Effect of Na3PO4·12H2O on foam glass-ceramics prepared from high titanium blast furnace slag

-

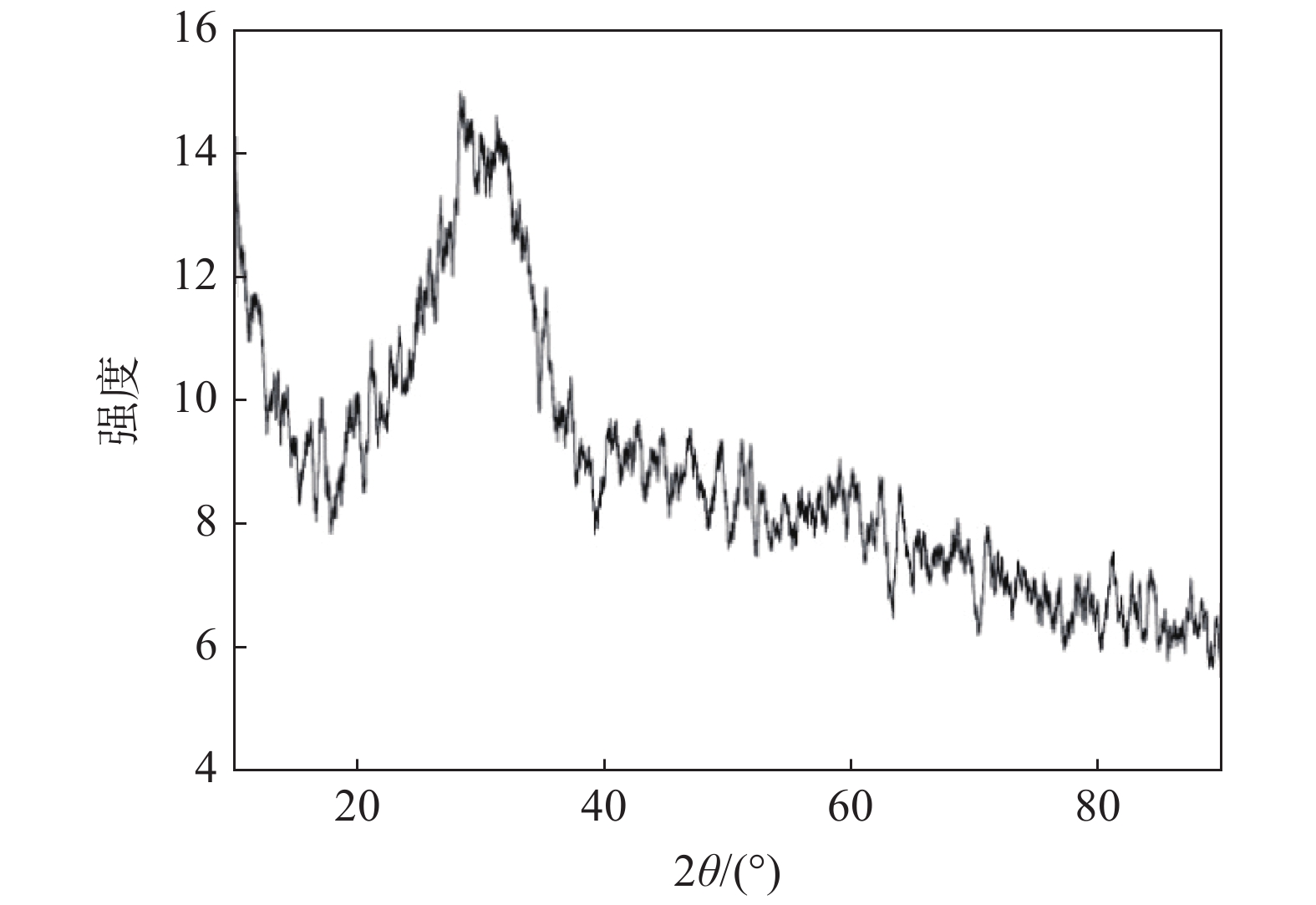

摘要: 以高钛型高炉渣和废玻璃粉为主要原料,碳酸钙为发泡剂,硼砂为助熔剂,采用“一步法”烧结在900 ℃低温下制备了微晶泡沫玻璃。借助DSC、XRD、SEM等分析测试手段,研究了磷酸三钠(Na3PO4·12H2O)添加量对制备微晶泡沫玻璃的影响。结果表明,在不同的磷酸三钠添加量(0%~10%,质量分数)下,微晶泡沫玻璃的主要物相变化不显著,均为透辉石Ca(Mg, Al)(Si, Al)2O6,富铁普通辉石Ca(Mg, Fe)(Si, Fe)2O6以及普通辉石CaMgSi2O6;随着Na3PO4·12H2O含量增加,微晶泡沫玻璃抗压强度和导热系数减小,体积密度和吸水率先减小后增大。当磷酸三钠添加量为6%时,微晶泡沫玻璃具有最优的综合性能。Abstract: Foam glass-ceramics was prepared by one step sintering method at 900 ℃, using high titanium blast furnace slag and waste glass powder as the main raw materials, with calcium carbonate and borax as the foaming agent and fluxing agent, respectively. The effects of Na3PO4·12H2O on the foam glass-ceramics were investigated by DSC, XRD and SEM. The results show that the main phase compositions of the glass-ceramics, which include diopside Ca(Mg, Al)(Si, Al)2O6, iron-rich common pyroxene Ca(Mg, Fe)(Si, Fe)2O6 and common pyroxene CaMgSi2O6, change scarcely with the variation of Na3PO4·12H2O addition (0% to 10%, mass fraction). As the content of Na3PO4·12H2O increases, the compressive strength and thermal conductivity of the foam glass-ceramics decrease, while the bulk density and water absorption decrease first and then increase. At the Na3PO4·12H2O content of 6%, the foam glass-ceramics has the best comprehensive performances.

-

表 1 两种原料的主要化学成分

Table 1. Main chemical compositions of the raw materials

% 原料 SiO2 CaO TiO2 Al2O3 MgO Fe2O3 Na2O K2O 其他 高钛高炉渣 24.72 28.39 21.40 13.64 7.05 2.76 0.26 0.56 1.22 废玻璃粉 71 8.91 1.47 0.07 13.1 0.83 4.62 -

[1] Li Z, Luo Z W, Li X Y, et al. Preparation and characterization of glass ceramic foams with waste quartz sand and coal gangue in different proportions[J]. Journal of Porous Mater, 2016,23(5):231−238. [2] Robson Couto da Silva. Foam glass using sodium hydroxide as foaming agent: study on the reaction mechanism in soda-lime glass matrix[J]. J. Non-Cryst. Solids, 2019,511:177−182. doi: 10.1016/j.jnoncrysol.2019.02.003 [3] Atilla Y, Guden M, Tasdemirci A. Foam glass processing using a polishing glass powder residue[J]. Ceram Int., 2013,39:5869−5877. doi: 10.1016/j.ceramint.2012.12.104 [4] Zhu M G, Ji R, Li Z M, et al. Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass[J]. Construction and Building Materials, 2016,112(6):398−405. [5] Fernandes H R, Tulyaganov D U, Ferreira J M F. Production and characterization of glass ceramic foams from recycled raw materials[J]. Advances in Applied Ceramics, 2009,108:9−13. doi: 10.1179/174367509X344971 [6] Nibedita Sasmal, Mrinmoy Garai, Basudeb Karmakar. Preparation and characterization of novel foamed porous glass-ceramics[J]. Materials Characterization, 2015,103:90−100. doi: 10.1016/j.matchar.2015.03.007 [7] Ponsot I, Bernardo E. Self glazed glass ceramic foams from metallurgical slag and recycled glass[J]. J. Clean. Prod, 2013,59:245−250. doi: 10.1016/j.jclepro.2013.06.029 [8] (甄玉兰. 攀枝花含钛高炉渣资源化利用新途径[D]. 北京: 北京科技大学, 2016.)Zhen Yulan. New ways of recycling titanium-bearing blast furnace slag in Panzhihua[D]. Beijing: University of Science and Technology Beijing, 2016. [9] Huo Hongying, Li Ruiping. Research process on photocatalytic materials of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2020,4:36−41. (霍红英, 李瑞萍. 高钛型高炉渣光催化材料研究进展[J]. 矿产综合利用, 2020,4:36−41. doi: 10.3969/j.issn.1000-6532.2020.04.006 [10] Yan Zidi, Feng Keqin, Chen Changhong, et al. Influence of La2O3 on foam glass-ceramics prepared from high titanium blast furnace slag[J]. Materials Review B: Research Papers, 2018,32(8):2763−2767. (严子迪, 冯可芹, 陈长鸿, 等. La2O3对高钛高炉渣制备微晶泡沫玻璃的影响[J]. 材料导报B: 研究篇, 2018,32(8):2763−2767. [11] Chen C, Feng K, Zhou Y, et al. Effect of sintering temperature on the microstructure and properties of foamed glass-ceramics prepared from high-titanium blast furnace slag and waste glass[J]. Int. J. Miner. Metall. Mater, 2017,24:931−936. doi: 10.1007/s12613-017-1480-8 [12] Xi Cuiping, Zheng Feng, Xu Jiahe, et al. Preparation of glass-ceramic foams using extracted titanium tailing and glass waste as raw materials[J]. Construction and Building Materials, 2018,190:896−909. doi: 10.1016/j.conbuildmat.2018.09.170 [13] Shi H, Feng K, Wang H, et al. Influence of aluminium nitride as a foaming agent on the preparation of foam glass-ceramics from high-titanium blast furnace slag[J]. Int. J. Miner. Metall. Mater, 2016,23:595−600. doi: 10.1007/s12613-016-1271-7 [14] (马明龙. 利用含钛高炉渣制备微晶泡沫玻璃的研究[D]. 沈阳: 东北大学, 2008.)Ma Minglong. Foamed glass-ceramics prepared by using titania-bearing blast furnace slag[D]. Shenyang: Northeastern University, 2008. [15] Tian Jian, Feng Keqin, Yan Zidi, et al. Comparative study on preparation of foam glass-ceramics from slow-cooling and water-quenched high titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2020,41(5):96−101. (田坚, 冯可芹, 严子迪, 等. 缓冷与水淬高钛型高炉渣制备微晶泡沫玻璃的对比研究[J]. 钢铁钒钛, 2020,41(5):96−101. -

下载:

下载: