Thermodynamic control of pearlite lamellar sheet spacing and its effect on mechanical properties of steel

-

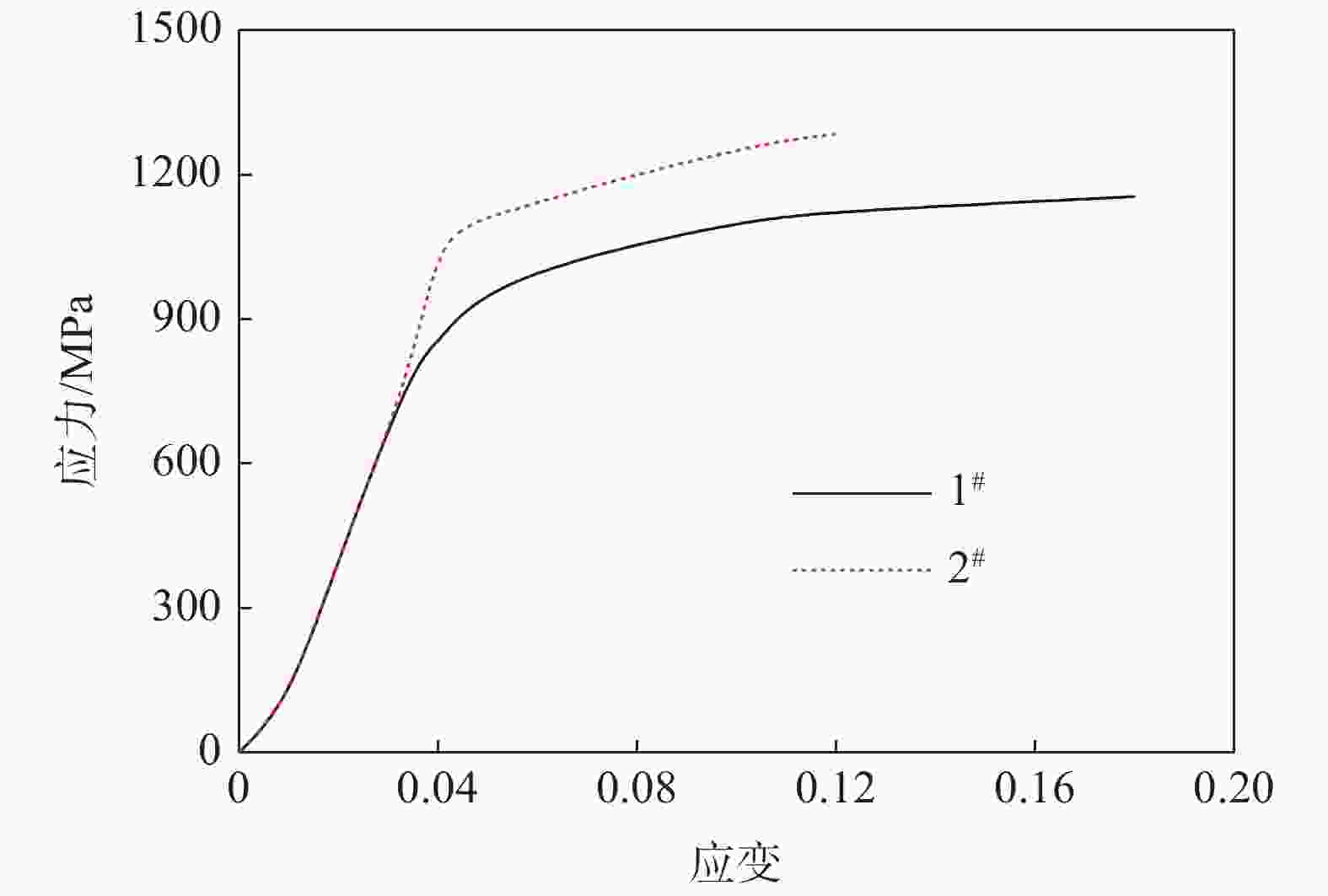

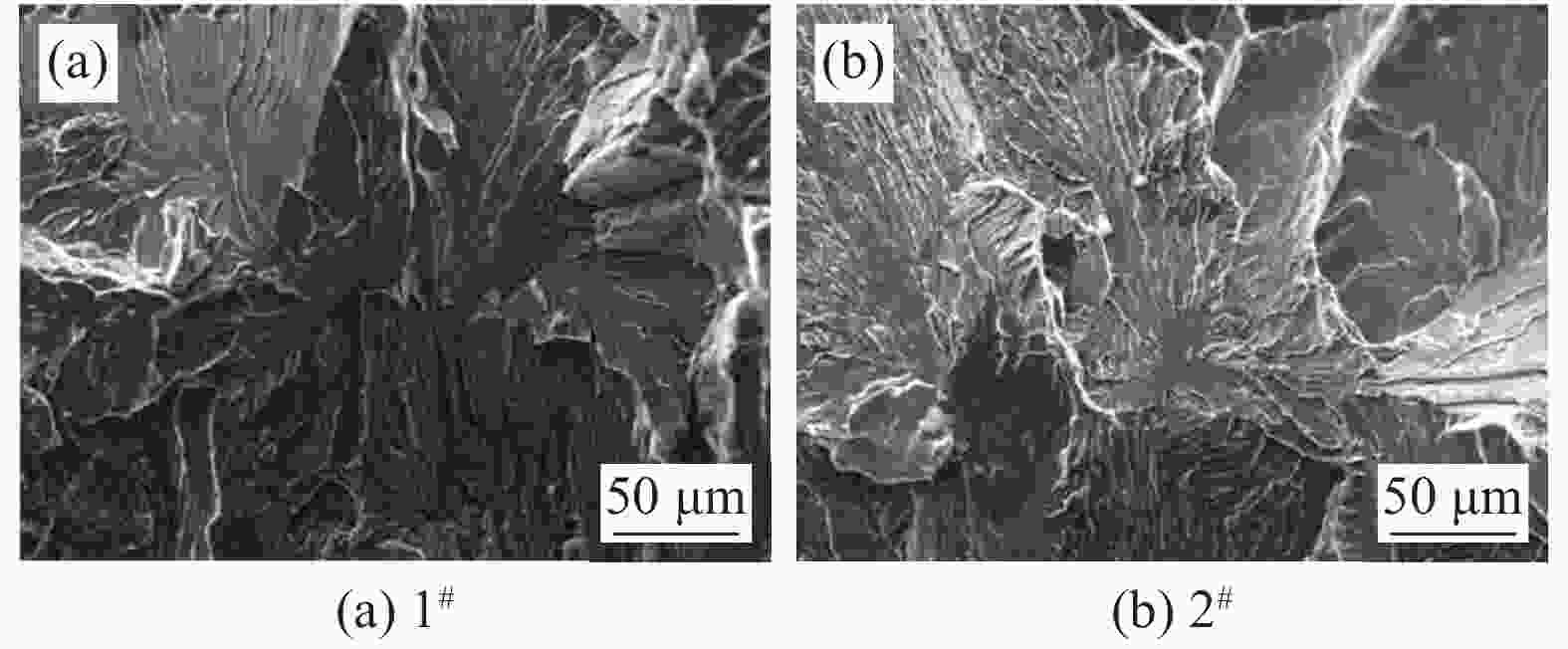

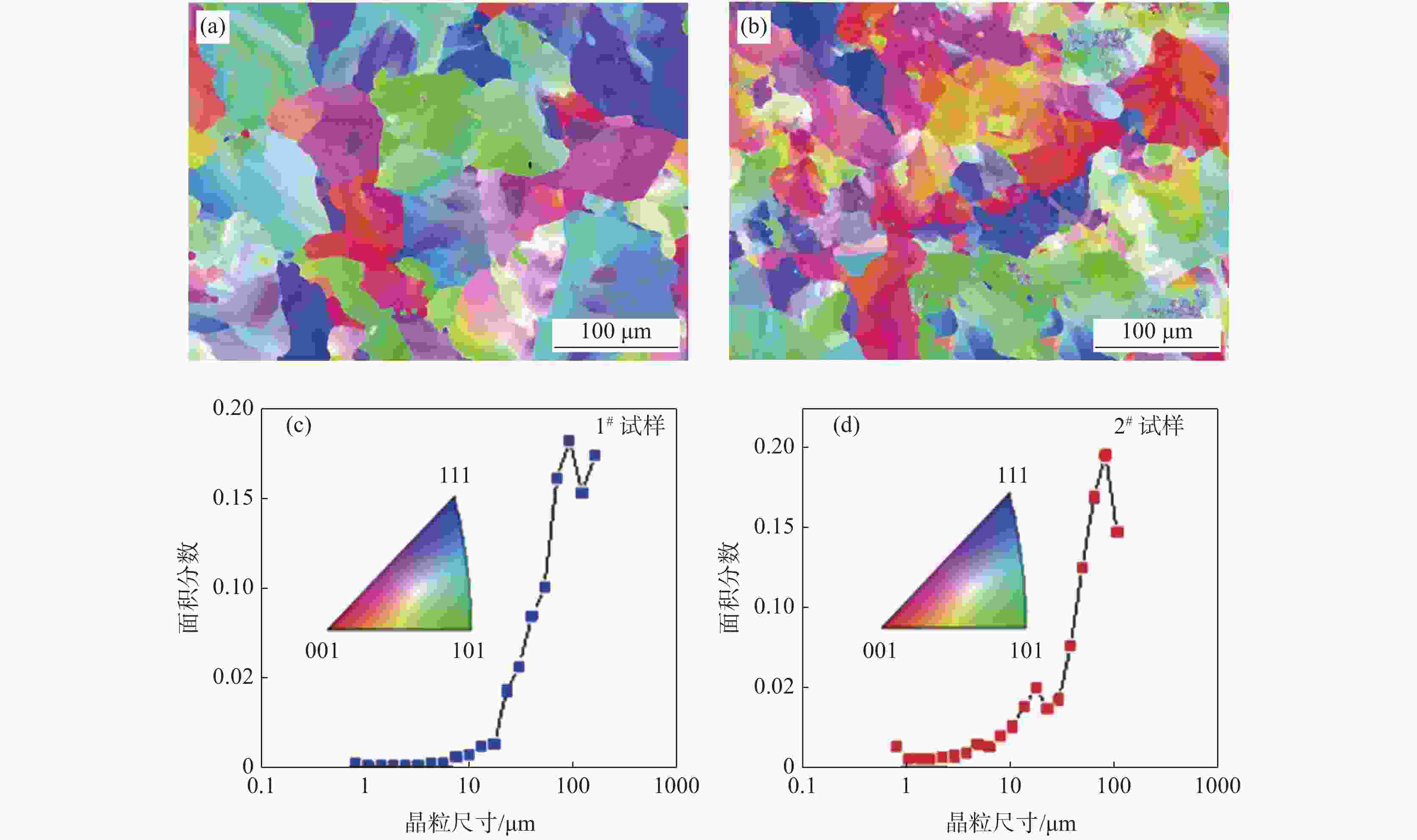

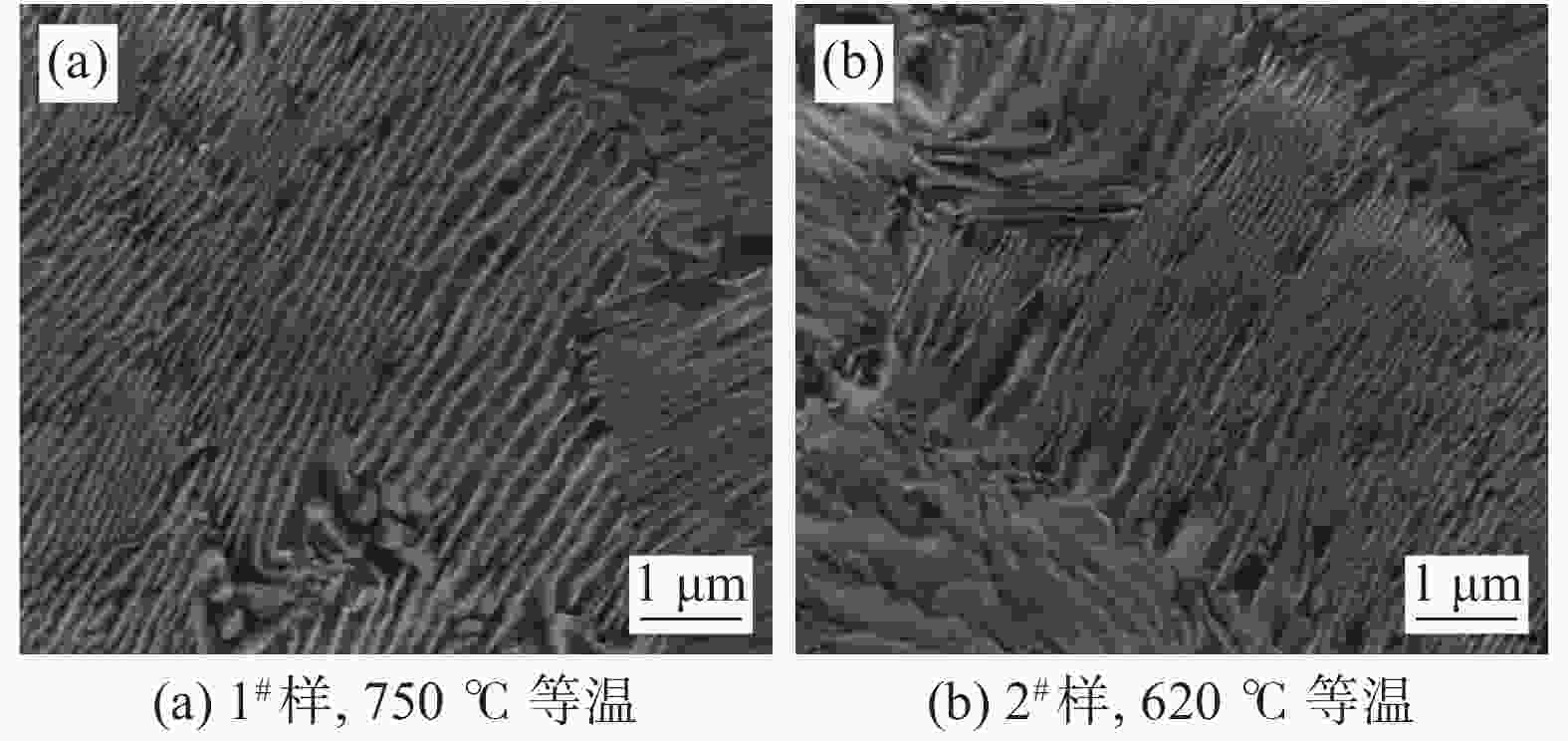

摘要: 利用实验室炼钢、轧制、热处理等手段获得了成分一致但珠光体片间距不同的两种材料,利用扫描电镜和万能试验机对比研究了珠光体片间距与力学性能之间的关系,得到以下结论:试验材料的珠光体片层间距的倒数Sp−1(μm−1)与其珠光体转变过冷度∆T(℃)满足线性关系Sp−1=9.0201+0.03358∆T,可知该材料进行550 ℃等温处理可获得理论上最细珠光体片间距(约61 nm)。随着极细珠光体片间距的细化,由105 nm降至72 nm时,材料强度上升的同时会出现塑性显著恶化,其极限变形应变值由0.18降至0.12,这与传统细晶强化理论不一致,其原因是细化的珠光体片层抑制了位错的自由运动。Abstract: A pearlite steel was prepared via laboratory steelmaking, and then after rolling and heat treatment to obtain two different samples with different pearlite lamellar spacing. The mechanical properties and microstructures of the materials were observed by scanning electron microscopy and universal testing machine. Results show that the reciprocal Sp−1(μm−1) of pearlite lamellae and transformation super cooling degree of pearlite ∆T(℃) satisfy the linear relationship of Sp−1=9.0201+0.03358∆T. This indicates that the theoretical minimum pearlite lamellae spacing(~61 nm) can be obtained by isothermal treatment at 550 ℃. With the thinning of the spacing between the very fine pearlite lamellar( from 105 to 72 nm), the strength increases but ductility will deteriorate significantly, and the ultimate deformation strain will decrease from 0.18 to 0.12. This result conflicts with the traditional grain refinement strengthening theory. The reason is that the refined pearlite lamellar restrains the free movement of dislocations.

-

Key words:

- high strength steel /

- pearlite /

- lamellar spacing /

- strength /

- ductility /

- EBSD

-

表 1 试验材料主要化学成分

Table 1. Main chemical compositions of test materials

% C Si Mn P S Cr Mo Co 0.72 1.35 0.55 0.009 0.012 0.80 0.35 3.02 表 2 试样的力学性能结果

Table 2. Mechanical properties of the specimens with different pearlite lamellar spacing

编号 平均珠光体片间距/nm 屈服强度/MPa 抗拉强度/MPa 伸长率/% 1# 105 790 1155 17.7 2# 72 1075 1285 11.6 -

[1] 刘永铨. 钢的热处理[M]. 北京: 冶金工业出版社, 1981.Liu Yongquan. Heat treatment of steel[M]. Beijing: Metallurgical Industry Press, 1981. [2] Gong Shuai, Ren Xuechong, Ma Yingxia, et al. Effect of heat-treatment on microstructure and fracture toughness of high-speed railway wheel steel[J]. Transactions of Materials and Heat Treatment, 2015,36(4):150−155. (龚帅, 任学冲, 马英霞, 等. 热处理工艺对高速车轮钢显微组织和断裂韧性的影响[J]. 材料热处理学报, 2015,36(4):150−155. [3] Yao Xusheng, Liu Yandong, Zuo Liang. Quantitative texture analysis of cold drawn pearlitic steel wires[J]. Iron and Steel, 2008,43(3):65−68. (姚旭升, 刘沿东, 左良. 冷拔珠光体钢丝帘线中织构演变的定量研究[J]. 钢铁, 2008,43(3):65−68. doi: 10.3321/j.issn:0449-749X.2008.03.015 [4] 吴礼文, 唐延川, 赵自飞, 等. 奥氏体化和等温转变温度对高碳钢盘条组织性能的影响[C]// 中国金属学会宝钢学术年会. 上海: 中国金属学会, 2015: 58−65.Wu Liwen, Tang Yanchuan, Zhao Zifei, et al. Effect of austenitizing and isothermal transformation temperature on microstructure and properties of high carbon steel wire rod[C]// China Society of Metals, Baosteel Academic Annual Meeting. Shanghai: China Society of Metals, 2015: 58-65. [5] Wu Qinghui, Yang Zhongmin, Chen Ying, et al. Effect of transformation temperature on microstructure and properties of fully pearlite rail steel[J]. Hot Working Technology, 2012,41(10):67−70. (吴庆辉, 杨忠民, 陈颖, 等. 相变温度对珠光体轨钢组织和性能的影响[J]. 热加工工艺, 2012,41(10):67−70. doi: 10.3969/j.issn.1001-3814.2012.10.021 [6] Jiang Tao, Lei Xinrong, Wu Hongdan, et al. Effect of heat treatment on hardness of carbon steel[J]. Hot Working Technology, 2011,(4):167−169. (蒋涛, 雷新荣, 吴红丹, 等. 热处理工艺对碳钢硬度的影响[J]. 热加工工艺, 2011,(4):167−169. doi: 10.3969/j.issn.1001-3814.2011.04.053 [7] Li Ping, Wang Lei, Zhou Qingfeng. Formation reasons and countermeasures of cementite network in the center of 82B wire rods[J]. Journal of Iron and Steel Research, 2014,26(9):33−36. (李平, 王雷, 周青峰. 82B中心网状渗碳体产生原因及改善方法[J]. 钢铁研究学报, 2014,26(9):33−36. [8] Kavishe F P, Baker T J. Effect of prior austensite grian size and pearlite interlamellar spacing on strength and fracture toughness of eutectoid rail[J]. Materials Science and Technology, 1986,2(8):816−822. doi: 10.1179/mst.1986.2.8.816 [9] Zhang C L, Liu Y Z, Zhou L Y. Influence of pearlite interlamellar spacing on the deformation behavior and fracture characteristics in spring steel 60Si2MnA[J]. Appl. Mech. Mater., 2014,456:388−391. [10] Lu Xiuyu, Sun Ruji, Jiang Yuedong, et al. Study on hot simulation of isothermal lead bath for high strength wire rod[J]. Hot Working Technology, 2017,(12):219−221. (鲁修宇, 孙汝继, 蒋跃东, 等. 高强线材等温铅浴热模拟研究[J]. 热加工工艺, 2017,(12):219−221. [11] 张云祥. 高强度线材热加工的组织演变和性能预报系统研究[D]. 武汉: 华中科技大学, 2010: 5-15.Zhang Yunxiang. Study on microstructure evolution and performance prediction system of high strength wire rod during hot working[D]. Wuhan: Huazhong University of Science and Technology, 2010: 5-15. [12] Zhu Shili, Hu Wenhao. Research on embrittlement mechanisms of lamellar pearlite in eutectoid steel[J]. Foundry Technology, 2010,31(5):584−588. (朱施利, 胡文豪. 共析钢中片状珠光体脆化钢材的机理研究[J]. 铸造技术, 2010,31(5):584−588. [13] Chen Xianzhong, Yan Guanglin, Xu Wei, et al. Development of high toughness and super-high strength zinc electro-plating steel wire for rope[J]. Hot Working Technology, 2009,(6):11−13. (陈贤忠, 鄢光霖, 徐伟, 等. 强韧性特高强度镀锌制绳钢丝的研制[J]. 热加工工艺, 2009,(6):11−13. -

下载:

下载: