Influence of temperature on dephosphorization of recycling converter gasification dephosphorization slag

-

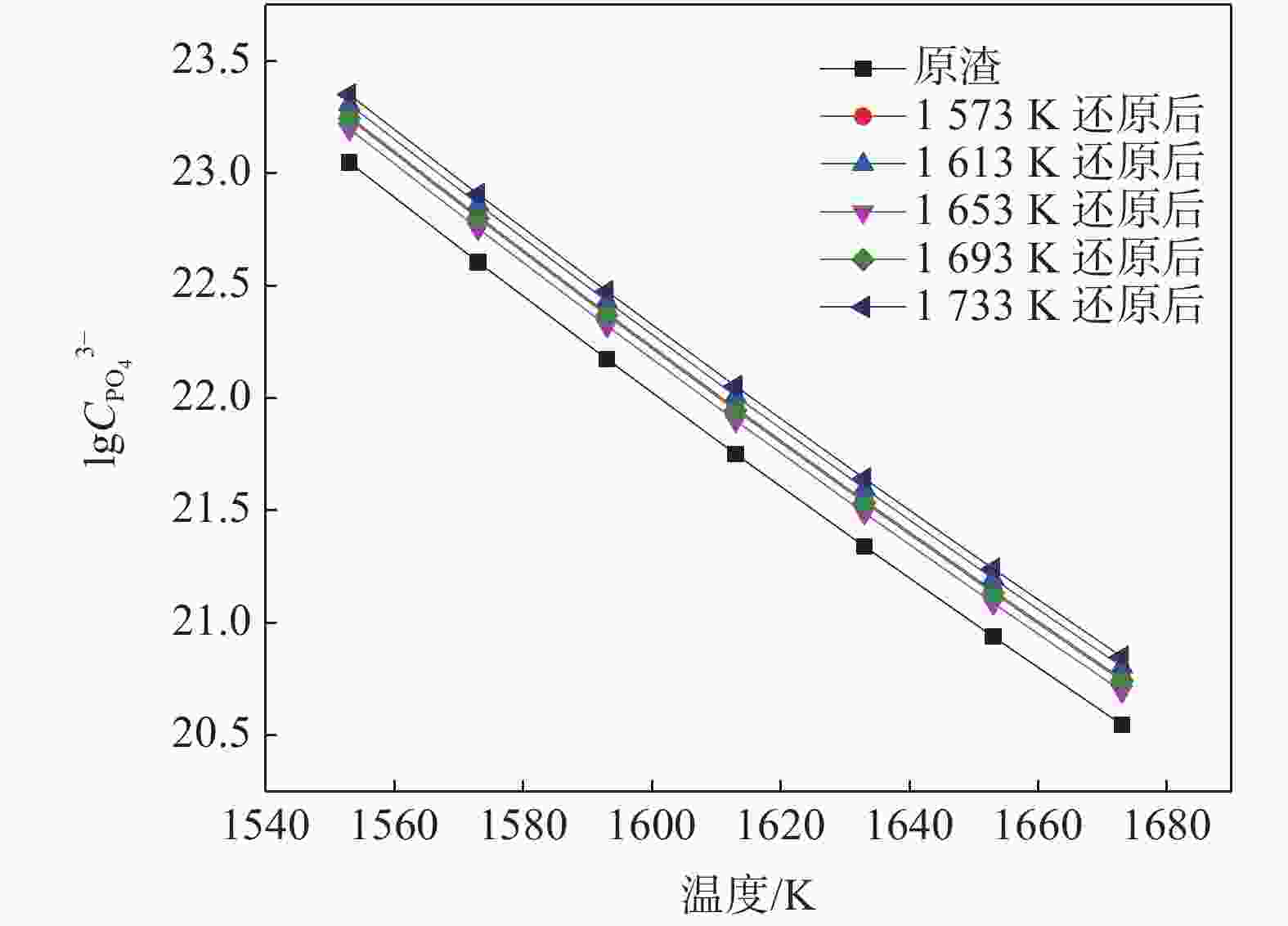

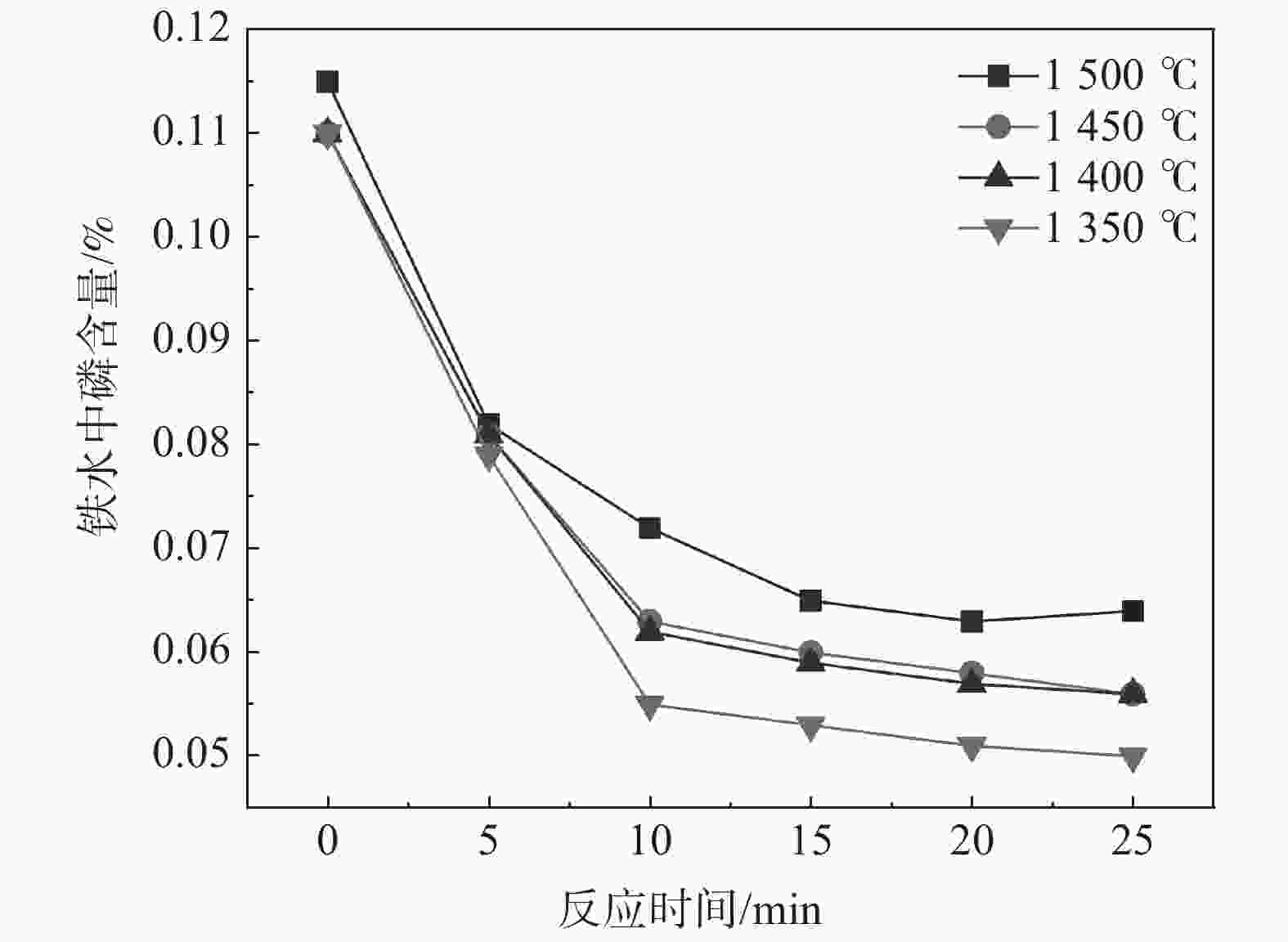

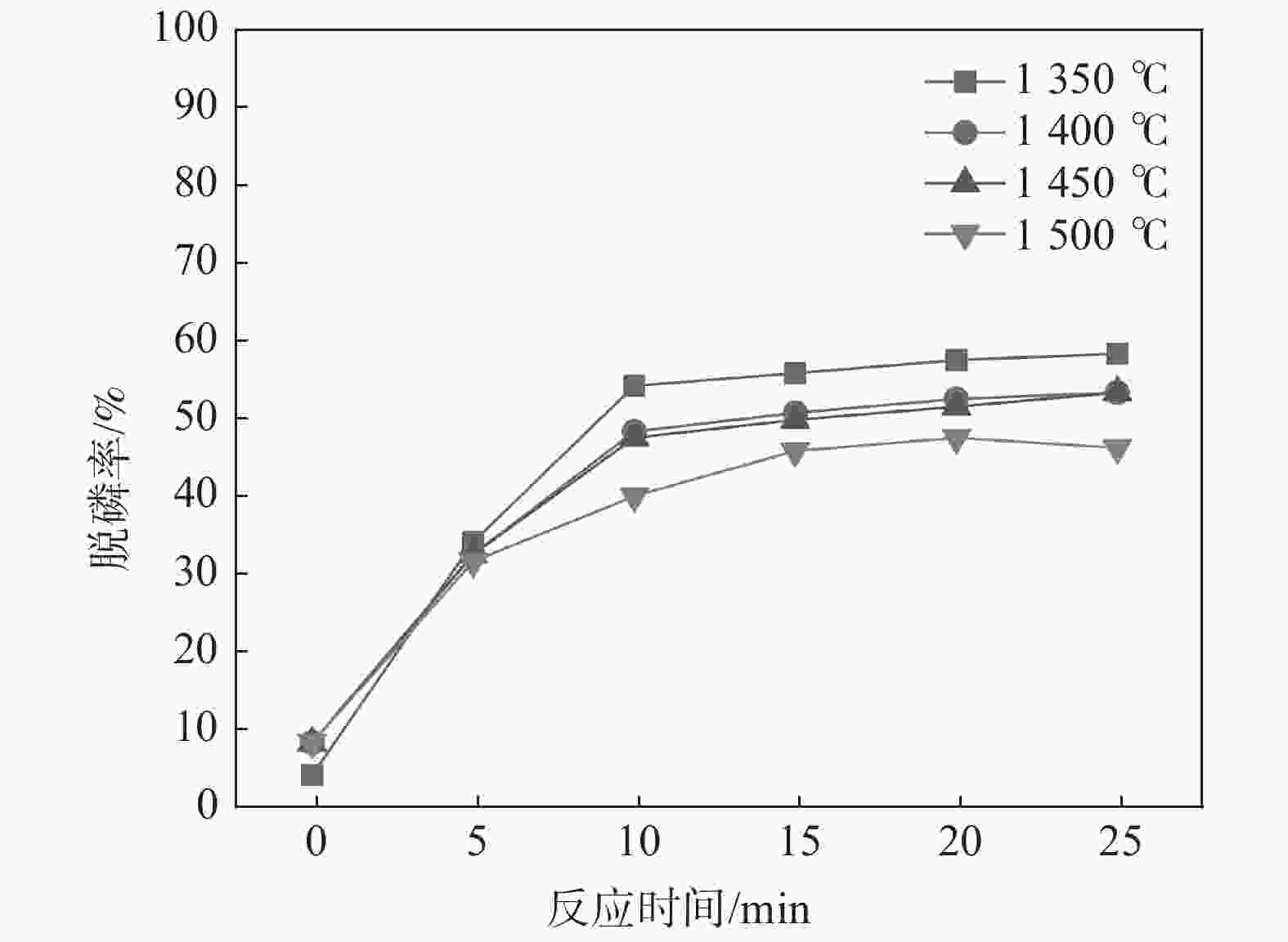

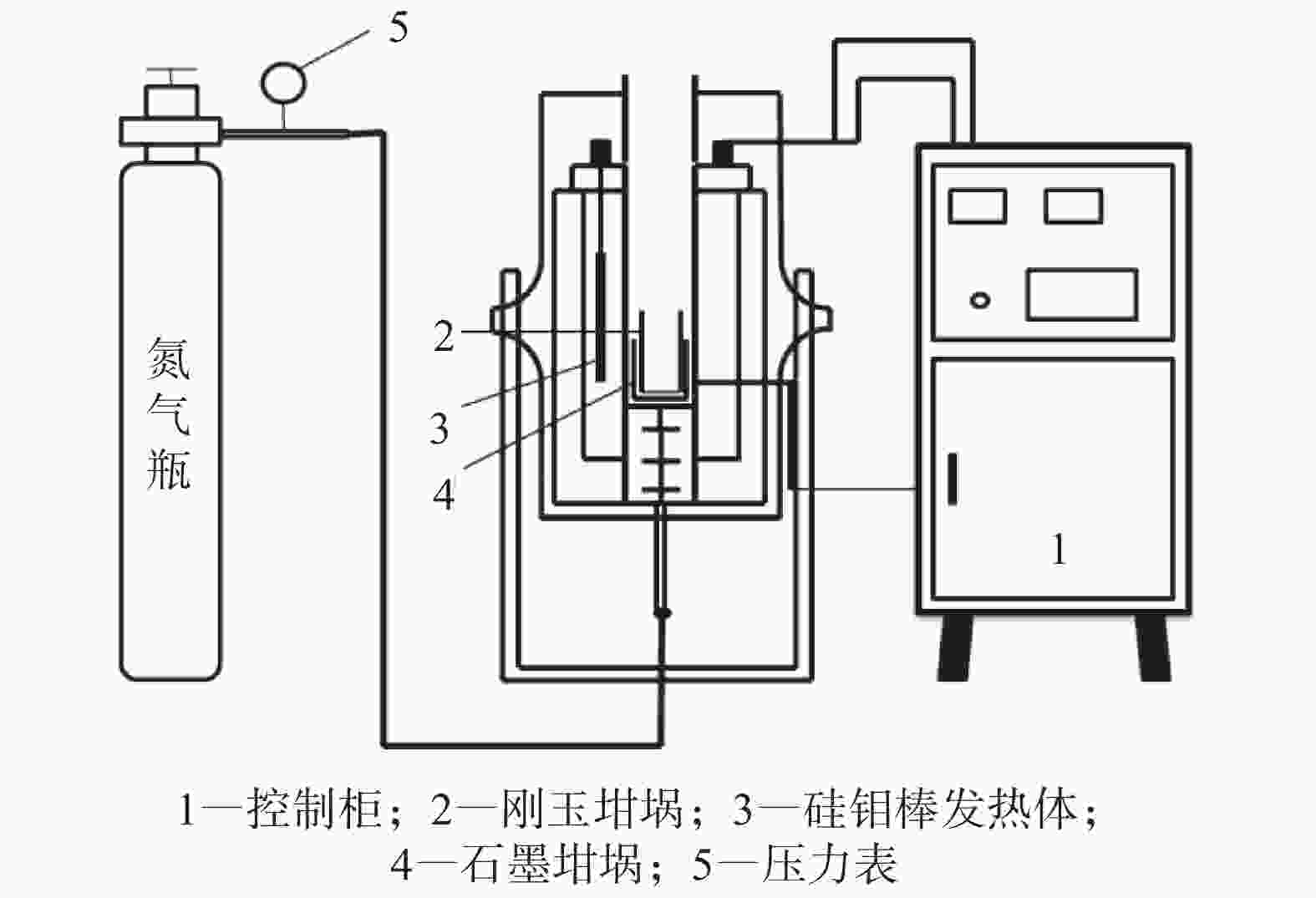

摘要: 采用理论分析与试验验证相结合的方法,研究了转炉气化脱磷渣循环再利用时的脱磷能力。以焦粉还原转炉渣制备气化脱磷渣,理论分析不同还原温度对气化脱磷渣的磷容量和磷分配比的影响规律。由理论分析得知:随着还原温度的升高,经还原后的炉渣的磷容量和磷分配比均增加。在实验室中采用气化脱磷渣进行铁水脱磷热态试验,设温度为单变量,研究气化脱磷渣再利用时的脱磷效果,结果表明:转炉气化脱磷渣具有新的脱磷能力,反应前期脱磷效果显著。随着温度的增加,气化脱磷渣脱磷能力降低,脱磷速度变慢,符合热力学规律。Abstract: In this paper theoretical analysis and experimental verification are combined in order to study the dephosphorization ability of the converter gasification dephosphorization slag when it is recycled and reused. Gasification dephosphorization slag had been prepared by using coke powder to reduce converter slag. The influence of different reduction temperatures on the phosphorus capacity and phosphorus distribution ratio of gasification dephosphorization slag has been theoretically analyzed. According to theoretical analysis, with the increase of reduction temperature, the phosphorus capacity and phosphorus distribution ratio of the slag after reduction both increase. In the laboratory, gasification dephosphorization slag is used to conduct hot metal dephosphorization experiments, and a single temperature variable is set to study the dephosphorization effect of gasification dephosphorization slag when it is reused. The results show that converter gasification dephosphorization slag has new dephosphorization, significant dephosphorization effect during the early stage of the reaction. With the increase of temperature, the dephosphorization capacity of gasified dephosphorization slag decreases, and the dephosphorization speed becomes slower, which is in agreement with thermodynamics law.

-

表 1 转炉渣成分

Table 1. Compositions of converter slag

% FeO CaO SiO2 MgO MnO P2O5 S 其他 15.62 46.46 18.38 11.29 3.06 2.53 0.12 2.54 表 2 焦炭成分

Table 2. Compositions of coke

% 固定碳 CaO SiO2 MgO MnO S 其他 86.7 1.37 6.77 0.24 3.06 0.71 4.21 表 3 气化脱磷渣成分

Table 3. The compositions of gasification dephosphorization slag

% FeO CaO SiO2 MgO MnO P2O5 S 12.33 48.78 19.47 10.52 2.01 1.39 0.12 表 4 试验用铁水主要化学成分

Table 4. Main composition of molten iron

% C Si Mn P S 4.32 0.40 0.22 0.12 0.029 表 5 不同反应时间铁水中P含量

Table 5. P content in hot metal with different reaction time

温度/℃wP/% 5 min 10 min 15 min 20 min 25 min 1350 0.079 0.055 0.053 0.051 0.050 1400 0.081 0.062 0.059 0.057 0.056 1450 0.081 0.063 0.060 0.058 0.056 1500 0.082 0.072 0.065 0.063 0.064 -

[1] Morita K, Guo M, Oka N, et al. Resurrection of the iron and phosphorus resource in steel-making slag[J]. Journal of Material Cycles & Waste Management, 2002,4(2):93−101. [2] Dippenaar, R. Industrial uses of slag the-use and re-use of iron and steelmaking slags[J]. Ironmaking & Steelmaking, 2005,32(1):35−46. [3] Jiang Maofa, Cui Yuyuan, Wang Deyong, et al. Effect of modification treatment for reduction of dephosphorization slag in hot metal bath[J]. Journal of Iron and Steel Research, International, 2013,20(1):1. doi: 10.1016/S1006-706X(13)60036-9 [4] Jeong Y S, Matsubae-Yokoyama K, Nagasaka T. Recovery of Mn and P from steelmaking slag with wet magnetic seperation[J]. Materials and Processes(材料とプロセス), 2009,22(2):993. [5] Fujita T, Iwasaki I. Phosphorus removal from steelmaking slag slow-cooled in a non-oxidizing atmosphere by magnetic separation/flotation[J]. I & S M, 1989,16(1):47. [6] Zhao Chenglin, Zhang Ning, Kang Lei, et al. Experiments on dephosphorization of BOF slag by carbothermal reduction[J]. Iron & Steel, 2016,51(5):41−44. (赵成林, 张宁, 康磊, 等. 碳热还原转炉渣脱磷的试验[J]. 钢铁, 2016,51(5):41−44. [7] (王书桓, 郝华强, 艾立群, 等. 转炉气化脱磷渣循环脱磷炼钢的方法: 中国, 201710588339[P]. 2019-07-16.)Wang Shuhuan, Hao Huaqiang, Ai Liqun, et al. Circulating dephosphorization steelmaking method for converter gasification dephosphorization slag: China, 201710588339[P]. 2019-07-16. [8] Wang Yici, Li Haiyang, Li Shuangwei, et al. Thermodynamic analysis and experiment of gasification dephosphorization reaction of converter steel slag[J]. Journal of Iron and Steel Research, 2016,28(6):31−34. (王艺慈, 李海洋, 李双威, 等. 转炉钢渣气化脱磷反应的热力学分析及试验[J]. 钢铁研究学报, 2016,28(6):31−34. [9] Zhou Chaogang, Ai Liqun, Wang Shuhuan, et al. Study on the mechanism of gasification dephosphorization and its influence on the next smelting process[J]. Iron Steel Vanadium Titanium, 2018,39(6):129−136. (周朝刚, 艾立群, 王书桓, 等. 气化脱磷机理及对下炉次冶炼过程的影响研究[J]. 钢铁钒钛, 2018,39(6):129−136. doi: 10.7513/j.issn.1004-7638.2018.06.021 [10] Guo Ruihua, Wang Shuhuan, Li Chenxiao, et al. Experimental on coke reduction dephosphorization converter slag gasification dephosphorization[J]. Iron & Steel, 2020,55(9):118−124. (郭瑞华, 王书桓, 李晨晓, 等. 焦炭还原脱磷转炉熔渣的气化脱磷试验[J]. 钢铁, 2020,55(9):118−124. [11] Xue Yuekai, Wang Shuhuan, Li Chenxiao, et al. Experimental study on recycling of 60 t converter slag after gasification and dephosphorization[J]. Steelmaking, 2018,34(1):20−24, 43. (薛月凯, 王书桓, 李晨晓, 等. 60 t转炉炉渣气化脱磷后循环利用试验研究[J]. 炼钢, 2018,34(1):20−24, 43. [12] Suito H, Inoue R. Phosphorus distribution between Mgo-saturated CaO-FetO-SiO2-P2O5-MnO slages and liquid iron[J]. Tetsu-to-Hagane, 1984,24(1):40. -

下载:

下载: