Corrosion behavior of high strength weathering steel for concrete pole

-

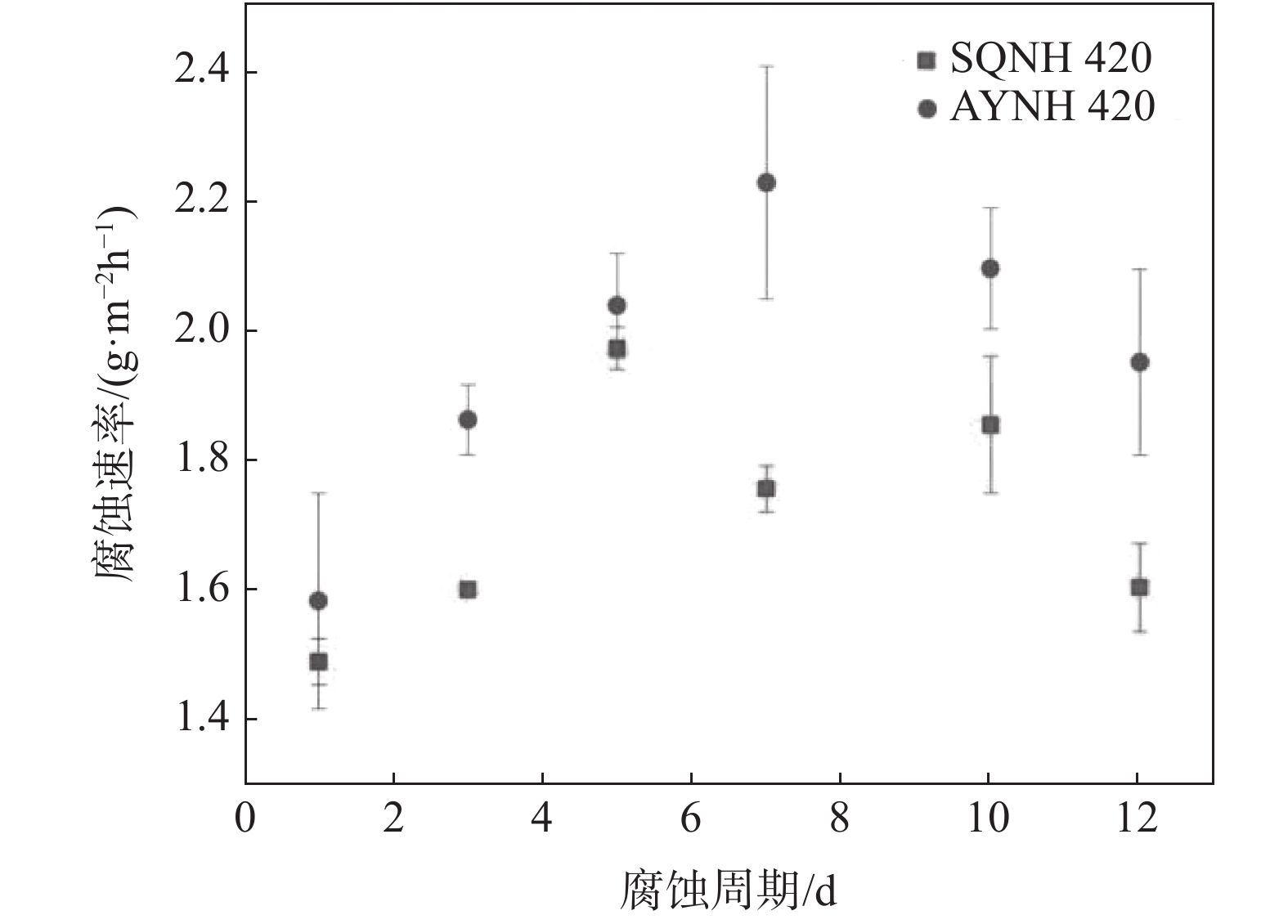

摘要: 使用室内加速腐蚀试验、XRD分析、电化学方法等测试方法研究了AYNH 420、SQNH 420两种耐候钢的腐蚀行为。使用失重测试的方法确定了两种试验钢的腐蚀速率,研究了试验钢的腐蚀动力学;通过对耐候钢锈层微观形貌、结构的表征,确定了两种钢锈层的成分和结构;并使用动电位极化曲线和交流阻抗谱的方法对耐候钢的腐蚀机制进行了探索。结果表明:同等条件下,SQNH 420的腐蚀速率低于AYNH 420;耐候钢的主要锈层产物是Fe3O4、α-FeOOH、β-FeOOH和γ-FeOOH等。锈层的组织结构分为内外两层,能起到保护作用的是附着性好,结构致密的内层。随着腐蚀时间的延长,腐蚀产物的增多,耐候钢的腐蚀倾向降低,电极反应由电极控制向扩散控制转变。Abstract: The corrosion behavior of two weathering steels, AYNH 420 and SQNH 420, was studied by using indoor accelerated corrosion tests, XRD analysis, and electrochemical methods. Weightlessness test was used to determine the corrosion rate of the two steels, and the corrosion kinetics of tow steels was studied. The micromorphology and structure of the corrosion products were characterized. Moreover, the corrosion mechanism of tested steels was studied by potentiodynamic polarization and AC impedance spectroscopy. The results indicate that under the same conditions, the corrosion rate of SQNH 420 is lower than that of AYNH 420. The compositions of corrosion products were Fe3O4, α-FeOOH, β-FeOOH and γ-FeOOH, etc. There are two layers in corrosion products, and the inner layer with good adhesion and compact structure plays a protective role. In addition, as the corrosion time increases, the corrosion products increase, and the corrosion tendency of two steels decreases, and the electrode reaction changes from electrode control to diffusion control.

-

Key words:

- weathering steel /

- concrete pole /

- corrosion behavior /

- corrosion products /

- electrode reaction

-

表 1 输电铁塔用耐候钢化学成分

Table 1. Chemical compositions of weathering steel for transmission tower

% 牌号 C Si Mn S P Cr Ni Cu Nb N Alt SQNH 420 0.05 0.29 0.61 ≤0.002 ≤0.01 0.39 0.50 0.38 0.034 ≤0.0030 0.041 AYNH 420 0.07 0.31 1.03 ≤0.005 ≤0.02 0.50 0.14 0.30 0.020 ≤0.0060 0.040 -

[1] Xie Zhen. Application prospect of weathering steel in transmission tower[J]. Special Structure, 2014,(4):29−33. (谢震. 展望耐候钢在输电杆塔中的应用[J]. 特种结构, 2014,(4):29−33. [2] Li Maohua, Yang Jinbo, Liu Siyuan. The latest progress of materials for transmission tower structure[J]. Journal of Wuhan University (Engineering Science Edition), 2011,(S1):191−195. (李茂华, 杨靖波, 刘思远. 输电杆塔结构用材料最新进展[J]. 武汉大学学报(工学版), 2011,(S1):191−195. [3] Prabha S L, Dattatreya J K, Neelamegam M, et al. Study on stress-strain properties of reactive powder concrete under uniaxial compression[J]. International Journal of Engineering Science and Technology, 2010,2(11):6408−6416. [4] Xing Haijun, Zhang Zifu, Qi Jinming, et al. Characteristics and application of ultra-high performance concrete poles: Interpretation of China electricity Union standard "ultra high performance concrete poles"[J]. China Electric Power Enterprise Management, 2017,(21):54−55. (邢海军, 张子富, 祁锦明, 等. 超高性能混凝土电杆的特点和应用−中电联标准《超高性能混凝土电杆》的解读[J]. 中国电力企业管理, 2017,(21):54−55. [5] Xing Haijun, Yue Ping, Wang Cancan, et al. Study on connection performance of D-type composite pipe[J]. China Electric Power, 2015,48(3):70−75. (邢海军, 岳平, 王灿灿, 等. D型复合材料管连接性能研究[J]. 中国电力, 2015,48(3):70−75. [6] Wang Xiantie, Zhou Chao, Jia Guiqiang, et al. Experimental study on seismic performance of thin steel plate wall structure with inner middle opening in concrete-filled square steel tubular column frame[J]. Journal of Building Structure, 2015,36(8):16−23. (王先铁, 周超, 贾贵强, 等. 方钢管混凝土柱框架内置中间开洞薄钢板墙结构抗震性能试验研究[J]. 建筑结构学报, 2015,36(8):16−23. [7] Yang Fengli, Han Junke, Yang Jinbo, et al. Experimental study on corrosion resistance of weathering steel joints for transmission towers[J]. Power Construction,, 2008,(9):23−28. (杨风利, 韩军科, 杨靖波, 等. 输电铁塔用耐候钢节点耐腐蚀性能试验研究[J]. 电力建设, 2008,(9):23−28. doi: 10.3969/j.issn.1000-7229.2008.09.006 [8] Yang Jinbo, Li Maohua, Yang Fengli, et al. New progress in the study of transmission tower structure of China[J]. Power Grid Technology, 2008,(22):77−83. (杨靖波, 李茂华, 杨风利, 等. 我国输电线路杆塔结构研究新进展[J]. 电网技术, 2008,(22):77−83. [9] Morcillo M, Díaz I, Chico B, et al. Weathering steels: From empirical development to scientific design: A review[J]. Corrosion Science, 2014,83:6−31. doi: 10.1016/j.corsci.2014.03.006 [10] Ge Zhaojun, Zhang Qiang, Huang Yao, et al. Corrosion behavior of weatherproof steel for transmission tower in different atmospheric environment[J]. China Electric Power, 2016,49(12):8−13. (葛兆军, 张强, 黄耀, 等. 输电铁塔耐候钢在不同大气环境下的腐蚀行为[J]. 中国电力, 2016,49(12):8−13. doi: 10.11930/j.issn.1004-9649.2016.12.008.07 [11] Luo Yihua, Huang Yao, Yang Xuefeng, et al. Effect of P element on mechanical properties and corrosionresistance of weathering high strength steel tower[J]. Iron Steel Vanadium Titanium, 2019,40(1):142−147. (罗义华, 黄耀, 杨雪锋, 等. P元素对耐候高强钢铁塔力学性能和腐蚀性能的影响[J]. 钢铁钒钛, 2019,40(1):142−147. doi: 10.7513/j.issn.1004-7638.2019.01.025 [12] Dillmann P, Mazaudier F, Hœrlé S. Advances in understanding atmospheric corrosion of iron. I. Rust characterisation of ancient ferrous artefacts exposed to indoor atmospheric corrosion[J]. Corrosion Science, 2004,46(6):1401−1429. doi: 10.1016/j.corsci.2003.09.027 [13] He Kun, Wang Li. Corrosion behavior of 316ng stainless steel in high purity water[J]. Corrosion and Protection, 2016,37(8):631−634. (何琨, 王理. 316NG不锈钢在高纯水环境中的腐蚀行为[J]. 腐蚀与防护, 2016,37(8):631−634. doi: 10.11973/fsyfh-201608005 [14] Fan Liyan, Zhong Tingzhi, Zou Ke, et al. Review of stainless steel and its intergranular corrosion[J]. Chemical Engineering and Equipment, 2013,(6):176−177. (范丽颜, 钟廷志, 邹克, 等. 不锈钢及其晶间腐蚀综述[J]. 化学工程与装备, 2013,(6):176−177. [15] Chen Y Y, Tzeng H J, Wei L I, et al. Corrosion resistance and mechanical properties of low-alloy steels under atmospheric conditions[J]. Corrosion Science, 2005,47(4):1001−1021. doi: 10.1016/j.corsci.2004.04.009 [16] Yamashita M, Shimizu T, Konishi H, et al. Structure and protective performance of atmospheric corrosion product of Fe–Cr alloy film analyzed by Mössbauer spectroscopy and with synchrotron radiation X-rays[J]. Corrosion Science, 2003,45(2):381−394. doi: 10.1016/S0010-938X(02)00093-8 [17] Asami K, Kikuchi M. In-depth distribution of rusts on a plain carbon steel and weathering steels exposed to coastal–industrial atmosphere for 17 years[J]. Corrosion Science, 2003,45(11):2671−2688. doi: 10.1016/S0010-938X(03)00070-2 [18] Yamashita M, Miyuki H, Matsuda Y, et al. The long term growth of the protective rust layer formed on weathering steel by atmospheric corrosion during a quarter of a century[J]. Corrosion Science, 1994,36(2):283−299. doi: 10.1016/0010-938X(94)90158-9 [19] Wang J, Wang Z Y, Ke W. A study of the evolution of rust on weathering steel submitted to the Qinghai salt lake atmospheric corrosion[J]. Materials Chemistry and Physics, 2013,139(1):225−232. doi: 10.1016/j.matchemphys.2013.01.028 [20] Zhang Quancheng, Wang Jianjun, Wu Jianshen, et al. Effect of corrosion resistance of weathering steel on corrosion resistance of weathering steel[J]. Acta Metallurgica Sinica, 2001,(2):193−196. (张全成, 王建军, 吴建生, 等. 锈层离子选择性对耐候钢抗海洋性大气腐蚀性能的影响[J]. 金属学报, 2001,(2):193−196. doi: 10.3321/j.issn:0412-1961.2001.02.017 [21] Diaz I, Cano H, De La Fuente D, et al. Atmospheric corrosion of Ni-advanced weathering steels in marine atmospheres of moderate salinity[J]. Corrosion Science, 2013,76:348−360. doi: 10.1016/j.corsci.2013.06.053 [22] Qian Y, Ma C, Niu D, et al. Influence of alloyed chromium on the atmospheric corrosion resistance of weathering steels[J]. Corrosion Science, 2013,74:424−429. doi: 10.1016/j.corsci.2013.05.008 [23] Zhou Y, Chen J, Liu Z. Corrosion behavior of rusted 550 MPa grade offshore platform steel[J]. Journal of Iron and Steel Research, International, 2013,20(3):66−73. doi: 10.1016/S1006-706X(13)60071-0 [24] Chen A, Xu J, Li R, et al. Corrosion resistance of high performance weathering steel for bridge building applications[J]. Journal of Iron and Steel Research, International, 2012,19(6):59−63. doi: 10.1016/S1006-706X(12)60128-9 [25] Chiavari C, Bernardi E, Martini C, et al. Atmospheric corrosion of Cor-Ten steel with different surface finish: Accelerated ageing and metal release[J]. Materials Chemistry and Physics, 2012,136(2-3):477−486. doi: 10.1016/j.matchemphys.2012.07.014 [26] Song Liying, Shi Hao, Wang Wei, et al. Study on the influence of corrosion product properties on metal atmospheric corrosion process[J]. Equipment Environmental Engineering, 2018,15(10):8−13. (宋立英, 石浩, 王巍, 等. 腐蚀产物性质对金属大气腐蚀过程影响的研究[J]. 装备环境工程, 2018,15(10):8−13. -

下载:

下载: