Review of continue casting slab electromagnetic stirring technology

-

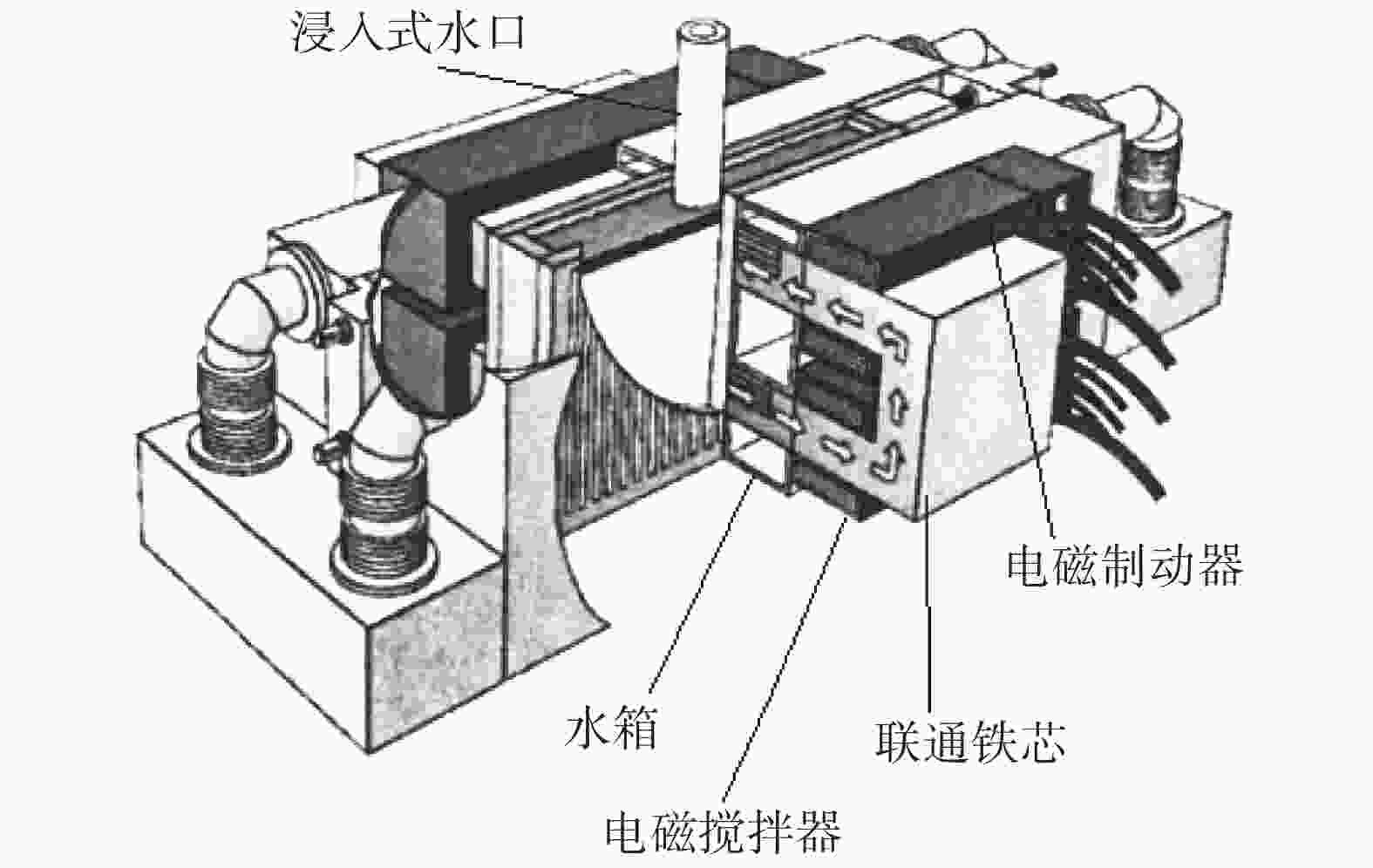

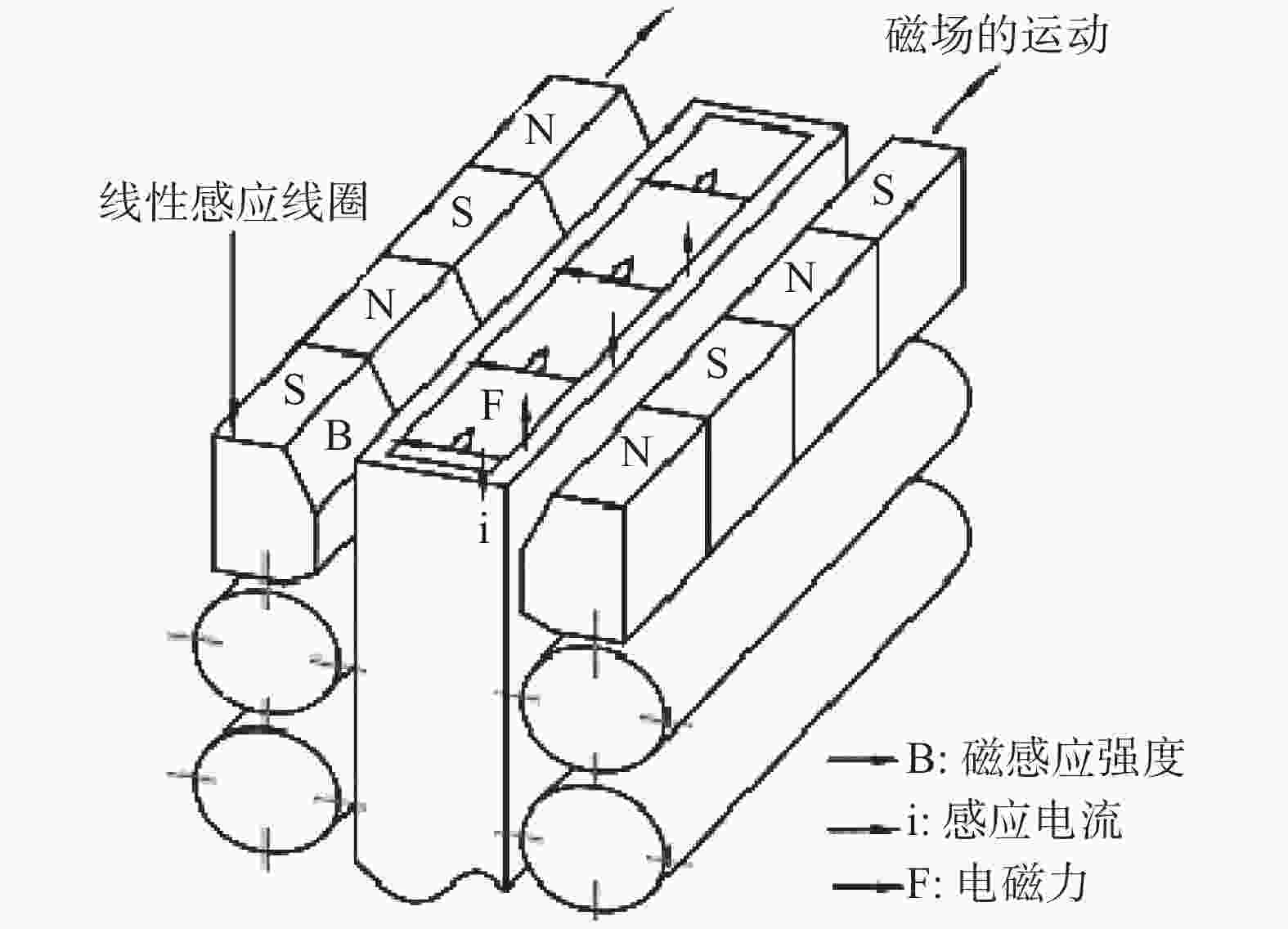

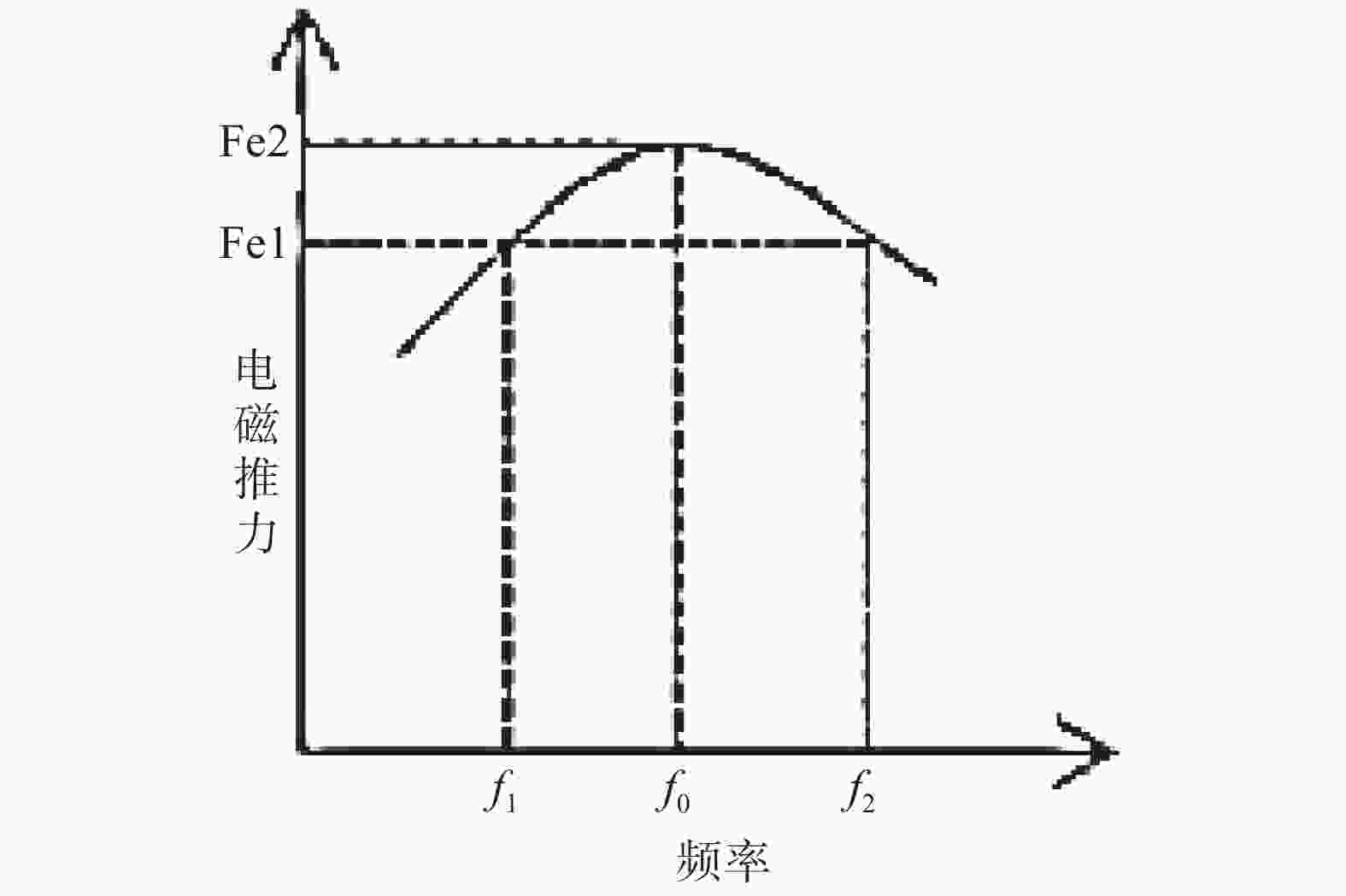

摘要: 简述了连铸板坯电磁搅拌技术的发展过程和现存问题,重点阐述了连铸板坯生产过程中结晶器内和二冷区电磁搅拌的工作原理和技术特点,对电磁搅拌器的安装位置进行了归纳,同时总结了板坯结晶器电磁搅拌和二冷区电磁搅拌的研究现状,探究了影响板坯电磁搅拌效果的因素及其主次关系,归纳了用于二冷区电磁搅拌支撑辊的作用及需继续探究的方向,分析了板坯电磁搅拌技术对铸坯内元素分布和等轴晶区间隙率的影响,为以后的板坯电磁搅拌研究者提供参考。Abstract: The development process and existing problems of electromagnetic stirring technology for continuous casting slabs were briefly described, focusing on the working principle and technical characteristics of electromagnetic stirring in the mold and the secondary cold zone during the production of continuous casting slabs. The installation position of the electromagnetic stirrer and the research status of electromagnetic stirring in the slab mold as well as electromagnetic stirring in the secondary cold zone were summarized. The factors affecting the electromagnetic stirring effect of slab and their primary and secondary relationships were discussed, and the electromagnetic stirring support roll used in the secondary cold zone was summarized. The role of slab electromagnetic stirring technology and the direction to be further explored were analyzed. The influence of slab electromagnetic stirring technology on the element distribution and equiaxed grain gap ratio in the cast slab was analyzed.

-

Key words:

- continue casting /

- slab /

- mold /

- electromagnetic stirring /

- secondary cooling zone

-

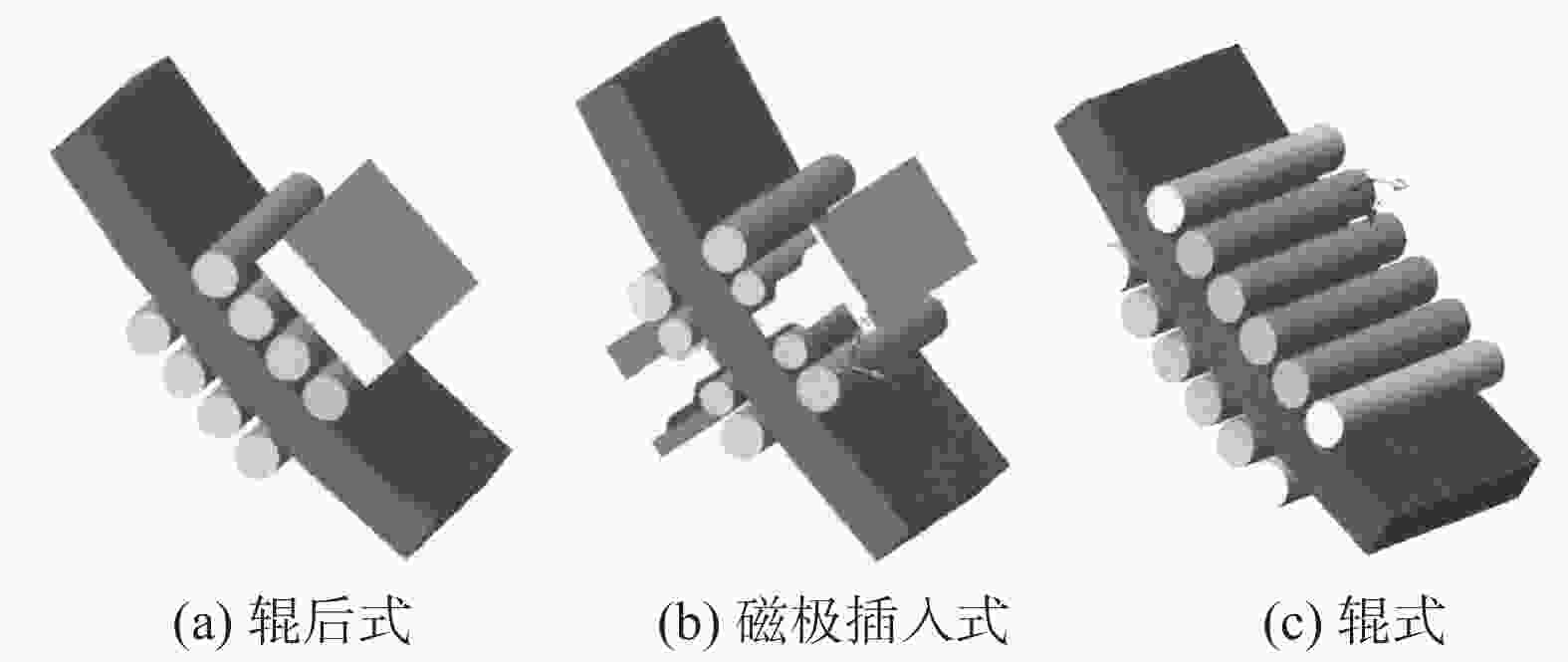

表 1 板坯连铸过程二冷区用电磁搅拌器的特点

Table 1. Characteristics of electromagnetic stirrer used in secondary cooling zone of slab continuous casting process

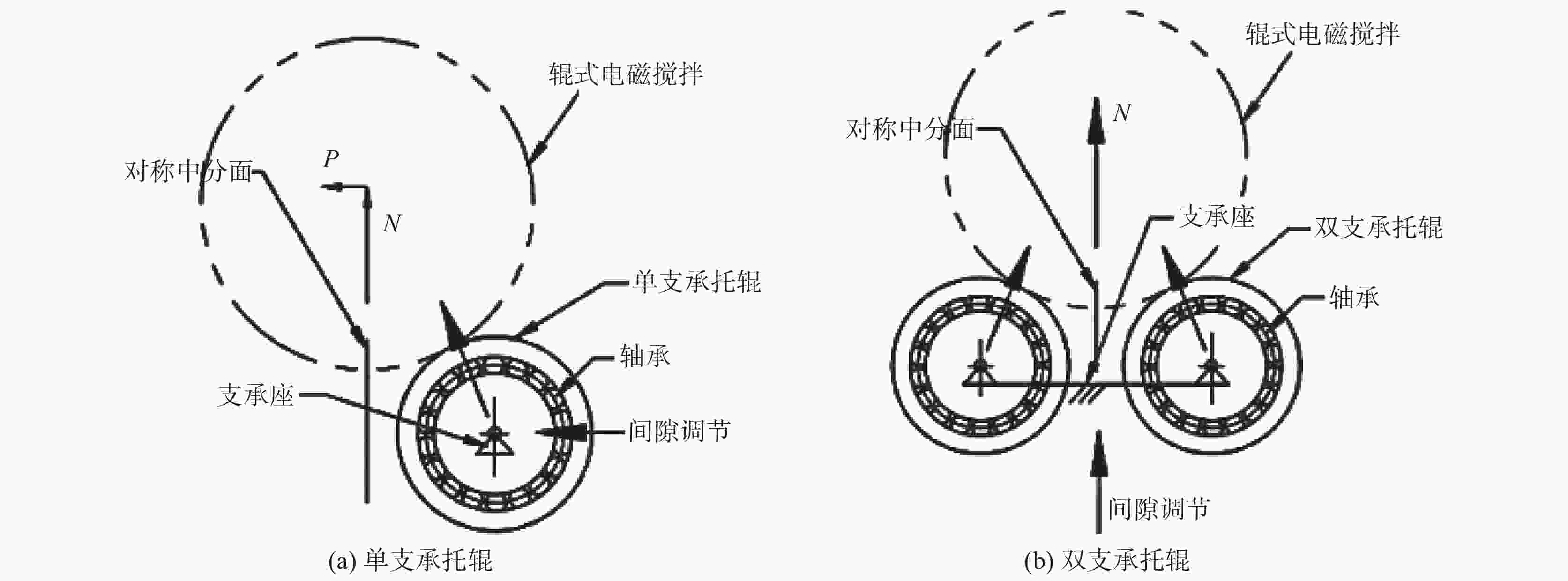

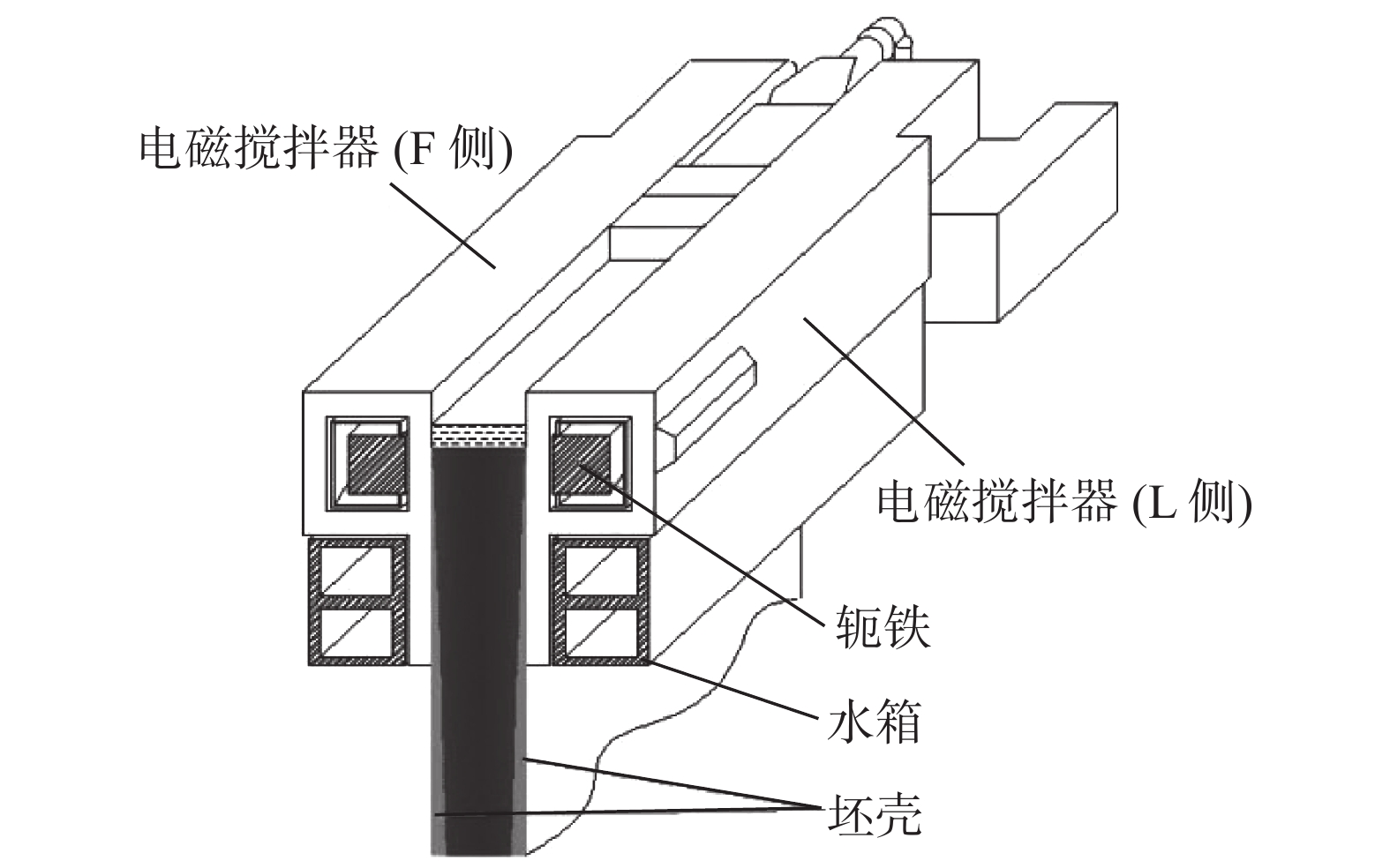

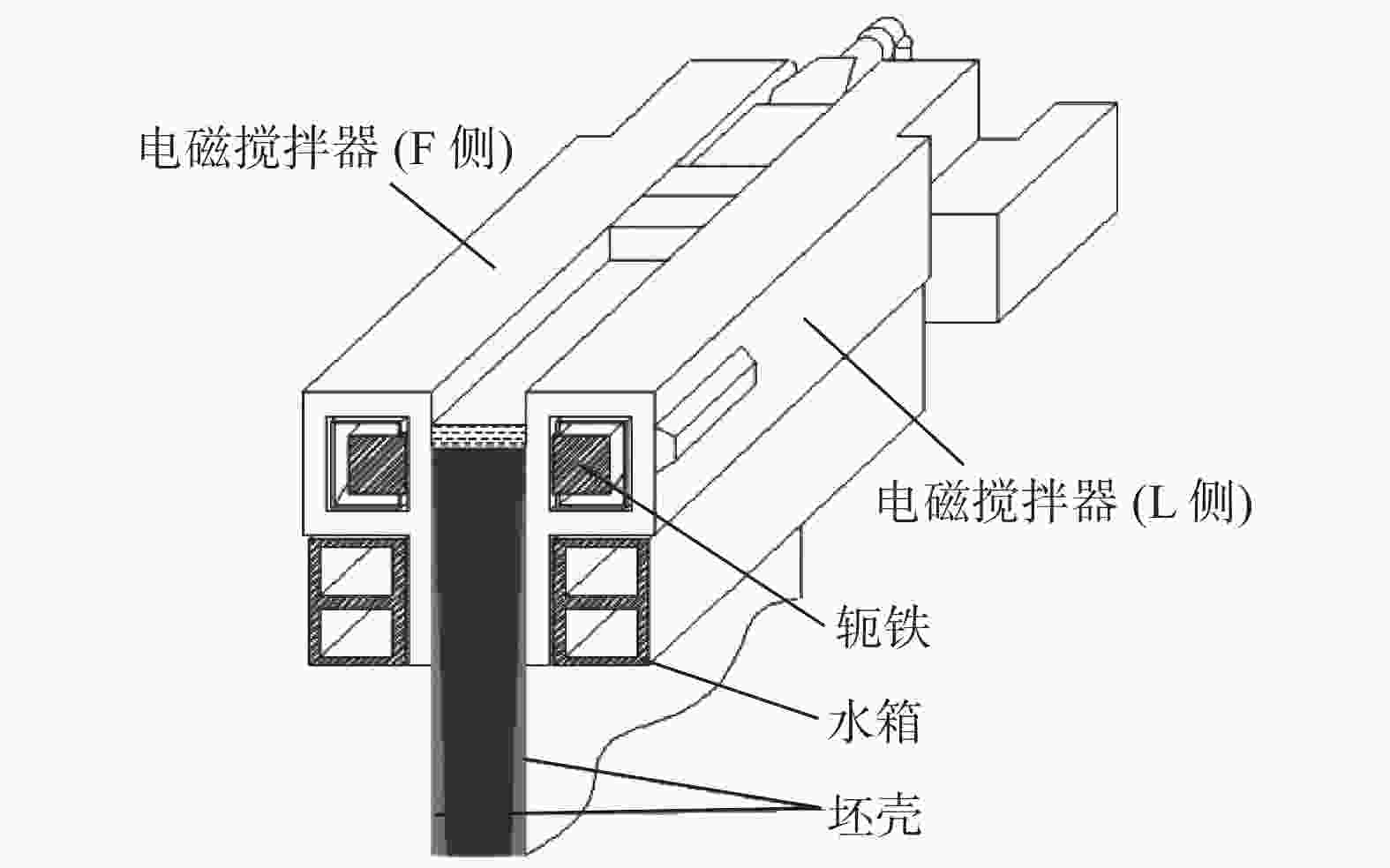

类型 感应器数量 感应器绕组 电流/A 中心电磁推力(mmFe) 作用面 对扇形段改造 优点 缺点 辊后式 1台,单面安装 铜管绕组,

迭绕式2000 35~50 单侧 连铸机结构及辊列需改造 寿命长 磁力小;

位置不可调磁极插入式 2台,对面安装 扁铜管绕组,克兰姆式 2×700 85~110 内外弧双侧 辊列结构

需改造磁力大;寿命长;适用范围广 需特制扇形段;铸坯易鼓肚 辊式 4根两对,

对面安装扁铜线绕组,

克兰姆式2×400 一对60~80;

两对并列:90~110内外弧双侧 - 安装位置灵活;

磁力大;

适用范围广寿命短;

维护较麻烦 -

[1] Nobuyuki Genma. The linear-motor type in-mold electromagnetic stirring technique for the slab continuous caster[J]. ISIJ International, 1989,19(12):1056−1062. [2] Li Tingju. Surface quality improvement of continuously cast metals by imposing intermittent high frequency magnetic field and synchronizing the field with mold oscillation[J]. ISIJ International, 1996,36(4):410−416. doi: 10.2355/isijinternational.36.410 [3] Gao Yunyan, Jia Guanglin, Shi Yusheng, et al. Mathematical model of metal motion law during linear electromagnetic stirring[J]. Journal of Northeastern University, 1991,2(3):292−297. (高允彦, 贾光霖, 史玉升, 等. 线性电磁搅拌时金属运动规律的数学模型[J]. 东北大学学报, 1991,2(3):292−297. [4] Kensuke Okazawa, Takehiko Toh, Jun Fukuda, et al. Fluid flow in a continuous casting mold driven by linear induction motors[J]. ISIJ International, 2001,(41):851−858. [5] Ambrish Maurya, Pradeep Kumar Jha. Influence of electromagnetic stirrer position on fluid flow and solidification in continuous casting mold[J]. Appl. Math. Model., 2017,(48):736−748. [6] Yin Yanbin, Zhang Jiongming, Lei Shaowu, et al. Numerical study on the capture of large inclusion in slab continuous casting with the effect of in-mold electromagnetic stirring[J]. ISIJ International, 2019,57(12):2165−2174. [7] Yin Yanbin, Zhang Jiongming, Wang Bo, et al. Effect of in-mould electromagnetic stirring on the flow, initial solidification and level fluctuation in a slab mould: a numerical simulation study[J]. Ironmaking & Steelmaking, 2018,46:1743−2812. [8] 葛成东. 不同参数下复合磁场对板坯结晶器内钢液流动的影响[D]. 沈阳: 东北大学, 2017.Ge Chengdong. Molten steel flow in slab mold of combine magnetic under different parameters[D]. Shengyang: Northeastern University, 2017. [9] Jin Baigang, Li Lixun, Wei Chunxin, et al. The influence of electromagnetic braking technology of slab mold on liquid level fluctuation[J]. China Metallurgy, 2013,13(7):40−44. (金百刚, 李立勋, 魏春新, 等. 板坯结晶器电磁制动技术对液面波动的影响[J]. 中国冶金, 2013,13(7):40−44. [10] 莫旭杰. 板坯连铸电磁搅拌控制系统的研究与实现[D]. 长沙: 湖南大学, 2011.Mo Xujie. Research and implementation of electromagnetic stirring control system for slab continuous casting[D]. Changsha: Hunan University, 2011. [11] 侯亚雄, 彭立新, 沈长华. 电磁搅拌技术及其应用[C]//第十届中国钢铁年会暨第六届宝钢学术年会论文集III. 上海: 中国金属学会, 2015.Hou Yaxiong, Peng Lixin, Shen Changhua. Electromagnetic stirring technology and its application[C]//Proceedings of the 10th China Iron and Steel Annual Conference and the 6th Baosteel Academic Annual Conference III. Shanghai: CSM, 2015. [12] 熊毅刚. 现代钢铁工业技术-板坯连铸[M]. 北京: 冶金工业出版社, 1994.Xiong Yigang. Modern steel industry technology-slab continuous casting[M]. Beijing: Metallurgical Industry Press, 1994. [13] 丁贺. 辊式二冷区电磁搅拌对板坯质量影响研究[D]. 昆明: 昆明理工大学, 2016.Ding He. Research on the influence of roller-type secondary cooling zone electromagnetic stirring on slab quality[D]. Kunming: Kunming University of Science and Technology, 2016. [14] Wang S, De Toledo G A, Välimaa K, et al. Magnetohydrodynamic phenomena, fluid control and computational modeling in the continuous casting of billet and bloom[J]. ISIJ Int., 2014,54(10):2273−2282. doi: 10.2355/isijinternational.54.2273 [15] Zheng Wenchao, Liu Zhiyong, Meng Qingyong, et al. The effect of electromagnetic stirring on strand center segregation at secondary cooling section of slab continuous caster[J]. Wide and Heavy Plate, 2016,22(5):14. [16] Wang Panfeng. Application of S-EMS to slab continuous casting machine[J]. Journal of University of Science and Technology Liaoning, 2016,39(5):339. [17] Huang Zunxian, Zhu Zumin. Application of electromagnetic stirring in slab continuous casting machine[J]. Technology of Bao Steel, 1994,(3):51−55. (黄尊贤, 朱祖民. 电磁搅拌在板坯连铸机上的应用[J]. 宝钢技术, 1994,(3):51−55. [18] Hu Zhaofan, Zhang Jiongming, Cai Zhen, et al. Effect of electromagnetic stirring of mold on surface cleanliness of IF steel continuous casting slab[J]. Journal of Iron and Steel Research, 2011,23(10):15−19. (胡招凡, 张炯明, 蔡珍, 等. 结晶器电磁搅拌对IF钢连铸坯表层纯净度的影响[J]. 钢铁研究学报, 2011,23(10):15−19. [19] He Xiufang. Electromagnetic stirring technology in the mold of slab caster[J]. Journal of Iron and Steel Research, 1992,(4):42. (贺秀芳. 板坯连铸机结晶器内电磁搅拌技术[J]. 钢铁研究学报, 1992,(4):42. [20] Li Bin, Lu Haibiao, Zhong Yunbo, et al. Numerical simulation for the influence of EMS position on fluid flow and inclusion removal in a slab continuous casting mold[J]. ISIJ International, 2020,60(6):1204−1212. doi: 10.2355/isijinternational.ISIJINT-2019-666 [21] Li Shaoxiang, Lan Peng, Zhang Jiaquan. Numerical simulation of turbulence flow and solidification in a bloom continuous casting mould with electromagnetic stirring[C]//Symposium on CFD Modeling and Simulation in Materials Processing, Phoenix, 2018. [22] 宿国栋. 板坯连铸二冷区电磁搅拌耦合分析[D]. 包头: 内蒙古科技大学, 2007.Su Guodong. Coupling analysis of electromagnetic stirring in the secondary cooling zone of slab continuous casting[D]. Baotou: Inner Mongolia University Science and Technology, 2007. [23] Nataraja T T, El-Kaddah N. Finite element analysis of electromagnetically sub-mold stirring of steel billets and slabs[J]. ISIJ International, 1998,38(7):680−689. doi: 10.2355/isijinternational.38.680 [24] Lu Muh Jung, Chen Jen Hsin, Tzeng Shuwen, et al. Numerical simulation of the electromagnetic stirring in mold for slab continuous casting[C]//The 2nd Asian Workshop on Electromagnetic Peocessing of Materials. Shenyang: Northeastern University Press, 2005. [25] Wen Hongquan, Wu Cunyou, Zhou Yueming. Molten steel level stability in continuous casting slab mold under electromagnetic stirring[J]. Baosteel Technical Research, 2019,13(1):25−31. [26] Li Bin, Lu Haibiao, Shen Zhe, et al. Physical modeling of asymmetrical flow in slab continuous casting mold due to submerged entry nozzle clogging with the effect of electromagnetic stirring[J]. ISIJ International, 2019,59(12):2264−2271. doi: 10.2355/isijinternational.ISIJINT-2018-866 [27] Huang Juntao, Wang Engang, He Jicheng. Numerical simulation of linear electromagnetic stirring in secondary cooling region of slab caster[J]. Journal of Iron and Steel Research International, 2003,10(3):16−21. [28] Ma Liguo, Huang Yuping, Tang Xuefeng, et al. Experimental research on improving solidification structure of slab by electromagnetic stirring[J]. Steelmaking, 2012,28(6):48−51. (马立国, 黄玉平, 唐雪峰, 等. 电磁搅拌改善板坯凝固组织的试验研究[J]. 炼钢, 2012,28(6):48−51. [29] Liu Yang, Wang Xinhua. The effect of electromagnetic stirring in the secondary cooling zone on the center segregation of continuous casting slab[J]. Journal of University of Science and Technology Beijing, 2007,29(6):582−586. (刘洋, 王新华. 二冷区电磁搅拌对连铸板坯中心偏析的影响[J]. 北京科技大学学报, 2007,29(6):582−586. doi: 10.3321/j.issn:1001-053X.2007.06.008 [30] Zheng Shengbin, He Hang, Liu Yonglong. The influence of electromagnetic stirring on the quality of pipeline slab and the performance of steel plate[J]. Steelmaking, 2015,31(3):26−29. (郑生斌, 何航, 刘永龙. 电磁搅拌对管线钢板坯质量和钢板性能的影响[J]. 炼钢, 2015,31(3):26−29. [31] 马文俊, 刘国梁, 李海波. 二冷段电磁搅拌对板坯内部质量的影响[C]//第三届全国电磁冶金与强磁场材料科学会议学术论文集. 焦作: 中国金属学会, 2016.Ma Wenjun, Liu Guoliang, Li Haibo. The influence of electromagnetic stirring in the secondary cooling section on the internal quality of slabs[C]//The 3rd National Conference on Electromagnetic Metallurgy and Strong Magnetic Field Materials Science. Jiaozuo: The Chinese Society for Metals, 2016. [32] Zheng Wenchao, Liu Zhongyong, Meng Qingyong, et al. The influence of electromagnetic stirring in the secondary cooling zone of a slab caster on center segregation[J]. Wide and Heavy Plate, 2016,22(5):14−17. (郑文超, 刘忠勇, 孟庆勇, 等. 板坯连铸机二冷区电磁搅拌对中心偏析的影响[J]. 宽厚板, 2016,22(5):14−17. doi: 10.3969/j.issn.1009-7864.2016.05.004 [33] He Jianzhong, Zhang Zhao, Wang Hao, et al. Optimization of electromagnetic stirring technology in the second cooling zone of wide and heavy plate caster and improvement of longevity[J]. Continuous Casting, 2017,42(3):16−20. (何建中, 张昭, 王皓, 等. 宽厚板铸机二冷区电磁搅拌工艺优化及长寿化攻关[J]. 连铸, 2017,42(3):16−20. [34] Xu Dangwei, An Liangliang, Yang Junfeng. The influence of electromagnetic stirring on the quality of slab and the mechanical properties of medium and heavy plates[J]. Henan Metallurgy, 2011,19(5):22−25. (徐党委, 安亮亮, 杨俊锋. 电磁搅拌对板坯质量及中厚板力学性能的影响[J]. 河南冶金, 2011,19(5):22−25. doi: 10.3969/j.issn.1006-3129.2011.05.008 [35] Du Yong, Jia Xugang, Li Zhichao, et al. Experiment and application of roller electromagnetic stirring in the secondary cold zone in slab[J]. Continuous Casting, 2011,(6):16−19. (杜勇, 贾旭岗, 李志超, 等. 二冷区辊式电磁搅拌在安钢板坯的试验和应用[J]. 连铸, 2011,(6):16−19. [36] Dong Zhen, Liu Ping, Jia Shengjian, et al. Application of roller electromagnetic stirring in the second cold zone in the continuous caster of cladding steel slab[J]. Special Steel, 2011,32(6):34−35. (董诊, 刘平, 贾生建, 等. 二冷区辊式电磁搅拌在包钢板坯连铸机的应用[J]. 特殊钢, 2011,32(6):34−35. doi: 10.3969/j.issn.1003-8620.2011.06.011 [37] Qu Tianpeng, Ren Bingzhi, Han Zhiwei, et al. Application and numerical simulation of electromagnetic stirring in secondary cooling zone during continuous casting of ultra-thick slab[C]//International Conference on Electromagnetic Processing of Materials. Beijing: CSM, 2012. [38] Liu Jun, Han Quanjun, Xu Guoqing, et al. Effects of electromagnetic stirring on super-thick continuous casting slabs and plate products[C]//The 2018 International Symposium on Sustainable Steelmaking Technology. Zhuhai: Japan Stainless Steel Association, International Nickel Association, 2018. [39] Ma Chao, Luan Huabing, Li Bo, et al. Numerical simulation and industrial application of secondary cooling electromagnetic stirring for medium manganese steel slab[J]. Journal of Liaoning University of Science and Technology, 2018,41(6):427−432. (马超, 栾花冰, 李泊, 等. 中锰钢板坯二冷电磁搅拌数值模拟和工业应用[J]. 辽宁科技大学学报, 2018,41(6):427−432. [40] Zhang Kai, Chen Shifu, Yang Bin, et al. The arrangement of electromagnetic stirring roller in the second cooling zone of slab[J]. Journal of Liaoning University of Science and Technology, 2018,41(5):335−341. (张开, 陈士富, 杨滨, 等. 板坯二冷区电磁搅拌辊布置方式[J]. 辽宁科技大学学报, 2018,41(5):335−341. [41] Liu Tianyu, Chen Shifu, Yang Bin, et al. Numerical simulation of rotating electromagnetic stirring in the secondary cold zone of slab[J]. Journal of Liaoning University of Science and Technology, 2018,41(5):327−341. (刘天宇, 陈士富, 杨滨, 等. 板坯二冷区旋转型电磁搅拌的数值模拟仿真[J]. 辽宁科技大学学报, 2018,41(5):327−341. [42] Wang Xuebing, Zhang Xingzhong, Qiu Shengtao, et al. Numerical simulation study of electromagnetic stirring in the secondary cold section of slab[J]. Hot Working Technology, 2019,48(7):117−120. (王学兵, 张兴中, 仇圣桃, 等. 板坯二冷段电磁搅拌数值模拟研究[J]. 热加工工艺, 2019,48(7):117−120. [43] Wu Shaojie, Wan Yong, Yu Yanchong, et al. Effect of electromagnetic stirring in secondary cooling zone on quality of continuous casting slab of non-oriented silicon steel[J]. Steelmaking, 2012,(1):11−14, 24. [44] Song Xiaopeng, Cheng Shusen, Zhang Lijun, et al. Magnetic field distribution and molten steel flow in a thin slab secondary cooling zone electromagnetically stirred cast slab[J]. Journal of University of Science and Technology Beijing, 2012,34(11):1276−1282. (宋小鹏, 程树森, 张丽君, 等. 薄板坯二冷区电磁搅拌铸坯内磁场分布和钢液流动[J]. 北京科技大学学报, 2012,34(11):1276−1282. [45] Martin Barna, Mirko Javurek, Peter Wimmer. Numeric simulation of the steel flow in a slab caster with a box-type electromagnetic stirrer[J]. Steel Research International, 2020. doi: 10.1002/srin.202000067 [46] Gao Jiechao. Electromagnetic stirring in continuous casting process[J]. Anshan Iron and Steel Technology, 1989,(12):5−10. (高杰超. 连铸工艺的电磁搅拌[J]. 鞍钢技术, 1989,(12):5−10. [47] 金百刚, 王军, 陈明, 等. 鞍钢板坯连铸机电磁搅拌应用实践研究[C]//第七届中国钢铁年会论文集. 北京: 中国金属学会, 2008.Jin Baigang, Wang Jun, Chen Ming, et al. Application practice research on electromagnetic stirring of Anshan steel slab continuous caster[C]// Proceedings of the Seventh China Iron and Steel Annual Conference. Beijing: CSM, 2008. -

下载:

下载: