Preparation and properties of Ti4AlN3 by powder metallurgy

-

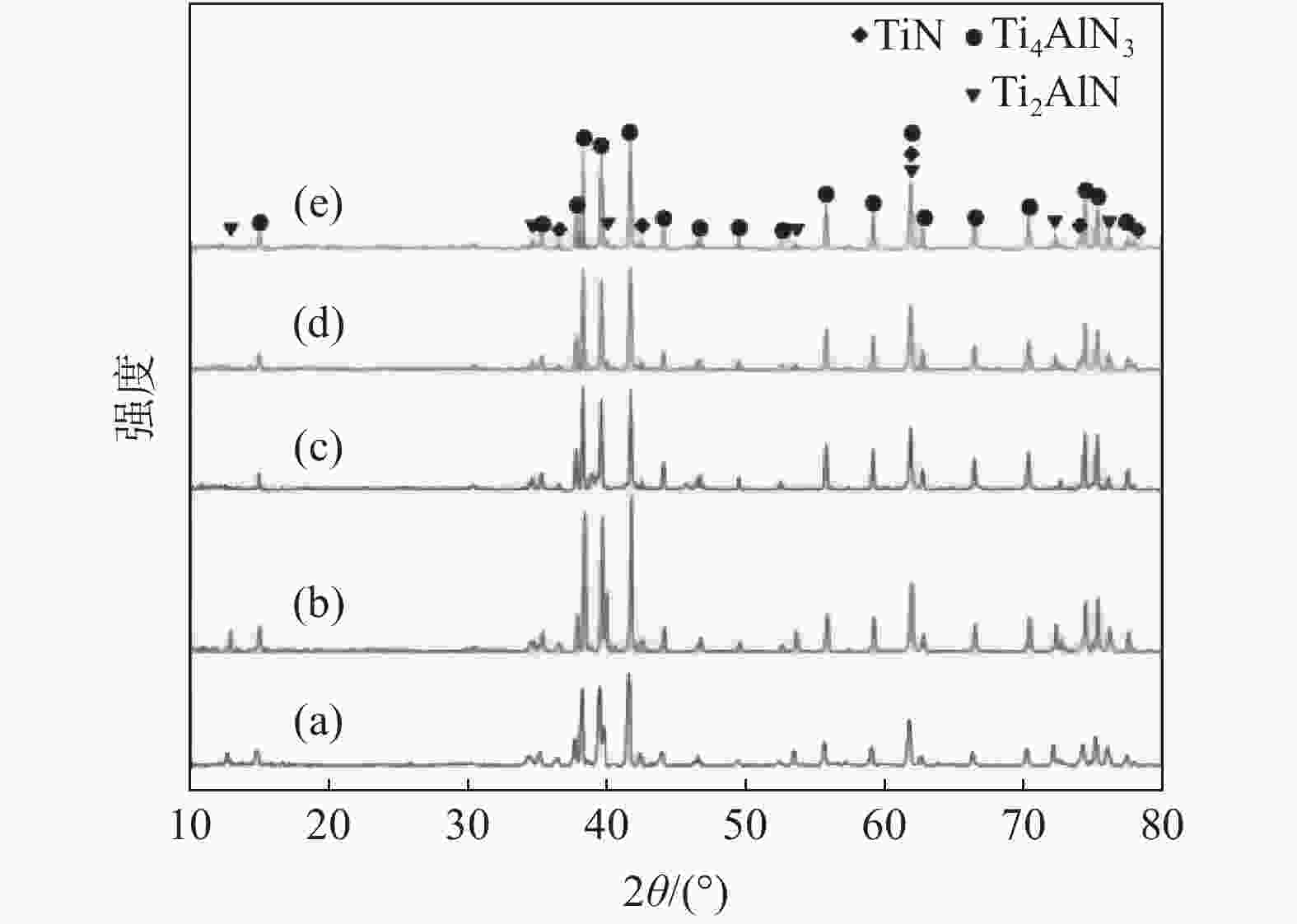

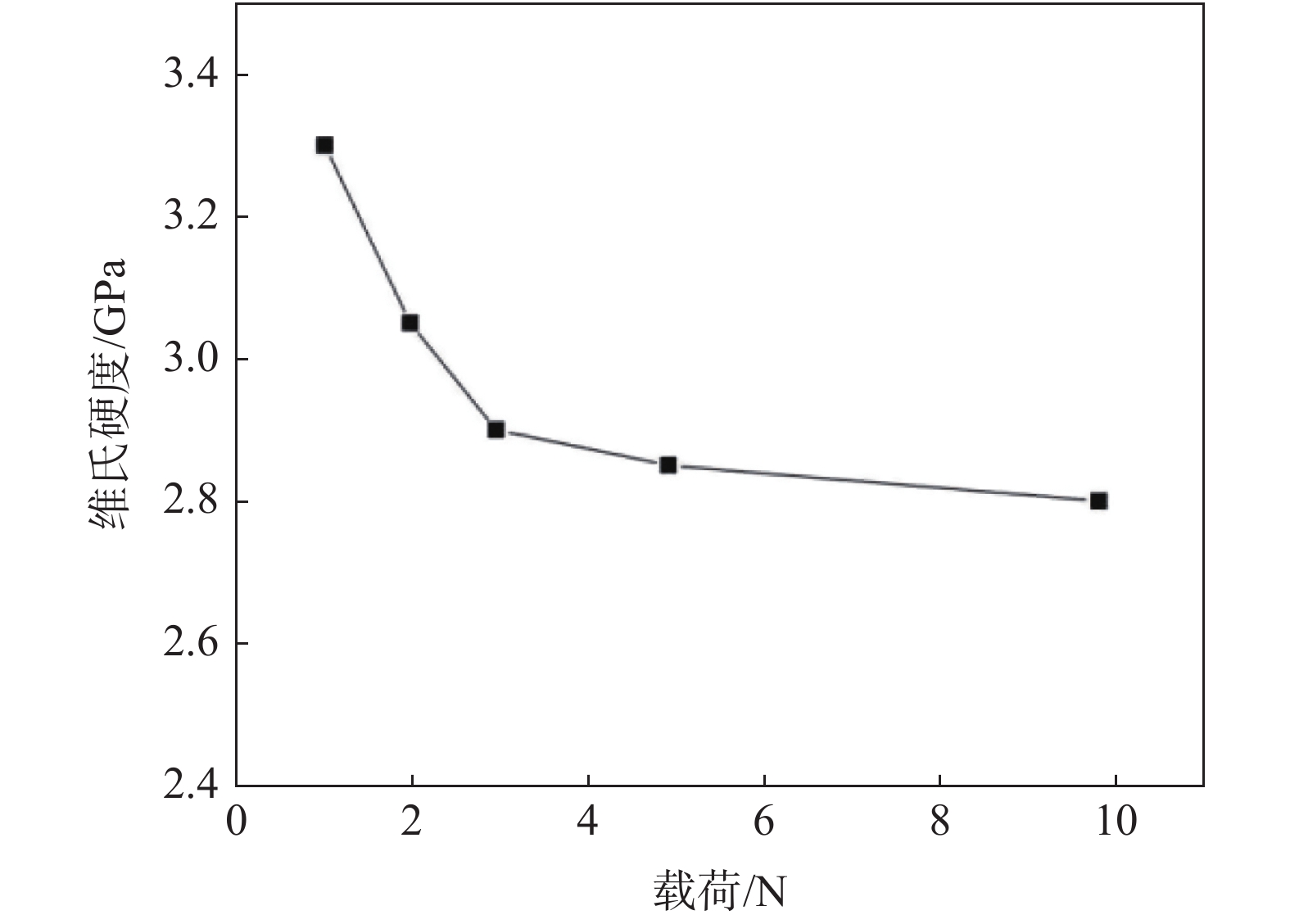

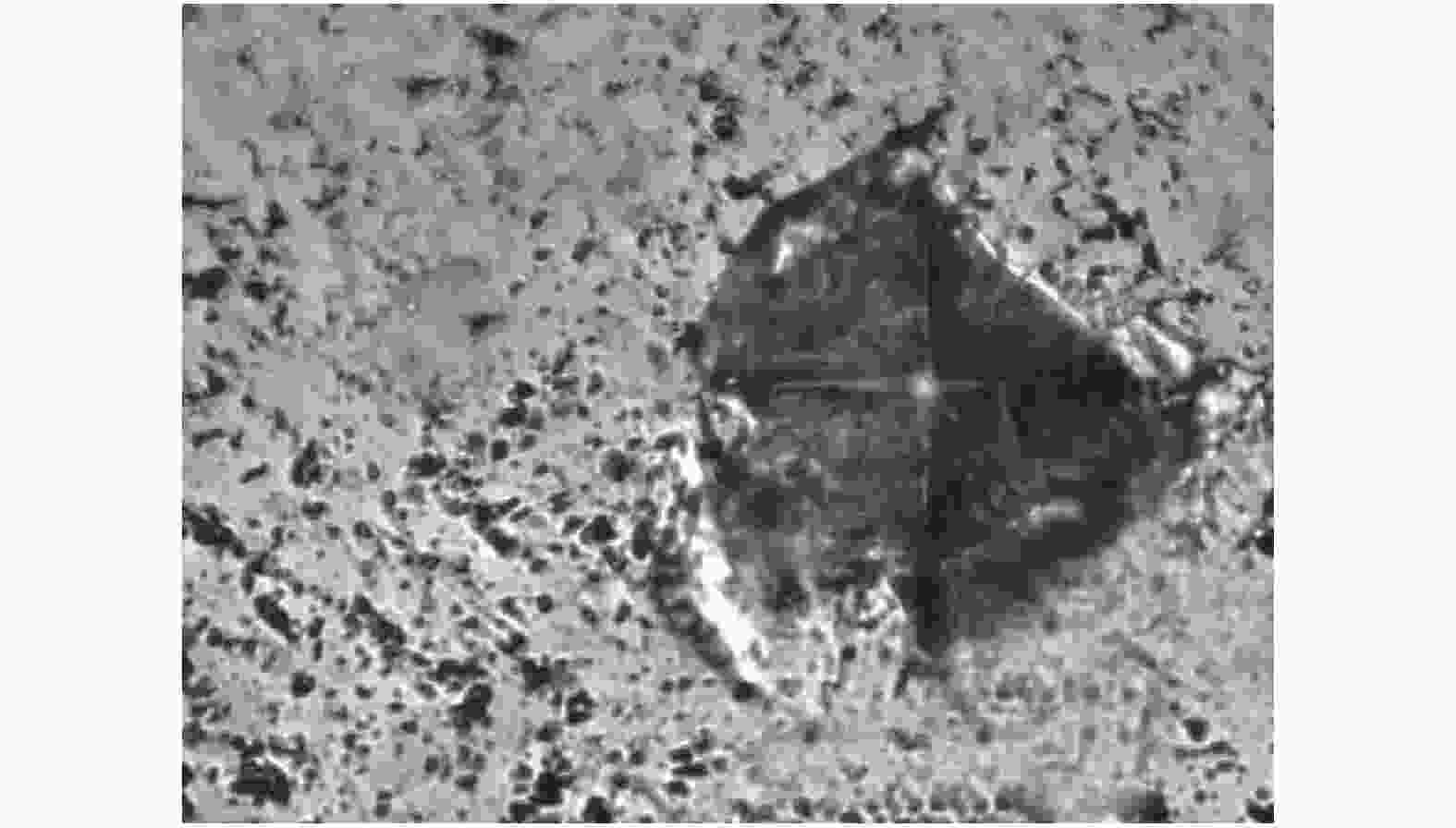

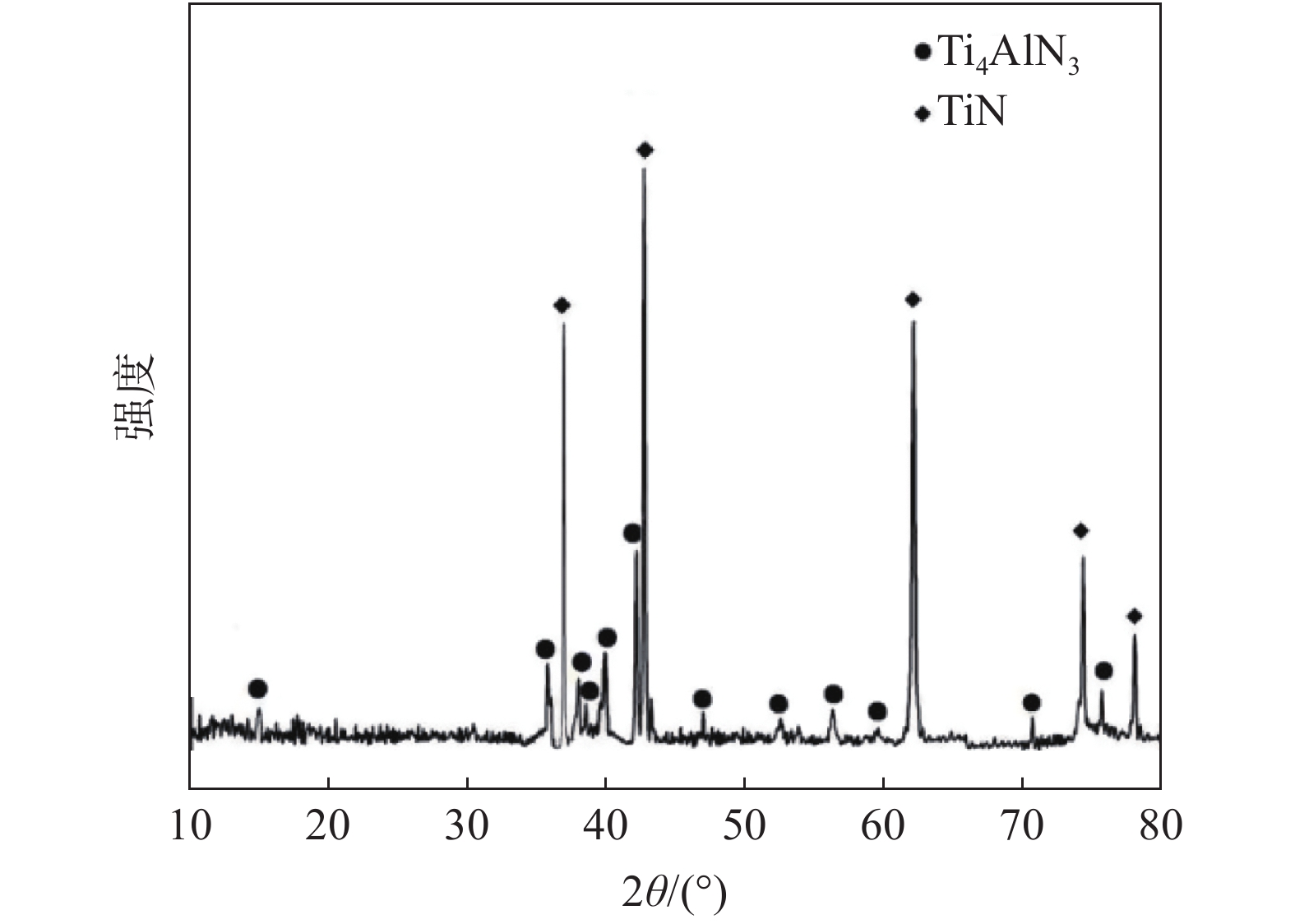

摘要: 采用粉末冶金法制备 Ti4AlN3三元层状金属陶瓷,研究不同的原料粉末、烧结温度和保温时间对其纯度的影响。利用X射线衍射仪(XRD)对烧结试样进行定性分析,并基于Rietveld法完成TOPAS定量分析,扫描电子显微镜(SEM)和能谱仪(EDS)分别表征Ti4AlN3的微观形貌和微区成分。结果表明,以Ti、Al和TiN 粉末为原料可以制备高纯Ti4AlN3块体。当保温时间为2 h、烧结温度1400 ℃时可制备出纯度较高(wTi4AlN3=98.03%)的Ti4AlN3陶瓷;与其他MAX相相比,Ti4AlN3的硬度较低,试验中随着载荷的增大,硬度值趋近于2.8 GPa。Abstract: The ternary layered cermet of Ti4AlN3 was prepared by powder metallurgy. The effects of raw powder, sintering temperature and holding time on the purity of Ti4AlN3 ceramic were studied. The samples were qualitatively analyzed by X-ray diffraction (XRD) and quantitatively analyzed by TOPAS based on Rietveld method. The microstructure and micro area composition of Ti4AlN3 were characterized by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The experimental results show that high purity Ti4AlN3 bulk can be prepared from Ti, Al and TiN powders. With the holding time of 2 h and the sintering temperature of 1 400 ℃, high purity Ti4AlN3 can be obtained (wTi4AlN3=98.03%). Compared with other Max phases, the hardness of Ti4AlN3 is lower. With the increase of load, the hardness of Ti4AlN3 is close to 2.8 GPa.

-

Key words:

- ceramic /

- Ti4AlN3 /

- powder metallurgy method /

- sintering temperature /

- holding time /

- purity /

- hardness

-

表 1 原料粉体的相关信息

Table 1. Related information of raw powder

药品名称 平均粒径/μm 纯度/% 厂家 Ti 48 99.8 上海麦克林生化科技有限公司 Al ≤75 99.0 天津市大茂化学试剂厂 TiN 2-10 99.0 上海麦克林生化科技有限公司 AlN 2 99.5 上海麦克林生化科技有限公司 表 2 烧结参数

Table 2. Sintering parameters

施压强度/MPa 升温速率/(℃·min−1) 烧结温度/℃ 保温时间/h 冷却方式 30 15 1300~1500 0.5~4 自然冷却 微区 y(Ti)/% y(Al)/% y(N)/% 化学式 谱图112 49.43 13.85 36.72 Ti4.04Al1.13N3 谱图115 50.29 13.30 36.41 Ti4.14Al1.10N3 谱图116 49.13 13.23 37.64 Ti3.91Al1.05N3 谱图118 50.72 13.17 36.10 Ti4.15Al1.04N3 平均值 49.89 13.39 36.72 Ti4.08Al1.09N3 -

[1] Liu Yunlong, Zhu Degui, Hu Chunfeng. Preparation of Max phase coating by Max phase and spraying method[J]. Modern Technical Ceramics, 2017,38(1):21−28. (刘云龙, 朱德贵, 胡春峰. MAX相及喷涂法制备MAX相涂层[J]. 现代技术陶瓷, 2017,38(1):21−28. [2] Guo Qi. Microstructural analysis of Al2O3/Ti2AlN composite materials[J]. Material Sciences, 2018,8(12):1088−1093. doi: 10.12677/MS.2018.812130 [3] Chen Leilei, Deng Zixuan, Li Mian, et al. Phase diagram thermodynamic study of new Max phase[J]. Journal of Inorganic Materials, 2020,35(1):35−40. (陈雷雷, 邓子旋, 李勉, 等. 新型MAX相的相图热力学研究[J]. 无机材料学报, 2020,35(1):35−40. [4] Elodie Drouelle, Veronique Brunet, Jonathan Cormier, et al. Oxidation resistance of Ti3AlC2 and Ti3Al0.8Sn0.2C2 MAX phases: A comparison[J]. Journal of the American Ceramic Society, 2020,103(2):1270−1280. doi: 10.1111/jace.16780 [5] Clark D W, Zinkle S J, Patel M K, et al. High temperature ion irradiation effects in MAX phase ceramics[J]. Acta Materialia, 2016,105:130−146. doi: 10.1016/j.actamat.2015.11.055 [6] Gonzalez‐Julian J, Mauer G, Sebold D, et al. Cr2AlC MAX phase as bond coat for thermal barrier coatings: Processing, testing under thermal gradient loading, and future challenges[J]. Journal of the American Ceramic Society, 2020,103(4):2362−2375. doi: 10.1111/jace.16935 [7] Jin Sen, Su Taichao, Hu Qianku, et al. Thermal conductivity and electrical transport properties of double-A-layer MAX phase Mo2Ga2C[J]. Materials Research Letters, 2020,8(4):158−164. doi: 10.1080/21663831.2020.1724204 [8] Sobolev K V, Kolincio K K, Emelyanov A, et al. Evolution of magnetic and transport properties in (Cr1−xMnx)2AlCMAX-phase synthesized by arc melting technique[J]. Journal of Magnetism and Magnetic Materials, 2020,493:165642/1−7. [9] Xu J, Zhao M Q, Wang Y, et al. Demonstration of Li-ion capacity of MAX phases[J]. ACS Energy Letters, 2016,1(6):1094−1099. doi: 10.1021/acsenergylett.6b00488 [10] Anasori B, Luhatskaya M R, Gogotsi Y. 2D metal carbides and nitrides(MXenes) for energy storage[J]. Nature Reviews Materials, 2017,2(2):1−17. [11] Hui Xiaobin, Ge Xiaoli, Zhao Ruizheng, et al. Interface chemistry on MXene‐based materials for enhanced energy storage and conversion performance[J]. Advanced Functional Materials, 2020,30(50):2005190/1−37. [12] Guo Z, Zhou J, Zhu L, et al. MXene: a promising photocatalyst for water splitting[J]. Journal of Materials Chemistry A. Materials for Energy and Sustainability, 2016,4(29):11446−11452. doi: 10.1039/C6TA04414J [13] Pang J, Mendes R G, Bachmatiuk A, et al. Applications of 2D MXenes in energy conversion and storage systems[J]. Chemical Society Reviews, 2019,48(1):72−133. doi: 10.1039/C8CS00324F [14] Wang Cong, Xu Jiawei, Wang Yunzheng, et al. MXene(Ti2NTx): Synthesis, characteristics and application as a thermo-optical switcher for all-optical wavelength tuning laser[J]. Science China Materials, 2020,64(1):1−7. [15] Yan Hanbing, Xu Jianguang, Wu Haijiang, et al. Synthesis of Ti4AlN3 powder by high energy ball milling combined with solid state reaction[J]. Mechanical Engineering Materials, 2014,38(2):36−38, 86. (严汉兵, 许剑光, 吴海江, 等. 高能球磨结合固相反应合成Ti4AlN3粉体[J]. 机械工程材料, 2014,38(2):36−38, 86. [16] Zhang Yanli. Study on microwave synthesis of titanium aluminum nitrogen materials[J]. Powder Metallurgy Technology, 2017,35(3):178−181, 201. (张艳丽. 微波合成钛铝氮材料的研究[J]. 粉末冶金技术, 2017,35(3):178−181, 201. [17] Wang Lei, Chen Nan. Preparation of Ti2AlN ternary compound ceramics by optimizing powder metallurgy process[J]. Industrial Technology Innovation, 2017,4(3):100−101, 105. (王蕾, 陈楠. 优选粉末冶金工艺制备Ti2AlN三元化合物陶瓷[J]. 工业技术创新, 2017,4(3):100−101, 105. [18] Muhammad Faraz Ud Din, Yang Chenhui, Tang Yi, et al. Efficient and cost-effective method to synthesize highly purified Ti4AlN3 and Ti2AlN[J]. Journal of Advanced Dielectrics, 2019,9(1):1950008/1−4. [19] Yang Tengfei, Wang Chenxu, Liu Wulong, et al. Comparison of irradiation tolerance of two MAX phases-Ti4AlN3 and Ti2AlN[J]. Journal of Nuclear Materials, 2018,513:120−128. [20] Firstov S A, Gorban V F, Pechkovskii I. Mechanical properties of porous Ti3SiC2/TiC, Ti3AlC2/TiC, and Ti4AlN3/TiN nanolaminates at 20 to 1 300 ℃[J]. Powder Metallurgy& Metal Ceramics, 2010,49(7-8):414−423. [21] Braverman B S, Lepakova O K, Maksimov Y M. Combustion of TiAl alloy in nitrogen[J]. Combustion Explosion & Shock Waves, 2015,51(4):457−461. [22] Barsoum M W, El-Raghy T, Procopio A. Synthesis of Ti4AlN3 and phase equilibria in the Ti-Al-N system[J]. Metallurgical and Materials Transactions A, 2000,31(2):373−378. doi: 10.1007/s11661-000-0273-1 [23] Green L. Studies on the synthesis and microstructure of Ti2AlN films and protective effect on ferritic steels[D]. Albert-Ludwigs University of Freiburg Doctoral Dissertation. 2020. (Grner L. Untersuchungen zur Synthese und Mikrostruktur von Ti2AlN-Dünnschichten sowie deren Schutzwirkung auf ferritische Sthle[D]. Albert-Ludwigs-Universität FreiburgDoctoral Dissertation. 2020.) [24] Hossein-Zadeh M, Mirzaee O, Mohammadian-Semnani H. An investigation into the microstructure and mechanical properties of V4AlC3 MAX phase prepared by spark plasma sintering[J]. Ceramics International, 2019,45(6):7446−7457. doi: 10.1016/j.ceramint.2019.01.036 [25] Zheng Liya, Zhou Yanchun, Feng Zhihai. Preparation, structure, properties and development trend of max phase ceramics[J]. Aerospace Materials Technology, 2013,43(6):1−23. (郑丽雅, 周延春, 冯志海. MAX相陶瓷的制备、结构、性能及发展趋势[J]. 宇航材料工艺, 2013,43(6):1−23. doi: 10.3969/j.issn.1007-2330.2013.06.001 [26] Gu Jian, Jiang Xinyan, Guo Wenfei, et al. Research progress of ternary layered ceramics Nb4AlC3[J]. Jiangsu Ceramics, 2016,49(5):6−8, 19. (顾坚, 蒋鑫焱, 郭文飞, 等. 三元层状陶瓷Nb4AlC3的研究进展[J]. 江苏陶瓷, 2016,49(5):6−8, 19. doi: 10.3969/j.issn.1006-7337.2016.05.003 -

下载:

下载: