Study on the microstructure of superalloy GH4065A solidified under high pressure

-

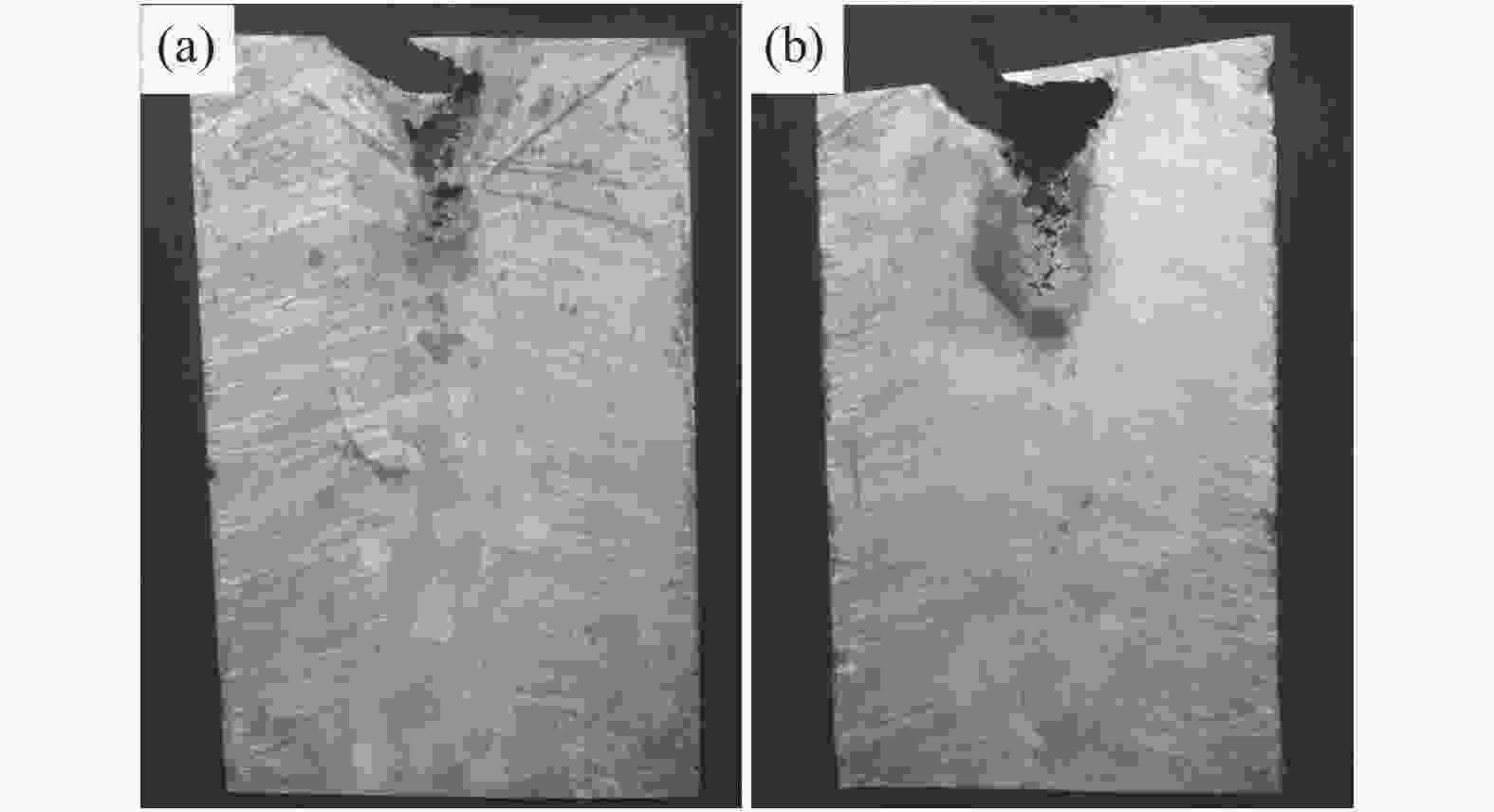

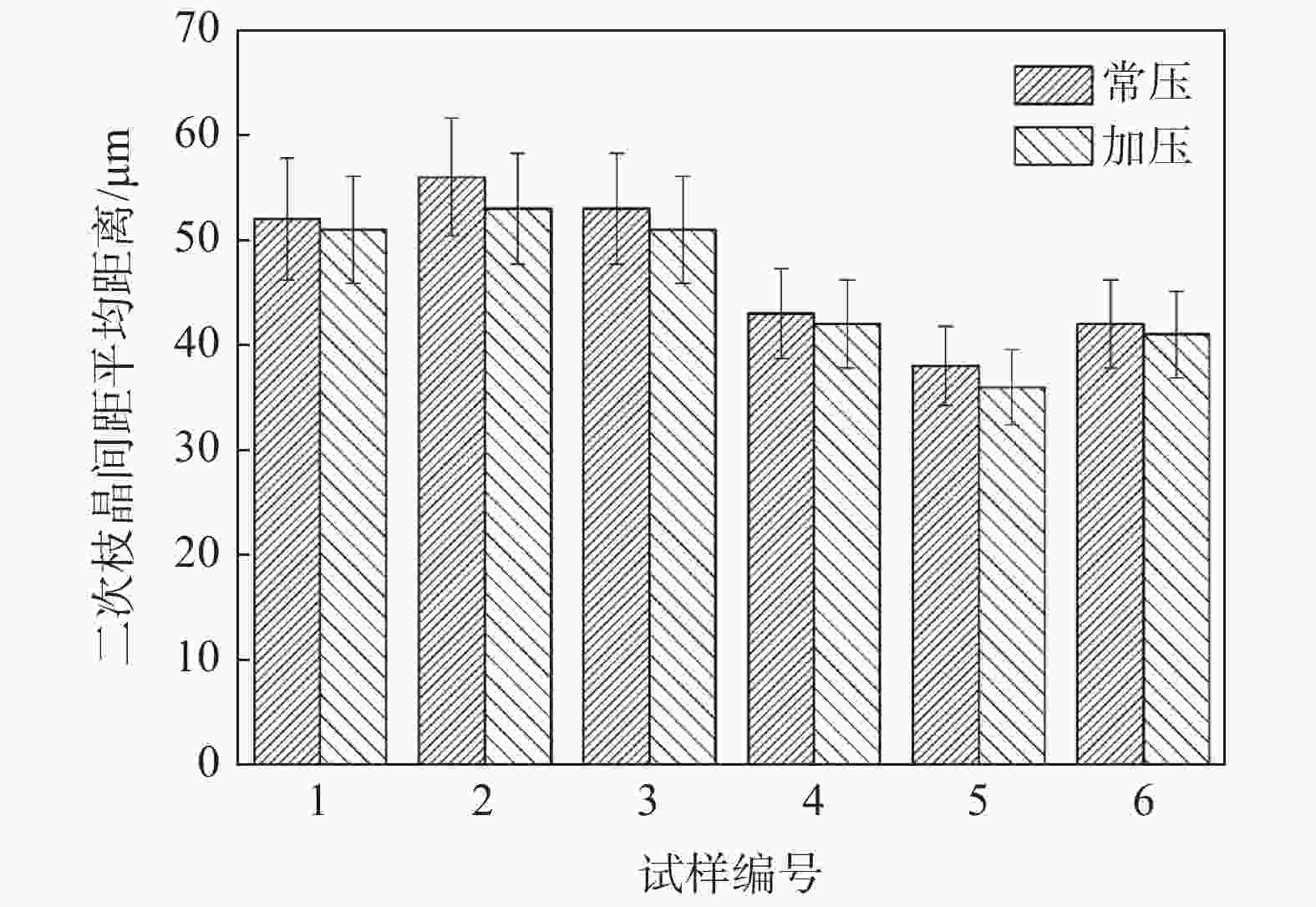

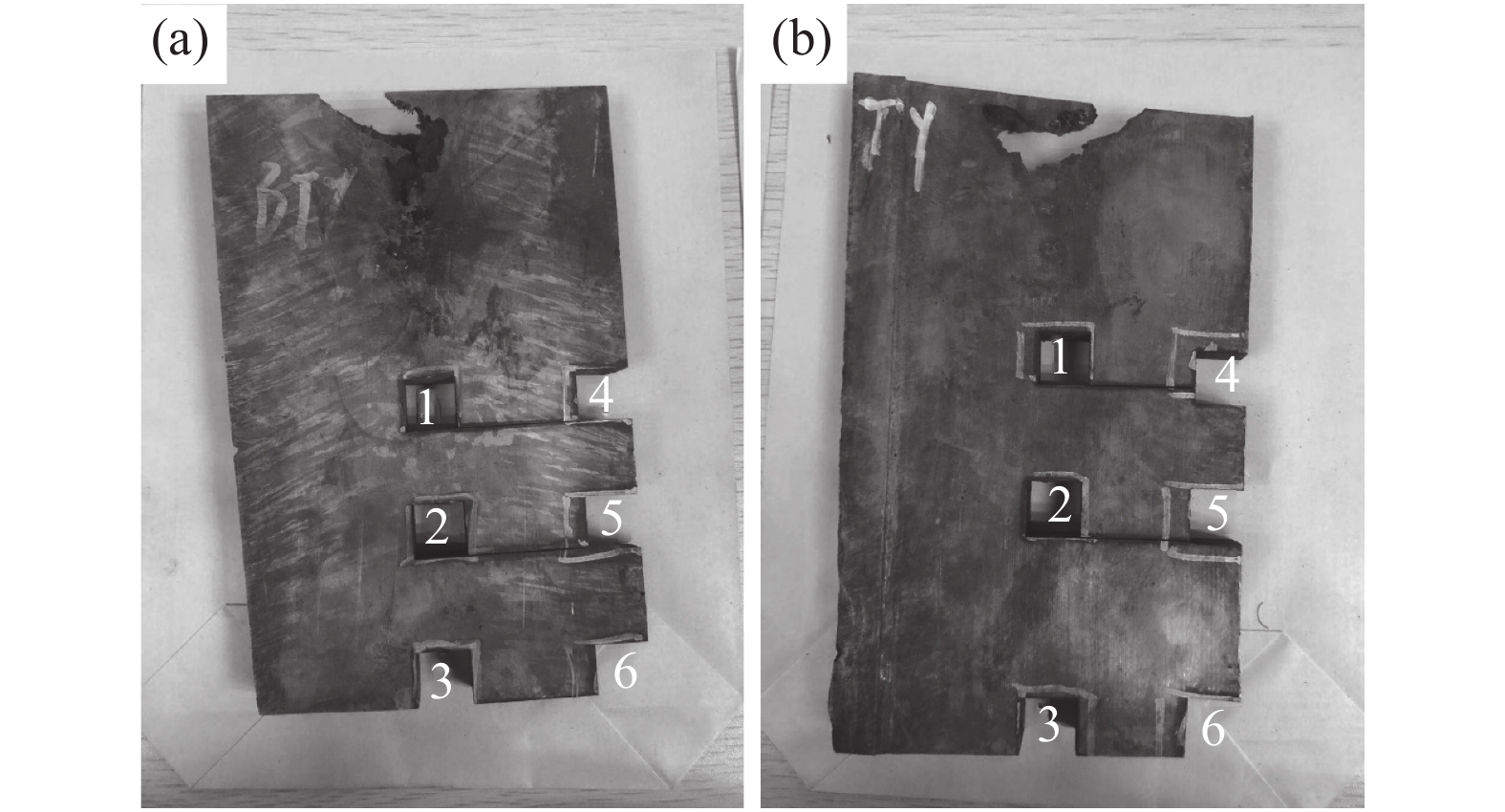

摘要: 通过OM和SEM观察了以常压和加压(2 MPa)两种凝固方式下的GH4065A铸锭显微组织,以分析加压对GH4065A铸锭凝固组织的影响。结果表明,常压下的铸态GH4065A有大量疏松缩孔,微观组织中主要析出相是γ’相,偏析最为严重的元素是Nb。在2 MPa下进行凝固,可以消除大量疏松缩孔,提高铸件的致密度,并使Nb元素的残余偏析指数大大降低;加压凝固可以使合金GH4065A的二次枝晶间距低于常压铸锭,这是由于加压使相变温度升高,从而增大熔体的相变驱动力,增加结晶数目,晶粒细化。上述结果表明加压凝固在高温合金中的巨大优势和应用前景,推广到更多的高温合金牌号,以发挥压力凝固的重要价值。Abstract: OM and SEM were used to observe the microstructure of GH4065A under two solidification modes: normal pressure and pressure (under 2 MPa) to analyze the effect of high pressure on the structure. The results show that the as-cast GH4065A structure under normal pressure has a large number of loose shrinkage cavities, the main precipitated phase in the microstructure is γ' phase, and the most severely segregated element is Nb. Solidification at 2 MPa can eliminate a large number of loose shrinkage cavities, increase the density of castings, and greatly reduce the residual segregation index of Nb element. At the same time, the pressure solidification can make the secondary dendrite spacing of alloy GH4065A lower than that of the normal pressure ingot. This is because the pressure increases the phase transition temperature, thereby increasing the phase transition driving force of the melt and refining the crystal grains. These results demonstrate that the great advantages and application prospects of pressurized solidification in superalloys, and it can be extended to other superalloy grades in order to exert the important value of pressurized solidification.

-

Key words:

- superalloy /

- pressurized solidification /

- microstructure /

- segregation characteristics

-

表 1 GH4065A合金的名义成分[7]

Table 1. Nominal chemical compositions of GH4065A alloy

% C Cr Co Fe Ti Al Nb Mo W B Zr Ni 0.011 16.0 13.0 1.0 3.7 2.1 0.7 4.0 4.0 0.015 0.05 余量 表 2 常压下凝固铸锭各元素不同位置偏析系数K

Table 2. Segregation coefficient K of various elements in different positions of non-pressurized solidified ingot

试样编号 Al Ti Cr Fe Co Ni Nb Mo W 1 1.04 2.34 0.86 0.64 0.91 1.02 5.62 1.19 0.60 2 1.08 2.35 0.90 0.87 0.90 1.01 3.86 1.17 0.63 3 0.84 2.98 0.84 1.04 0.89 0.97 11.38 1.40 0.60 4 0.97 1.79 0.96 1.04 0.95 0.99 3.38 1.14 0.78 5 0.97 1.42 0.95 1.05 0.96 1.00 2.06 1.09 0.83 6 0.91 2.94 0.85 0.74 0.86 0.94 14.02 1.22 0.88 表 3 加压凝固铸锭各元素不同位置偏析系数K

Table 3. Segregation coefficient K of various elements in different positions of pressurized solidification ingot

试样编号 Al Ti Cr Fe Co Ni Nb Mo W 1 1.09 2.19 0.94 0.99 0.89 1.00 3.75 1.23 0.61 2 1.05 2.16 0.92 0.98 0.91 0.98 3.77 1.20 0.63 3 1.11 2.42 0.85 0.49 0.87 1.03 4.78 1.19 0.55 4 0.93 1.66 0.98 0.90 0.98 0.99 2.86 1.19 0.77 5 0.99 1.61 0.93 0.80 0.95 1.01 2.33 1.12 0.73 6 0.92 2.87 0.87 0.82 0.89 0.96 8.04 1.31 0.78 -

[1] Stefanescu D M. Science and engineering of casting solidification[M]. New York: Kluwer Academic/Plenum Publishers, 2002. [2] Han Bo, Wu Sujun. Microstructural evolution of high manganese steel solidified under superhigh pressure[J]. Materials Letters, 2011:70(1):7-10. [3] 朱红春, 姜周华, 李花兵, 等. 加压技术在高品质特殊钢冶炼和凝固中的作用[J]. 钢铁, 2015, 50(11): 37-44.Zhu Hongchun, Jiang Zhouhua, Li Huabing, et al. Effect of pressurization technology on steel-making and solidification of high-grade special steels[J]. Iron and Steel, 2015, 50(11): 37-44. [4] Wang Meng, Zeng Jianmin, Huang Weidong. Adjusted pressure casting technique for precision casting of large-scale complicated & thin-wall components[J]. Foundry Technology, 2004,(5):353−358. (王猛, 曾建民, 黄卫东. 大型复杂薄壁铸件高品质高精度调压铸造技术[J]. 铸造技术, 2004,(5):353−358. doi: 10.3969/j.issn.1000-8365.2004.05.015 [5] He Shuxian, Liu Yahui, Wang Jun, et al. Research progress of metals and alloys pressurized solidification[J]. Foundry Technology, 2017,38(6):1253−1257. (何树先, 刘雅辉, 王俊, 等. 金属与合金加压凝固研究进展[J]. 铸造技术, 2017,38(6):1253−1257. [6] Ghanti S B. The effects of solidification under pressure on properties of cast aluminum alloys[D]. Alabama: The University of Alabama at Birmingham, 2011. [7] Zhao Guangpu, Huang Shuo, Zhang Beijiang, et al. Microstructure control and mechanical properties of the newest nickel-based wrought superalloy GH4065A[J]. Journal of Iron and Steel Research, 2015,27(2):37−44. (赵光普, 黄烁, 张北江, 等. 新一代镍基变形高温合金GH4065A的组织控制与力学性能[J]. 钢铁研究学报, 2015,27(2):37−44. [8] Batyshev K A. Casting of aluminum alloys with pressure crystal lization. Part 2[J]. Met Sci Heat Treat, 2012,54:55−62. doi: 10.1007/s11041-012-9454-y [9] 苏志权, 孟照亮, 孙昌建. 真空增压铸造技术及其应用前景[J]. 特种铸造及有色合金, 2003(5): 38-40.Su Zhiquan, Meng Zhaoliang, Sun Changjian. Vacuum pressurized casting technology and its application prospects[J]. Special Casting & Nonferrous Alloys, 2003(5): 38-40. [10] Huang Shuo, Zhang Beijiang, Tian Qiang, et al. Isothermal and static oxidation behavior of superalloy GH4065A[J]. Journal of Iron and Steel Research, 2016,28(7):55−60. (黄烁, 张北江, 田强, 等. 高温合金GH4065A的恒温静态氧化行为[J]. 钢铁研究学报, 2016,28(7):55−60. [11] Zhang Beijiang, Zhao Guangpu, Zhang Wenyun, et al. Investigation of high performance disc alloy GH4065 and associated advanced processing techniques[J]. Acta Metallurgica Sinica, 2015,51(10):1227−1234. (张北江, 赵光普, 张文云, 等. 高性能涡轮盘材料GH4065及其先进制备技术研究[J]. 金属学报, 2015,51(10):1227−1234. [12] Tomasz Wojcik, Markus Rath, Ernst Kozeschnik. Characterisation of secondary phases in Ni-base superalloy Rene 65[J]. Materials Science and Technology, 2018, 34(13). [13] Wang Zixing, Huang Shuo, Zhang Beijiang, et al. Study on freckle of a high-alloyed GH4065 nickel base wrought superalloy[J]. Acta Metallurgica Sinica, 2019,55(3):417−426. (王资兴, 黄烁, 张北江, 等. 高合金化GH4065镍基变形高温合金点状偏析研究[J]. 金属学报, 2019,55(3):417−426. [14] Sosenushkin E N, Frantsuzova L S, Kozlova E M. Effect of pressure and temperature factors on the solidification of cast iron and its structure in liquid forging[J]. Metal Science & Heat Treatment, 2015. -

下载:

下载: