Performance optimization of die casting aluminum alloy containing vanadium for mechanical parts

-

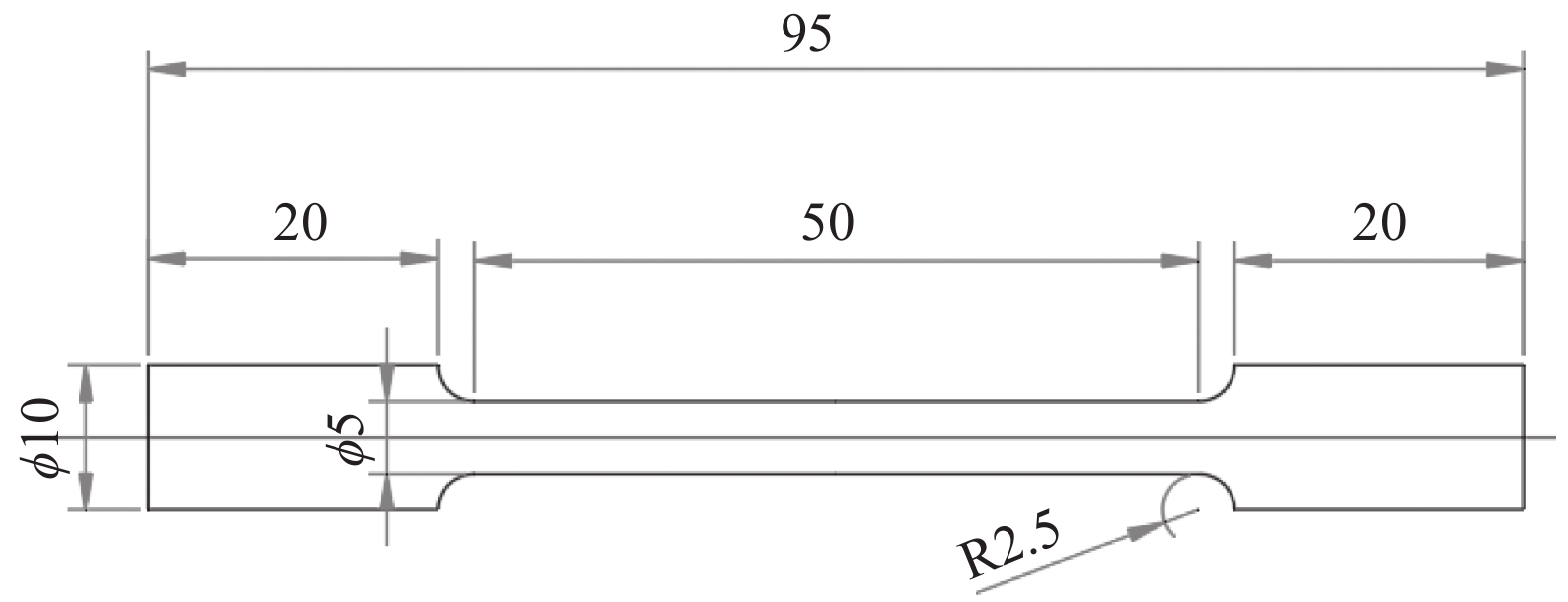

摘要: 采用不同压射比压和压射速度进行了机械零件用含钒压铸铝合金Al-10Si-2.5Cu-0.3V的压铸试验,并进行了合金力学性能和耐磨损性能的测试与分析。结果表明:随压射比压由650 MPa增大到750 MPa、压射速度从250 mm/s加快到450 mm/s时,合金的力学性能和耐磨损性能均先提高后下降。合金的压射比压优选725 MPa、压射速度优选350 mm/s。与压射比压650 MPa相比,当压射比压增加到725 MPa时合金的抗拉强度增大18 MPa、断后伸长率减小0.6%、磨损体积减小8×10−3 mm3。与压射速度450 mm/s相比,当压射速度为350 mm/s时合金的抗拉强度增大20 MPa、断后伸长率减小0.7%、磨损体积减小了10×10−3 mm3。Abstract: The die-casting experiments of Al-10Si-2.5Cu-0.3V die-casting aluminum alloy containing vanadium for mechanical parts were carried out with different injection ratio and injection speed, and the mechanical properties and wear resistance of the alloy were tested and analyzed. The results show that the mechanical properties and wear resistance of the alloy increase firstly and then decrease with the increase of injection pressure from 650 MPa to 750 MPa and injection speed from 250 mm/s to 450 mm/s. The injection specific pressure and injection velocity of the alloy are 725 MPa and 350 mm/s, respectively. Compared with results from injection pressure of 650 MPa, when the injection pressure increases to 725 MPa, the tensile strength increases by 18 MPa, total elongation after fracture decreases by 0.6%, and the wear volume decreases by 8 ×10−3 mm3. Compared with results from injection rate of 450 mm/s, when the injection rate is 350 mm/s, the tensile strength of the alloy increases by 20 MPa, and total elongation after fracture decreases by 0.7%, and the wear volume decreases by 10×10−3 mm3.

-

表 1 合金试样化学成分

Table 1. Chemical compositions of the alloy specimens

% 试样 Si Cu V Mg Fe Mn Ni Zn Al 1 10.124 2.489 0.291 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 2 10.126 2.486 0.293 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 3 10.123 2.487 0.292 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 4 10.122 2.485 0.294 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 5 10.125 2.489 0.291 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 6 10.124 2.486 0.293 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 7 10.127 2.486 0.292 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 8 10.125 2.488 0.294 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 9 10.123 2.485 0.292 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 10(对比试样) 10.124 2.487 0 <0.2 <0.6 <0.3 <0.3 <0.6 Bal. 表 2 试样压铸工艺参数

Table 2. Die casting process parameters of the specimens

试样编号 压射比压/

MPa压射速度/

(mm·s−1)快压速度/

(m·s−1)浇注温度/

℃1 650 350 8 635 2 675 350 8 635 3 700 350 8 635 4 725 350 8 635 5 750 350 8 635 6 725 250 8 635 7 725 300 8 635 8 725 400 8 635 9 725 450 8 635 10(对比试样) 725 350 8 635 表 3 添加钒对合金性能的影响

Table 3. The result show the effect of vanadium addition on mechanical properties of alloy

试样编号 抗拉强度/MPa 断后伸长率/% 磨损体积/mm3 4 256 1.5 13×10−3 10(对比试样) 235 1 24×10−3 -

[1] Liang Wenbo. Analysis and research on the way to improve the machining efficiency of aluminum alloy[J]. China Metal Bulletin, 2019,(2):167−168. (梁文波. 铝合金机械加工效率的提升方式分析与研究[J]. 中国金属通报, 2019,(2):167−168. doi: 10.3969/j.issn.1672-1667.2019.02.103 [2] Qian Chunhua, Cui Haitao, Gao Chao, et al. Study on thermo-mechanical fatigue behavior of E319 cast aluminum alloy[J]. Mechanical Science and Technology for Aerospace Engineering, 2019,38(4):634−638. (钱春华, 崔海涛, 高超, 等. E319铸铝合金热机械疲劳行为研究[J]. 机械科学与技术, 2019,38(4):634−638. [3] Dong Xianming, Jian Chao. Present status and prospect of aluminum alloy die casting standards[J]. Foundry, 2017,66(10):1122−1124. (董显明, 蹇超. 铝合金压铸标准现状及展望[J]. 铸造, 2017,66(10):1122−1124. doi: 10.3969/j.issn.1001-4977.2017.10.020 [4] Zhang Zhiqiang, Zhang Xiaokai, He Dongye. Study on machining technology of aluminum alloy materials[J]. Forging & Stamping Technology, 2018,43(12):16−19. (张志强, 张晓凯, 何东野. 6016铝合金热冲压数值模拟研究[J]. 锻压技术, 2018,43(12):16−19. [5] Zhao Ertuan, Tian Yujing, Sun Shichen, et al. Optimization of permanent casting process for aluminum alloy combined shell[J]. Special Casting & Nonferrous Alloys, 2018,38(12):1317−1320. (赵而团, 田玉晶, 孙世臣, 等. 铝合金组合壳体铸件的金属型铸造工艺优化[J]. 特种铸造及有色合金, 2018,38(12):1317−1320. [6] Zhang Junchao, Zhong Gu, Zou Chun, et al. Research progress of the high Vacuum die-casting aluminum alloys[J]. Materials Review, 2018,32(z2):375−378. (张俊超, 钟鼓, 邹纯, 等. 高真空压铸铝合金的研究进展[J]. 材料导报, 2018,32(z2):375−378. [7] Tan Lin. The influence of low pressure casting parameters on the mechanical properties of aluminum alloy wheels was studied China venture capita[J]. China Science and Technology Investment, 2017,(36):313. (覃琳. 关于低压铸造参数对铝合金车轮机械性能的影响研究[J]. 中国科技投资, 2017,(36):313. doi: 10.3969/j.issn.1673-5811.2017.36.272 [8] Ni Hongjun, Chen Ke, Zhang Fubao, et al. Research status and prospect on die-casting aluminum alloy[J]. Light Metals, 2019,(3):51−55. (倪红军, 陈科, 张福豹, 等. 压铸铝合金研究现状及展望[J]. 轻金属, 2019,(3):51−55. [9] Guo Lianjin, Jin Linkui, Meng Xinpei, et al. Failure analysis on early cracking of die-casting mold for NOS425 steel-aluminum alloy[J]. Forging & Stamping Technology, 2019,44(8):129−136. (郭联金, 金林奎, 孟鑫沛, 等. NOS425钢铝合金压铸模早期开裂失效分析[J]. 锻压技术, 2019,44(8):129−136. [10] Jing Han. Reaction kinetics of vanadium-aluminum alloy preparation by thermite method[J]. Iron Steel Vanadium Titanium, 2017,38(4):40−43. (景涵. 铝热法制备钒铝合金的动力学研究[J]. 钢铁钒钛, 2017,38(4):40−43. doi: 10.7513/j.issn.1004-7638.2017.04.008 [11] Li Jianbing. Summary on the process of producing vanadium-aluminum alloy[J]. Ferro-Alloys, 2017,48(6):13−15. (李建兵. 钒铝合金的生产方法综述[J]. 铁合金, 2017,48(6):13−15. [12] Hu Zhankui, Ke Shanshan. Influence of V content on microstructure and properties of 3102 aluminum alloy[J]. Aluminium Fabrication, 2017,(1):4−9. (胡展奎, 柯珊珊. 钒含量对3102铝合金组织及性能的影响[J]. 铝加工, 2017,(1):4−9. doi: 10.3969/j.issn.1005-4898.2017.01.01 [13] Wang Chaowen, Lin Chong, Wu Hebao, et al. Effects of V on microstructure and mechanical properties of A380 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2019,39(5):552−555. (王朝闻, 林冲, 吴和保, 等. V对A380铝合金显微组织和力学性能的影响[J]. 特种铸造及有色合金, 2019,39(5):552−555. [14] Liu Hai’e, Zhang Jianchao. High temperature properties of cast Al-Si-V aluminum alloy for mechanical parts[J]. Hot Working Technology, 2019,48(1):103−105. (刘海娥, 张建超. 机械零件用铸造Al-Si-V铝合金的高温性能[J]. 热加工工艺, 2019,48(1):103−105. [15] Liu Lu, Chen Jianghua, Xia Shenlin, et al. Effect of element V on microstructure and mechanical properties of 2519 alloy[J]. Transactions of Materials and Heat Treatment, 2014,35(4):78−83. (刘路, 陈江华, 夏申琳, 等. V元素对2519铝合金组织与力学性能的影响[J]. 材料热处理学报, 2014,35(4):78−83. -

下载:

下载: