Experimental study on vanadium extraction from alkaline vanadium-containing powder

-

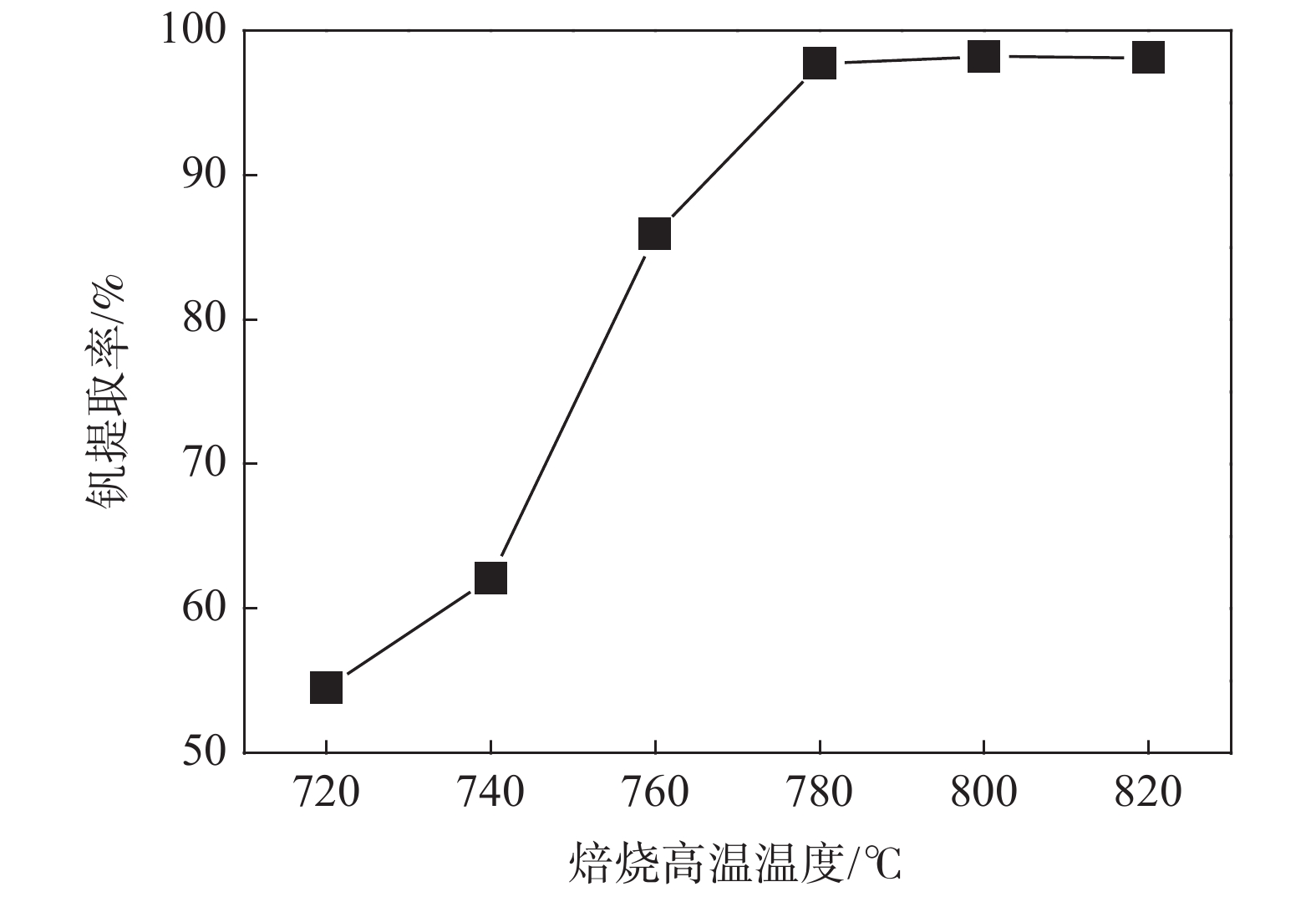

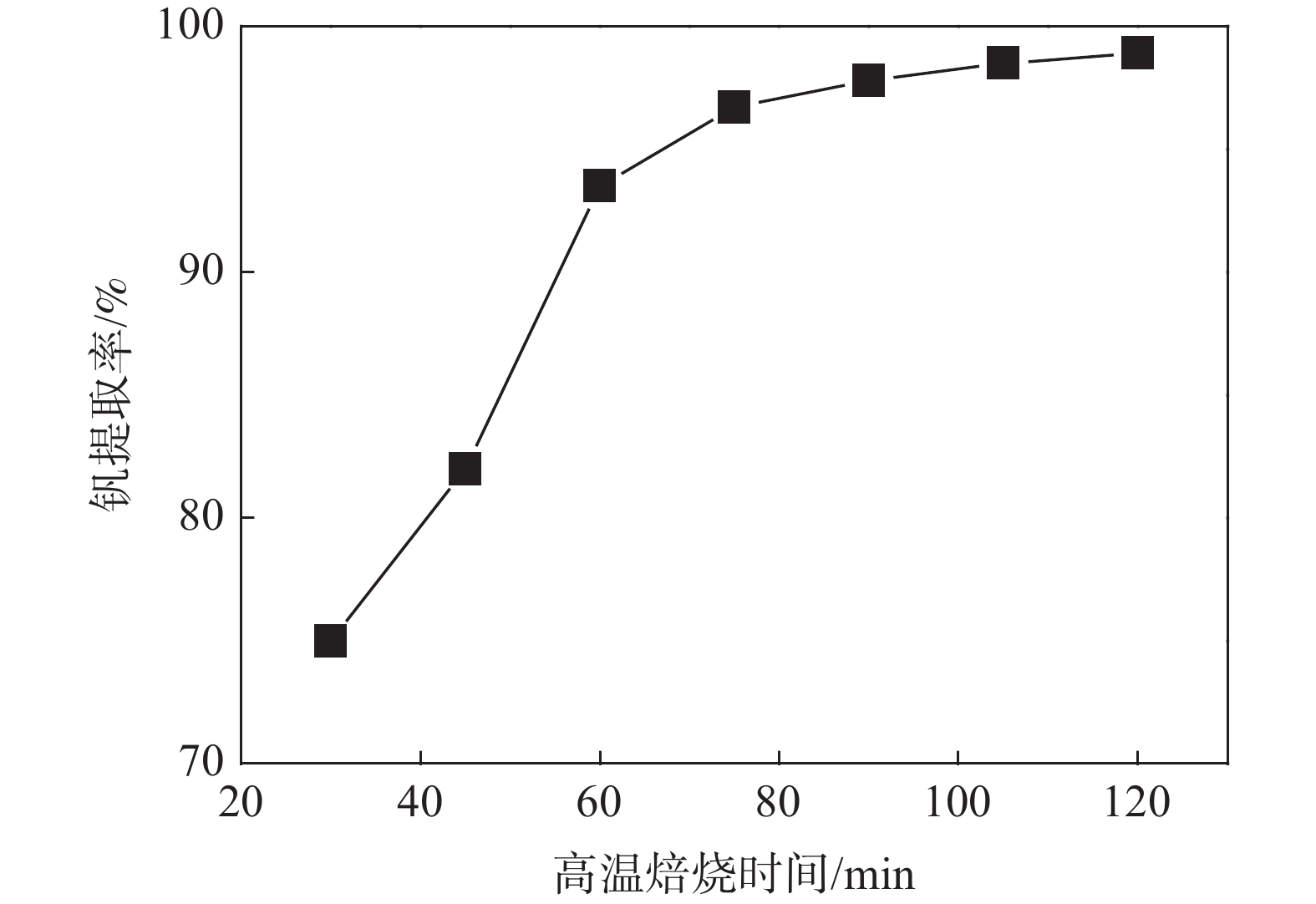

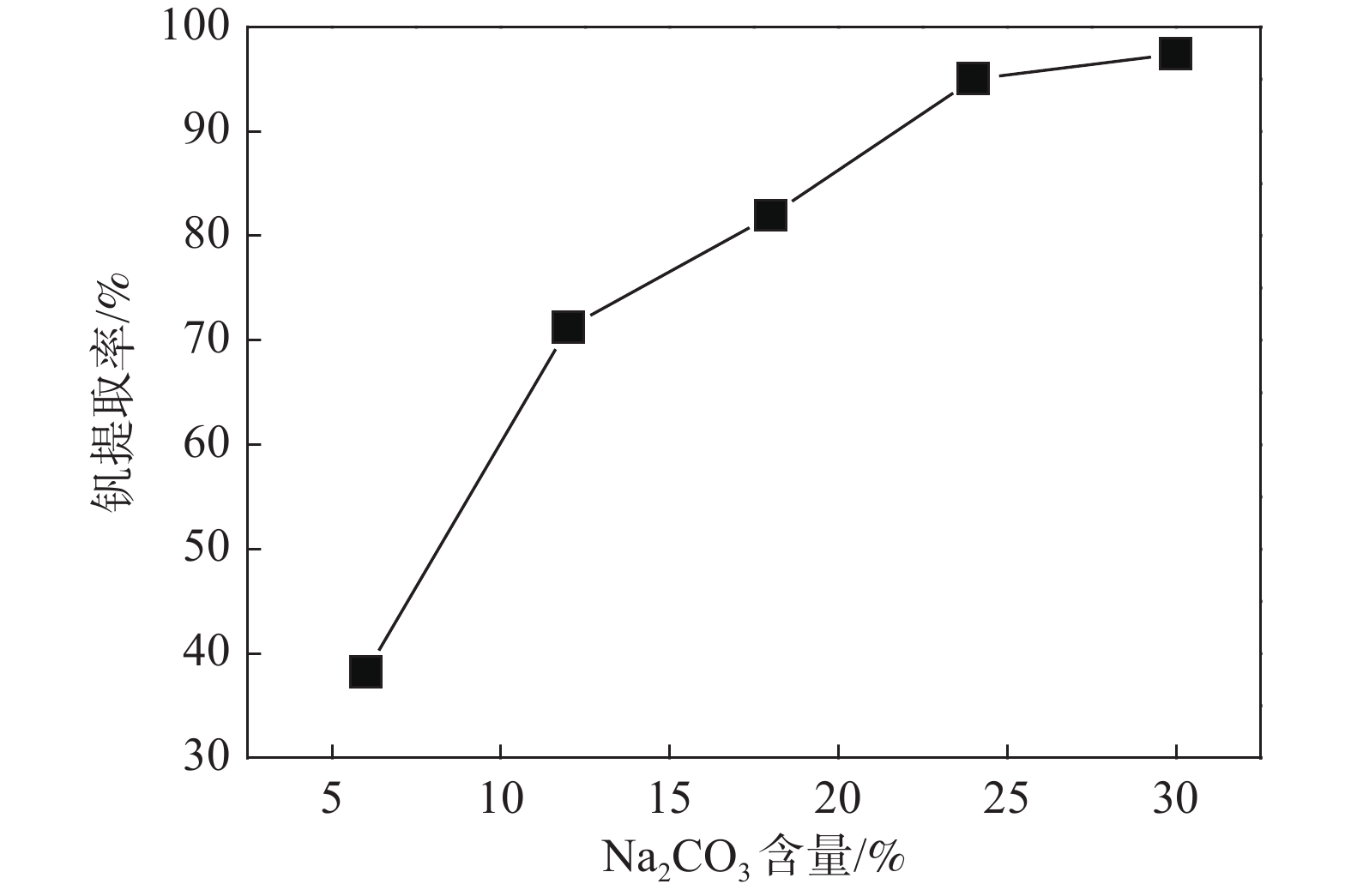

摘要: 某碱性粉料主要成分为硫酸钠,含V2O5 3.4%。该类碱性粉料无法直接酸溶、碱溶,如果直接焙烧再提钒,钒被氧化后,钒和大量硫酸钠均进入溶液中,形成一种低钒高钠的低钒溶液,后续从溶液中回收钒更困难。以该碱性低钒粉料为提钒原料,以水为溶剂溶解过滤后,可分离出87.94%的钒进入滤渣中,该滤渣中含V2O5 34%。对富含钒的滤渣开展了直接酸溶、碱溶、钠化焙烧提钒探索试验,选择钠化焙烧-水浸工艺对滤渣开展提钒技术研究,试验结果表明:滤渣干重100 g外配30 g碳酸钠,780 ℃煅烧90 min,焙烧熟料水浸,钒提取率可达97.96%,钒总收率可达86.15%。该技术研究为此类碱性低钒粉料提供一条提钒新思路。Abstract: In this study, the alkaline powder is mainly sodium sulfate, containing 3.4% V2O5, which can not be dissolved in acid or alkali. If vanadium is directly roasted and then extracted, vanadium and a large amount of sodium sulfate will enter the solution and form a low vanadium solution with low vanadium and high sodium, and the subsequent recovery of vanadium from the solution is more difficult. With the alkaline low vanadium powder used as the raw material for extracting vanadium, 87.94% vanadium can be separated into the filter residue after water dissolution and filtration, and the filter residue contains V2O5 34%. Exploratory tests on vanadium extraction from vanadium-rich filter residue by direct acid dissolution, alkali dissolution and sodium roasting were carried out. The sodium roasting-water leaching process was selected for vanadium extraction technology research on the filter residue. The experimental results showed that the extraction rate of vanadium could reach 97.96% and the total yield of vanadium could reach 86.15%, according to the dry weight of 100 g with 30 g sodium carbonate, calcination at 780 ℃ for 90 min and water leaching of the roasted residue. The study of this technology provides a new approach for extracting vanadium from this kind of alkaline low vanadium powder.

-

表 1 含钒粉料的主要成分

Table 1. Main compositions of the vanadium powder

% V2O5 Na2SO4 SiO2 Cl− Fe2O3 NiO CaO K2O CaO 其它 3.4 90 0.8 0.9 0.9 1.2 0.3 0.5 0.3 1.7 其它为没有给出的元素,可能为易挥发的H、O、C等元素。 表 2 滤渣的主要成分

Table 2. Main compositions of the filter residue

% V2O5 Na2SO4 SiO2 Al2O3 Fe2O3 NiO CaO K2O MgO TiO2 其它 34 2.37 11 4.1 16 18 2.7 0.7 0.8 1.0 9.33 表 3 滤渣提钒探索试验结果

Table 3. The experimental results for extracting vanadium from the filter residue

试验工艺 现象 分析 直接酸浸 钒无浸出 无法酸溶出 直接碱浸 基本无浸出 无法碱溶出 钠化焙烧-水浸 大量钒浸出 可以钠化焙烧浸出 表 4 验证试验钒收率结果

Table 4. results of verification test on vanadium yield

% 试验样 钒分离率 钒提取率 钒总收率 1 87.94 97.92 86.11 2 87.94 98.01 86.19 3 87.94 97.96 86.15 均值 87.94 97.96 86.15 -

[1] Yang Zicheng, Zhao Bin. Review on the extraction of vanadium from V-bearing solid wastes[J]. Guangzhou Chemical Industry, 2015,43(12):39−40. (杨紫成, 赵彬. 从含钒废弃物中钒资源回收研究进展[J]. 广州化工, 2015,43(12):39−40. doi: 10.3969/j.issn.1001-9677.2015.12.017 [2] 许碧琼. 从废钒触媒中回收钒氧化物[J]. 化工进展, 2002, 21(3): 200-202.Xu Biqiong. Research on abstracting V2O5 from spent vanadium catalyst[J]. Chemical Industry and Engineering Progress, 2002, 21(3): 200-202. [3] Xu Biqiong, Wu Yutong. Recovery of vanadium resource from waste vanadium catalyst[J]. Journal of Huaqiao University, 1995,16(1):90−93. (许碧琼, 吴玉通. 从废钒催化剂中回收钒资源的研究[J]. 华侨大学学报, 1995,16(1):90−93. [4] 薛福连. 废钒催化剂的综合利用[J]. 化工物资1997, (4): 43.Xue Fulian. Comprehensive utilization of spent vanadium catalyst[J]. Huagong Wuzi, 1997, (4): 43. [5] Liang Fupei, Pan Enting. Recovery and utilization of waste vanadium catalyst[J]. Guangxi Chemical Industry, 1993,22(2):45−48. (梁福沛, 潘恩霆. 废钒催化剂中回收利用方法[J]. 广西化工, 1993,22(2):45−48. [6] Xi Xin, Yao Qian, Hu Kejun. Present status of vanadium extraction from vanadium-bearing petroleum residue abroad[J]. World Nonferrous Metals, 2001,(5):36−40. (席歆, 姚谦, 胡克俊. 国外含钒石油渣提钒生产技术现状[J]. 世界有色金属, 2001,(5):36−40. [7] Liu Anhua, Li Liaosha, Yu Liang. Vanadium recovery from solid waste containing vanadium[J]. Metal Mine, 2003,(10):61−64. (刘安华, 李辽沙, 余亮. 含钒固废提钒技术及展望[J]. 金属矿山, 2003,(10):61−64. doi: 10.3321/j.issn:1001-1250.2003.10.021 [8] Li Xiaowei, Zhu Tiequn, Dai Weina, et al. Red mud recycling technology[J]. Guangdong Chemical Industry, 2010,37(10):114−116. (李小伟, 朱铁群, 代伟娜, 等. 赤泥的回收利用技术[J]. 广东化工, 2010,37(10):114−116. doi: 10.3969/j.issn.1007-1865.2010.10.059 [9] Ding Mantang. Research on utilization of vanadium extraction from vanadium-bearing steel slag[J]. Multipurpose Utilization of Mineral Resources, 2020,(6):69−72. (丁满堂. 含钒钢渣提钒利用研究[J]. 矿产综合利用, 2020,(6):69−72. [10] 廖世明, 柏谈论.国外钒冶金[M].北京: 冶金工业出版社, 1985: 147−160.Liao Shiming, Bai Tanlun. Vanadium metallurgy abroad[M]. Beijing: Metallurgical Industry Press, 1985: 147−160. -

下载:

下载: