Industrial practice of deep dephosphorization technology with less slag in converter

-

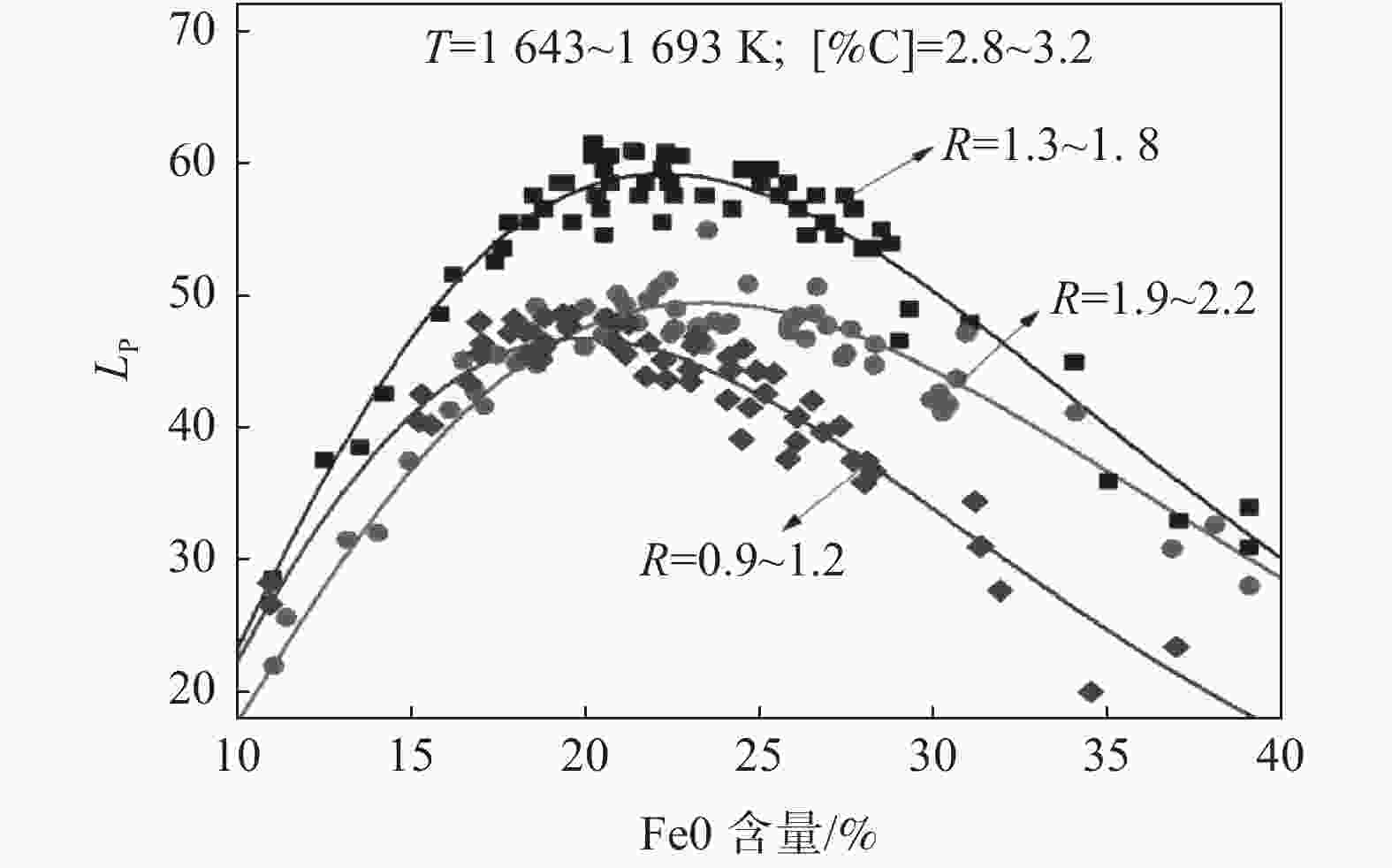

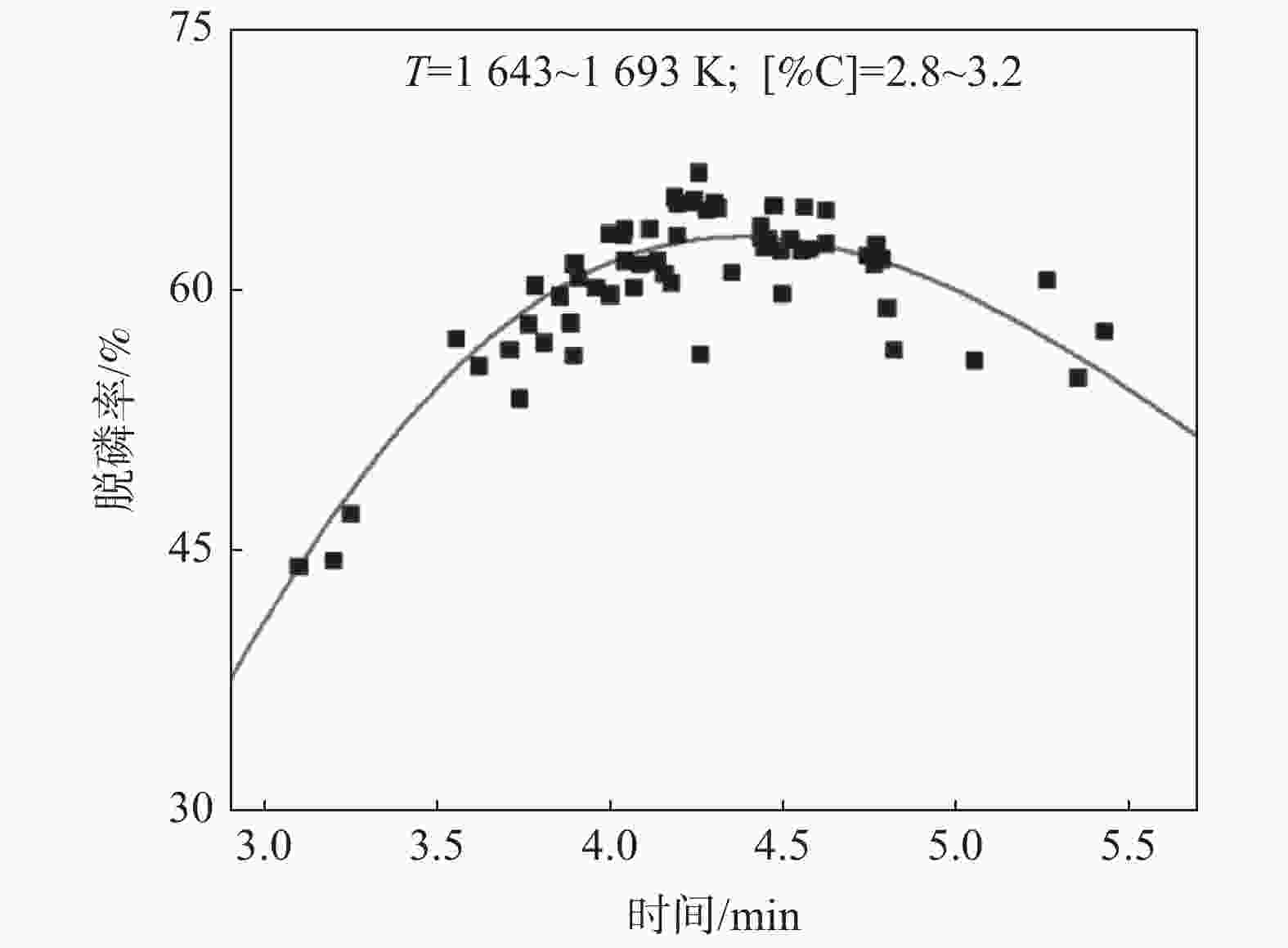

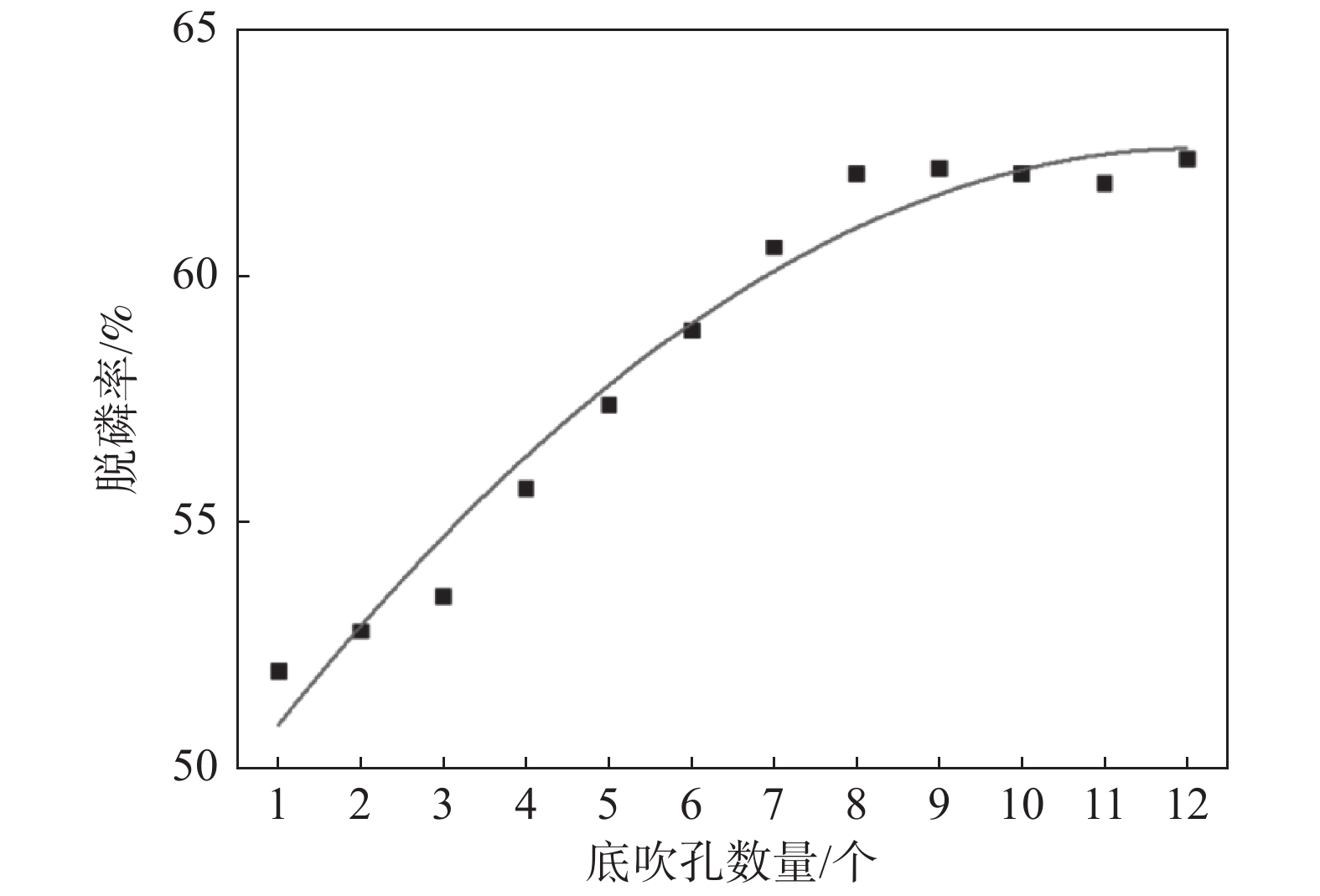

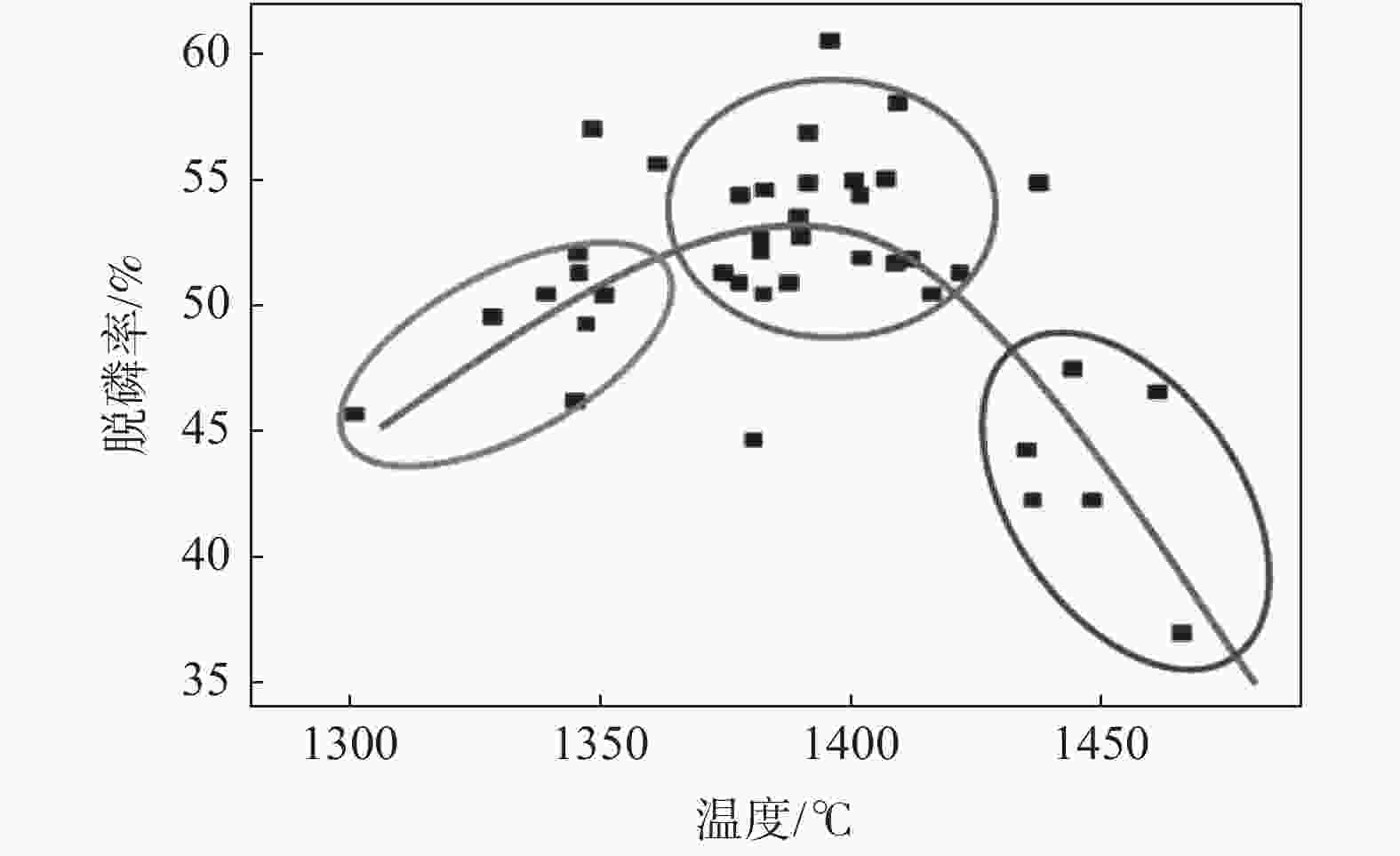

摘要: 在梅钢250 t转炉上进行了脱磷期少渣深脱磷工业实践,研究了冶炼温度、炉渣成分、吹炼制度等参数对脱磷的影响规律。实践表明,转炉冶炼脱磷期结束时适宜的熔池温度为1 370~1 420 ℃、炉渣碱度为1.3~1.8、渣中FeO含量为18%~28%;合适的吹氧量为总氧气流量的24%~28%、废钢比为12%~16%、底吹孔数在8个以上;改进后,梅钢转炉冶炼脱磷期的平均脱磷率由不足50%提高至63.2%,实现了少渣工艺的稳定运行,2012年至2019年,少渣冶炼比例由0提高至83.7%,吨钢石灰消耗由53.3 kg降低至23.2 kg,降低了56.5%。Abstract: In this paper, the industrial practice of deep dephosphorization with less slag in dephosphorization period was carried out on 250 ton converter of Meigang. The effects of smelting temperature, slag composition and blowing system on phosphorus content in molten steel were studied. The practice shows that at the end of the dephosphorization period of converter smelting, the appropriate bath temperature is 1370~1420 ℃, the basicity of slag is 1.3~1.8, and the FeO content in slag is 18%~28%; The suitable oxygen blowing amount in the dephosphorization period of converter smelting is 24%~28% of the total oxygen flow, the scrap ratio is controlled at 12%~16%, and the number of bottom blowing holes is more than 8. Through above parameters optimization, average dephosphorization rate in converter smelting dephosphorization period of Meigang was increased from less than 50% to 63.2%, and finally achieved stable operation of the less slag process. During period from year 2012 to 2019, the less slag smelting proportion was increased from 0 to 83.7%, and the lime consumption per ton of steel was reduced from 53.3 kg to 23.2 kg, decrease by 56.5%.

-

Key words:

- converter /

- less slag smelting /

- dephosphorization

-

表 1 梅钢250 t转炉冶炼参数

Table 1. Smelting parameters of 250 t converter in Meigang

氧枪马赫数 氧枪喷孔/个 氧枪供氧强度/(m3·t−1·min−1) 底吹孔数/个 底吹供气强度/(m3·t−1·min−1) 废钢比/% 2.05~2.10 5 3.4~3.6 12 0.03~0.10 0~25 表 2 铁水成分

Table 2. Hot metal compositions

w/% 温度/℃ C Si Mn P S 4.3~4.7 0.1~0.8 0.14~0.20 0.1~0.14 0.013~0.065 1200~1450 表 3 转炉主要渣料成分

Table 3. Compositions of main slag material for converter

名称 w/% 烧损/% CaO SiO2 MgO TFe 石灰 88~95 2~5 3~8 轻烧白云石 55~60 2~5 34~40 4~10 矿石 3~5 62~65 2~9 表 4 典型半钢钢水成分

Table 4. Typical molten steel composition of semi steel

% C Si Mn P S 2.8 0.012 0.052 0.055 0.009 表 5 典型脱磷渣成分

Table 5. Typical dephosphorization slag composition

% CaO SiO2 Al2O3 Fe2O3 MnO MgO P2O5 36.28 21.27 2.17 18.75 5.76 6.54 4.46 -

[1] 中国钢铁工业年鉴编委会. 中国钢铁工业年鉴2020[M]. 北京: 冶金工业出版社, 2020.The Editorial Board of China Steel Yearbook. China steel yearbook 2020[M]. Beijing: Metallurgical Industry Press, 2020 [2] Xia Yunjin, Guo Xin, Ma Weijie, et al. Effect of change of slag phase on dephosphorization of “double-slag+slag-remaining” steelmaking technology[J]. Journal of Iron and Steel Research, 2018,30(6):434−440. (夏云进, 郭鑫, 马伟杰, 等. 炉渣物相变化对“双渣+留渣”冶炼脱磷的影响研究[J]. 钢铁研究学报, 2018,30(6):434−440. [3] Inoue R, Suito H. Phosphorous partition between 2CaO·SiO2 particles and CaO-SiO2-FetO slags[J]. ISIJ International, 2006,46(2):174−179. doi: 10.2355/isijinternational.46.174 [4] Suito H, Inoue R. Behavior of phosphorous transfer from CaO-FetO-P2O5(-SiO2) slag to CaO particles[J]. ISIJ International, 2006,46(2):180−187. doi: 10.2355/isijinternational.46.180 [5] Inoue R, Suito H. Mechanism of dephosphorization with CaO-SiO2-FetO slags containing mesoscopic scale 2CaO·SiO2 particles[J]. ISIJ International, 2006,46(2):188−194. doi: 10.2355/isijinternational.46.188 [6] Kashiwaya Y, Son P K. Growing process of crystal precipitated in the dephosphorization slag and phosphorous partition between crystal and liquid[J]. Tetsu-to-Hagané, 2009,95(3):251−257. [7] Fukagai S, Hamano T , Tsukihashi F. Formation reaction of phosphate compound in multi phase flux at 1573 K[J]. ISIJ Int. 2007, 47(1): 187-189. [8] Saito R, Matsuura H, Nakask K, et al. Microscopic formation mechanisms of P2O5-containing phase at the interface between solid CaO and molten slag[J]. Tetsu-to-Hagané, 2009,95(3):258−267. [9] Xia Y J, Li J, Fan D D, et al. Effects of interfacial oxygen potential and slag phase changing during slag formation process on dephosphorization behavior[J]. ISIJ Int., 2019,59(9):1519−1526. doi: 10.2355/isijinternational.ISIJINT-2019-052 [10] Xia Y J, Li J, Fan D D, et al. Effect of adding mode of iron oxide on dephosphorization behavior with the recycling of decarburization slag[J]. Steel Research Int., 2018,89(2):1800104. [11] Wang Xinhua, Zhu Guosen, Li Haibo, et al. Investigation on “slag-remaining+double-slag” BOF steelmaking technology[J]. China Metallurgy, 2013,23(4):40−46. (王新华, 朱国森, 李海波, 等. 氧气转炉“留渣+双渣”炼钢工艺技术研究[J]. 中国冶金, 2013,23(4):40−46. [12] 陈家祥. 钢铁冶金学[M]. 北京: 冶金工业出版社, 2005: 82.Chen Jiaxiang. Ferrous metallurgy[M]. Beijing: Metallurgical Industry Press, 2005: 82. -

下载:

下载: