Research progress of notched specimen fatigue

-

摘要: 综述了环境因素、载荷方式、工件几何形状以及工艺处理对缺口件疲劳行为的影响,并介绍了对缺口件疲劳寿命分析的方法和强化缺口件疲劳性能的工艺方法。对国内外有限元软件在研究缺口件疲劳行为方面的应用进行了简述,通过有限元模拟可以获得危险位置的应力应变分布,并将有限元模拟结果和寿命预测模型相结合,从而对缺口件疲劳寿命进行有效预测。最后总结目前研究成果,对缺口件研究的方向和前景进行展望。Abstract: In this paper, the effects of environmental factors, loading mode, workpiece geometry and technological treatment on fatigue behavior of notched parts are summarized, and the methods of fatigue life analysis of notched parts and the technological methods of strengthening fatigue performance of notched parts are introduced. The application of finite element software on studying the fatigue behavior of notched parts at home and abroad is briefly introduced. Stress and strain distribution of the dangerous position can be obtained through finite element simulation, and the fatigue life of notched parts can be effectively predicted by combining simulation results with the life prediction model. Finally, the current research progress are summarized and the research direction and prospect of notched parts are proposed.

-

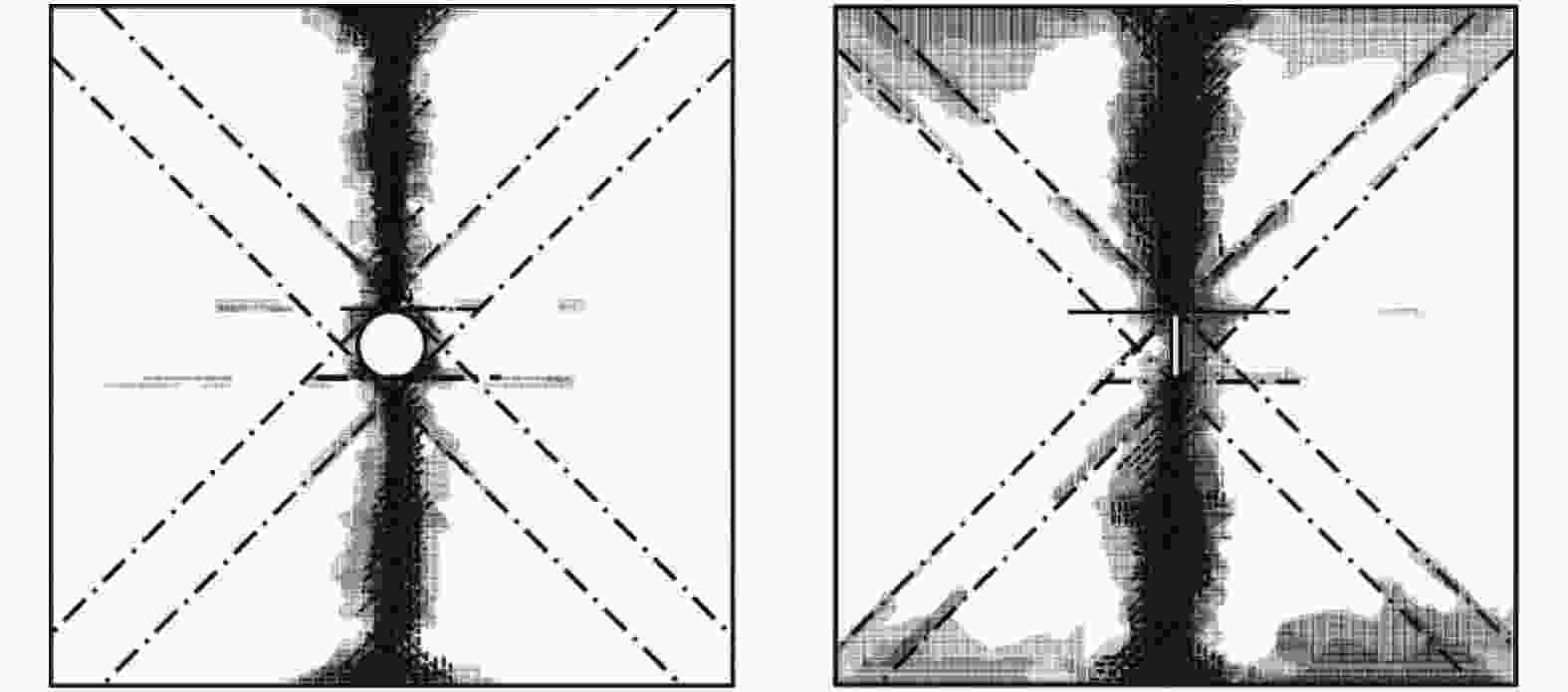

图 2 圆孔层合板与裂缝层合板破坏示意[41]

Figure 2. Schematic diagram of circular hole laminated plate and cracked laminated plate failure

表 1 25MnTiBR钢渗碳,碳氮共渗及表面滚压的疲劳强度[50]

Table 1. Fatigue strength of carburizing, carbonitriding and surface rolling of 25MnTiBR steel

热处理制度 光滑件疲劳极限 缺口疲劳极限 热处理方式 回火温度/℃ (未滚压)/MPa 未滚压/MPa 滚压/MPa 提高比例/% 渗碳,未回火 820 600 1070 78.3 渗碳,回火 200 700 480 1060 120.8 碳氮共渗,回火 180 840 550 1000 81.8 -

[1] Luo Yunrong, Wang Qingyuan, Fu Lei, et al. Effect of seismic frequency on ultra-low cycle fatigue behavior of Q235 steel structure materials[J]. Experimental Mechanics, 2018,33(5):743−750. (罗云蓉, 王清远, 付磊, 等. 地震频率对Q235钢结构材料超低周疲劳行为的影响[J]. 实验力学, 2018,33(5):743−750. [2] Huang Ning, Li Suyun. Fatigue behavior of notched parts[J]. Journal of Nanchang University (Engineering & Technology Edition), 2018,40(2):174−178. (黄宁, 李素云. 缺口件的疲劳行为[J]. 南昌大学学报(工科版), 2018,40(2):174−178. [3] Zheng Ziming. Analysis of failure of steel plate parts caused by stress concentration[J]. Automotive Technology and Materials, 2017,(10):32−35. (郑子明. 应力集中导致钢板零件失效的问题分析[J]. 汽车工艺与材料, 2017,(10):32−35. doi: 10.3969/j.issn.1003-8817.2017.10.007 [4] Chaves V, Navarro A. Fatigue limits for notches of arbitrary profile[J]. International Journal of Fatigue, 2013,48:68−79. doi: 10.1016/j.ijfatigue.2012.10.004 [5] Gladskyi M, Fatemi A. Notched fatigue behavior including load sequence effects under axial and torsional loadings[J]. International Journal of Fatigue, 2013,55:43−53. doi: 10.1016/j.ijfatigue.2013.05.003 [6] Singh, Mn K. Notch tip stress strain analysis in bodies subjected to non-proportional cyclic loads microform[D].Canada Waterloo:University of Waterloo , 1998. [7] Li Zheng, Xiong Changhong, Xu Jiandong, et al. Analysis of notch fatigue strength of aluminum alloy wire used for cable in wet environment[J]. Casting Technology, 2015,36(8):1950−1952. (李征, 熊长虹, 许建东, 等. 电缆用铝合金导线在潮湿环境下的缺口疲劳强度分析[J]. 铸造技术, 2015,36(8):1950−1952. [8] 冯先锋, 叶序斌, 叶笃毅, 等. 潮湿空气环境下2024-T351铝合金的缺口疲劳强度[J]. 材料科学与工程学报, 2014, 32(3): 417-420.Feng Xianfeng, Ye Xubin, Ye Duyi, et al. Notch fatigue strength of aluminum alloy 2024-T351 in humid air [J]. Journal of Materials Science and Engineering, 2014, 32(3): 417-420. [9] Wu Ximao, Xie Guangzong, Zhang Guangping. Microstructure and notched fatigue strength of X20CrMoV12-1 steel[J]. Journal of Materials Research, 2008,(2):220−224. (吴细毛, 谢光宗, 张广平. X20CrMoV12-1钢的组织结构和缺口疲劳强度[J]. 材料研究学报, 2008,(2):220−224. doi: 10.3321/j.issn:1005-3093.2008.02.022 [10] Hu Lin, Gao Zhikun. Study on the genesis of crack and equiaxial crystal in rotor blade of DD6 single crystal alloy turbine[J]. Aeroengine, 2018,44(6):91−96. (胡霖, 高志坤. DD6单晶合金涡轮转子叶片裂纹与内腔等轴晶成因研究[J]. 航空发动机, 2018,44(6):91−96. [11] Shi Zhenxue, Li Jiarong, Han Mei, et al. Notched fatigue properties of DD6 single crystal superalloy[J]. Journal of Iron and Steel Research, 2011,23(S2):345−348. (史振学, 李嘉荣, 韩梅, 等. DD6单晶高温合金的缺口疲劳性能[J]. 钢铁研究学报, 2011,23(S2):345−348. [12] Yang K, Zhong B, Huang Q, et al. Stress ratio effect on notched fatigue behavior of a Ti-8Al-1Mo-1V alloy in the very high cycle fatigue regime[J]. International Journal of Fatigue, 2018,116:80−89. doi: 10.1016/j.ijfatigue.2018.05.032 [13] Htoo A T, Miyashita Y, Otsuka Y, et al. Variation of local stress ratio and its effect on notch fatigue behavior of 2024-T4 aluminum alloy[J]. International Journal of Fatigue, 2016,88:19−28. doi: 10.1016/j.ijfatigue.2016.03.001 [14] Blasón S, Rodríguez C, Belzunce J, et al. Fatigue behaviour improvement on notched specimens of two different steels through deep rolling, a surface cold treatment[J]. Theoretical and Applied Fracture Mechanics, 2017,92:223−228. doi: 10.1016/j.tafmec.2017.08.003 [15] Xi Wei. Sensitivity analysis of fatigue life distribution of notched parts[J]. Science, Technology and Engineering, 2015,15(14):97−101. (奚蔚. 缺口件疲劳寿命分布的敏度分析[J]. 科学技术与工程, 2015,15(14):97−101. doi: 10.3969/j.issn.1671-1815.2015.14.018 [16] Berto F, Razavi S M J, Ayatollahi M R. Fatigue behaviour of notched specimens made of 40CrMoV13.9 under multiaxial loading[J]. Procedia Structural Integrity, 2017,3:85−92. doi: 10.1016/j.prostr.2017.04.012 [17] Nicoletto G. Directional and notch effects on the fatigue behavior of as-built DMLS Ti6Al4V[J]. International Journal of Fatigue, 2018,106:124−131. doi: 10.1016/j.ijfatigue.2017.10.004 [18] Huang Wei, Chen Wei, Pan Hui, et al. Effect of external damage on high cycle fatigue strength of titanium alloy TC4[J]. Mechanical Strength, 2014,36(3):357−362. (黄伟, 陈伟, 潘辉, 等. 外物损伤对钛合金TC4高周疲劳强度的影响研究[J]. 机械强度, 2014,36(3):357−362. [19] Mo Lihua, Gao Jie, Li Fengqi. Study on artificial notch fatigue test of high strength cylinder[J]. Pressure Vessel, 2005,(9):13−15,12. (莫立华, 高杰, 李凤岐. 高强度钢瓶人工缺口疲劳试验的研究[J]. 压力容器, 2005,(9):13−15,12. doi: 10.3969/j.issn.1001-4837.2005.09.004 [20] Zhang Qingling, Ju Xuening, Wang Qingru, et al. Fatigue fracture behavior of Ti-15-3 titanium alloy[J]. Materials Engineering, 1998,(3):25−28. (张庆玲, 居学宁, 王庆如, 等. Ti-15-3钛合金的疲劳断裂行为研究[J]. 材料工程, 1998,(3):25−28. [21] Łagoda T, Biłous P, Blacha Ł. Investigation on the effect of geometric and structural notch on the fatigue notch factor in steel welded joints[J]. International Journal of Fatigue, 2017,101:224−231. doi: 10.1016/j.ijfatigue.2016.09.006 [22] Liu Xiaoyan, He Xiaomei, Dong Jie. Fatigue crack initiation and propagation behavior of 2Cr13 steel[J]. Thermal Processing Technology, 2012,41(2):49−51,54. (刘晓燕, 何晓梅, 董洁. 2Cr13钢的疲劳裂纹萌生与扩展行为[J]. 热加工工艺, 2012,41(2):49−51,54. doi: 10.3969/j.issn.1001-3814.2012.02.014 [23] Shan Zhaohui, Wang Zhongguang, Zhang Yun, et al. Study on short fatigue crack behavior of Al-Li alloy[J]. Journal of Materials Research, 1994,(6):524−526. (单朝晖, 王中光, 张匀, 等. Al-Li合金缺口疲劳短裂纹行为的研究[J]. 材料研究学报, 1994,(6):524−526. [24] Owolabi G, Okeyoyin O, Bamiduro O, et al. The effects of notch size and material microstructure on the notch sensitivity factor for notched components[J]. Engineering Fracture Mechanics, 2015,145:181−196. doi: 10.1016/j.engfracmech.2015.03.026 [25] Zhang Chengcheng, Yao Weixing. Method for fatigue life analysis of typical notched parts[J]. Journal of Aeronautical Dynamics, 2013,28(6):1223−1230. (张成成, 姚卫星. 典型缺口件疲劳寿命分析方法[J]. 航空动力学报, 2013,28(6):1223−1230. [26] Adib H, Pluvinage G. Theoretical and numerical aspects of the volumetric approach for fatigue life prediction in notched components[J]. International Journal of Fatigue, 2003,25(1):67−76. doi: 10.1016/S0142-1123(02)00040-3 [27] Xi Wei, Yao Weixing. Effective stress method for predicting the fatigue life distribution of notched parts[J]. Chinese Journal of Solid Mechanics, 2013,34(2):205−212. (奚蔚, 姚卫星. 缺口件疲劳寿命分布预测的有效应力法[J]. 固体力学学报, 2013,34(2):205−212. doi: 10.3969/j.issn.0254-7805.2013.02.014 [28] Xi Wei, Yao Weixing. A method for predicting the fatigue life of notched parts considering the size effect[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2013,45(4):497−502. (奚蔚, 姚卫星. 一种考虑尺寸效应的缺口件疲劳寿命预测方法[J]. 南京航空航天大学学报, 2013,45(4):497−502. doi: 10.3969/j.issn.1005-2615.2013.04.010 [29] Madia M, Zerbst U. Application of the cyclic R-curve method to notch fatigue analysis[J]. International Journal of Fatigue, 2016,82:71−79. doi: 10.1016/j.ijfatigue.2015.06.015 [30] Tanaka K, Akiniwa Y. Resistance-curve method for predicting propagation threshold of short fatigue cracks at notches[J]. Engineering Fracture Mechanics, 1988,30(6):863−876. doi: 10.1016/0013-7944(88)90146-4 [31] Tabernig B, Pippan R. Determination of the length dependence of the threshold for fatigue crack propagation[J]. Engineering Fracture Mechanics, 2002,69(8):899−907. doi: 10.1016/S0013-7944(01)00129-1 [32] Medekshas H, Balina V. Assessment of low cycle fatigue strength of notched components[J]. Materials & Design, 2006,27(2):132−140. [33] Kwon K, Frangopol D M. Bridge fatigue reliability assessment using probability density functions of equivalent stress range based on field monitoring data[J]. International Journal of Fatigue, 2010,32(8):1221−1232. doi: 10.1016/j.ijfatigue.2010.01.002 [34] Ayyub B M, Assakkaf I A, Kihl D P, et al. Reliability-based design guidelines for fatigue of ship structures[J]. Naval Engineers Journal, 2010,114(2):113−138. [35] Lim H J, Lee Y J, Sohn H. Continuous fatigue crack length estimation for aluminum 6061-T6 plates with a notch[J]. Mechanical Systems and Signal Processing, 2019,120:356−364. doi: 10.1016/j.ymssp.2018.10.018 [36] Sun J, Ding Z, Huang Q. Corrosion fatigue life prediction for steel bar in concrete based on fatigue crack propagation and equivalent initial flaw size[J]. Construction and Building Materials, 2019,195:208−217. doi: 10.1016/j.conbuildmat.2018.11.056 [37] Liu J, Zhang R, Wei Y, et al. A new method for estimating fatigue life of notched specimen[J]. Theoretical and Applied Fracture Mechanics, 2018,93:137−143. doi: 10.1016/j.tafmec.2017.07.017 [38] Hurley P J, Whittaker M T, Williams S J, et al. Prediction of fatigue initiation lives in notched Ti 6246 specimens[J]. International Journal of Fatigue, 2008,30(4):623−634. doi: 10.1016/j.ijfatigue.2007.05.013 [39] Htoo A T, Miyashita Y, Otsuka Y, et al. Notch fatigue behavior of Ti-6Al-4V alloy in transition region between low and high cycle fatigue[J]. International Journal of Fatigue, 2017,95:194−203. doi: 10.1016/j.ijfatigue.2016.10.024 [40] Jin Dan, Gou Zhifei. A new method for fatigue life prediction of notched parts[J]. Journal of Aeronautical Materials, 2017,37(2):81−87. (金丹, 缑之飞. 缺口件疲劳寿命预测新方法[J]. 航空材料学报, 2017,37(2):81−87. [41] Bao Hongchen, Liu Guangyan. Numerical simulation of gap size and shape effect of fiber reinforced composite laminates[J]. Journal of Composite Materials, 2017,34(5):987−995. (鲍宏琛, 刘广彦. 纤维增强复合材料层合板缺口尺寸及形状效应数值模拟[J]. 复合材料学报, 2017,34(5):987−995. [42] Dong Qin, Yang Ping, Yu Zhifeng. CTOD theory and numerical simulation of ship notched plate considering cumulative plastic failure under cyclic loading[J]. Ship Mechanics, 2018,22(7):865−872. (董琴, 杨平, 余志锋. 循环载荷下考虑累积塑性破坏的船体缺口板CTOD理论及数值模拟研究[J]. 船舶力学, 2018,22(7):865−872. doi: 10.3969/j.issn.1007-7294.2018.07.010 [43] Alshahbouni T, Güngör A. Designing and modeling U-notch fatigue sensor to predict the fatigue life of structural components[J]. Engineering Science and Technology, an International Journal, 2019,22(2):405−415. doi: 10.1016/j.jestch.2018.09.011 [44] Zhang Dingquan. Effect of residual stress on fatigue strength of metal[J]. Physical and Chemical Examination (Physical Volume), 2002,(6):231−235. (张定铨. 残余应力对金属疲劳强度的影响[J]. 理化检验(物理分册), 2002,(6):231−235. [45] Zhang D, Xu K, He J. Aspects of the residual stress field at a notch and its effect on fatigue[J]. Materials Science & Engineering A, 1991,91(136):79−83. [46] Xu Kewei, Zhang Hui, Hu Naisai. The effect of a pre overload on the notch fatigue strength of aluminum alloy before and after shot peening[J]. Journal of Aeronautics, 1993,(6):317−320. (徐可为, 张晖, 胡奈赛. 一次预过载对铝合金喷丸前后缺口疲劳强度的影响[J]. 航空学报, 1993,(6):317−320. doi: 10.3321/j.issn:1000-6893.1993.06.020 [47] Wang Xin, Wang Kechang, Luo Xuekun, et al. Effect of powder alloy FGH95 shot peening on high temperature notch fatigue property[J]. Aviation Manufacturing Technology, 2018,61(z2):40−45. (王欣, 王科昌, 罗学昆, 等. 粉末合金FGH95喷丸强化对高温缺口疲劳性能的影响[J]. 航空制造技术, 2018,61(z2):40−45. [48] Li Li, Zhu Youli, Lv Guangyi, et al. Study on ultrasonic deep roll surface strengthening technology of TC4 titanium alloy[J]. Materials Engineering, 2008,(11):68−70,74. (李礼, 朱有利, 吕光义, 等. TC4钛合金超声深滚表面强化技术的研究[J]. 材料工程, 2008,(11):68−70,74. doi: 10.3969/j.issn.1001-4381.2008.11.016 [49] Zhu Youli, Bian Feilong, Wang Yanli, et al. Ultrasonic deep roll anti-fatigue strengthening treatment of surface small notch damage[J]. Journal of Armored Force Engineering College, 2014,28(5):82−86. (朱有利, 边飞龙, 王燕礼, 等. 表面小缺口损伤的超声深滚抗疲劳强化处理[J]. 装甲兵工程学院学报, 2014,28(5):82−86. [50] Feng Zhongxin. Study on the influence of surface rolling on the notch fatigue strength of carburized steel[J]. Journal of Xi'an Jiaotong University, 1995,(8):90−94. (冯忠信. 表面滚压对渗碳钢缺口疲劳强度影响的研究[J]. 西安交通大学学报, 1995,(8):90−94. -

下载:

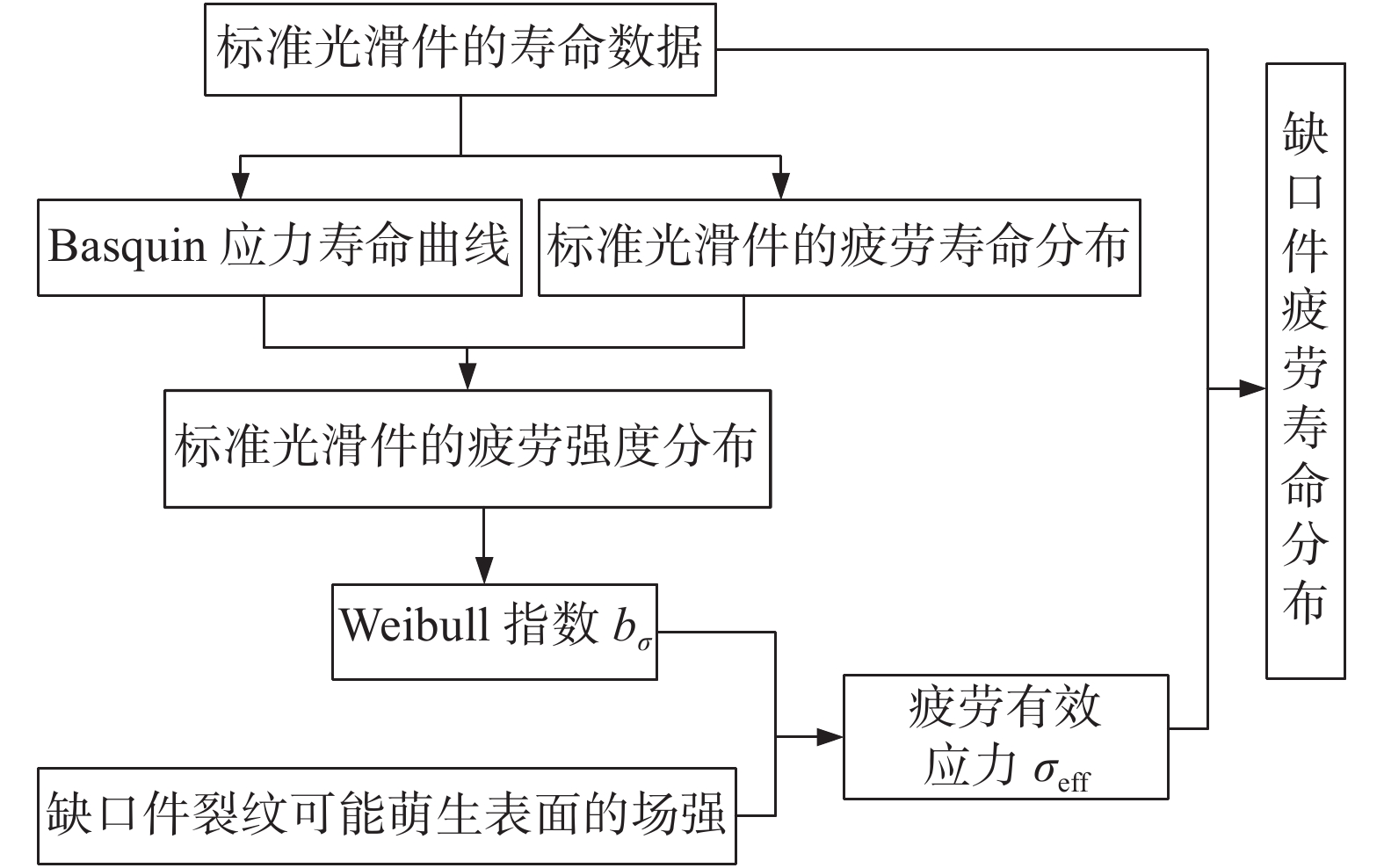

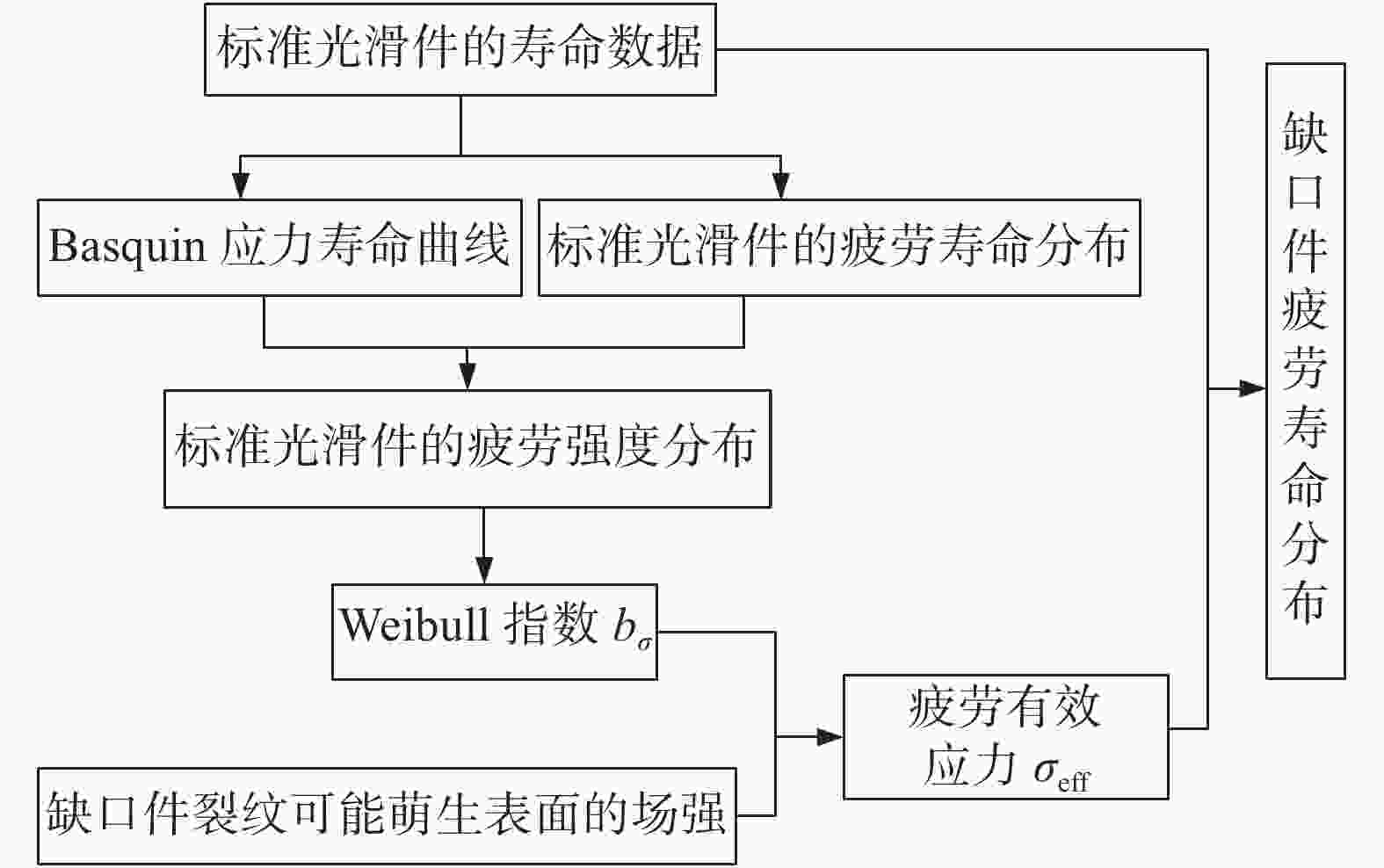

下载: