M J, Bolivar J P, Vaca F, et al. Evaluation of the use of TiO2 industry red gypsum waste in cement production[J]. Cement and Concrete Composites, 2013,(37):76−81. [5] Geng Fei, Gui Jingneng, Cao Xinxin, et al. Physical and mechanical properties test of desulfurized gypsum based composite cementitious materials[J]. Journal of Nanjing University of Aeronautics & Astronatics, 2019,51(1):124−130. (耿飞, 桂敬能, 曹欣欣, 等. 脱硫石膏基复合胶凝材料的物理力学性能试验[J]. 南京航空航天大学学报, 2019,51(1):124−130. [6] Wang Wenlong, Wang Xujiang, Zhu Jianping. et al. Experimental investigation and modeling of sulfoaluminate cement preparation using desulfurization gypsum and red mud[J]. Industrial & Engineering Chemistry Research, 2013,(52):1261−1266. [7] Gazquez M J, Bolivar J P, Vaca F, et al. Use of the red gypsum industrial waste as sudstitute of natural gypsum for commercial cements manufacturing[J]. Materiales de Construccion, 2012,62:183−198. doi: 10.3989/mc.2011.63910 [8] Shi Li’an, Lu Shengfa, Li Qihua, et al. Research on active characteristics and stimulating activity of titanium slag[J]. Bulletin of the Chinese Ceramic Society, 2012,31(6):1554−1558. (石立安, 陆生发, 李启华, 等. 钛渣活性特征及激发活性技术研究[J]. 硅酸盐通报, 2012,31(6):1554−1558. [9] Zhang Jiufu, Yan Yun, Hu Zhihua, et al. Properties and hydration behavior of Ti-extracted residues-red gypsum based cementitious materials[J]. Construction and Building Materials, 2019,218:610−617. doi: 10.1016/j.conbuildmat.2019.05.099 [10] Liu Minrong, Tian Ying, Zhao Shuai. Effect of alkali activator on properties of titanium gypsum/fly ash compound cementitious material[J]. Coal Ash, 2008,20(6):15−17. (刘民荣, 田颖, 赵帅. 碱性激发剂对钛石膏-粉煤灰复合胶结材料性能的影响[J]. 粉煤灰, 2008,20(6):15−17. [11] Sui Su, Gao Zidong, Li Guozhong. Study on modification and mechanical property of titanium gypsum[J]. Bulletin of the Chinese Ceramic Society, 2010,29(1):89−93. (隋肃, 高子栋, 李国忠. 钛石膏的改性处理和力学性能研究[J]. 硅酸盐通报, 2010,29(1):89−93. [12] (刘巧玲. 钛石膏杂质分析及其建材资源化研究[D]. 重庆: 重庆大学, 2004.)Liu Qiaoling. Study on analysis of impurities in titanium gypsum and titanium gypsum as building materials[D]. Chongqing: Chongqing University, 2004. [13] (杨贺. 攀西地区钛石膏在新型建筑材料中的改性研究[D]. 成都: 西华大学, 2020.)Yang He. Study on modification of titanium gypsum of Panxi area in new building materials[D]. Chengdu: Xihua University, 2020. [14] Qian Jueshi, Yu Jincheng, Sun Huaqiang, et al. Formation and function of ettringite in cement hydrates[J]. Journal of The Chinese Ceramic Society, 2017,45(11):1569−1581. (钱觉时, 余金城, 孙化强, 等. 钙矾石的形成与作用[J]. 硅酸盐学报, 2017,45(11):1569−1581. [15] Du Chuanwei, Li Guozhong, Chen Juan. Simulation of titanium gypsum with morphology and composition of natural gypsum and its property[J]. Journal of Building Materials, 2014,17(3):511−516. (杜传伟, 李国忠, 陈娟. 利用天然石膏形态组成模拟钛石膏及其性能研究[J]. 建筑材料学报, 2014,17(3):511−516. doi: 10.3969/j.issn.1007-9629.2014.03.025 [16] Yang He, Liang Hezhi, Pu Yunhe, et al. Study on mechanical properties of titanium gypsum-FGD composite cementitious materials[J]. Non-Metallic Mines, 2020,43(2):99−102. (杨贺, 梁贺之, 浦云鹤, 等. 钛石膏-脱硫石膏复合胶凝材料力学性能研究[J]. 非金属矿, 2020,43(2):99−102. doi: 10.3969/j.issn.1000-8098.2020.02.027 [17] Zhang Jiufu, Yan Yun, Hu Zhihua. Preparation and characterization of foamed concrete with Ti-extracted residues and red gypsum[J]. Construction and Building Materials, 2018,171:109−119. [18] Li Xiaoying, Li Jun, Lu Zhongyuan, et al. Preparation and properties of reactive powder concrete by using titanium slag aggregates[J]. Construction and Building Materials, 2020,234:1−14. -

下载:

下载: