Influence of solution treatment on microstructure and mechanical properties of Ti6Al4V ELI titanium alloy

-

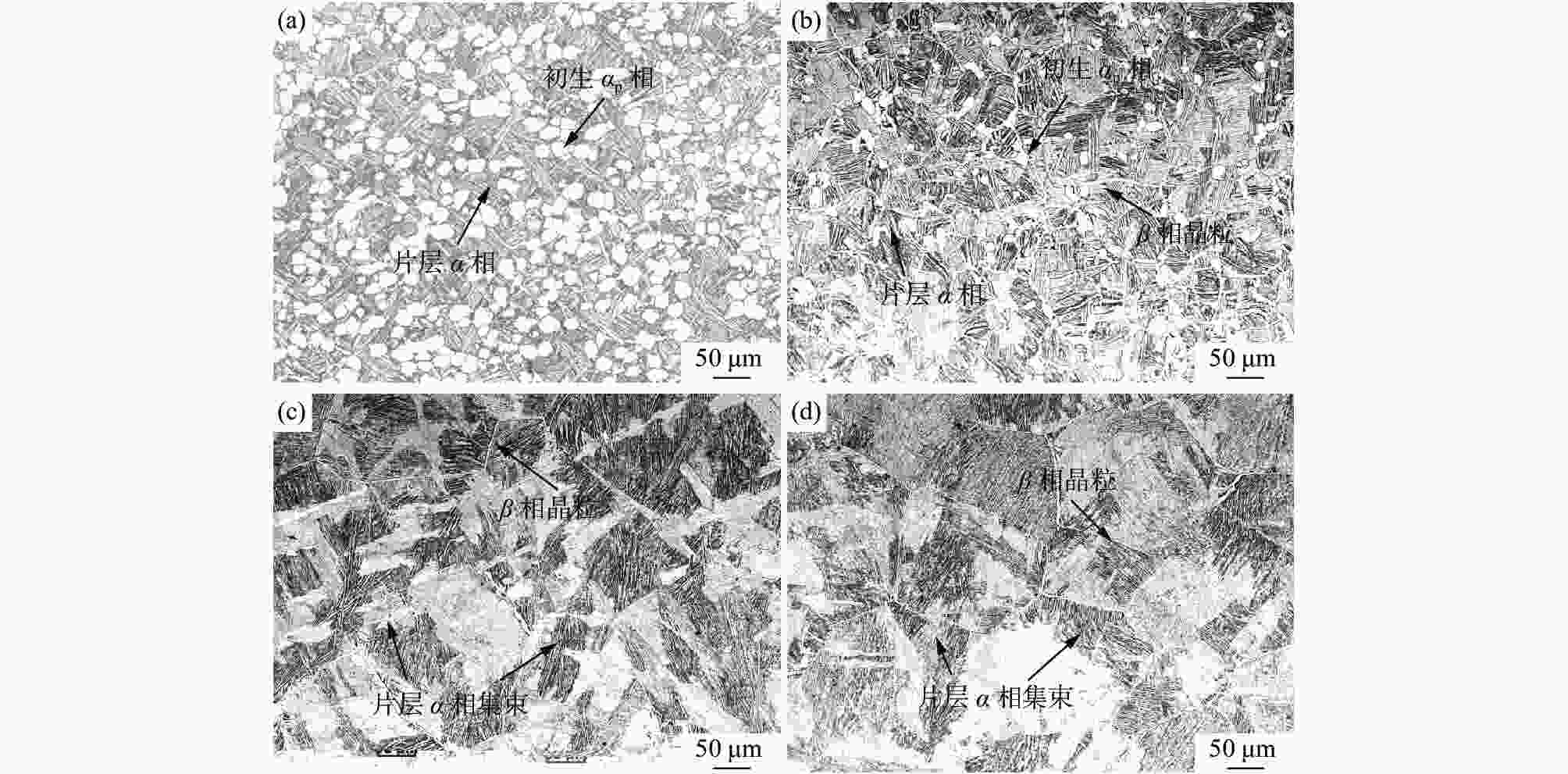

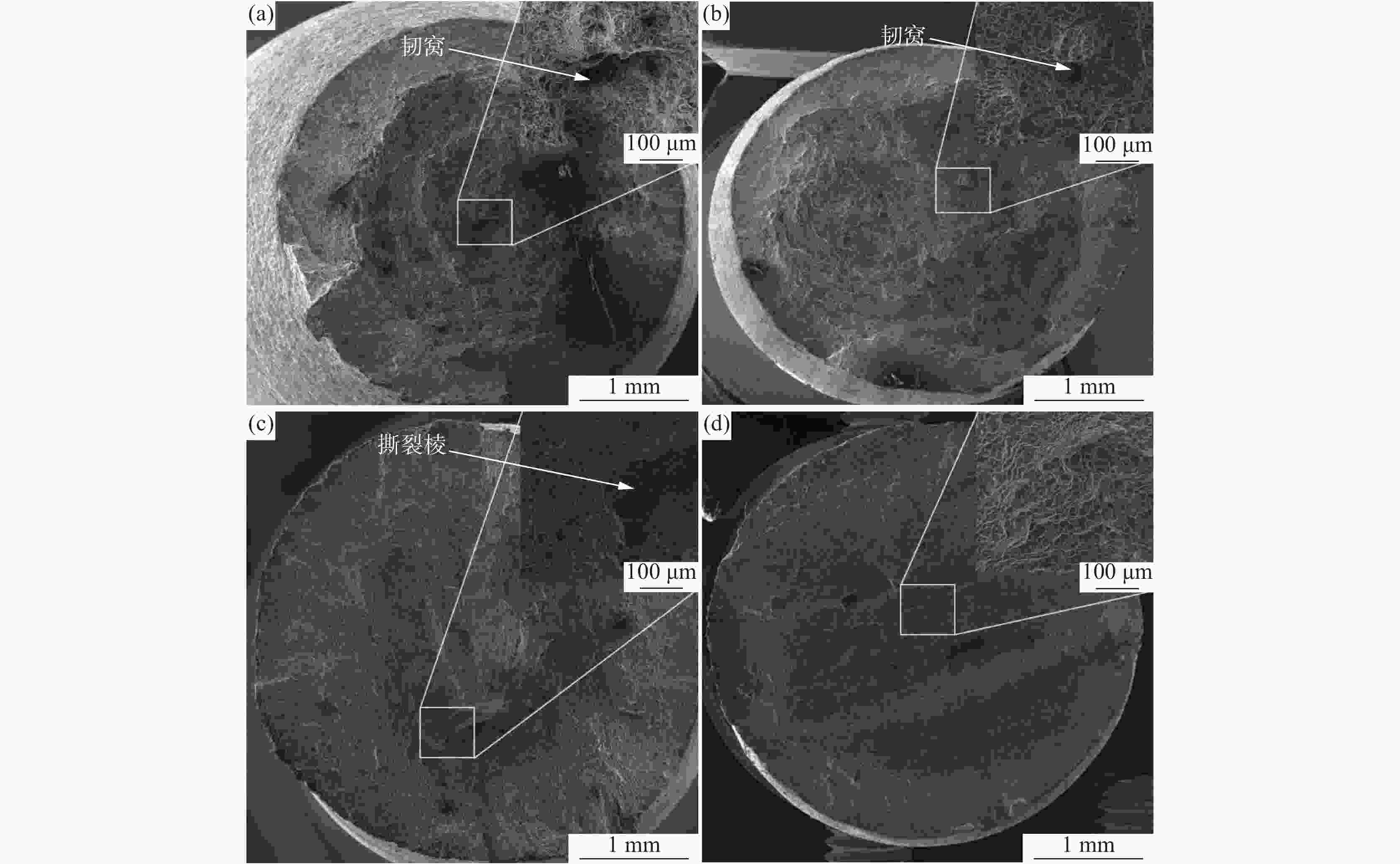

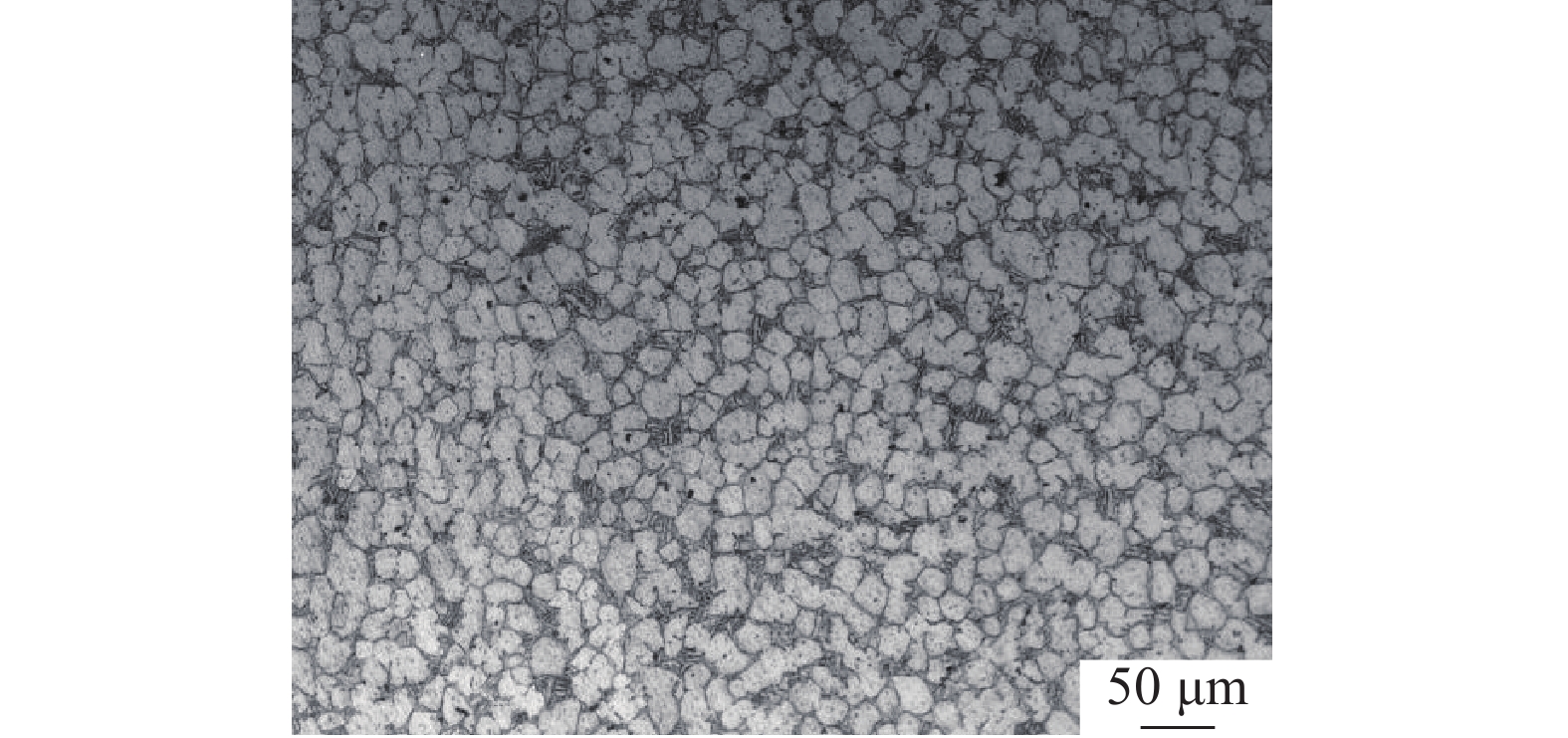

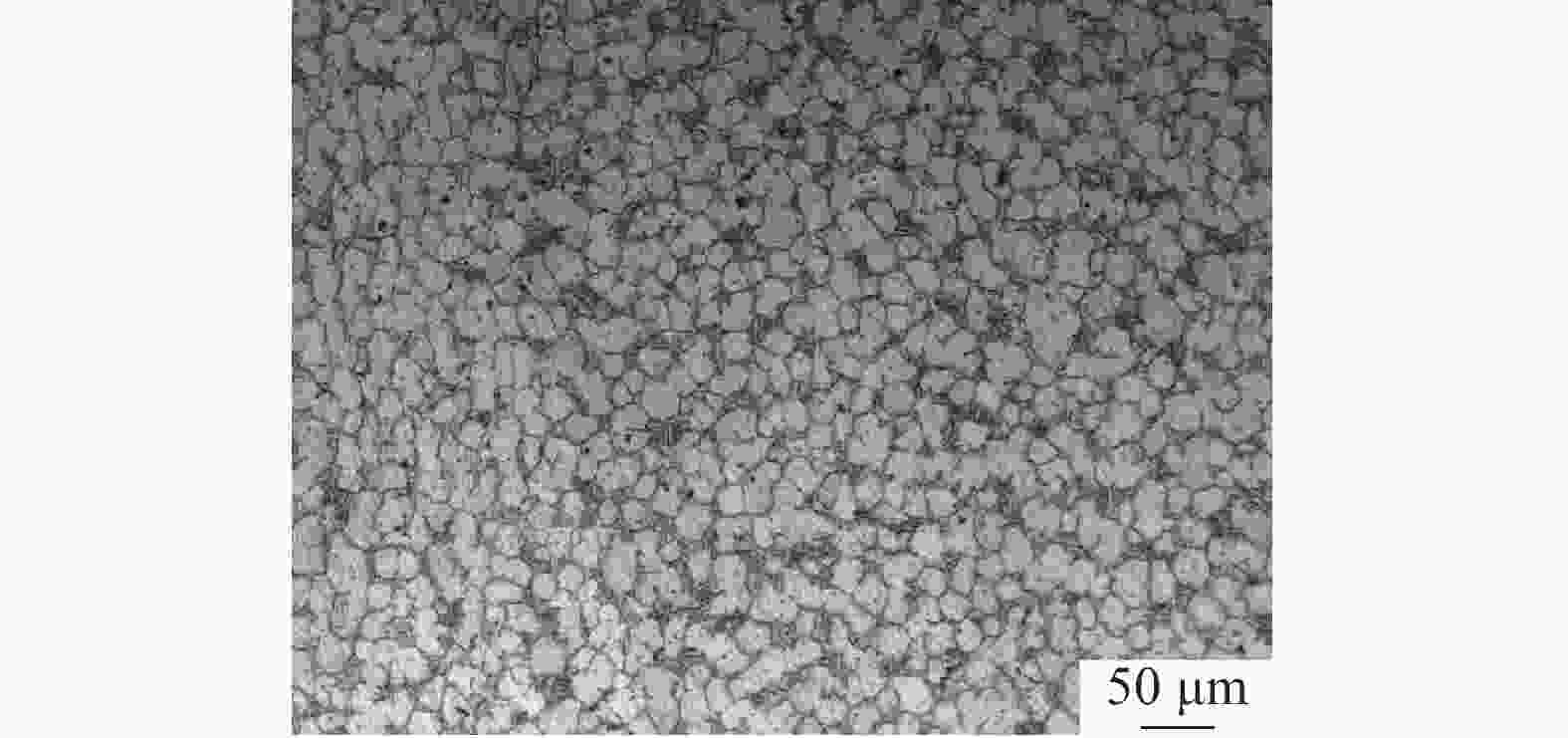

摘要: 采用扫描电镜(SEM)和金相显微镜(OM)研究了固溶热处理对Ti6Al4V ELI钛合金显微组织的演变规律,以及显微组织对力学性能的影响关系,结果表明:随着固溶温度的升高,Ti6Al4V ELI钛合金初生αp相含量降低,片层α相厚度和β晶粒尺寸均增加;钛合金强度和塑性均随着固溶温度的升高而降低,在952 ℃固溶后时效,抗拉强度可达915 MPa,延伸率16.8%,断裂韧性仅为84 MPa·m1/2;在997 ℃进行固溶后时效,钛合金抗拉强度降低至861 MPa,延伸率9.6%,断裂韧性达115 MPa·m1/2。在952 ℃进行固溶,Ti6Al4V ELI钛合金为韧性断裂,提高固溶温度后合金呈韧脆混合型断裂。

-

关键词:

- Ti6Al4V ELI钛合金 /

- 固溶温度 /

- 显微组织 /

- 力学性能

Abstract: The scanning electron microscope (SEM) and optical microscope (OM) were employed to investigate the influence of solution treatment on microstructure evolution of Ti6Al4V ELI titanium alloy, and the relationship between microstructure and mechanical properties were discussed. The results show that the content of the primary αp phase of Ti6Al4V ELI titanium alloy decreases, and the thickness of lamellar α phase and β grain size increase with the increase of solution treatment temperature. The strength and plasticity of Ti6Al4V ELI titanium alloy decrease with the increase of solution temperature. When the solution treatment is 952 ℃, the tensile strength, elongation and fracture toughness values of Ti6Al4V ELI titanium alloy are 915 MPa, 16.8% and 84 MPa·m1/2, respectively. At the solution treatment up to 997℃, the tensile strength and elongation values decrease to 861 MPa and 9.4%, respectively, but the fracture toughness increases to 115 MPa·m1/2. It shows a ductile fracture with solution treatment at 952 ℃ while ductile-brittle mixed fracture as the temperature increases. -

表 1 Ti6Al4V ELI钛合金棒材化学成分

Table 1. Chemical compositions of Ti6Al4V ELI alloy

% 合金 Ti Al V Fe C H O N 棒材 Bal. 6.21 4.25 0.06 0.009 0.001 0.09 0.006 Ti6Al4V ELI Bal. 5.6~6.3 3.6~4.4 ≤0.25 ≤0.05 ≤0.125 ≤0.13 ≤0.03 表 2 不同固溶温度条件下Ti6Al4V ELI钛合金显微组织参数

Table 2. Microstructure parameters of Ti6Al4V ELI titanium alloy at various solution treatment temperatures

编号 初生αp相

含量/%片层

α相平均尺寸/μmβ相晶粒平均

尺寸/μmⅠ 30 2.8 Ⅱ 10 4.8 75 Ⅲ 5.5 138 Ⅳ 5.7 215 表 3 Ti6Al4 V ELI钛合金在不同热处理制度下的室温力学性能

Table 3. Tensile and fracture toughness of Ti6Al4V ELI titanium alloy at various solution treatments

编号 Rm/MPa Rp0.2/MPa A/% Z/% KIC/(MPa·m1/2) Ⅰ 915 846 16.8 45 84 Ⅱ 875 801 11.2 26 91 Ⅲ 861 792 9.6 19 115 Ⅳ 843 775 8.2 16 103 -

[1] Yuan Hong, Yu Huai, Wang Jinxue, et al. Damage tolerance properties of electron beam welded joints of TC4-DT titanium alloy[J]. Materials Engineering, 2007,(8):18−20. (袁鸿, 余槐, 王金雪, 等. TC4-DT钛合金电子束焊接接头的损伤容限性能[J]. 材料工程, 2007,(8):18−20. [2] Akahori T, Niinomi M, Fukunaga K I. An investigation of the effect of fatigue deformation on the residual mechanical properties of Ti-6Al-4V ELI[J]. Metallurgical & Materials Transactions A, 2000,31(8):1937−1948. [3] Semenova I P, Saitova L R, Raab G I, et al. Microstructural features and mechanical properties of the Ti-6Al-4V ELI alloy processed by severe plastic deformation[J]. Materials Science Forum, 2006,(1):128−131. [4] Xu Liang, Zhao Qing, Hui Li, et al. Influence of corrosion evironments on corrosion fatigue property of per-corroded TC-DT titanium alloy[J]. Hot Working Technology, 2019,(20):125−129. (许良, 赵晴, 回丽, 等. 腐蚀环境对预腐蚀TC4-DT钛合金疲劳性能的影响[J]. 热加工工艺, 2019,(20):125−129. [5] Chen Lianguo, Wang Wensheng, Zhu Zhishou, et al. Development and application of large size damage tolerant titanium alloy TC4-DT[J]. Journal of Aeronautics (Special Issue of Fighter), 2020,41(6):36−41. (陈联国, 王文盛, 朱知寿, 等. 大规格损伤容限钛合金TC4-DT的研制及应用[J]. 航空学报(战斗机专刊), 2020,41(6):36−41. [6] Yu Lanlan, Mao Xiaonan, Li Hui, et al. Research on high cycle fatigue behavior of TC4-DT titanium alloy[J]. Titanium Industry Progress, 2012,29(6):11−14. (于兰兰, 毛小南, 李辉, 等. TC4-DT钛合金高周疲劳行为研究[J]. 钛工业进展, 2012,29(6):11−14. [7] Venkatesh B D, Chen D L, Bhole S D. Effect of heat treatment on mechanical properties of Ti-6 Al-4 V ELI alloy[J]. Materials Science and Engineering, 2009,(1):121−125. [8] Peng X, Guo H, Shi Z, et al. Study on the hot deformation behavior of TC4-DT alloy with equiaxed α+β starting structure based on processing map–Science direct[J]. Materials Science and Engineering:A, 2014,605:80−88. doi: 10.1016/j.msea.2014.03.047 [9] Lu Y, Xu X, Zhang B, et al. Microstructural analysis and mechanical behavior of TC4 titanium alloy and 304 stainless steel by friction stir lap welding[J]. Welding in the World, 2021:1−16. [10] Liu Jinhao, Liu Jiansheng, Xiong Yunsen, et al. Study on thermal deformation behavior and machining drawing of TC4-DT titanium alloy[J]. Rare Metal Materials and Engineering, 2013,(8):1674−1678. (刘金豪, 刘建生, 熊运森, 等. TC4-DT钛合金的热变形行为研究及加工图[J]. 稀有金属材料与工程, 2013,(8):1674−1678. doi: 10.3969/j.issn.1002-185X.2013.08.027 [11] Lei Wenguang, Mao Xiaonan, Lu Yafeng. Effect of heat treatment process on microstructure and properties of TC4-DT titanium alloy thick plate[J]. Metal Heat Treatment, 2012,37(9):102−105. (雷文光, 毛小南, 卢亚锋. 热处理工艺对TC4-DT钛合金厚板组织和性能的影响[J]. 金属热处理, 2012,37(9):102−105. [12] Zhu Liwei, Wang Xinnan, Zhu Zhishou. Microstructure and mechanical properties of TC4-DT titanium alloy under different heat treatment processes[J]. Titanium Industry Progress, 2012,(1):14−17. (祝力伟, 王新南, 朱知寿. 不同热处理工艺下TC4-DT钛合金的显微组织及力学性能[J]. 钛工业进展, 2012,(1):14−17. [13] Li Jing, Zhu Zhishou, Wang Xinnan, et al. β effect of heat treatment process on crack propagation behavior of TC4-DT titanium alloy[J]. Rare Metals, 2017,41(7):745−750. (李静, 朱知寿, 王新南, 等. 准β热处理工艺对TC4-DT钛合金裂纹扩展行为的影响[J]. 稀有金属, 2017,41(7):745−750. [14] Li Hui, Qu Henglei, Zhao Yongqing, et al. Effect of heat treatment on microstructure and properties of Ti-6Al-4V ELI alloy thick plate[J]. Rare Metals, 2005,(6):841−844. (李辉, 曲恒磊, 赵永庆, 等. 热处理对Ti-6Al-4V ELI合金厚板组织与性能的影响[J]. 稀有金属, 2005,(6):841−844. doi: 10.3969/j.issn.0258-7076.2005.06.009 [15] Wang Xinnan, Zhu Zhishou, Shang Guoqiang, et al. Effect of heat treatment process on mechanical properties of Ti-6Al-4V ELI alloy thick section forgings[J]. Titanium Industry Progress, 2019,(2):29−33. (王新南, 朱知寿, 商国强, 等. 热处理工艺对Ti-6Al-4V ELI合金厚截面锻件力学性能的影响[J]. 钛工业进展, 2019,(2):29−33. [16] Wang Zhe, Wang Xinnan, Zhu Liwei, et al. Grain growth behavior in β phase of TB17 titanium alloy[J]. Titanium Industry Progress, 2016,33(6):11−15. (王哲, 王新南, 祝力伟, 等. TB17钛合金β相区晶粒长大行为[J]. 钛工业进展, 2016,33(6):11−15. [17] Wang B, Cheng L, Cui W, et al. Effect of forging process on high cycle and very high cycle fatigue properties of TC4 titanium alloy under three-point bending[J]. Fatigue & Fracture of Engineering Materials & Structures, 2021,(1):36−40. [18] Tian Chenchao, Gao Yang, Zhang Juan, et al. Comparative analysis of fatigue crack growth rate of TC4-DT and TC21 titanium alloys[J]. Welded Pipe, 2019,42(11):31−34. (田晨超, 高阳, 张娟, 等. TC4-DT及TC21钛合金疲劳裂纹扩展速率的对比分析[J]. 焊管, 2019,42(11):31−34. [19] Cui W, Chen X, Cheng L, et al. Fatigue property and failure mechanism of TC4 titanium alloy in the HCF and VHCF region considering different forging processes[J]. Materials Research Express, 2021,(3):48−52. [20] Guo P, Zhao Y, Hong Q, et al. Microscopic mechanism of fatigue crack propagation in TC4-DT titanium alloy[J]. Materials Reports, 2019,(5):28−32. [21] Wang B H, Cheng L, Bao X C. Effect of heat treatment on very high cycle fatigue properties of TC4[J]. Key Engineering Materials, 2021,881:3−11. doi: 10.4028/www.scientific.net/KEM.881.3 [22] Naydenkin E V, Soldatenkov A P, Mishin I P, et al. Very high cycle fatigue failure of near β titanium alloy[J]. Physical Mesomechanics, 2021,24(3):326−334. doi: 10.1134/S1029959921030115 [23] Shi Xiaoyun, Gao Yushe, Wang Wensheng. Effect of heat treatment on microstructure and mechanical properties of TC4-DT titanium alloy bar[J]. Hot Working Process, 2013,42(14):163−165. (史小云, 高玉社, 王文盛. 热处理对TC4-DT钛合金棒材组织和力学性能的影响[J]. 热加工工艺, 2013,42(14):163−165. [24] Liu G, Huang C, Sun S, et al. Effect of microstructure on high-speed cutting modified anti-fatigue performance of Incoloy A286 and titanium alloy TC17[J]. The International Journal of Advanced Manufacturing Technology, 2021,113(3):855−866. -

下载:

下载: