Research progress on wear resistance of titanium matrix composites

-

摘要: 钛合金因具有高比强度、高比模量、耐腐蚀、耐低温、无磁等性能特点而被广泛应用。然而,与传统钢铁材料相比,钛合金存在弹性模量低、耐热性能不足、耐磨性差等局限,阻碍其在航空航天、兵器行业等领域的推广应用。与钛合金相比,钛基复合材料可将基体钛合金高强塑性与增强体高模量、高耐磨的优势相结合,具有比钛合金更高的弹性模量、耐磨性及高温性能,从而满足一些高承载、抗冲击、高耐磨和高温抗氧化等极端工况条件下的使用要求。从钛基复合材料发展历程出发,对钛基复合材料耐磨性研究进展加以概述,主要介绍了钛基复合材料耐磨性表征方法和摩擦磨损行为,对钛基复合材料良好耐磨性能、高耐磨钛基复合材料的设计及TMCs表面耐磨改性技术进行阐述,最后进行总结与展望。Abstract: Titanium alloys are widely used because of their excellent comprehensive properties such as high specific strength, high specific modulus, corrosion resistance, low temperature resistance, and non-magnetism. However, compared with traditional steel materials, titanium alloys have limitations such as low elastic modulus, insufficient heat resistance and poor wear resistance, which hinder their promotion and application in the aerospace, weapon and other industries. Compared with titanium alloys, titanium matrix composites can combine the advantages of high-strength plasticity of the matrix titanium alloy and the high modulus and high wear resistance of the reinforcement. Titanium matrix composites have higher elastic modulus, wear resistance and high-temperature performance than titanium alloys. It meets the requirements of extreme working conditions such as high load, impact resistance, high wear resistance and high temperature oxidation resistance. Starting from the development history of titanium matrix composites, this paper summarized the research progress on wear resistance of titanium matrix composites, and the characterization methods of wear resistance, friction and wear behaviors of titanium matrix composites were also introduced. The good wear resistance mechanism of titanium matrix composites, the design of high wear-resistance titanium matrix composites and wear resistant surface modification technology were also described.

-

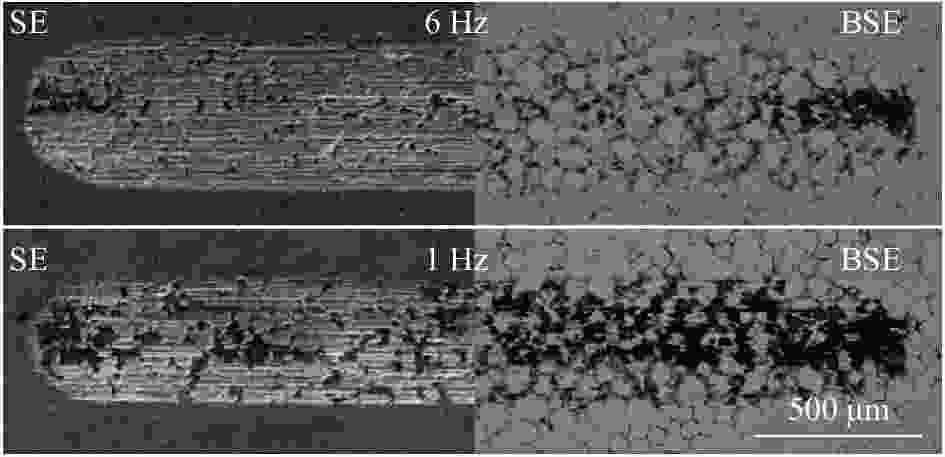

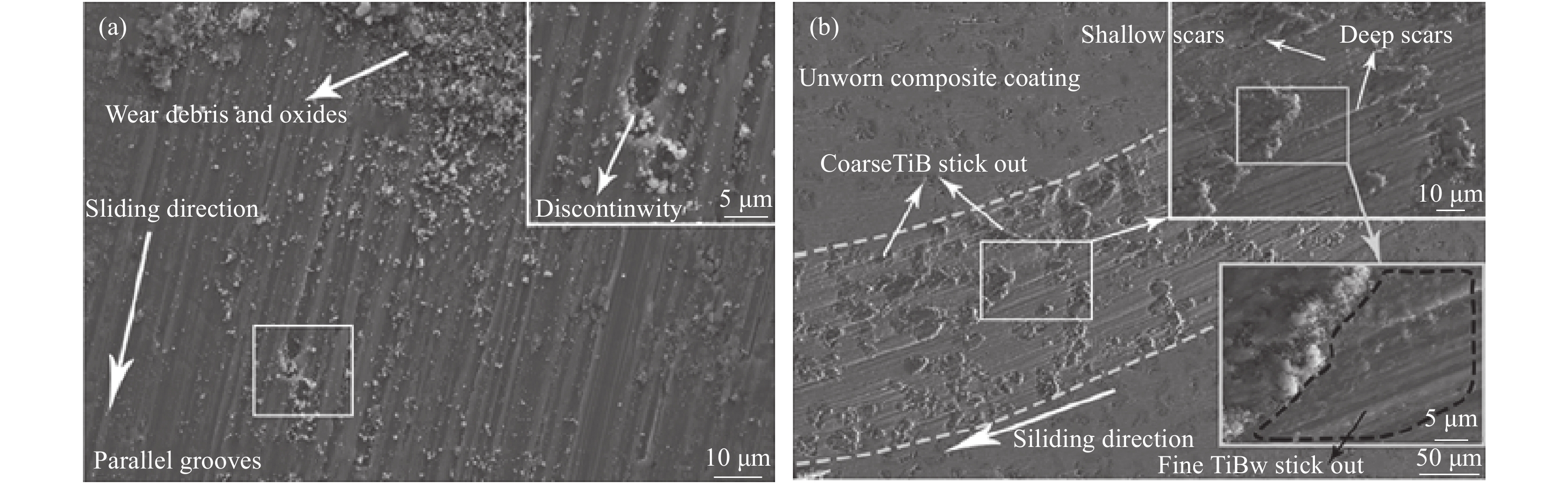

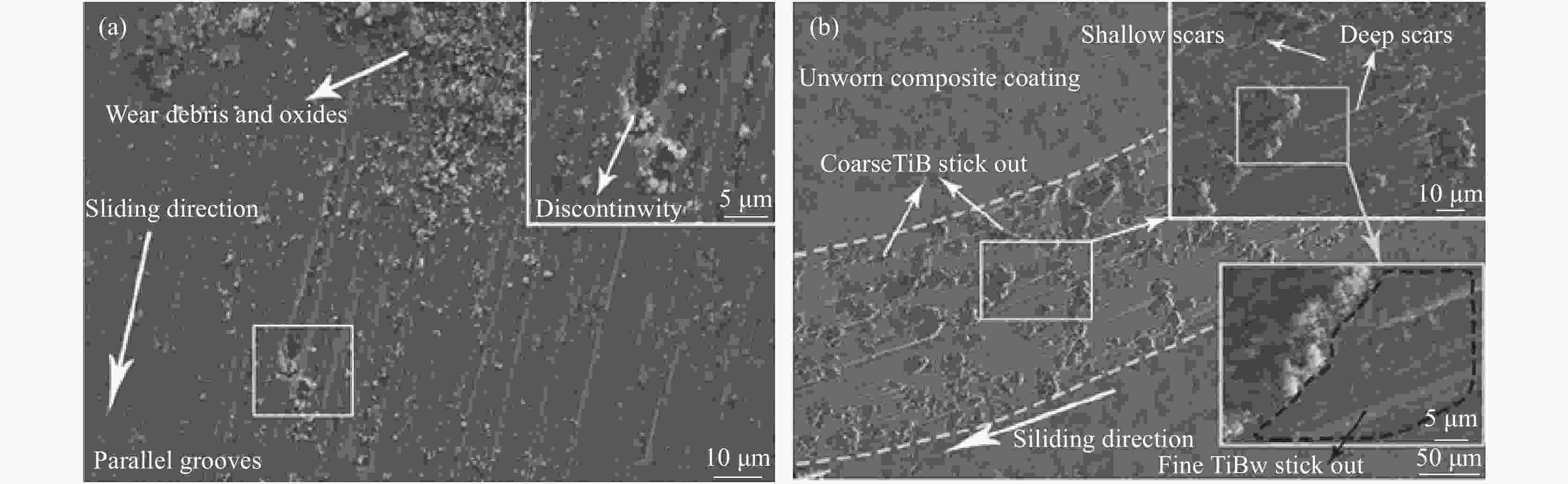

图 1 典型TMCs摩擦磨损典型的表面形貌[22]

Figure 1. Typical surface morphology of TMCs friction and wear

图 2 蜂窝状的多孔TiC/Ti-6Al-4V结构[37]

Figure 2. SEM images of honeycomb porous TiC/Ti-6Al-4V structure

-

[1] Jiang Hong, Zhang Xiaodan. Research and application status of titanium alloys at domestic and abroad[J]. New Material Industry, 2017,(3):7−10. (江洪, 张晓丹. 国内外钛合金研究及应用现状[J]. 新材料产业, 2017,(3):7−10. doi: 10.3969/j.issn.1008-892X.2017.03.003 [2] Zhu Zhishou, Shang Guoqiang, Wang Xinnan, et al. Microstructure controlling technology and mechanical properties relationship of titanium alloys for aviation applications[J]. Journal of Aeronautical Materials, 2020,40(3):1−10. (朱知寿, 商国强, 王新南, 等. 航空用钛合金显微组织控制和力学性能关系[J]. 航空材料学报, 2020,40(3):1−10. doi: 10.11868/j.issn.1005-5053.2020.000086 [3] Li Zhong, Chen Wei, Wang Xianmei, et al. The application of titanium in automobiles[J]. World Nonferrous Metals, 2010,(6):66−69. (李中, 陈伟, 王宪梅, 等. 钛在汽车上的应用[J]. 世界有色金属, 2010,(6):66−69. [4] Yu Zhentao, Yu Sen, Cheng Jun, et al. Development and application of novel biomedical titanium alloy materials[J]. Acta Metallurgica Sinica, 2017,53(10):1238−1264. (于振涛, 余森, 程军, 等. 新型医用钛合金材料的研发和应用现状[J]. 金属学报, 2017,53(10):1238−1264. doi: 10.11900/0412.1961.2017.00288 [5] Tan Qiming, Sui Nan. Research and progress of particle-reinforced titanium matrix composites[J]. New Materials Industry, 2019,(1):59−64. (谭启明, 隋楠. 颗粒增强钛基复合材料的研究与进展[J]. 新材料产业, 2019,(1):59−64. [6] Tjong S C, Ma Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites[J]. Materials Science and Engineering: R, 2000,29:49−113. doi: 10.1016/S0927-796X(00)00024-3 [7] 曲赫威. 原位自生高体积分数钛基复合材料制备及组织性能研究[D]. 北京: 机械科学研究总院, 2018.Qu Hewei. The research of microstructures and mechanical properties of high volume fraction titanium matrix composites prepared by in-situ synthesized method [D]. Beijing: Central Academy of Mechanical Sciences, 2018. [8] 赵勋. 原位自生TiC增强钛基复合材料的制备与性能研究[D]. 北京: 北京交通大学, 2019.Zhao Xun. Preparation and properties of in-situ TiC reinforced titanium matrix composites[D]. Beijing: Beijing Jiaotong University, 2019. [9] Tjong S C, Mai Y W. Processing-structure-property aspects of particulate and whisker-reinforced titanium matrix composites[J]. Composites Science and Technology, 2008,68(3-4):583−601. doi: 10.1016/j.compscitech.2007.07.016 [10] Lu W J, Zhang D, Zhang X N, et al. Microstructure and tensile properties of in situ (TiB+TiC)/Ti6242 (TiB:TiC=1:1) composites prepared by common casting technique[J]. Materials Science & Engineering A, 2001,311(1-2):142−150. [11] Jiao Y, Huang L J, Wang S, et al. Effects of first-scale TiBw on secondary-scale Ti5Si3 characteristics and mechanical properties of in-situ (Ti5Si3+TiBw)/Ti6Al4V composites[J]. Journal of Alloys & Compounds, 2017,704:269−281. [12] Chávez J, Olmos L, Jiménez O, et al. Sintering behaviour and mechanical characterisation of Ti64/x TiN composites and bilayer components[J]. Powder Metallurgy, 2017,60(4):257−266. doi: 10.1080/00325899.2017.1280585 [13] Lai Xiaojun, Li Shaopeng, Han Yuanfei, et al. Progress on composite design and development of advanced processing technology of multi-phase and multi-scale reinforced titanium matrix composites[J]. Titanium Industry Progress, 2020,37(3):40−48. (来晓君, 李劭鹏, 韩远飞, 等. 多元多尺度增强钛基复合材料复合设计与先进加工技术研究进展[J]. 钛工业进展, 2020,37(3):40−48. [14] 刘正林. 摩擦学原理[M]. 北京: 高等教育出版社, 2009.Liu Zhenglin. Principles of tribology[M]. Beijing: Higher Education Press, 2009. [15] Archard J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953,24(8):981−988. doi: 10.1063/1.1721448 [16] Larsen-Basse J. Basic theory of solid friction[J]. Materials Park, OH:ASM International, 1992:27−36. [17] 孙亮. 原位自生(TiC+TiB)增强钛基复合材料组织调控与耐磨性[D]. 沈阳: 沈阳工业大学, 2018.Sun Liang. Microstructure control and wear resistance of (TiC+TiB) reinforced titanium matrix composites synthesized using in-situ technology [D]. Shenyang: Shenyang University of Technology, 2018. [18] Gürbüz M, Mutuk T, Uyan P. Mechanical, wear and thermal behaviors of graphene reinforced titanium composites[J]. Metals and Materials International, 2020,118:1−9. [19] Farias I, Olmos L, Jimenez O, et al. Wear modes in open porosity titanium matrix composites with TiC addition processed by spark plasma sintering[J]. Transactions of Nonferrous Metals Society of China, 2019,29(8):1653−1664. doi: 10.1016/S1003-6326(19)65072-7 [20] Xie H, Jin Y, Niu M, et al. Effect of multilayer graphene/nano-Fe2O3 composite additions on dry sliding wear behavior of titanium matrix composites[J]. Journal of Iron and Steel Research International, 2020,27(9):1117−1126. doi: 10.1007/s42243-020-00460-7 [21] Choi B J. Effect of contact load on wear property of (TiB+TiC) particulates reinforced titanium matrix composites[J]. Journal of Korea Foundry Society, 2017,37(4):115−122. [22] An Q, Huang L, Jiang S, et al. Two-scale TiB/Ti64 composite coating fabricated by two-step process[J]. Journal of Alloys and Compounds, 2018,755:29−40. doi: 10.1016/j.jallcom.2018.05.002 [23] He Bo, Lan Jiaojiao, Yang Guang, et al. Microstructure and wear-resistant properties of in situ TiB-TiC reinforced titanium matrix composites by laser deposition manufacturing[J]. Rare Metal Materials and Engineering, 2017,377(12):233−238. (何波, 兰姣姣, 杨光, 等. 激光原位合成TiB-TiC颗粒增强钛基复合材料的组织与其耐磨性能[J]. 稀有金属材料与工程, 2017,377(12):233−238. [24] Zheng B, Dong F, Yuan X, et al. Evaluation on tribological characteristics of (TiC+TiB)/Ti–6Al–4V composite in the range from 25 °C to 600 °C[J]. Wear, 2020:203−256. [25] Zheng B, Dong F, Yuan X, et al. Insights into wear behavior of (TiC+TiB)/TC4 composites against different counterface materials[J]. Materials Research Express, 2019,6(11):116584. doi: 10.1088/2053-1591/ab4bac [26] 王健硕. 钛基Y-PSZ/Ti颗粒增强复合材料的研究[D]. 沈阳: 沈阳理工大学, 2020.Wang Jianshuo. Titanium-based matrix Y-PSZ/ Ti particle reinforced composites research [D]. Shenyang: Shenyang University of Technology, 2020. [27] Liu Y Y, Yao Z, Zhang S, et al. The formation mechanism and wear behavior of TiC+ Ti3SiC2+ Ti5Si3 reinforced Ti6Al4V with network microstructure fabricated by electron beam melting[J]. Materials Research Express, 2019,6(9):0965c3. doi: 10.1088/2053-1591/ab0b5a [28] Wang Wei, Zhou Haixiong, Wang Qingjuan, et al. Tribological properties of graphene reinforced titanium matrix composites[J]. Ordnance Material Science and Engineering, 2019,42(1):26−32. (王伟, 周海雄, 王庆娟, 等. 石墨烯增强钛基复合材料的摩擦学性能研究[J]. 兵器材料科学与工程, 2019,42(1):26−32. [29] Salehikahrizsangi P, Karimzadeh F, Enayati M H, et al. Investigation of the effects of grain size and nano-sized reinforcements on tribological properties of Ti6Al4V alloy[J]. Wear, 2013,305(1-2):51−57. doi: 10.1016/j.wear.2013.05.008 [30] Yang B, Lujun H, Qi A, et al. Wire-feed deposition TiB reinforced Ti composite coating: Formation mechanism and tribological properties[J]. Materials Letters, 2018,229:221−224. doi: 10.1016/j.matlet.2018.07.022 [31] 王玉林. TiC/Ti 基复合材料摩擦磨损性能与氧化行为的研究[D]. 长沙: 中南大学, 2011.Wang Yulin. Friction and wear properties of TiC particle reinforced titanium matrix composite [D]. Changsha: Central South University, 2011. [32] Hashin Z, Shtrikman S. A variational approach to the theory of the elastic behaviour of polycrystals[J]. Journal of the Mechanics & Physics of Solids, 1962,10(4):343−352. [33] 焦阳. 两级网状结构(Ti5Si3+TiBw)/Ti6Al4V复合材料研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.Jiao Yang. Research on (Ti5Si3+TiBw)/Ti6Al4V composites with two-level network structure[D]. Harbin: Harbin Institute of Technology, 2018. [34] Mu X N, Zhang H M, Cai H N, et al. Microstructure evolution and superior tensile properties of low content graphene nanoplatelets reinforced pure Ti matrix composites[J]. Materials Science and Engineering: A, 2017,687:164−174. doi: 10.1016/j.msea.2017.01.072 [35] Su Ying, Zuo Qian, Yang Gang, et al. Compressive properties of the grahpene reinforced titanium composites[J]. Rare Metal Materials and Engineering, 2017,46(12):3882−3886. (苏颖, 左倩, 杨刚, 等. 石墨烯增强钛基复合材料的压缩变形行为研究[J]. 稀有金属材料与工程, 2017,46(12):3882−3886. [36] Cai C, Song B, Qiu C, et al. Hot isostatic pressing of in-situ TiB/Ti-6Al-4V composites with novel reinforcement architecture, enhanced hardness and elevated tribological properties[J]. Journal of Alloys and Compounds, 2017,710:364−374. doi: 10.1016/j.jallcom.2017.03.160 [37] Bai M, Mohsen R, Xu Y, et al. In-situ Ti-6Al-4V/TiC composites synthesized by reactive spark plasma sintering: processing, microstructure, and dry sliding wear behaviour[J]. Wear, 2019,432-433:202944. doi: 10.1016/j.wear.2019.202944 [38] Xu X, Liu Y, Tabie V, et al. High-temperature oxidation resistance of a Ti–Al–Sn–Zr titanium matrix composites reinforced with in situ TiC and Ti5Si3 fabricated by powder metallurgy[J]. Applied Physics A, 2020,126(4):1−10. [39] Odetola P I, Ajenifuja E, Popoola A P I, et al. Effects of silicon carbide contents on microstructure and mechanical properties of spark plasma–sintered titanium-based metal matrix[J]. The International Journal of Advanced Manufacturing Technology, 2019,105(5-6):2491−2500. doi: 10.1007/s00170-019-04317-6 [40] Zhang F, Du M, Fan K, et al. Fabrication and mechanical properties of network structured titanium alloy matrix composites reinforced with Ti2AlC particulates[J]. Materials Science and Engineering, 2020,776(3):139065.1−139065.9. [41] 李争显, 王少鹏, 慕伟意, 等. 钛表面处理技术的研究现状[C]// 第十届全国表面工程大会暨第六届全国青年表面工程论文集. 武汉: 中国机械工程学会, 中国表面工程协会, 2014: 76.Li Zhengxian, Wang Shaopeng, Mu Weiyi, et al. Research status of titanium surface treatment technology [C]//Proceedings of the 10th Nationnal Surface Engineering Conference and 6th National Youth Surface Engineering Forum. Wuhan: Chinese Society of Mechanical Engineering, China Surface Engineering Association, 2014: 76. [42] 陆伟. 钛表面激光熔覆纳米碳管组织与性能的研究[D]. 大连: 大连理工大学, 2014.Lu Wei. Study on microstructure and properties of laser cladding titanium with CNTs[D]. Dalian: Dalian University of Technology, 2014. [43] 姬寿长, 李京龙, 李争显, 等. TC21钛合金表面处理技术的研究现状[J/OL]. 热加工工艺, 2021(4): 17-20, 24[2021-03-01]. https://doi.org/10.14158/j.cnki.1001-3814.20192423.Ji Shouchang, Li Jinglong, Li Zhengxian, et al. Research status surface treatment technology on TC21 titanium alloy [J/OL]. Hot Working Process, 2021 (4): 17-20, 24. [2021-03-01] https://doi.org/10.14158/j.cnki.1001-3814.20192423. [44] Wang Qinghong, Wang Hongying. Wear resistance of surface layer of TC4 alloy after laser surface modification[J]. Casting Technology, 2015,(1):8. (王庆红, 王红英. 激光表面改性后TC4钛合金的表面层耐磨性分析[J]. 铸造技术, 2015,(1):8. [45] Huang Xueli, Tan Junguo, Zhang Tengfei, et al. Deposition and anti-wear/corrosion properties of nano-multilayer TiN/CrN films on titanium alloy[J]. Materials Guide, 2021,35(4):4139−4143. (黄雪丽, 谭君国, 张腾飞, 等. 钛合金表面TiN/CrN纳米多层薄膜的制备及耐磨、耐腐蚀性能[J]. 材料导报, 2021,35(4):4139−4143. doi: 10.11896/cldb.19070256 [46] Liu Yuancai, Sun Qisheng, Liu Zhiyuan, et al. Effect of BN on micro arc oxidation film and wear resistance of TB8 titanium alloy[J]. Journal of Qingdao University of Technology, 2020,41(6):102−107. (刘元才, 孙启胜, 刘志远, 等. 氮化硼对TB8钛合金微弧氧化膜及其耐磨性的影响[J]. 青岛理工大学学报, 2020,41(6):102−107. doi: 10.3969/j.issn.1673-4602.2020.06.015 [47] Yang Yucheng, Pan Yu, Lu Xin, et al. Research progress on particle-reinforced titanium matrix composites prepared by powder metallurgy method[J]. Powder Metallurgy Technology, 2020,(2):11. (杨宇承, 潘宇, 路新, 等. 粉末冶金法制备颗粒增强钛基复合材料的研究进展[J]. 粉末冶金技术, 2020,(2):11. [48] Al-Sayed Ali S R, Hussein A H A, Nofal A A M S, et al. Laser powder cladding of Ti-6Al-4V α/β alloy[J]. Materials, 2017,10(10):1178. doi: 10.3390/ma10101178 -

下载:

下载: