Effect of annealing temperature on microstructure and mechanical properties of vanadium microalloyed 780 MPa cold rolled dual phase steel

-

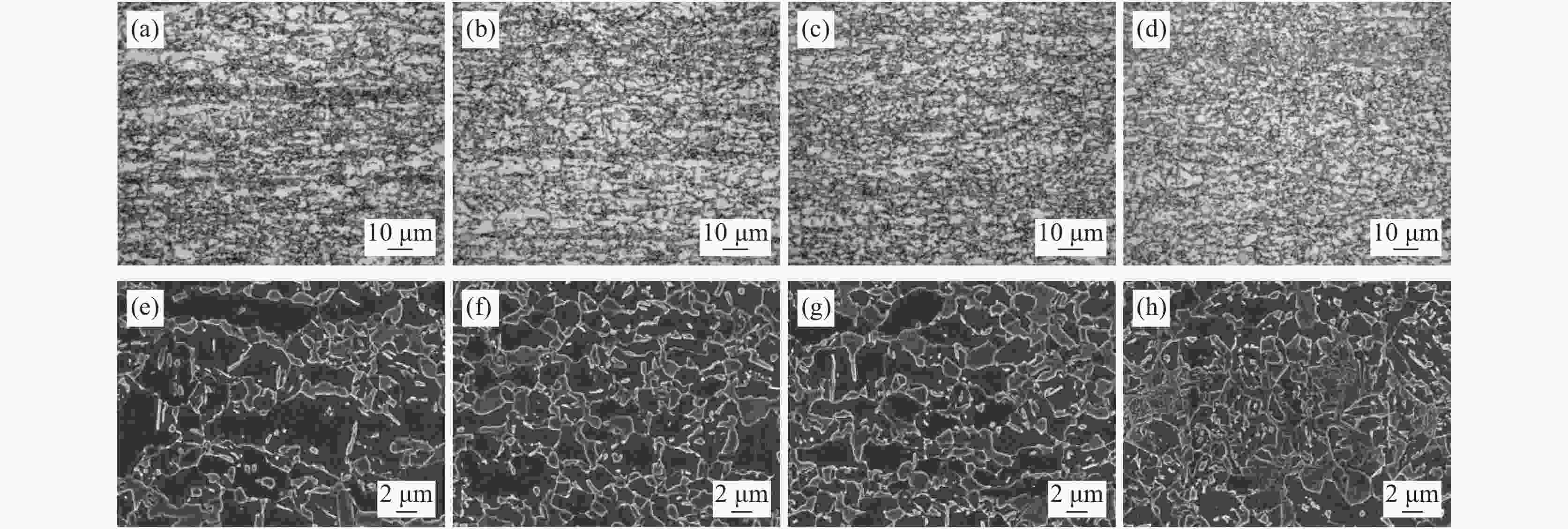

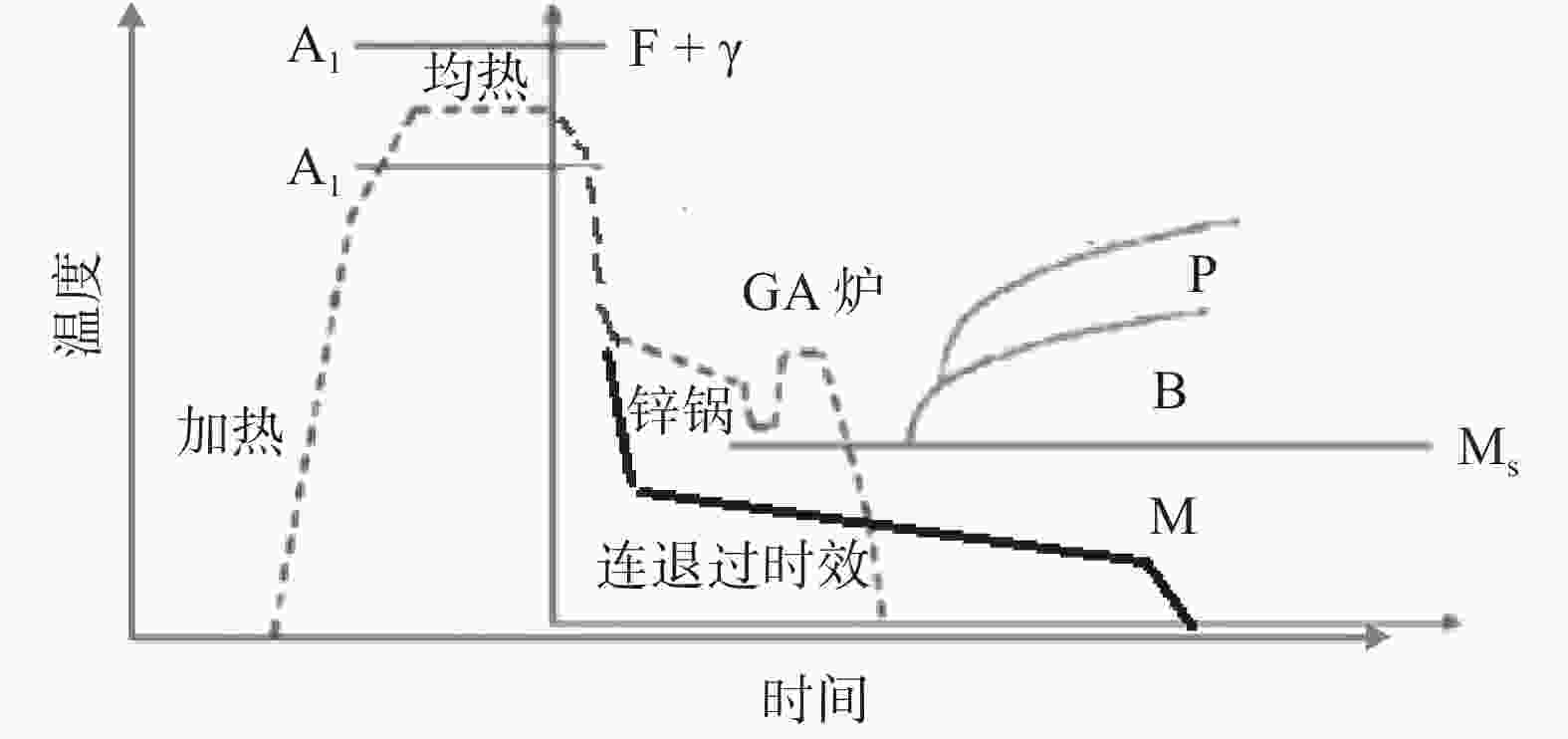

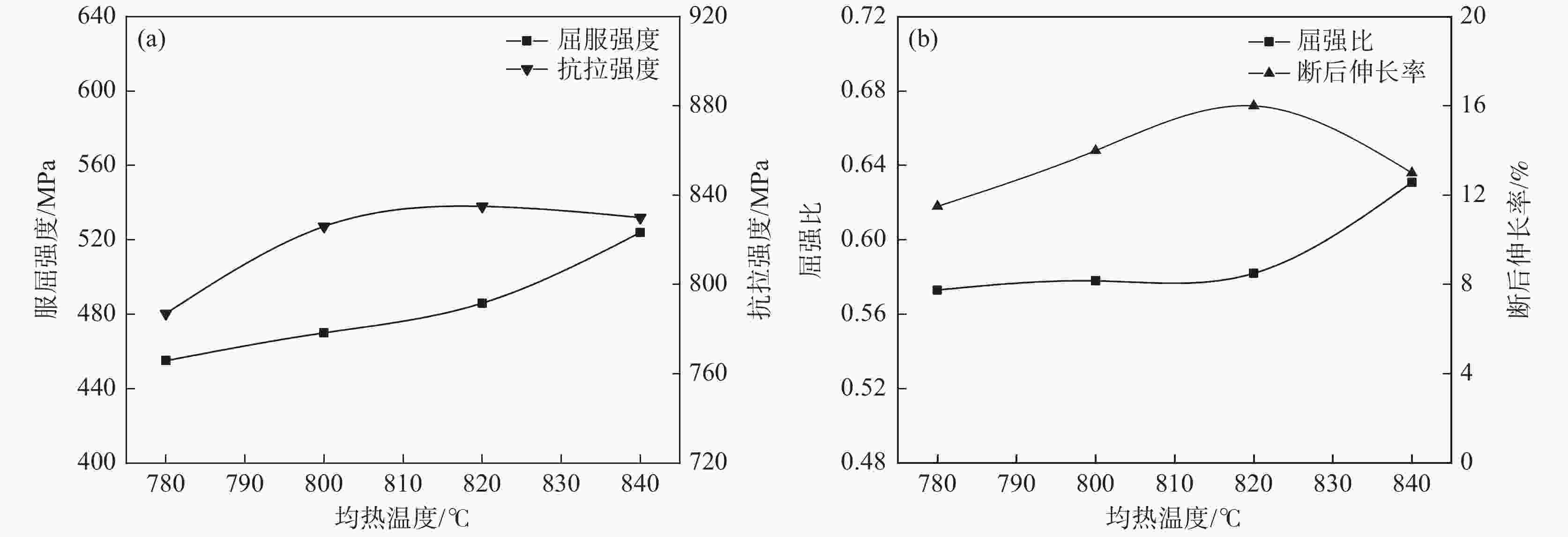

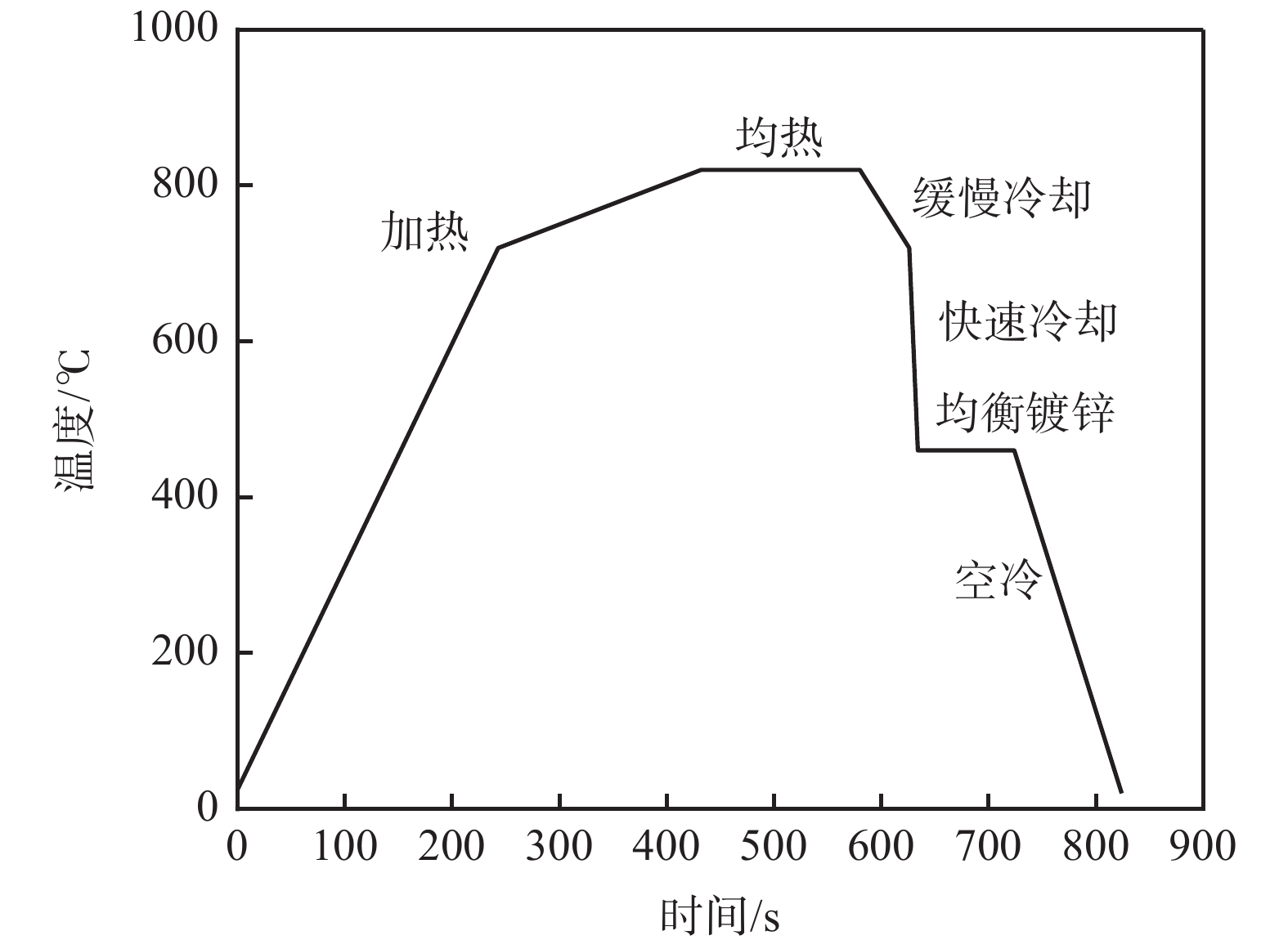

摘要: 将钒微合金化试验钢分别加热至780、800、820 ℃和840 ℃保温一段时间后,依次经过缓慢冷却、快速冷却、模拟镀锌后,空冷至室温。研究结果表明,780 ℃退火时微观组织均匀性较差且发现未溶解的碳化物,导致强度和塑性均不佳。随着退火温度的升高,铁素体尺寸及分数逐渐降低,中低温转变产物含量逐步增加且其尺寸有所粗化。当退火温度为800 ℃时,马氏体含量达到最大,当退火温度进一步升高时,马氏体含量有所降低,而贝氏体含量则有所增加,导致抗拉强度在800~840 ℃范围内变化不大,而延伸率先升高后降低。当退火温度为820 ℃ 时,带钢获得较佳的力学性能,屈服强度、抗拉强度、屈强比、断后伸长率A80和扩孔率分别为486 MPa、835 MPa、0.58、16.0%和27%。Abstract: The vanadium microalloyed tested steel was heated to 780 ℃, 800 ℃, 820 ℃ and 840 ℃, respectively and then held for a few minutes, followed by different cooling modes such as slow cooling, rapid cooling, simulated galvanizing, and air cooling to room temperature. Microstructure observation by SEM shows that microstructure uniformity is poor during annealing at 780 ℃ and undissolved carbides are found, leading to a weak combination of strength and plasticity. With the increase of annealing temperature, the size and fraction of ferrite gradually decrease, the volume fraction of mid-low temperature transformation products gradually increases and its size becomes coarser. When the annealing temperature was 800 ℃, the fraction of martensite reaches the maximum. When the annealing temperature further increases, the fraction of martensite decreases, while the fraction of bainite increases, resulting in a relatively stable tensile strength when annealing temperature of 800 ~840 ℃ range, however, the elongation firstly increases and then decreases. When the annealing temperature was 820 ℃, the steel strip obtains better mechanical properties. The yield strength, tensile strength, yield ratio, elongation after fracture A80 and hole expansion rate are 486 MPa, 835 MPa, 0.58, 16.0% and 27%, respectively.

-

表 1 试验钢主要化学成分

Table 1. Main chemical compositions of experimental steel

% C Si Mn P S Als Cr Mo V 0.087 0.25 1.82 0.0065 0.0020 0.047 添加 添加 添加 表 2 不同退火温度下试验钢的微观组织及相比例

Table 2. Microstructure and phase ratio of tested steel after simulated annealing process at soaking temperature comparison

退火温度/℃ 微观组织 铁素体平均晶粒尺寸/μm M分数/% B分数/% 780 F+M+碳化物 6 30 0 800 F+M+B微量 4.5 37 微量(≤3) 820 F+M+B 4 35 8 840 F+M+B 3 33 12 表 3 固溶C原子在铁素体中的扩散系数和质量分数

Table 3. Diffusion coefficient and mass fraction of solid solution C atom in ferrite

退火温度/ ℃ 扩散系数×107 /(cm2·s−1) w(C)/% 铁素体中 奥氏体中 780 4.52 0.03 0.89 800 5.72 0.04 0.96 820 7.36 0.05 1.00 840 8.49 0.06 1.37 表 4 扩孔试验孔径测试及扩孔率

Table 4. Test of the hole diameter of the hole expansion experiment and the hole expansion rate

退火温度/℃ 扩孔前直径

/mm破裂后圆孔直径/mm 扩孔率/% 测试值 均值 780 10.00 12.28 12.30 12.28 12.29 23 800 10.00 12.50 12.52 12.5 12.51 25 820 10.00 12.70 12.69 12.71 12.70 27 840 10.00 12.90 12.90 12.92 12.91 29 -

[1] Wang Li, Zhu Xiaodong, Zhang Pijun, et al. Lightweight automotive and advanced high-strength steel plates[J]. Baosteel Technology, 2003,(5):53−59. (王利, 朱晓东, 张丕军, 等. 汽车轻量化与先进的高强度钢板[J]. 宝钢技术, 2003,(5):53−59. doi: 10.3969/j.issn.1008-0716.2003.05.014 [2] Lu Jiangxin, Wang Li. Production and use of high strength automobile steel plates[J]. Automobile Technology and Materials, 2004,(2):1−6. (陆匠心, 王利. 高强度汽车钢板的生产与使用[J]. 汽车工艺与材料, 2004,(2):1−6. doi: 10.3969/j.issn.1003-8817.2004.02.001 [3] Bao Chengren, Li Zhong, An Zhe. Effect of cooling rate for continuous annealing on microstructure and properties of galvanizing dual phase steel[J]. Heat Treatment of Metals, 2010,35(1):103−105. (鲍成人, 李众, 安哲. 连续退火冷却速率对热镀锌双相钢组织性能的影响[J]. 金属热处理, 2010,35(1):103−105. [4] Ma Mingtu, Shi M F. Advanced high strength steel and it’s applications in automobile industry[J]. Iron and Steel, 2004,39(7):68−72. (马鸣图, Shi M F. 先进的高强度钢及其在汽车工业中的应用[J]. 钢铁, 2004,39(7):68−72. doi: 10.3321/j.issn:0449-749X.2004.07.018 [5] Tang Di, Mi Zhenli, Chen Yulai. Technology and research and development of advanced automobile steel abroad[J]. Iron and Steel, 2005,40(6):1−5. (唐荻, 米振莉, 陈雨来. 国外新型汽车用钢的技术要求及研究开发现状[J]. 钢铁, 2005,40(6):1−5. doi: 10.3321/j.issn:0449-749X.2005.06.001 [6] Kang Yonglin, Kuang Shuang, Yin Xiandong, et al. Research on progress and development[J]. Automobile Technology & Material, 2006,(5):1−5. (康永林, 邝 霜, 尹显东, 等. 汽车用双相钢板的开发与研究进展[J]. 汽车工艺与材料, 2006,(5):1−5. doi: 10.3969/j.issn.1003-8817.2006.05.001 [7] Zhao Zhengzhi, Niu Feng, Tang Di, et al. Microstructure and properties of ultra-high strength cold-rolled dual phase steel[J]. Journal of University of Science and Technology Beijing, 2010,32(10):1287−1291. (赵征志, 牛枫, 唐荻, 等. 超高强度冷轧双相钢组织与性能[J]. 北京科技大学学报, 2010,32(10):1287−1291. [8] Fang Gang, Ma Mingtu, Dongun Kim, et al. Three kinds of strength level of DP steel formability[J]. Engineering Sciences, 2014,(1):66−70. (方钢, 马鸣图, Dongun Kim, 等. 三种强度级别的双相钢成形性能的研究[J]. 中国工程科学, 2014,(1):66−70. doi: 10.3969/j.issn.1009-1742.2014.01.009 [9] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.Yong Qilong, The second phase in steel materials[M]. Beijing: Metallurgical Industry Press, 2006. [10] Zhang Xuehui, Zhu Guohui, Mao Weimin. Effect of interaction between recrystallization and transformation on microstructure of dual phase steel[J]. Iron & Steel, 2009,44(9):86−89. (张学辉, 朱国辉, 毛卫民. 再结晶和相变的交互作用对双相钢组织特征的影响[J]. 钢铁, 2009,44(9):86−89. doi: 10.3321/j.issn:0449-749X.2009.09.020 [11] 赵征志, 郗洪雷, 梁江涛, 等. 600 MPa级热镀锌双相钢性能优化[J]金属热处理, 2016, 44(3), 110-113.Zhao Zhengzhi, Xi Honglei, Liang Jiangtao, et al. Microstructure and Properties optimization of 600 MPa hot dipping DP steel[J]. Heat Teartment of Metals, 2016, 44(3), 110-113. [12] 邝春福, 郑之旺, 王礞. 退火温度对590 MPa级热镀锌双相钢组织与性能的影响. [J]金属热处理, 2016, 41(5), 133-136.Kuang Chunfu, Zheng Zhiwang, Wang Meng. Effect of soaking temperature on microstructure and properties of 590 MPa grade hot-dip galvanized dual phase steel. [J]. Heat Teartment of Metals, 2016, 41(5), 133-136. [13] Huang Qunfei, He Yanlin, Luo Juanjuan, et al. Effect of different volume fraction of martensite on deformation behavior of dual phase steels[J]. Iron & Steel, 2009,44(4):60−63. (黄群飞, 何燕霖, 罗娟娟, 等. 马氏体体积分数对双相钢变形行为的影响[J]. 钢铁, 2009,44(4):60−63. doi: 10.3321/j.issn:0449-749X.2009.04.014 -

下载:

下载: