High-temperature simulation of slag foaming induced by various gas sources

-

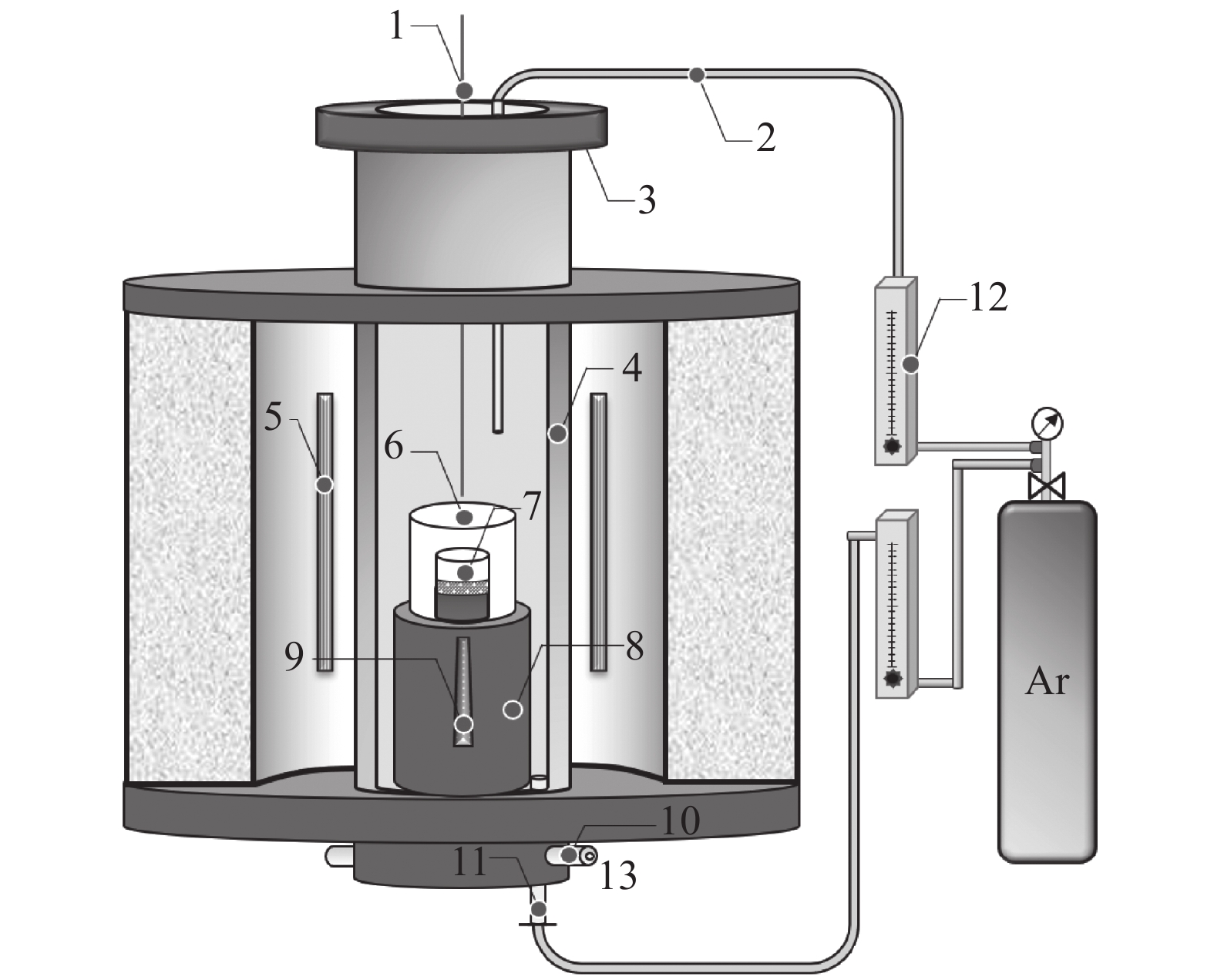

摘要: 熔渣泡沫化的有效控制对冶金工艺的稳定控制具有重要的现实意义。开展了外引和内生两种气源条件下熔渣泡沫化的高温模拟研究,得到如下结论:在外引气源条件下,泡沫渣由尺寸为7~15 mm的多面体气泡堆积而成,泡沫化高度随气体流量增加先升高后降低;在内生气源条件下,泡沫渣由尺寸为0.5~1.0 mm的球形气泡堆积而成,泡沫化高度随气体产生量的增加和熔渣碱度的降低而升高。典型炼钢辅料的消泡效果对比如下:活性石灰>纯碱>石灰石>白云石>菱镁矿。Abstract: The effective control of slag foaming has an important practical significance for stability of metallurgical process. In this paper high-temperature simulation of slag foaming induced by interior and exterior gas sources had been conducted. Under present experimental conditions, the following conclusions are obtained. Induced by exterior gas source, the foamed slag consisted of polyhedral bubbles with a size of 7~15 mm. The foaming height firstly increased and afterwards decreased with increasing gas flowrate. When induced by interior gas source, the foamed slag was stacked with spherical bubbles with a size of 0.5~1.0 mm; the foaming height increased with increasing gas amount released by slag-metal reaction and decreasing slag basicity. The defoaming agent were classified depending on their effects: active lime > soda ash > limestone > dolomite > magnesite.

-

Key words:

- slag , foaming /

- foam structure /

- foaming height /

- exterior gas source /

- interior gas source /

- defoaming agent /

-

表 1 试验渣化学成分设计

Table 1. Chemical compositions of experimental slag

序号 碱度R w/% CaO SiO2 TFe MgO 试验渣 A 0.5 24.00 48.00 20.00 8.00 试验渣 B 0.75 30.86 41.14 20.00 8.00 试验渣 C 1.0 31.72 31.72 20.00 8.00 试验渣 D 1.25 40.00 32.00 20.00 8.00 表 2 生铁的化学成分

Table 2. Chemical compositions of pig iron

% Fe C Si Mn P S 94.80 4.60 0.36 0.12 0.08 0.04 -

[1] Qiu Guibao, Shan Cheng, Zhang Xu, et al. Physical modelling of slag foaming phenomenon resulted from inside origin gas formation reaction[J]. Ironmaking and Steelmaking, 2017,44(4):246−254. doi: 10.1080/03019233.2016.1210360 [2] Zhang Y, Fruehan R J. Effect of carbonaceous particles on slag foaming[J]. Metallurgical and Materials Transactions B, 1995,26(4):813−819. doi: 10.1007/BF02651728 [3] Zhang Dakui, Yu Shujuan, Geng Jishuang, et al. Formation and control of foaming slag in torpedo ladle[J]. Iron and Steel, 2012,47 (11):89−92. (张大奎, 于淑娟, 耿继双, 等. 鱼雷罐中泡沫渣的成因与控制[J]. 钢铁, 2012,47 (11):89−92. [4] Guo Chuanqi, Liu Qian. Optimization process oxygen lance position control to reduce the splash of the blowing BOF steelmaking[J]. China Metallurgy, 2015,25(3):45−47. (郭传奇, 刘谦. 优化过程枪位控制减少复吹转炉炼钢喷溅[J]. 中国冶金, 2015,25(3):45−47. [5] Ito K, Fruehan R J. Study on the foaming of CaO-SiO2-FeO slags: Part I. Foaming parameters and experimental results[J]. Metallurgical Transactions B, 1989,20B:509−514. [6] Corbari R, Matsuura H, Halder S, et al. Foaming and the rate of the carbon-iron oxide reaction in slag[J]. Metallurgical and Materials Transactions B, 2009,40B:940−948. [7] Wang Ruifang, Zhang Bo, Liu Chengjun, et al. Physical modelling of dynamic evolution of metallurgical slag foaming[J]. Experimental Thermal and Fluid Science, 2020,113:110014. doi: 10.1016/j.expthermflusci.2019.110014 [8] Li Xiang, Bao Yanping, Wang Min, et al. Distribution characteristic and formation process of bubbles in foaming slag in a converter[J]. Chinese Journal of Engineering, 2016,38(6):773−779. (李翔, 包燕平, 王敏, 等. 转炉泡沫渣气泡分布特点及形成过程[J]. 工程科学学报, 2016,38(6):773−779. [9] Niu Qiang, Chu Shaojun, Wu Keng, et al. Morphotype conversion of foams in metallurgical melts[J]. Journal of University of Science and Technology Beijing, 2000,22(2):109−112. (牛强, 储少军, 吴铿, 等. 冶金熔体泡沫演化中的转型[J]. 北京科技大学学报, 2000,22(2):109−112. doi: 10.3321/j.issn:1001-053X.2000.02.004 [10] Guo Zhancheng, Yang Xuemin, Ai Jing, et al. Investigation on the reduction of FetO by CO in foam slag[J]. Iron and Steel, 1996,31(9):10−14. (郭占成, 杨学民, 艾菁, 等. 泡沫渣中CO还原FetO的实验研究[J]. 钢铁, 1996,31(9):10−14. [11] Porracin P, Onesti D, Grosso A, et al. Slag foaming and dynamic optimization of AC EAF[J]. Iron and Steel, 2007,42(6):88−90. (Porracin P, Onesti D, Grosso A, 等. 泡沫渣的生成和交流电弧炉动态最优化控制[J]. 钢铁, 2007,42(6):88−90. doi: 10.3321/j.issn:0449-749X.2007.06.020 [12] Wang Jie, Zeng Jiaqing, Yang Libin. Research status of slag foaming behaviors during steelmaking process[J]. China Metallurgy, 2016,26(9):1−5. (王杰, 曾加庆, 杨利彬. 炼钢过程中熔渣泡沫化的研究现状[J]. 中国冶金, 2016,26(9):1−5. [13] Cheng Li. Cause of the problems and solving measures in molten iron pretreatment[J]. Continuous Casting, 2016,41(2):20−23. (程立. 太钢铁水预处理常见问题的原因及解决措施[J]. 连铸, 2016,41(2):20−23. -

下载:

下载: