Experimental study of high carbon ferrochrome slag used in C40 concrete

-

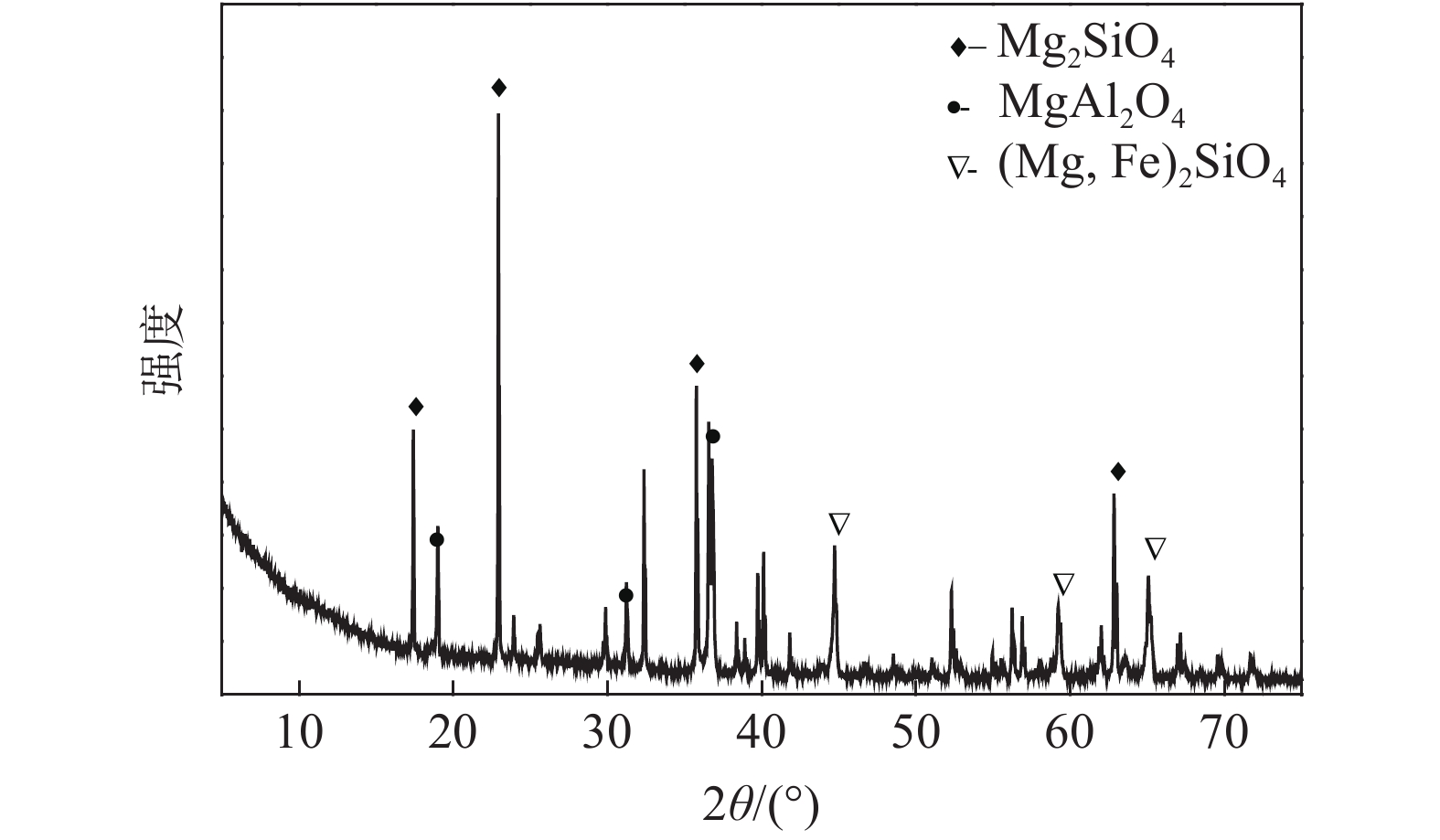

摘要: 以高碳铬铁合金渣作为粗细集料来配制C40混凝土,通过对含高碳铬铁合金渣混凝土抗压强度、抗氯离子渗透性能和抗碳化性能等进行试验研究,对六价铬离子Cr(VI)在水泥混凝土中固化效果进行了评价。结果表明:高碳铬铁渣骨料混凝土养护28 d的抗压强度高于普通C40碎石混凝土。由于高碳铬渣的表面多孔和较高的孔隙率,导致用高碳铬渣制备的混凝土抗氯离子渗透性能和抗碳化性能优于对照组,而混凝土浸泡90 d的铬离子表面浸出浓度低于标准规定铬离子0.05 mg/L的临界允许浓度,从应用和环境的角度初步说明高碳铬铁合金渣作为骨料配制C40混凝土基本可行。Abstract: In this paper the high carbon ferrochrome slag used as coarse and fine aggregate in the preparation of C40 concrete was carried out. The compressive strength and carbonization resistance of concrete containing high carbon ferrochrome slag weree investigated and the solidification effect of hexavalent chromium ion in cement concrete was evaluated. The results indicate that the compressive strength of concrete with high carbon ferrochrome slag at 28 days is slight higher than the ordinary C40 concrete. The resulted concrete with incorporation of high carbon ferrochrome slag is superior to the reference concrete regarding the resistance to chloride penetration and carbonization due to its surface porosity and high porosity. Whereas, the surface leaching concentration of concrete incorporating high carbon ferrochrome slag is relatively low and less than the critical value of 0.05 mg/L. From the perspective of application and environment, it can indicate that the preparation of C40 concrete with high carbon ferrochrome slag as aggregate is feasible.

-

表 1 原材料的化学成分

Table 1. Chemical components of raw materials used in this work

% 种类 SiO2 Al2O3 CaO MgO Fe2O3 Cr2O3 Na2O K2O SO3 LOI 水泥 21.50 5.86 59.81 2.23 2.85 0.20 0.67 2.06 3.70 粉煤灰 56.38 26.37 3.10 0.33 6.45 2.20 0.38 1.05 1.32 高碳铬铁渣 32.11 19.54 6.72 23.98 3.23 8.27 0.17 0.08 1.35 2.23 表 2 碎石和铬铁渣的物理性质

Table 2. Physical properties of gravel and ferrochrome slag

集料 含泥量/% 表观密度/(kg·m−3) 松散堆积密度/(kg·m−3) 紧密堆积密度/(kg·m−3) 孔隙率/% 压碎值/% 碎石 0.2 2700 1450 1620 46.2 8.7 铬铁渣 0.1 3220 1680 1 860 48.1 5.3 表 3 高碳铬渣混凝土配合比

Table 3. Mix proportion of high carbon ferrochrome slag concrete

kg/m3 编号 水泥 粉煤灰 细集料 粗集料 水 减水剂 河砂 铬铁渣碎屑 碎石 铬铁渣 C0 340 60 775 0 1155 0 160 4.0 CH1 340 60 0 775 1155 0 160 4.2 CH2 340 60 775 0 0 1155 160 4.4 CH3 340 60 0 775 0 1155 160 4.8 表 4 铬铁渣混凝土的表面铬离子浸出浓度

Table 4. Surface chrome leaching concentration of high carbon ferrochrome slag concrete

试样 浸出浓度/(mg·L−1) 28 d 56 d 90 d CH1 0.031 0.019 0.012 CH2 0.038 0.024 0.018 CH3 0.048 0.029 0.025 -

[1] Meng Fansheng. Pollution charateristics of soils polluted by chromium slag in China[J]. Environmental Pollution & Control, 2016,38(6):50−53. (孟凡生. 中国铬渣污染场地土壤污染特征[J]. 环境污染与防治, 2016,38(6):50−53. [2] Yang Xiangxin, Li Tao. Discussion on technology of production high carbon ferrochrome of low carbon level[J]. Ferro-alloys, 2010,41(1):15−18. (杨香新, 李涛. 低碳级高碳铬铁生产工艺探讨[J]. 铁合金, 2010,41(1):15−18. [3] Xu Yanzhong, Qin Xuna, Liu Xianghong, et al. The study of chromium pollution and ecological fffects[J]. Environmental Science and Technology, 2002,25(S1):8−9. (徐衍忠, 秦绪娜, 刘祥红, 等. 铬污染及其生态效应[J]. 环境科学与技术, 2002,25(S1):8−9. [4] Zhang Shaohua, Liu Laibao, Tan Kefeng, et al. Sintering research on lightweight aggregate produced from high carbon ferrochrome slag[J]. Journal of Wuhan University of Technology, 2014,36(8):12−16. (张韶华, 刘来宝, 谭克锋, 等. 利用高碳铬铁合金渣制备轻骨料的实验研究[J]. 武汉理工大学学报, 2014,36(8):12−16. [5] Acharya Prasanna K, Patro Sanjaya K. Utilization of ferrochrome wastes such as ferrochrome ash and ferrochrome slag in concrete manufacturing[J]. Waste Management & Research, 2016:0734242X16654751. [6] Shi H S, Kan L L. Study on the properties of chromium residue-cement matrices (CRCM) and the influences of superplasticizers on chromium(VI)-immobilising capability of cement matrices[J]. Journal of Hazardous Materials, 2009,162(2−3):913−919. doi: 10.1016/j.jhazmat.2008.05.117 [7] Ding Jianchu, Li Congjing. Study on the substitution of chromium slag and barium slag for natural sand to prepare concrete[J]. Recycling Research, 2004,(4):29−31. (丁建础, 李崇景. 铬渣钡渣代替天然砂制作混凝土的研究[J]. 再生资源研究, 2004,(4):29−31. [8] (程海丽, 张亮, 董瑞龙, 等. 高碳铬铁合金渣透水混凝土试验研究[J].再生资源与循环经济, 2018,11(1):30-32.)Cheng Haili, Zhang Liang, Dong Ruilong, et al. Experimental study on high carbon ferrochrome slag permeable concrete[J].Renewable Resources & Circular Economy, 2018,11(1):30-32. [9] Panda C R, Mishra K K. Environmental and technical assessment of ferrochrome slag as concrete aggregate material[J]. Construction and Building Materials, 2013,(49):262−267. [10] Tang Luping, Nilsson Lars-Olof. Chloride binding capacity and binding isotherms of OPC pastes and mortars[J]. Cement and Concrete Research, 1993,23(2):247−253. doi: 10.1016/0008-8846(93)90089-R [11] Morandeau A, Thiéry M, Dangla P. Investigation of the carbonation mechanism of C-H and C-S-H in terms of kinetics, microstructure changes and moisture properties[J]. Cement and Concrete Research, 2014,56:153−170. doi: 10.1016/j.cemconres.2013.11.015 [12] Kanagaraj J, Senthilvelan T, Panda R C, et al. Eco-friendly waste management strategies for greener environment towards sustainable development in leather industry: A comprehensive review[J]. Journal of Cleaner Production, 2015,89:1−17. doi: 10.1016/j.jclepro.2014.11.013 -

下载:

下载: