Application of sub-micron α phase alumina powder in PE membrane coating of lithium ion battery

-

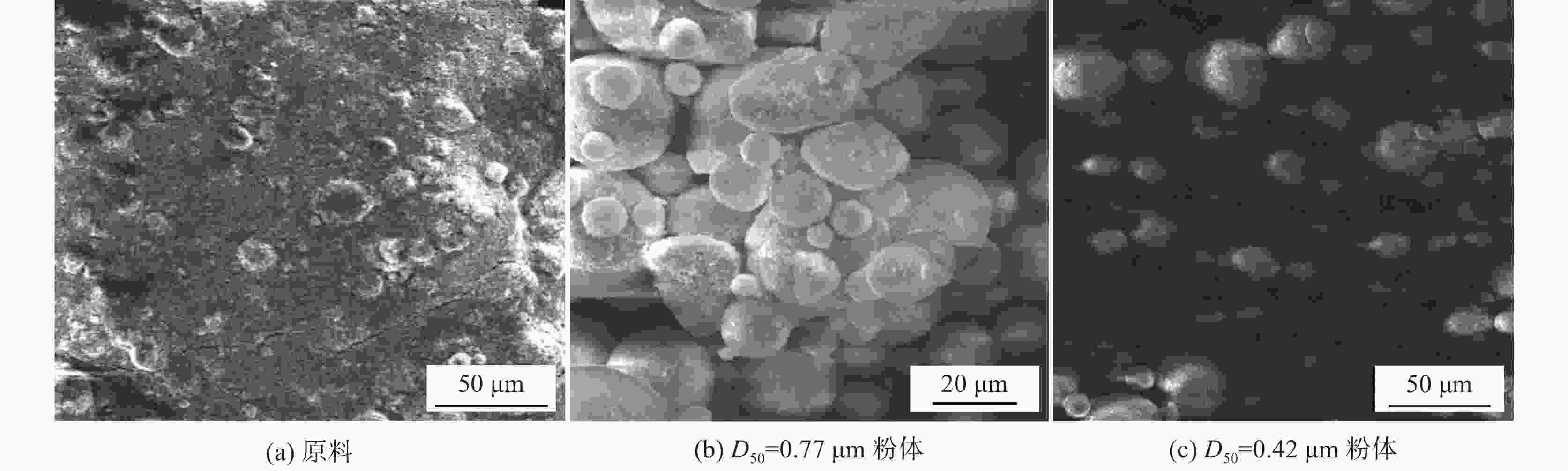

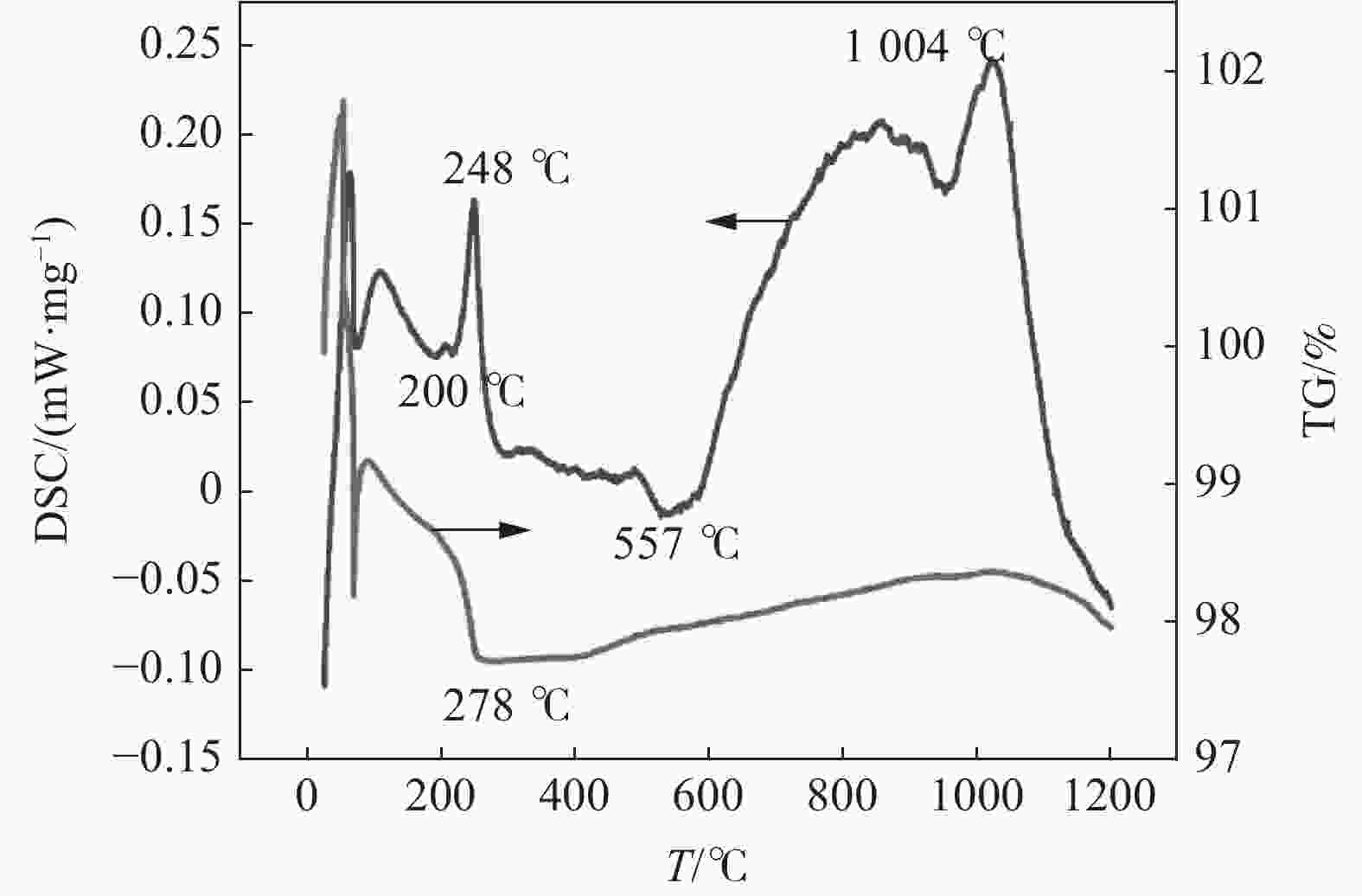

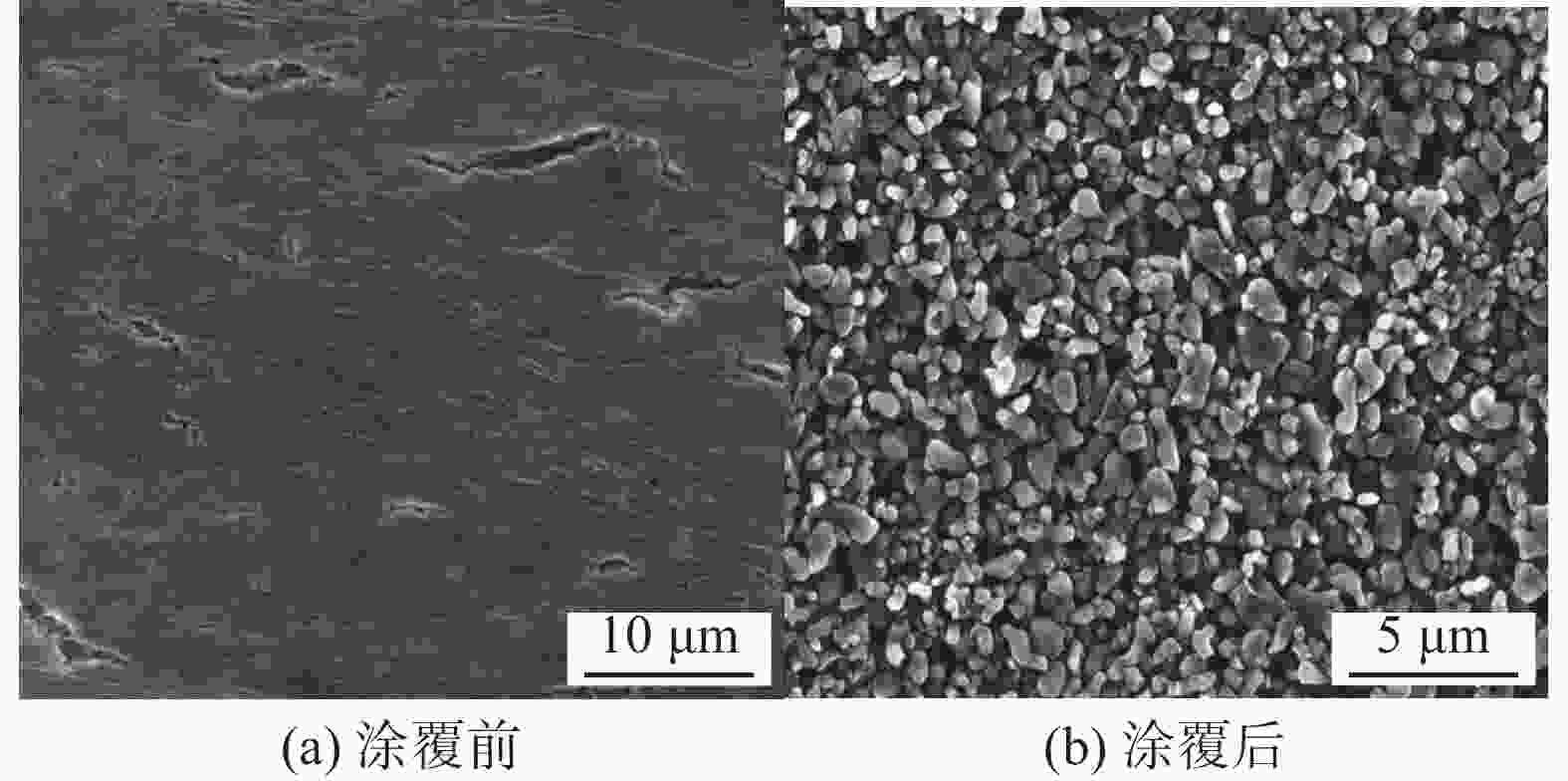

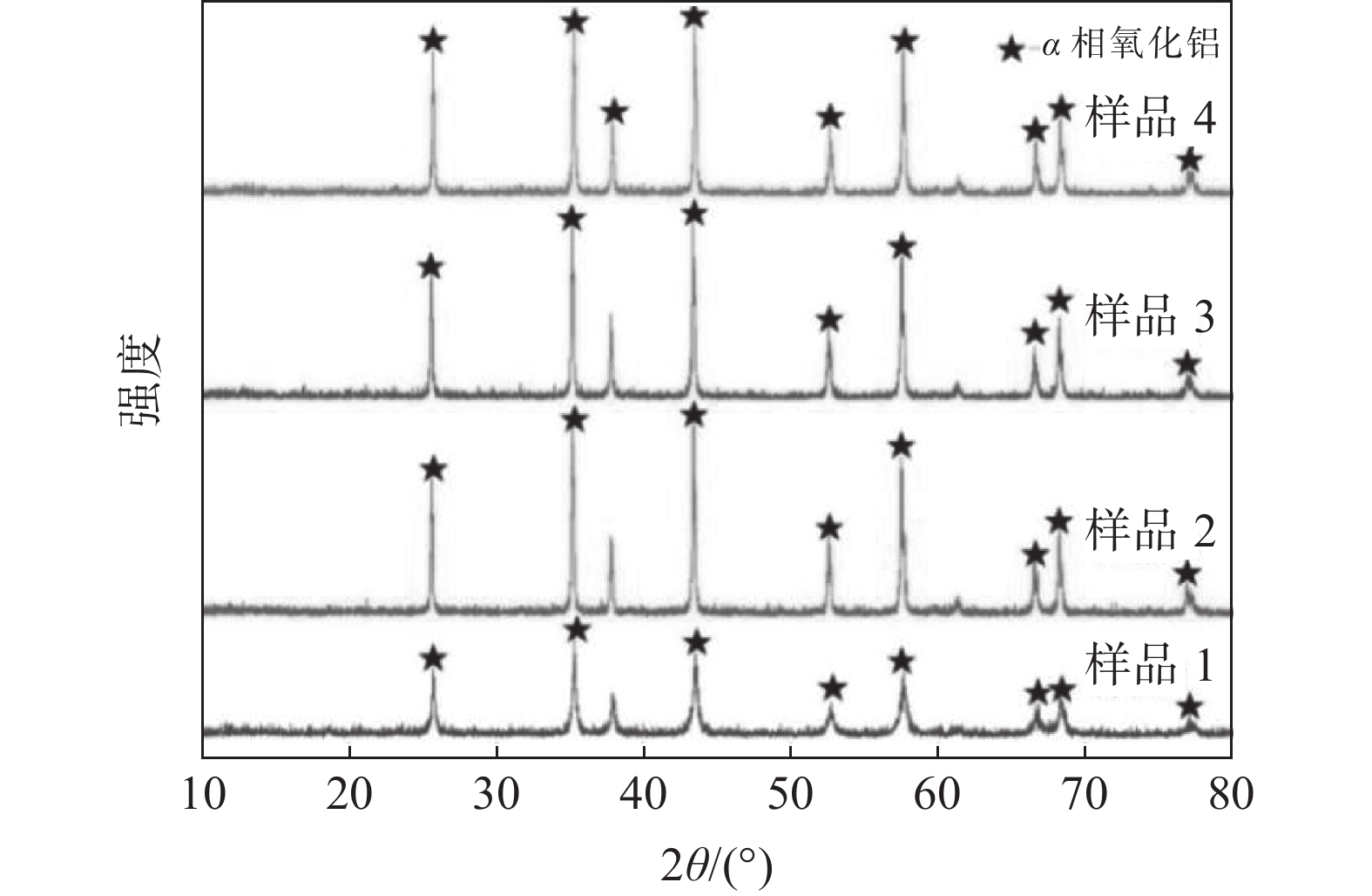

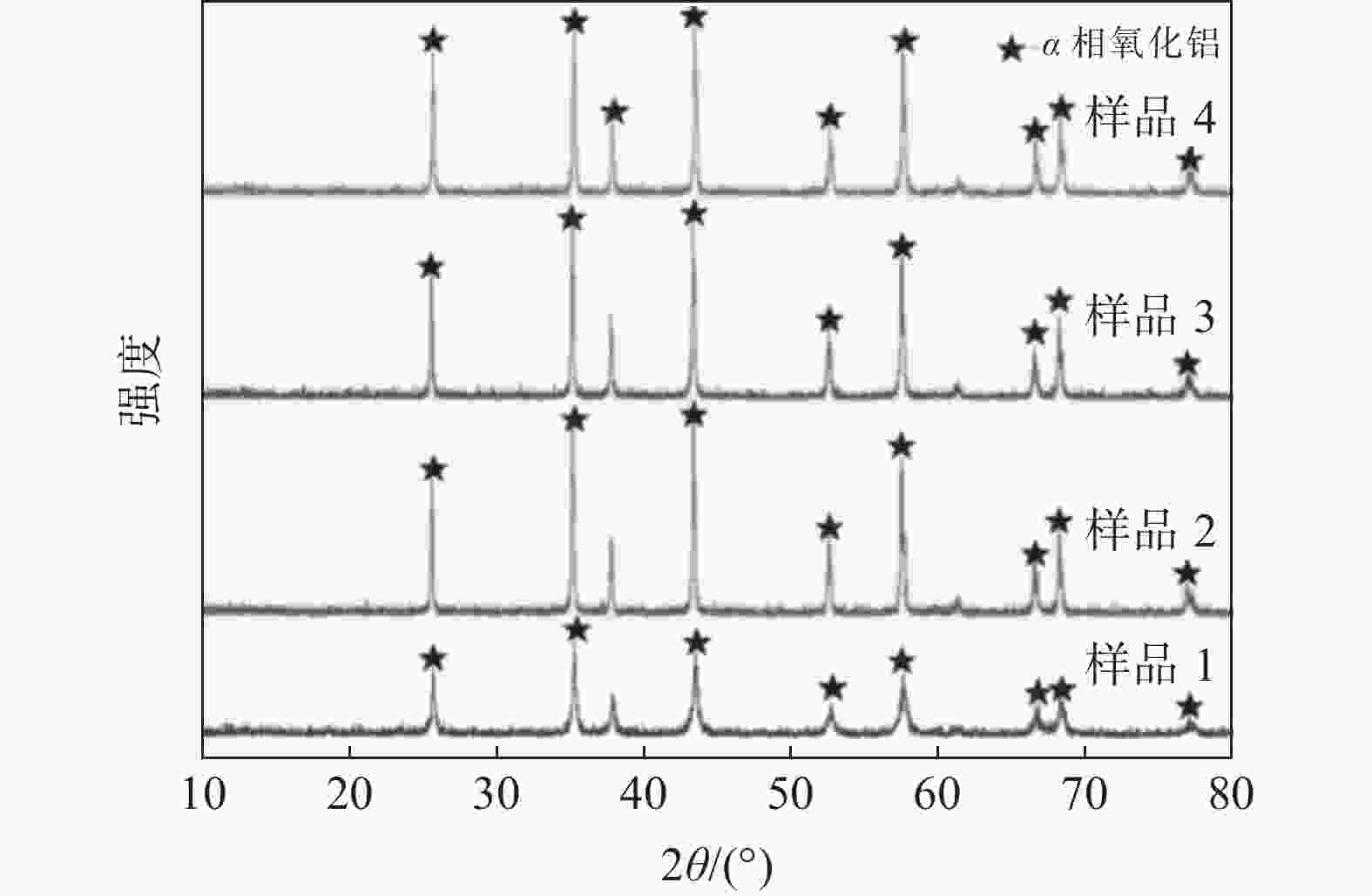

摘要: 对D50=1.08 μm的α-氧化铝粉体原料,通过物理法机械球磨制备亚微米级α-氧化铝粉体,然后将其应用在锂离子电池隔膜涂覆改性方面。将亚微米级α-氧化铝粉体应用于锂离子电池PE隔膜涂层,对比了涂覆前后PE隔膜性能的改变。结果表明:涂层致密平整,氧化铝颗粒均匀分布在PE隔膜表面,膜厚2.5 μm,涂覆后面密度增加了4.0 g/m2,透气度增加0.482 s/mL,纵向和横向的热收缩率分别降低了1.3%和0.3%,拉伸强度分别提升了26.4 MPa和3 MPa。Abstract: In this paper, sub-micron α-alμmina powders were prepared by physical mechanical milling of α-alumina powder with D50 = 1.08 μm, and then applied to lithium-ion battery separator coating modification. The sub-micron α-alumina powder was applied to the PE membrane coating of lithium-ion battery. The results show that the coating is compact and flat, and the alumina particles are evenly distributed on the surface of PE film. The thickness of the film is 2.5 μm. After the coating, the density increases by 4.0 g/m2, the air permeability increases by 48.2 s, the thermal shrinkage decreases by 1.3% and 0.3%, and the tensile strength increases by 26.4 MPa and 3 MPa, respectively.

-

Key words:

- α-alumina powder /

- lithium-ion battery /

- PE film coating /

- air permeability /

- tensile strength

-

表 1 涂覆亚微米级α-氧化铝前后PE隔膜的基本性状

Table 1. Basic properties of PE membrane coated with sub-micron α-alumina

状态 厚度/μm 面密度/(g·m−2) 透气度/(s·mL−1) 孔隙率/% 涂覆前 6.2 5.2 1.75 40 涂覆后 8.7 9.2 2.232 38.1 注:厚度检测方法按照GB/T 6672—2001进行;透气度检测方法按照GB/T 458—2008进行;面密度和孔隙率采用重量法检测。 表 2 涂覆亚微米级α-氧化铝前后PE隔膜的热收缩率对比

Table 2. Comparison of the thermal shrinkage of PE membrane before and after submicron α-alumina coating

状态 热收缩率/% 纵向MD 横向TD 涂覆前 3.2 0.6 涂覆后 1.9 0.3 表 3 涂覆亚微米级α-氧化铝前后PE隔膜的拉伸强度对比

Table 3. Comparison of the tensile strength of PE membrane before and after submicron α-alumina coating

状态 拉伸强度/MPa 纵向MD 横向TD 涂覆前 157 106 涂覆后 183.4 109 -

[1] Wang Chang, Wu Dayong. Lithium ion battery separator and technical progress[J]. Energy Storage Science and Technology, 2016,5(2):120−128. (王畅, 吴大勇. 锂离子电池隔膜及技术进展[J]. 储能科学与技术, 2016,5(2):120−128. doi: 10.3969/j.issn.2095-4239.2016.02.002 [2] Xiao Wei, Gong Yaqun, Wang Hong, et al. Advances in lithium-ion battery separator technology[J]. Energy Storage Science and Technology, 2016,5(2):188−196. (肖伟, 巩亚群, 王红, 等. 锂离子电池隔膜技术进展[J]. 储能科学与技术, 2016,5(2):188−196. doi: 10.3969/j.issn.2095-4239.2016.02.010 [3] Zhao H L, Chen J T, Rao G Y, et al. Enhancing photocatalytic CO2 reduction by coating an ultrathin Al2O3 layer on oxygen deficient TiO2 nanorods through atomic layer deposition[J]. Applied Surface Science, 2017,404(15):49−56. [4] Shi Linpu, Zhao Yanfei, Xue Jianqiang, et al. Size and molding pressure on sintering behavior of α-alumina powder[J]. Material Development and Application, 2020,35(1):1−4. (师琳璞, 赵延飞, 薛建强, 等. 粒径及成型压力对α氧化铝粉体烧结行为的影响[J]. 材料开发与应用, 2020,35(1):1−4. [5] Wang Shifeng, Wang Huanping, Zhou Guangmiao, et al. Preparation and characterization of α-Al2O3 submicron powders synthesized at low temperature by sol-gel method[J]. CIESC Journal, 2010,61(12):3290−3295. (王世锋, 王焕平, 周广淼, 等. 溶胶-凝胶法低温合成亚微米α-Al2O3的制备与表征[J]. 化工学报, 2010,61(12):3290−3295. [6] He Wenlong, Yu Yang, He Chen. Preparation of nano-Al2O3 and its application in ceramic ultrafiltration membrane[J]. Chinese Ceramics, 2019,55(7):1−8. (何文龙, 余阳, 和丞. 纳米Al2O3的制备及在陶瓷超滤膜制备上的应用研究[J]. 中国陶瓷, 2019,55(7):1−8. [7] Mirzaeian M, Abbas Q, Hunt M, et al. Pseudocapacitive effect of carbons doped with different functional groups as electrode materials for electrochemical capacitors[J]. Energies, 2020,13(21):5577−5579. doi: 10.3390/en13215577 [8] Kumar S, Asit Kumar K, Roy J. Processing and properties of sintered submicron IR transparent alumina derived through sol–gel method[J]. Journal of Sol Gel Science and Technology, 2018,86(2):374−382. doi: 10.1007/s10971-018-4651-9 [9] Xu Jian, He Linli, Jing Xiwei, et al. Preparation and properties of polyethylene separator modified by alumina / acrylate emulsion[J]. Fine Chemical Industry, 2019,36(7):1321−1325. (徐健, 何林莉, 景希玮, 等. 氧化铝/丙烯酸酯乳液改性聚乙烯隔膜的制备及性能[J]. 精细化工, 2019,36(7):1321−1325. [10] Ibrahim A, Zhao Jiaqi, Shi Meng, et al. Cyclic stability of Al-doped lithium manganese materials in water-based lithium ion batteries[J]. Energy Storage Science and Technology, 2021,(4):1330−1337. (Ibrahim A, 赵佳琦, 师萌, 等. Al掺杂锰酸锂材料在水系锂离子电池中的循环稳定性[J]. 储能科学与技术, 2021,(4):1330−1337. [11] Chinelatto A S A, Tomasi R. Influence of processing atmosphere on the microstructural evolution of submicron alumina powder during sintering[J]. Ceramics International, 2009,35(7):2915−2920. doi: 10.1016/j.ceramint.2009.03.037 [12] Sun Z Q, La B Q, Peng H, et al. Alumina ceramics with uniform grains prepared from Al2O3 nanospheres[J]. Journal of Alloys and Compounds, 2016,688(3):933−938. [13] Liu H M, Li M, Dao T, et al. Design of Pd Au alloy plasmonic nanoparticles for improved catalytic performance in CO2 reduction with visible light irradiation[J]. Nano Energy, 2016,26(12):398−404. -

下载:

下载: