Application of laser induced fluorescence technology in mixing effect analysis of oxidation furnace at titanium dioxide via chloride process

-

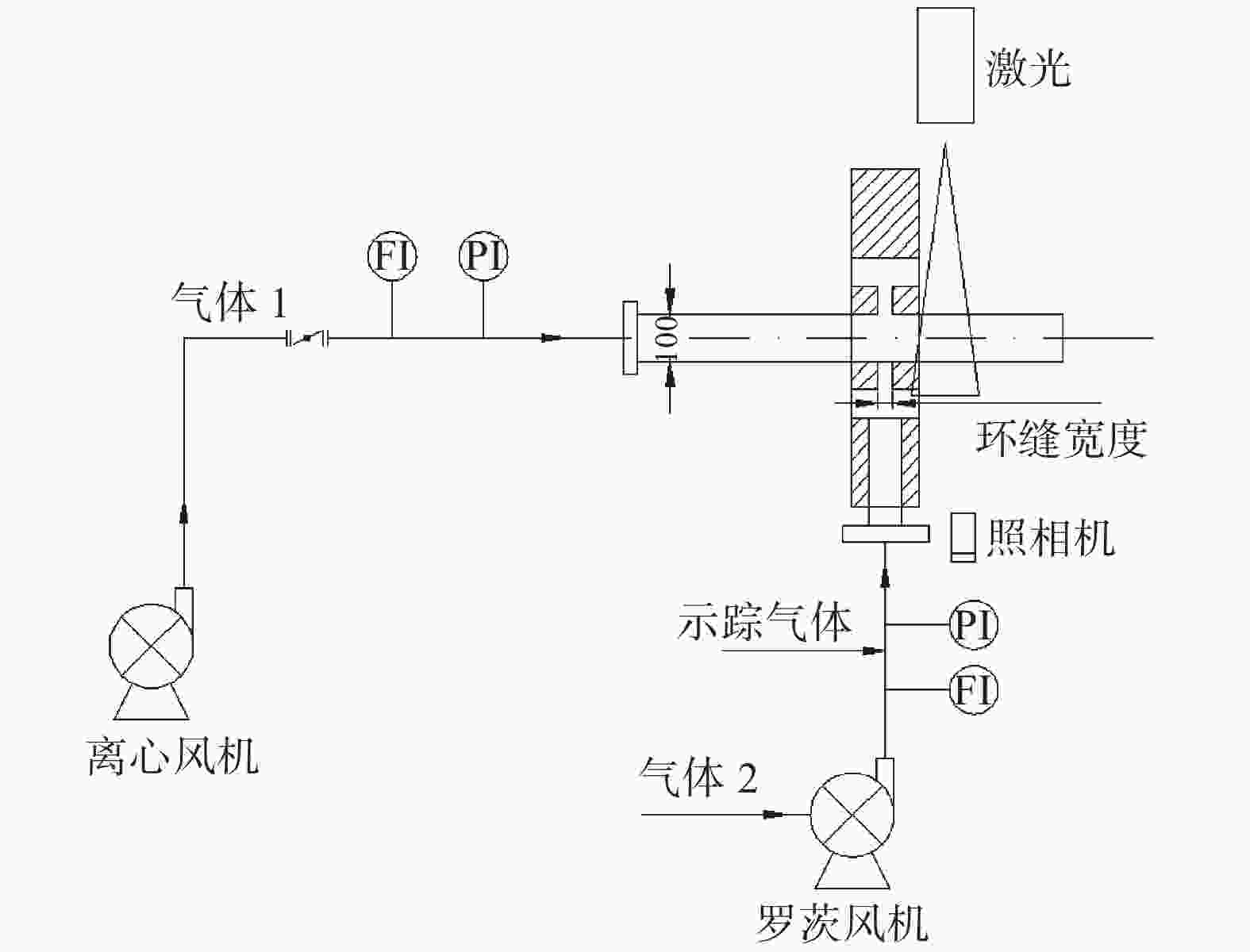

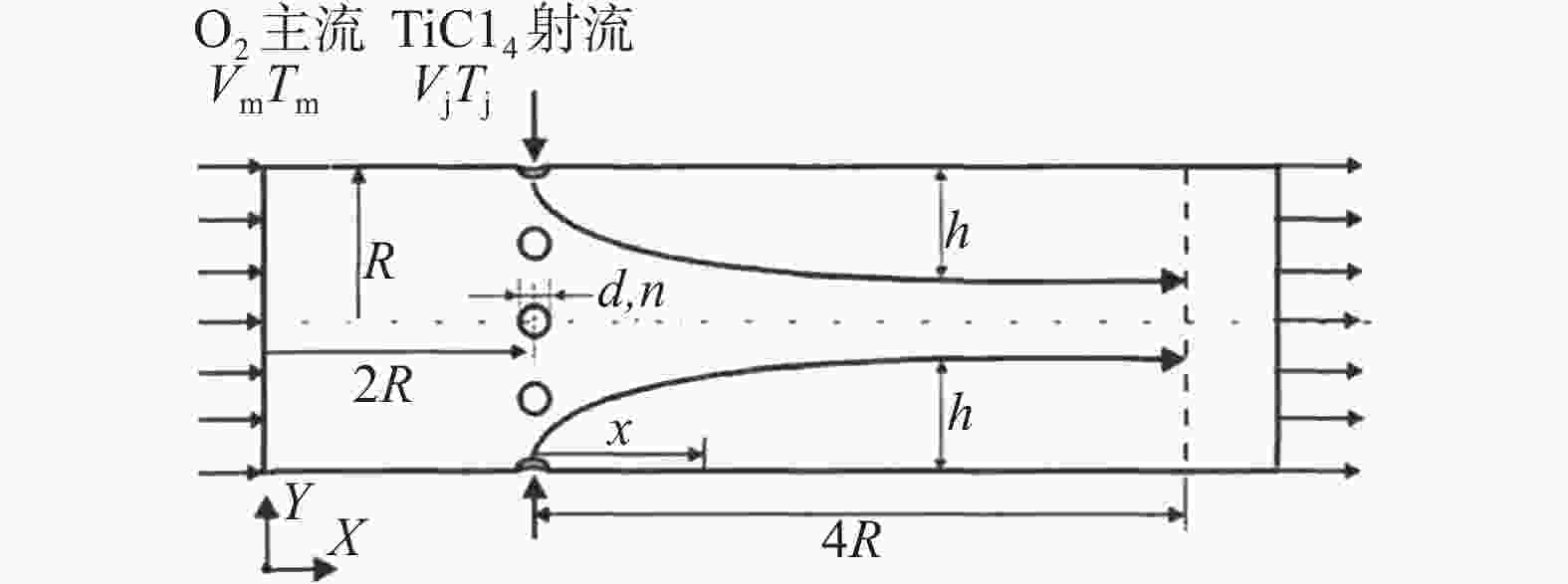

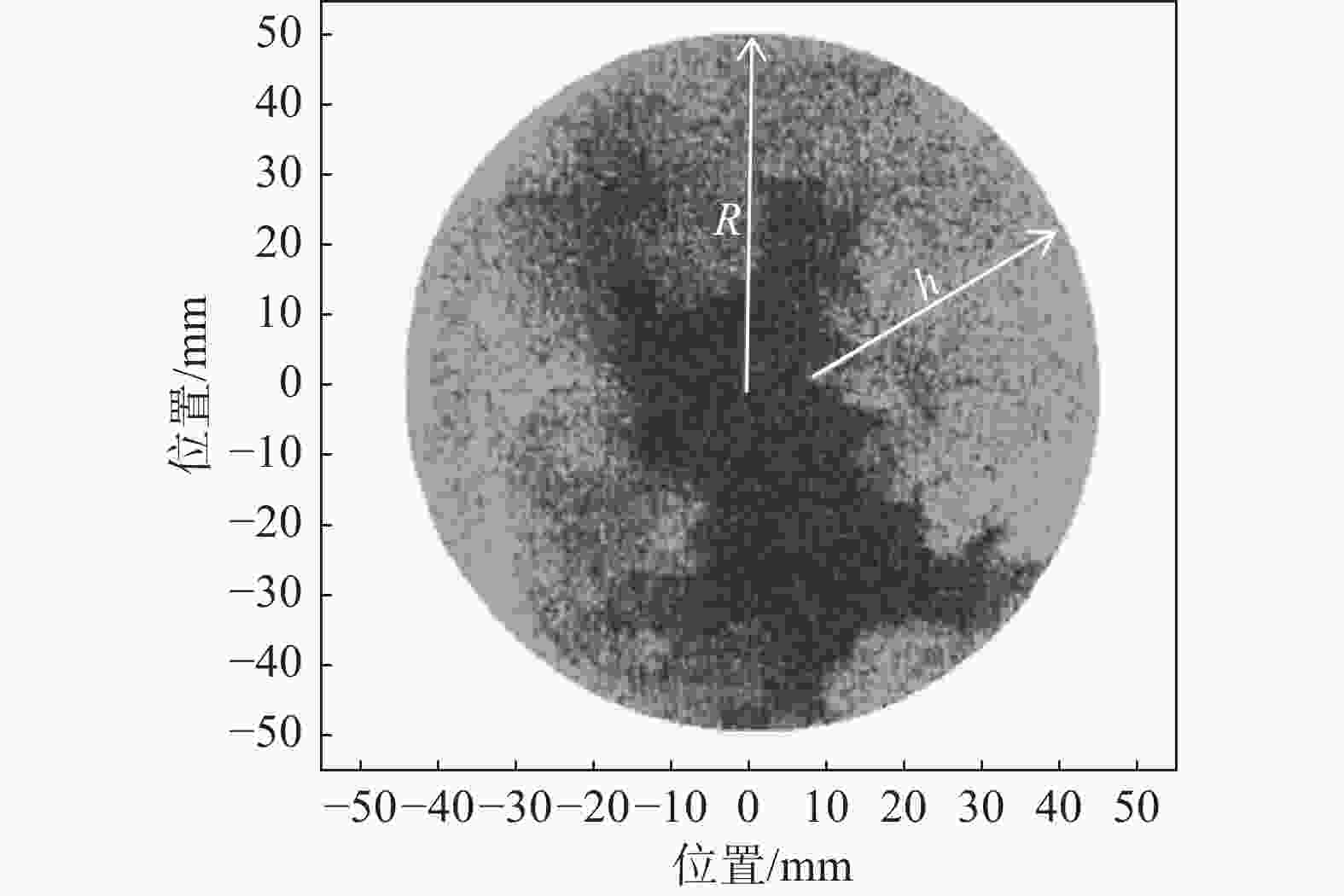

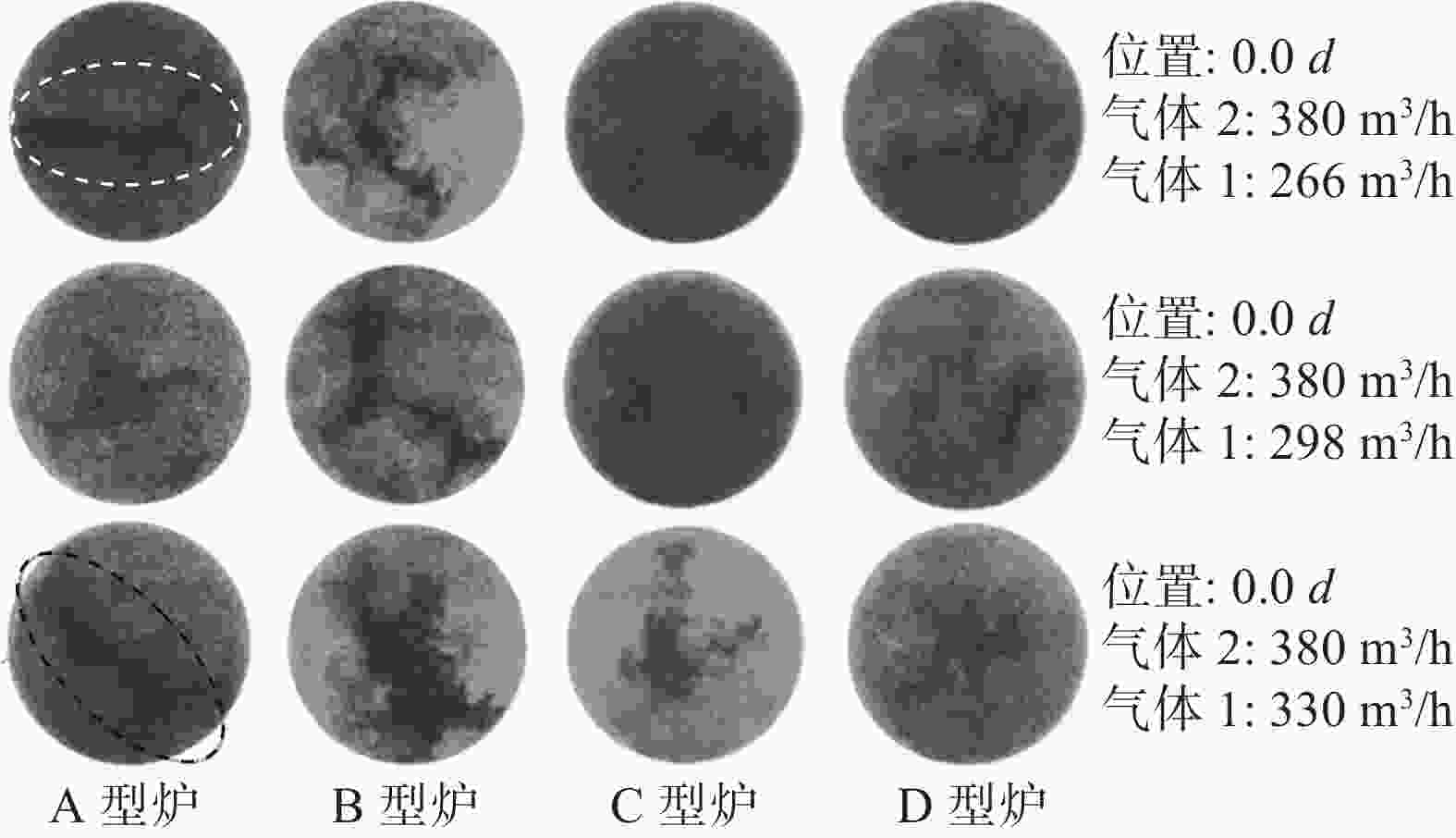

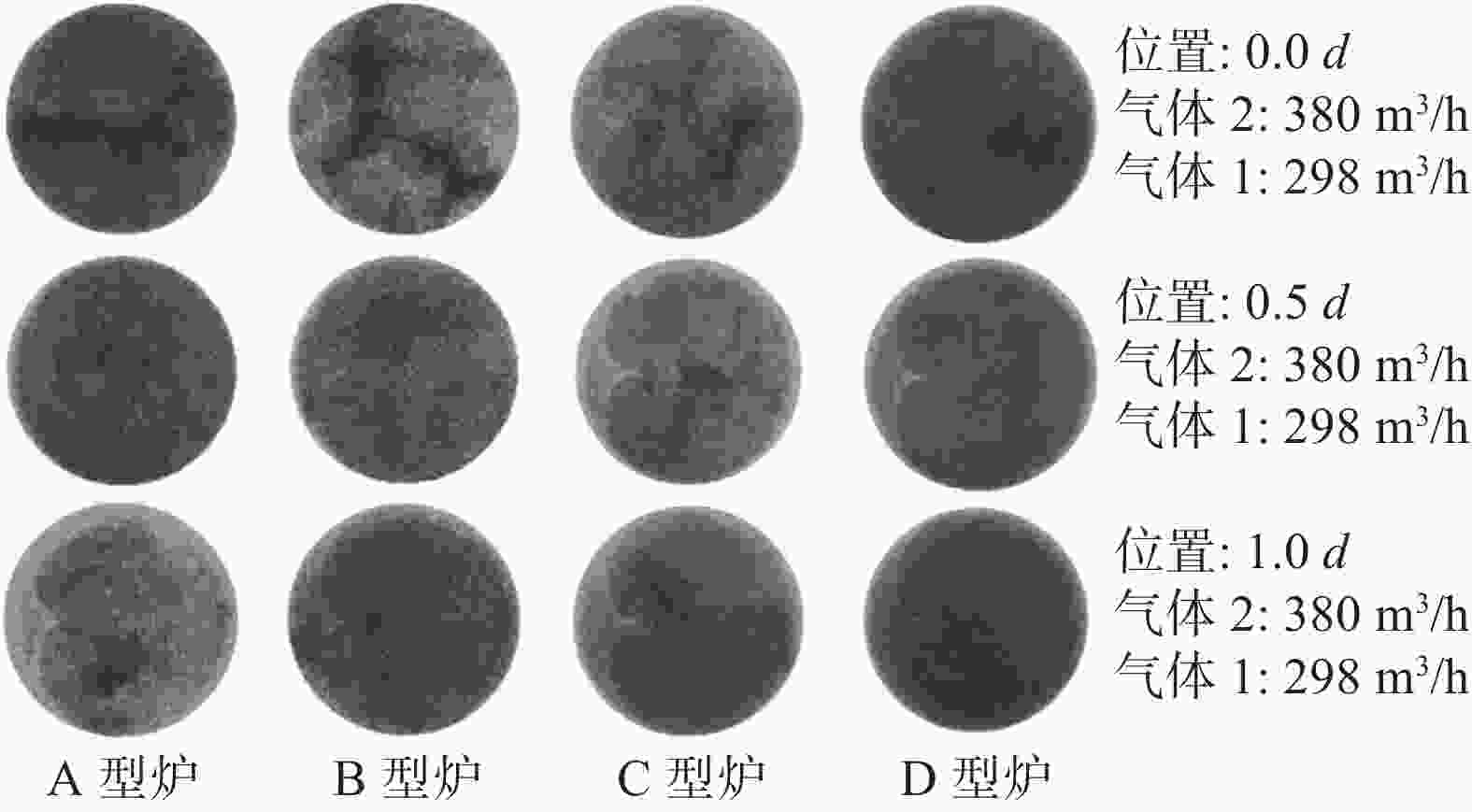

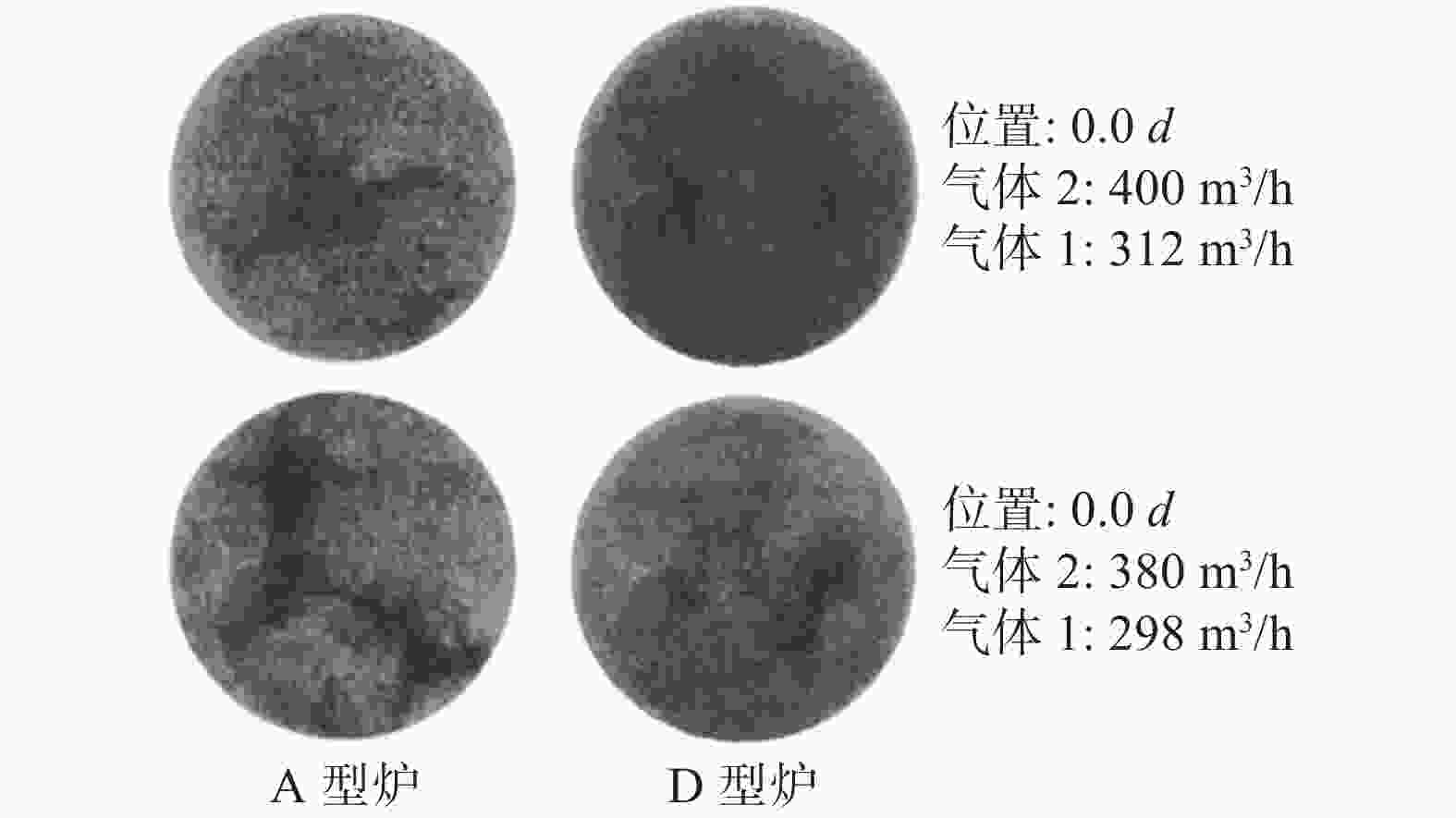

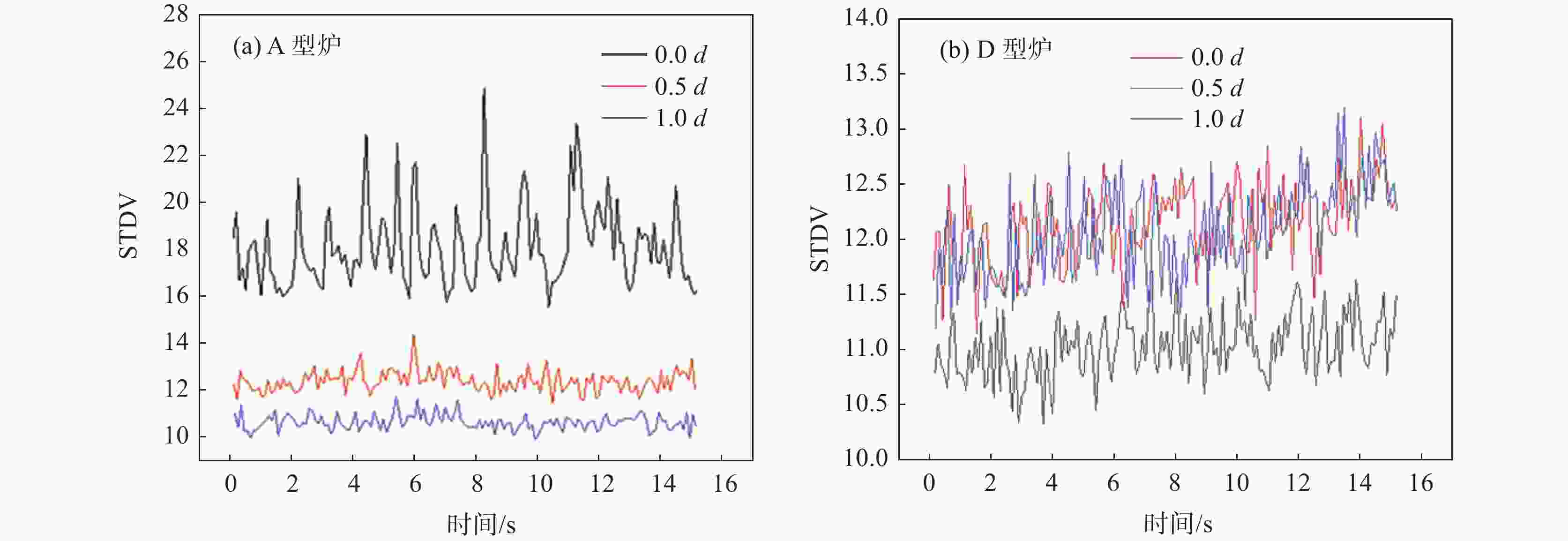

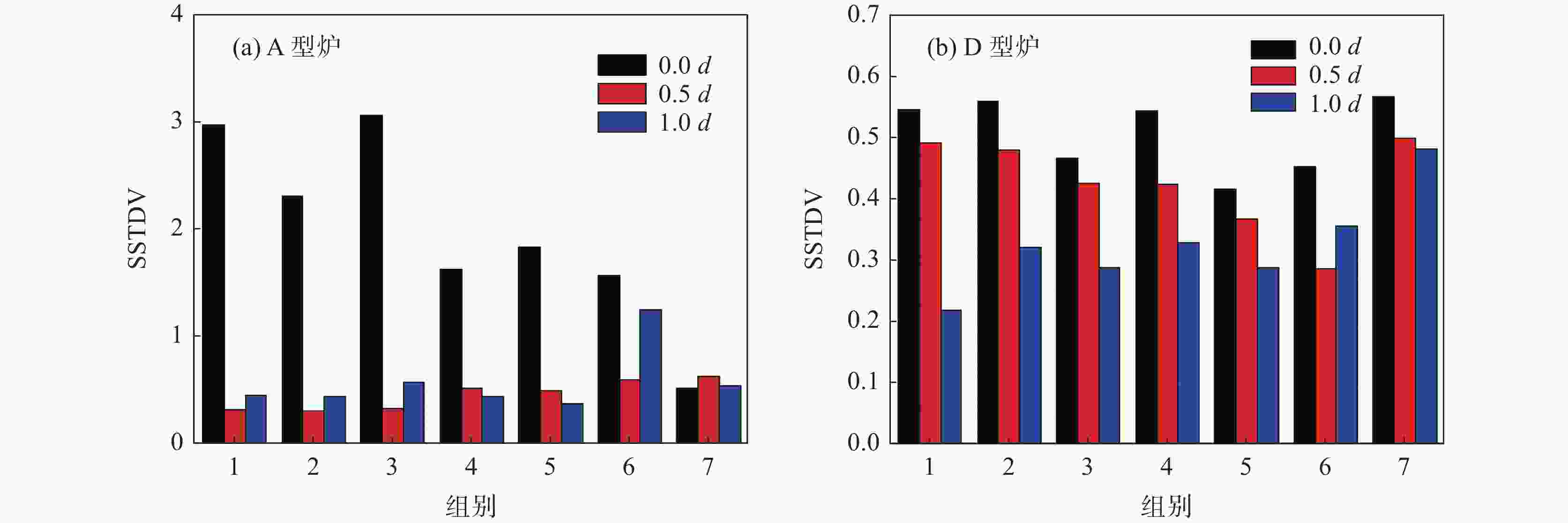

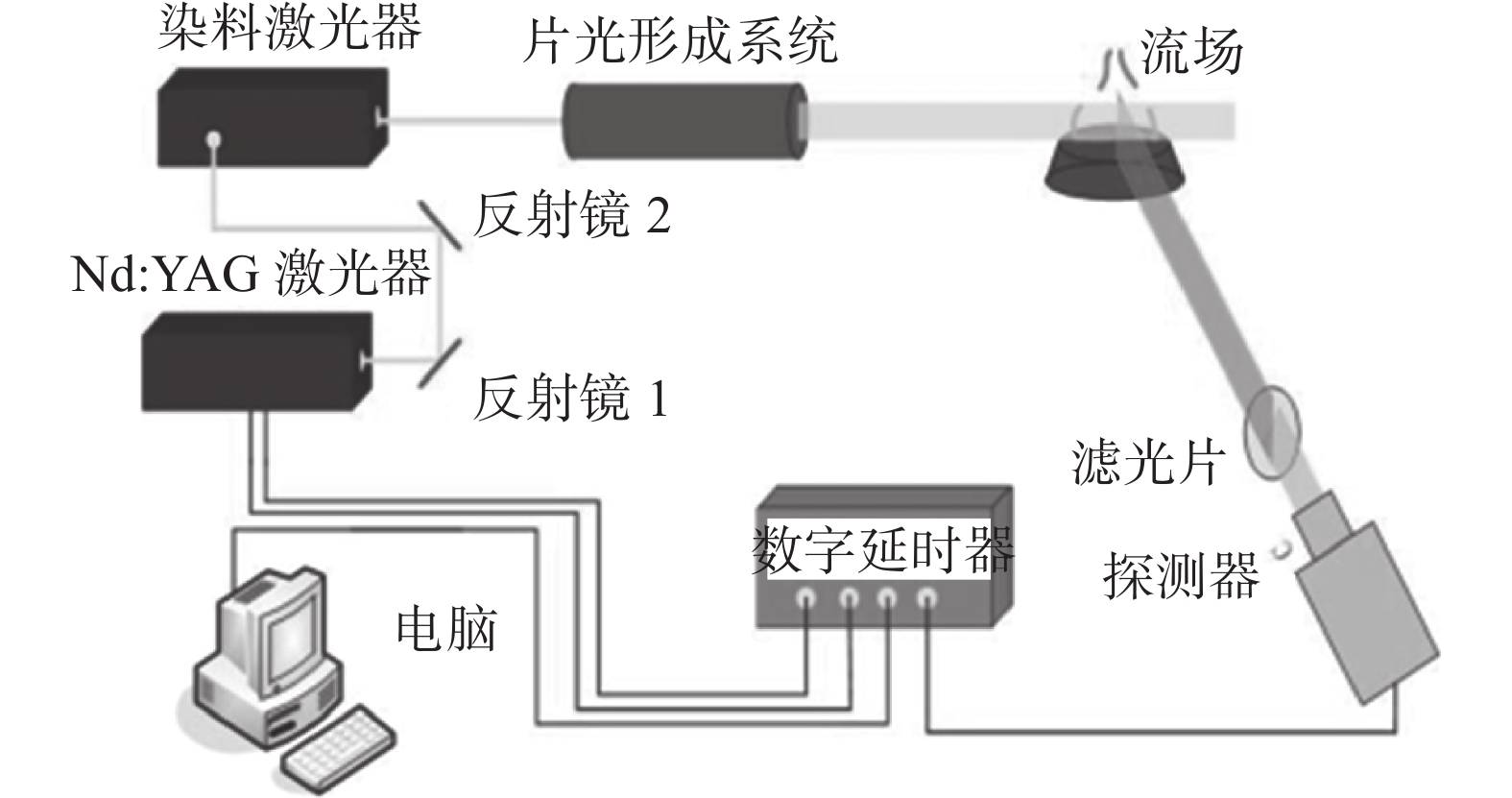

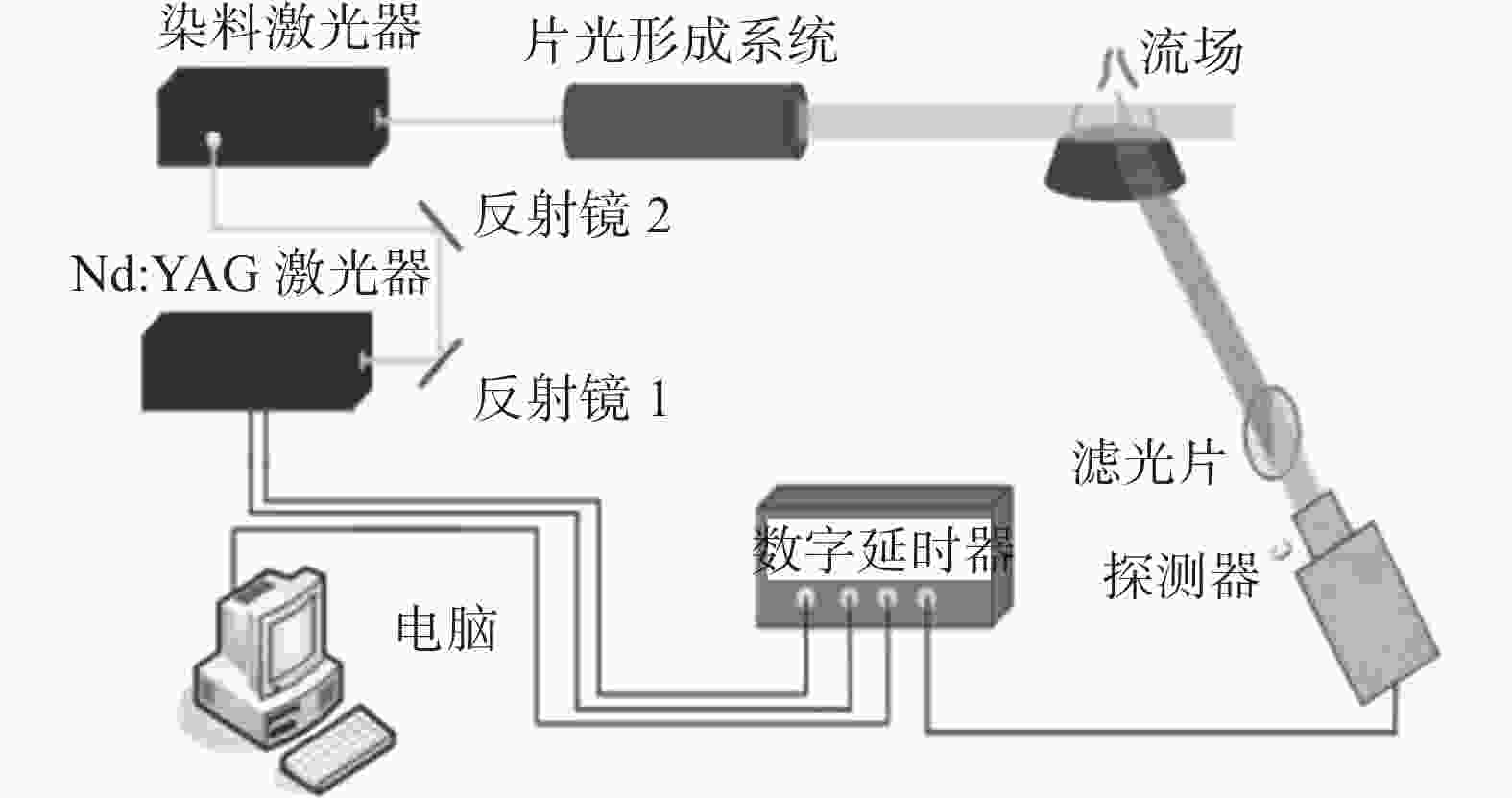

摘要: 氯化法生产钛白是现今国际上钛白工业的主流生产技术,而氧化反应器的结构设计是氯化法生产钛白的一项关键技术。TiCl4和O2的混合情况对于钛白粉的颗粒粒径及分布、颗粒晶型等产品性能有决定性作用,进而影响到产品的质量。因此,掌握不同工况条件下两种物料气流混合效果,对于氧化反应器的设计以及实际操作参数的优化具有重要意义。然而,现有的研究工作表明,传统的测量技术难以适应复杂流场的高速、非稳定等特性,迫切需要高精度的现代诊断技术。该研究从试验方法上进行了创新,采用无扰动非接触的激光诱导荧光技术(LIF)测量了不同工况下模拟反应器内不同位置处的气体浓度分布,研究了两股气体在不同结构氧化炉及不同物料比下的混合效果及其变化规律,找出了影响混合效果的关键因素。该研究为氧化炉的结构设计和操作工艺条件的控制提供必要的参考,为相关理论模型和数值仿真提供重要的试验参数,对于促进我国钛白生产工艺的发展具有重要的科学意义和实际意义。Abstract: Titanium dioxide (TiO2) through chloride process is the mainstream production technology of titanium dioxide industry in the world nowadays, and the structure design of oxidation reactor is a key technology for the production of titanium dioxide by chlorination. The mixture of TiCl4 and O2 plays a decisive role in the properties of TiO2, such as particle size, distribution and crystal shape, and then affects the quality of the product. Therefore, it is of great significance to monitor the mixing effect of two kinds of material airflow under different working conditions for the design of oxidation reactor and the optimization of practical operation parameters. However, the existing research shows that the traditional measurement technology is difficult to adapt to the characteristics of high speed and instability of complex flow field, so the modern diagnosis technology with high precision is urgently needed. Herein, using the undisturbed non-contact laser induced fluorescence (LIF) the gas concentration distribution in different location of the reactor was measured by simulation under different working condition. The mixing effect and its variation law of the two gases in different oxidation furnace structure and different materials were studied, and the key factors influencing the mixing effect were found out. This study provides necessary reference for the structure design of the oxidation furnace and the control of the operation process conditions, as well as important experimental parameters for the relevant theoretical model and numerical simulation. It shows important scientific and practical significance to promote the development of TiO2 production process in China.

-

表 1 气体流量控制条件

Table 1. Gas flow control conditions

气流

工况气体1流量/

(m3·h−1)气体2流量/

(m3·h−1)气流比

(气体2/气体1)1 266 380 1.43 2 298 380 1.28 3 330 380 1.15 4 365 380 1.04 5 280 400 1.43 6 312 400 1.28 7 380 400 1.05 -

[1] Zhao Weian, Liu Zhoulin, Bai Chunpei, et al. Simulation experimenton gas current mixingina titanium white reaetor[J]. Chemical Metallurgy, 1987,8(1):66−75. (赵维安, 刘洲林, 白春沛, 等. 钛白反应器气流混合模化实验[J]. 化工冶金, 1987,8(1):66−75. [2] 杨波. 氯化法钛白氧化反应器的冷态模拟试验研究[D]. 大连: 大连理工大学, 1998.Yang Bo. Cold simulation test of oxidation reactor for chlorination titanium dioxide[D]. Dalian: Dalian University of Technology, 1998. [3] Zhang Shuming. Study on cold model experiment of titanium dioxide by chlorination[J]. Coating Industry, 2000,(5):20−21. (张曙明. 氯化法钛白冷模实验研究[J]. 涂料工业, 2000,(5):20−21. doi: 10.3969/j.issn.0253-4312.2000.05.008 [4] Lv Zhimin, Li Chunzhong, Cong Dezi, et al. Study on jet mixing characters in the oxidation reactors for titanium dioxide powder production by chlorination process[J]. Chemical Engineering, 2001,29(3):25−29. (吕志敏, 李春忠, 丛德滋, 等. 氯化法制备钛白氧化反应器内射流混合特性研究[J]. 化学工程, 2001,29(3):25−29. doi: 10.3969/j.issn.1005-9954.2001.03.005 [5] Cheng Yi, Liu Zhe, Luo Peicheng, et al. Gas cross-flow mixing in TiO2 oxidation reactors of chlorination process[J]. Journal of Chemical Industry and Engineering, 2006,57(12):2840−2846. (程易, 刘喆, 骆培成, 等. 氯化法钛白氧化反应器气体错流混合[J]. 化工学报, 2006,57(12):2840−2846. doi: 10.3321/j.issn:0438-1157.2006.12.010 [6] 李春忠, 丛德滋, 吕志敏, 等. 氯化钛白氧化反应器, 中国专利: CN00116465.1[P]. 2000-12-27.Li Chunzhong, Cong Dezi, Lv Zhiming, et al. Oxidation reactors for chlorination titanium dioxide, China: CN00116465.1[P]. 2000-12-27. [7] 刘飞生. 氯化法钛白氧化过程中气体混合数值模拟[D]. 昆明: 昆明理工大学, 2015.Liu Feisheng. Numerical simulation of gas mixing in the oxidation of titanium dioxide by chlorination[D]. Kunming: Kunming University of Science and Technology, 2015. [8] 李亚东. 氯化法生产钛白中氧化反应器内流体动力学的研究及建模[D]. 昆明: 昆明理工大学, 2016.Li Yadong. Study and modeling of hydrodynamics in oxidation reactor for titanium dioxide production by chlorination[D]. Kunming: Kunming University of Science and Technology, 2016. [9] Zhou E, Zheng Shaohua, Yuan Zhangfu, et al. Structure analysis and modeling on the oxidation reactor in the titanium white synthesis with chloride process[J]. Titanium Industry Progress, 2004,21(6):35−39. (周峨, 郑少华, 袁章福, 等. 氯化法钛白氧化反应器结构分析与模拟[J]. 钛工业进展, 2004,21(6):35−39. doi: 10.3969/j.issn.1009-9964.2004.06.010 [10] Wu You. Summary on characteristics of oxidation reactor for titanium dioxide production by chloride process[J]. Iron Steel Vanadium Tatanium, 2016,37(2):92−96. (吴优. 国外氯化法钛白氧化反应器特点及分析[J]. 钢铁钒钛, 2016,37(2):92−96. -

下载:

下载: