Comparative study on wear resistance of plastic die steels NAK80 and S136

-

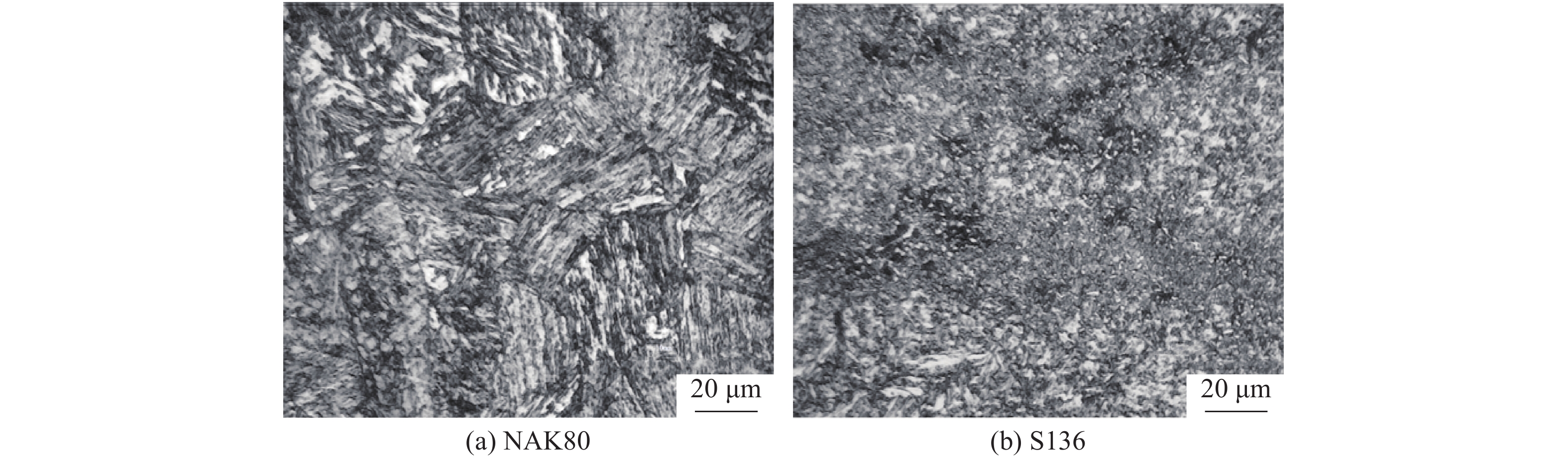

摘要: 以预硬化塑料模具钢NAK80和S136为研究对象,对比研究了两者的显微硬度、金相组织以及不同载荷下的摩擦磨损行为。结果表明: NAK80 钢金相组织为板条状马氏体和粒状贝氏体,S136钢的金相组织为铁素体基体和细小碳化物,显微硬度(HV)分别为405.01 ± 10.63 和354.21 ± 6.14 。NAK80和S136钢的摩擦系数均随着载荷的增加而降低,在60 N时,两者都达到各自最低的摩擦系数(0.34和0.37),当载荷增加至80 N,摩擦系数反而上升。整体而言,S136的摩擦系数高于NAK80。不同载荷条件下,NAK80的磨损行为具有高的载荷敏感性;而S136具有更加稳定的耐磨性。低载荷时,以磨粒磨损和剥层磨损为主,NAK80耐磨性优于S136;高载荷时,以粘着磨损和磨粒磨损为主,S136钢耐磨性优于NAK80。Abstract: The microhardness, microstructure, friction and wear behavior of pre-hardened plastic die steels NAK80 and S136 were studied. The results show that the microstructure of NAK80 steel consists of lath martensite and granular bainite, while that of S136 steel are ferrite matrix and fine carbides, and the microhardness is 405.01 ± 63 HV and 354.21 HV ± 6.14 HV respectively. The friction coefficients of NAK80 and S136 steel decrease with the increase of load. At 60N, the friction coefficients of NAK80 and S136 steel reach their lowest values (0.34 and 0.37). However, when the load increases to 80 N, the friction coefficient increases. Overall, the friction coefficient of S136 is higher than that of NAK80. The wear behavior of NAK80 has high load sensitivity under different load conditions while S136 has more stable wear resistance. At low load, abrasive wear and delamination wear are dominant, and the wear resistance of NAK80 is better than that of S136. At high load, adhesive wear and abrasive wear are dominant, and the wear resistance of S136 steel is better than that of NAK80.

-

Key words:

- die steel /

- load /

- hardness /

- microstructure /

- wear resistance properties

-

表 1 试验钢的主要化学成分

Table 1. Main chemical compositions of tested steels

% 牌号 C Si Mn Ni Cu Al Mo NAK80 0.15 0.3 1.5 3 1 1 0.3 牌号 C Si Mn Cr V S P S136 0.38 0.9 0.5 13.6 0.3 ≤0.03 ≤0.03 表 2 试验钢磨痕数据

Table 2. Wear track data of tested steels

载荷/N 磨痕宽度/mm 磨痕深度/μm 磨损量/mm3 NAK80 S136 NAK80 S136 NAK80 S136 20 0.989 1.149 66.033 73.428 0.045 0.111 40 1.427 1.524 58.201 60.095 0.234 0.245 60 1.704 1.490 118.003 107.620 0.532 0.307 80 1.918 1.838 119.513 102.997 0.704 0.579 -

[1] Lv Chuanjiang, Wu Xiaochun. Research status and prospect of advanced mirror plastic mold steel[J]. Die & Mould Manufacture, 2017,17(10):93−98. (吕穿江, 吴晓春. 高级镜面塑料模具钢研究现状及展望[J]. 模具制造, 2017,17(10):93−98. doi: 10.3969/j.issn.1671-3508.2017.10.025 [2] Zhang Xianming. Several kinds of new plastic mold steel properties and research of the heat treatment process[J]. Die & Mould Manufacture, 2015,15(5):83−86. (张先鸣. 几种新型塑料模具钢性能及热处理工艺的研究[J]. 模具制造, 2015,15(5):83−86. doi: 10.3969/j.issn.1671-3508.2015.05.025 [3] Cai Wu. Comparative analysis on steel quality of typical plastic mold at home and abroad[J]. Special Steel Technology, 2018,24(1):8−12. (蔡武. 国内外典型塑料模具钢质量对比分析研究[J]. 特钢技术, 2018,24(1):8−12. [4] Zhang Kuan, Zhen Fan, Qu Jinbo. Effect of solution and aging treatment on microstructure and hardness of plastic mold steel NAK80[J]. Hot Working Technology, 2014,43(20):193−197. (张宽, 镇凡, 曲锦波. 固溶和时效处理对塑料模具钢NAK80组织和硬度的影响[J]. 热加工工艺, 2014,43(20):193−197. [5] Li Ainong, Zhou Dan, Zhao Yuhong, et al. Comparison for microstructure and properties of several pre-hardened plastic mould steels[J]. Materials for Mechanical Engineering, 2012,36(10):50−53. (李爱农, 周丹, 赵玉宏, 等. 几种预硬塑料模具钢的组织与性能对比[J]. 机械工程材料, 2012,36(10):50−53. -

下载:

下载: