Study on numerical simulation for flow field optimization in argon blowing VD ladle

-

摘要: 以某钢厂150 t VD钢包炉为研究对象,采用商业软件Ansys-Fluent,建立钢包底吹氩气模型,结合正交设计方法,模拟了不同钢液量,两个吹氩口不同吹氩量工艺条件下钢包内流场和流速变化,同时考虑了静置10 min后钢包炉内钢液流动情况。所有试验均监测钢包下部同一位置的速度大小,通过正交设计方法选择最优的生产方案。研究结果表明:钢包内钢液量和底吹氩气量在小范围内变动对钢包内钢液流场和流速影响不大,且钢液量和氩气口吹氩量对静置10 min后钢液内流场流速的影响可以忽略不计。吹氩量过大会导致渣眼开度较大引起卷渣和吸气现象,吹气量过小钢液流速较低则导致形成稳定循环流场所需时间较长。最终通过对比分析得出在钢液高度选用3590 mm,1#和2#氩气口流量均采用0.9 m3/h时钢包炉内综合流动效果较好,减少了钢水受污染程度,提高了生产效率。Abstract: Taking a steel plant VD ladle furnace as research object and using commercial software ANSYS-Fluent, a 150 t ladle bottom-blown argon gas model was established to simulate different molten steel volumes and two argon-blowing ports with different argon-blowing volume. The flow field and velocity were changed, and the flow of molten steel in ladle furnace after standing for 10 minutes was also considered. All tests monitored the speed of same position at lower part of ladle, and selected the optimal production plan through the orthogonal design method. The results show that variation of molten steel volume and bottom-blown argon flow in ladle within a small range have little effect on flow field and flow velocity of molten steel in ladle. And the influence of steel and argon blowing volume on the internal flow field after standing for 10 minutes is negligible. Excessive argon blowing will result in a larger slag hole opening, which will cause slag entrapment and gas suction. If the blowing amount is too small, lower flow rate of molten steel will result in a longer time for the formation of a stable circulating flow field. Finally, through comparative analysis, it is concluded that when the height of molten steel is 3 590 mm and the flow rate of No. 1 and No. 2 argon ports are both 0.9 m3/h, the comprehensive flow effect in ladle furnace is better, which reduces contamination degree of molten steel and improves production efficiency.

-

Key words:

- VD ladle furnace /

- bottom-blown argon /

- flow field /

- numerical simulation /

- two-phase flow /

- argon blowing period /

- standing period

-

表 1 正交试验因素及水平

Table 1. Factors and level of orthogonal experiment

水平A

钢液高度/mmB

1号氩气口流量/(m3·h−1)C

2号氩气口流量/(m3·h−1)1 3890 0.6 0.6 2 3590 0.9 0.9 3 3290 1.2 1.2 表 2 试验计划

Table 2. Experimental matrix

试样号A

钢液高度B

1号氩气口流量C

2号氩气口流量D

空白列1# A1 B1 C1 D1 2# A1 B2 C2 D2 3# A1 B3 C3 D3 4# A2 B1 C2 D3 5# A2 B2 C3 D1 6# A2 B3 C1 D2 7# A3 B1 C3 D2 8# A3 B2 C1 D3 9# A3 B3 C2 D1 表 3 钢包实体尺寸

Table 3. Dimensions of solid ladle

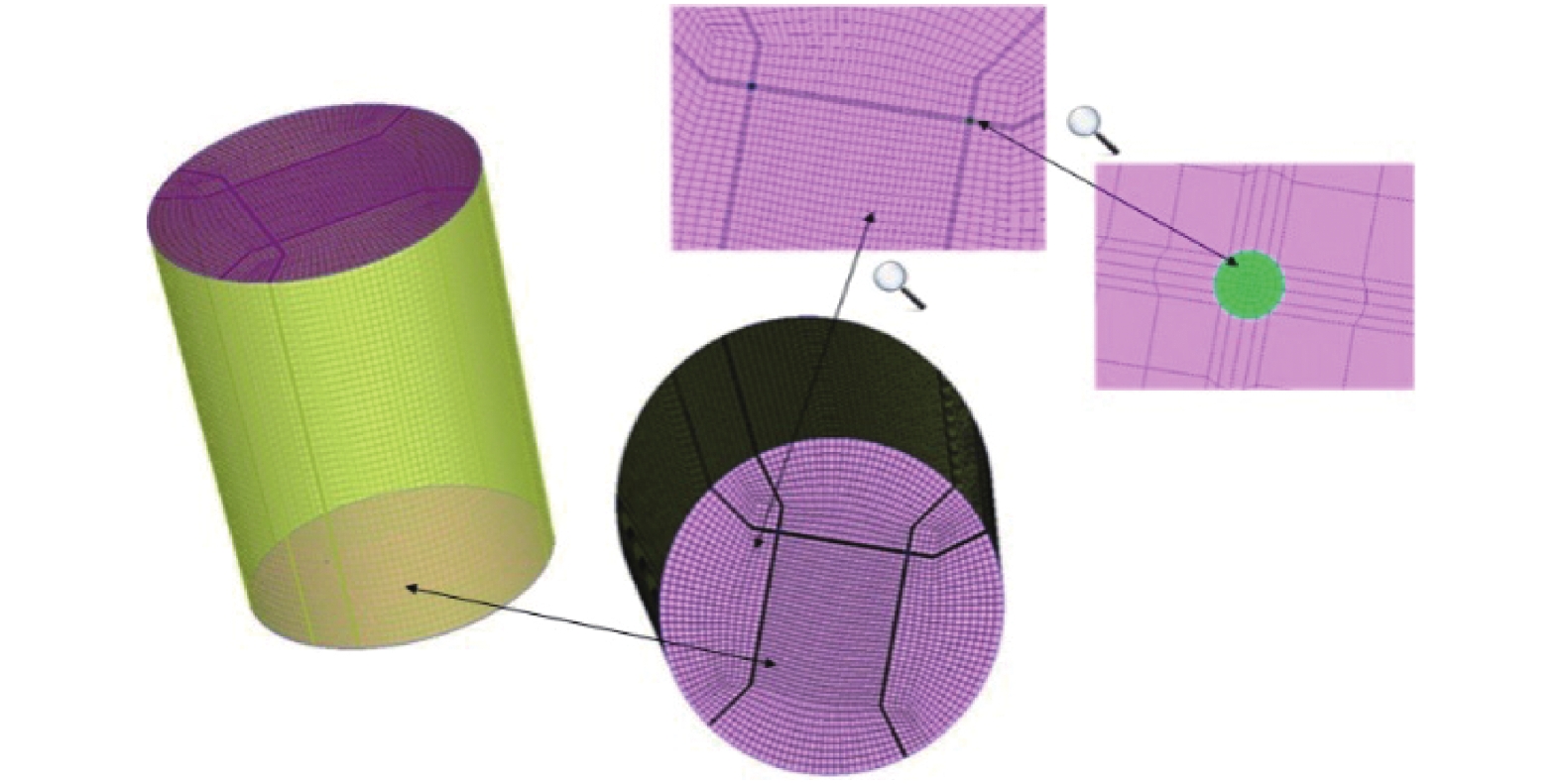

钢液高度/mm 钢液上部直径/mm 钢液底部直径/mm 网格1 3890 3028 2764 网格2 3590 3008 2764 网格3 3290 2987 2764 表 4 钢包底吹口布置

Table 4. Ladle bottom mouthpiece arrangement

两氩气口中心到钢

包炉中心角度/(°)氩气口线距

底面中心/mm氩气口等

效直径/mm90 750 40 表 5 数值模拟材料参数

Table 5. Material parameters used for numerical simulation

材料 密度/(kg·m−3) 粘度/(kg·m−1·s−1) 比热/(J·kg−1·K−1) 导热系数/(W·m−1·K−1) 参考温度/K 相对原子质量 钢液 7020 0.0067 750 41 1 860 56 氩气 1.6228 2.125E-05 520 0.0242 300 39.95 表 6 速度入口设置参数

Table 6. Ssetting parameters of inlet speed

氩气流量/(m3·h−1) 氩气口流速/(m·s−1) k/(m2·s−2) e/(m2·s−3) 0.6 0.132629 0.000176 0.000117 0.9 0.198944 0.000396 0.000394 1.2 0.265258 0.000704 0.000933 表 7 试验结果

Table 7. Experimental results

试样号 A

钢液

高度B

1#氩气

口流量C

2#氩气

口流量D

空白

列检测点x y z三个

方向速度总和/

(m·s−1)1# A1 B1 C1 D1 0.0125 2# A1 B2 C2 D2 0.0277 3# A1 B3 C3 D3 0.0319 4# A2 B1 C2 D3 0.0248 5# A2 B2 C3 D1 0.0296 6# A2 B3 C1 D2 0.0291 7# A3 B1 C3 D2 0.0173 8# A3 B2 C1 D3 0.0259 9# A3 B3 C2 D1 0.0251 Ⅰ 0.0721 0.0546 0.0675 0.0672 T=0.2239

$\mu = \dfrac{T}{9} = 0.024\;9$Ⅱ 0.0835 0.0832 0.0776 0.0741 Ⅲ 0.0683 0.0861 0.0788 0.0862 Ⅰ/3 0.0240 0.0182 0.0225 0.0224 Ⅱ/3 0.0278 0.0277 0.0259 0.0247 Ⅲ/3 0.0228 0.0287 0.0263 0.0287 表 8 数据偏离值

Table 8. Data deviation values

钢液高度A 1号氩气口流量B 2号氩气口流量C Ⅰ/3−$\mu $ −0.0009 −0.0067 −0.0024 Ⅱ/3−$\mu $ 0.0029 0.0028 0.001 Ⅲ/3−$\mu $ −0.0021 0.0038 0.0014 -

[1] Ren Ying, Zhang Lifeng, Li Yanlong, et al. Numberical simulation of fluid flow and alloy dispersion in an argon gas stirred ladle[J]. Journal of Iron and Steel Research, 2014,26(7):28−34. (任英, 张立峰, 李燕龙, 等. 底吹氩钢包内钢液流动与合金扩散的数值模拟[J]. 钢铁研究学报, 2014,26(7):28−34. [2] Pirker S, König B, Puttinger S, et al. A glance on turbulence modelling in simulating bubble stirred ladle flow[J]. BHM Berg- und Hüttenmännische Monatshefte, 2013,158(11):472−474. [3] Liu Y, Liu Y, Ersson M, et al. A review of physical and numerical approaches for the study of gas stirring in ladle metallurgy[J]. Metallurgical and Materials Transactions B, 2019,50(1):555−577. doi: 10.1007/s11663-018-1446-x [4] Bellot J, Bellot J, De Felice V, et al. Coupling of CFD and PBE calculations to simulate the behavior of an inclusion population in a gas-stirring ladle[J]. Metallurgical and Materials Transactions B, 2014,45(1):13−21. doi: 10.1007/s11663-013-9940-7 [5] Geng D, Lei H, He J. Optimization of mixing time in a ladle with dual plugs[J]. International Journal of Minerals, Metallurgy, and Materials, 2010,17(6):709−714. doi: 10.1007/s12613-010-0378-5 [6] Zheng Shuguo, Zhu Miaoyong. Physica modeling of inclusion behavior in ladle witheccentric bottom blowing argon[J]. Journal of Iron and Steel Research, 2008,(6):18−22. (郑淑国, 朱苗勇. 偏心底吹氩钢包内夹杂物行为的物理模拟[J]. 钢铁研究学报, 2008,(6):18−22. [7] Yan Huicheng, He Qing, Guo Zheng, et al. Water modeling of slight stirring in ladle[J]. Journal of Iron and Steel Research, 2006,(2):15−20. (颜慧成, 贺庆, 郭征, 等. 钢包弱搅拌水模拟实验研究[J]. 钢铁研究学报, 2006,(2):15−20. doi: 10.3321/j.issn:1001-0963.2006.02.004 [8] Lee H, Yi K. Development of a numerical model to predict areas of plume eye of ladle furnace process[J]. Metals and Materials International, 2015,21(3):511−520. doi: 10.1007/s12540-015-4291-3 [9] Hoang Q N, Ramírez-Argáez M A, Conejo A N, et al. Numerical modeling of liquid–liquid mass transfer and the influence of mixing in gas-stirred ladles[J]. JOM, 2018,70(10):2109−2118. doi: 10.1007/s11837-018-3056-0 [10] Liu W, Tang H, Yang S, et al. Numerical simulation of slag eye formation and slag entrapment in a bottom-blown argon-stirred Ladle[J]. Metallurgical and Materials Transactions B, 2018,49(5):2681−2691. doi: 10.1007/s11663-018-1308-6 [11] Guo Zhenhe, Deng Liqin, Qu Tianpeng. Numerical simulation on fluid flow and mixingbehavior in argon blowing ladle[J]. Steelmaking, 2018,34(3):18−24. (郭振和, 邓丽琴, 屈天鹏. 吹氩钢包内气液两相流动及均混行为的数值模拟[J]. 炼钢, 2018,34(3):18−24. [12] Pan S M, Chiang J D, Hwang W S. Simulation of large bubble/molten steel interaction for gas-injected ladle[J]. Journal of Materials Engineering and Performance, 1999,8(2):236−244. doi: 10.1361/105994999770347098 [13] Alexiadis A, Gardin P, Domgin J F. Spot turbulence, breakup, and coalescence of bubbles released from a porous plug injector into a gas-stirred ladle[J]. Metallurgical and Materials Transactions B, 2004,35(5):949−956. doi: 10.1007/s11663-004-0089-2 [14] Lou W, Zhu M. Numerical simulation of gas and liquid two-phase flow in gas-stirred systems based on euler–euler approach[J]. Metallurgical and Materials Transactions B, 2013,44(5):1251−1263. doi: 10.1007/s11663-013-9897-6 [15] Li L, Liu Z, Cao M, et al. Large eddy simulation of bubbly flow and slag layer behavior in ladle with discrete phase model (DPM)–Volume of fluid (VOF) coupled model[J]. JOM, 2015,67(7):1459−1467. doi: 10.1007/s11837-015-1465-x [16] Xia J L, Ahokainen T. Transient flow and heat transfer in a steelmaking ladle during the holding period[J]. Metallurgical and Materials Transactions B, 2001,32(4):733−741. doi: 10.1007/s11663-001-0127-2 [17] Launder B E, Spalding D B. Lectures in mathematical model of turbulence[M]. England. London: Academic Press, 1972. -

下载:

下载: