Effect of hot deformation parameters on the rheological behavior of two-phase region of titanium alloy

-

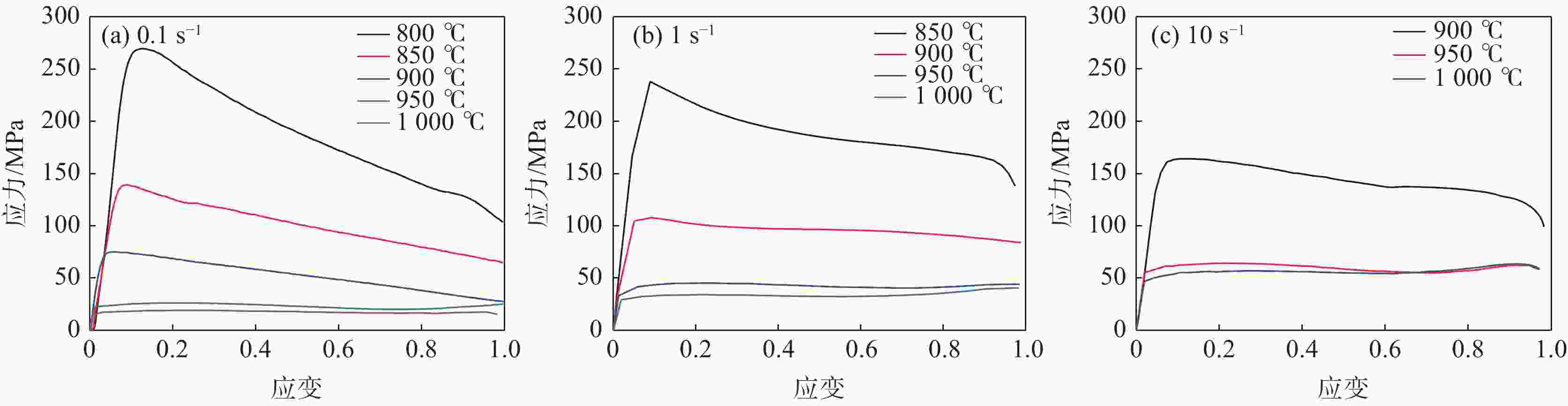

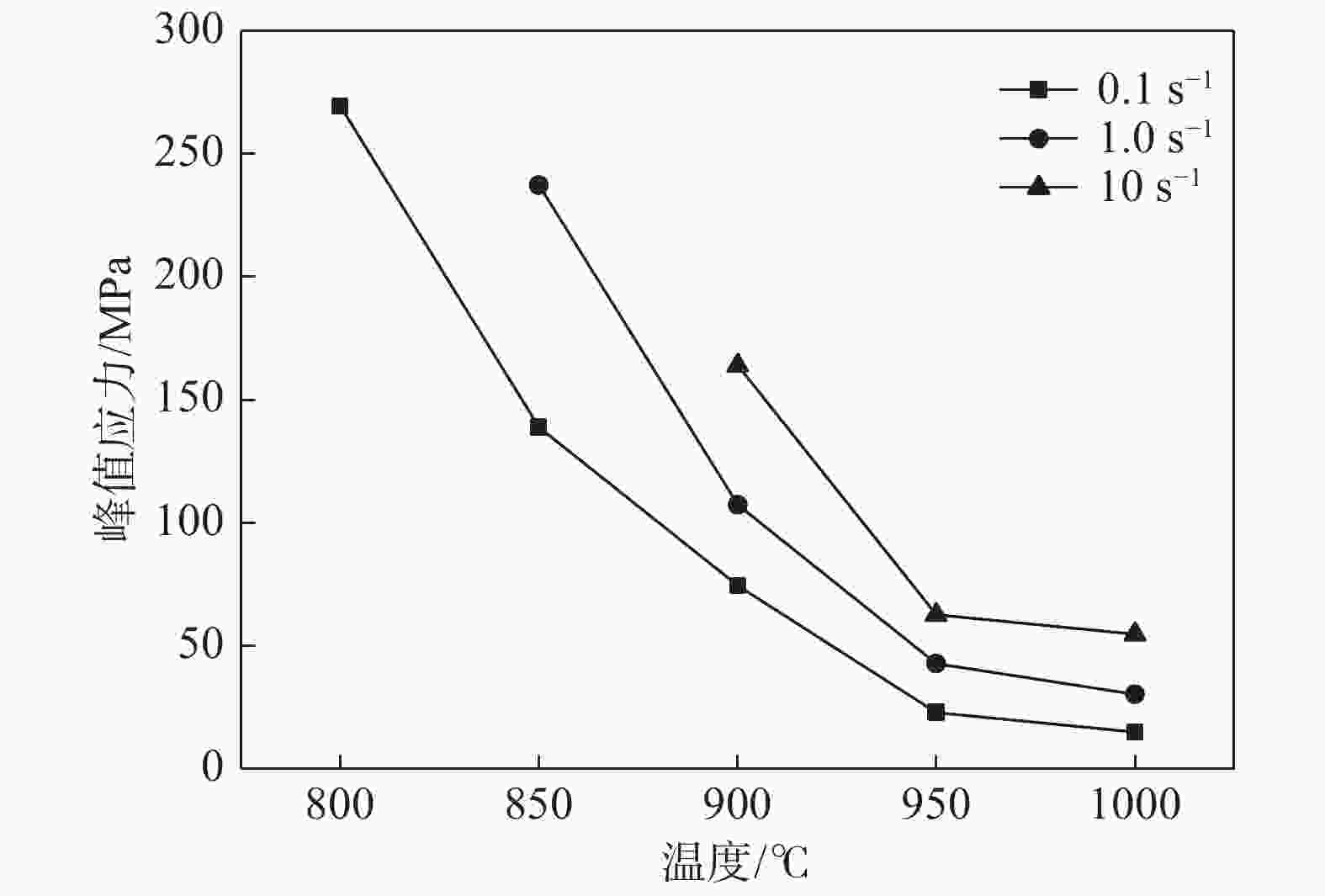

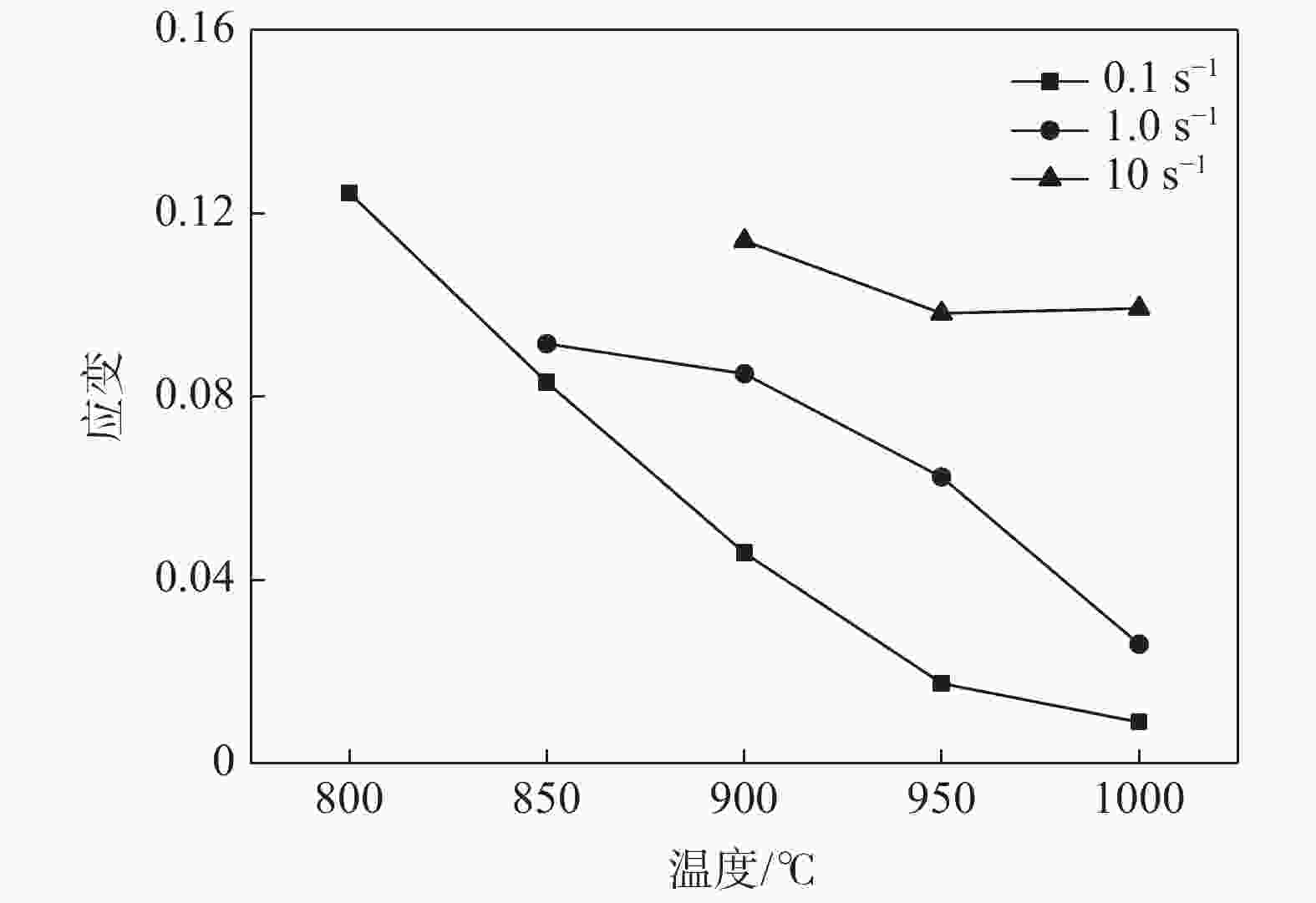

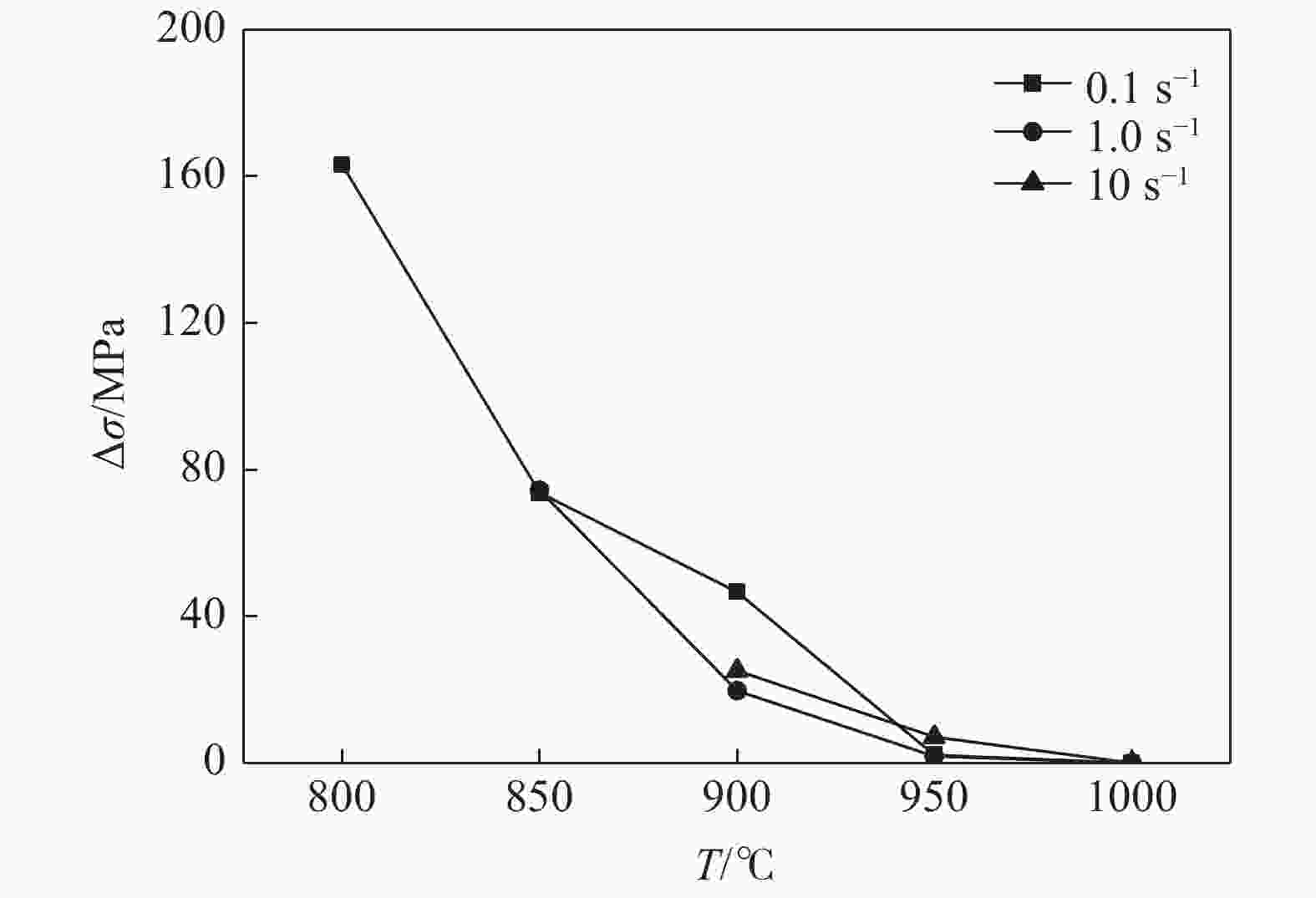

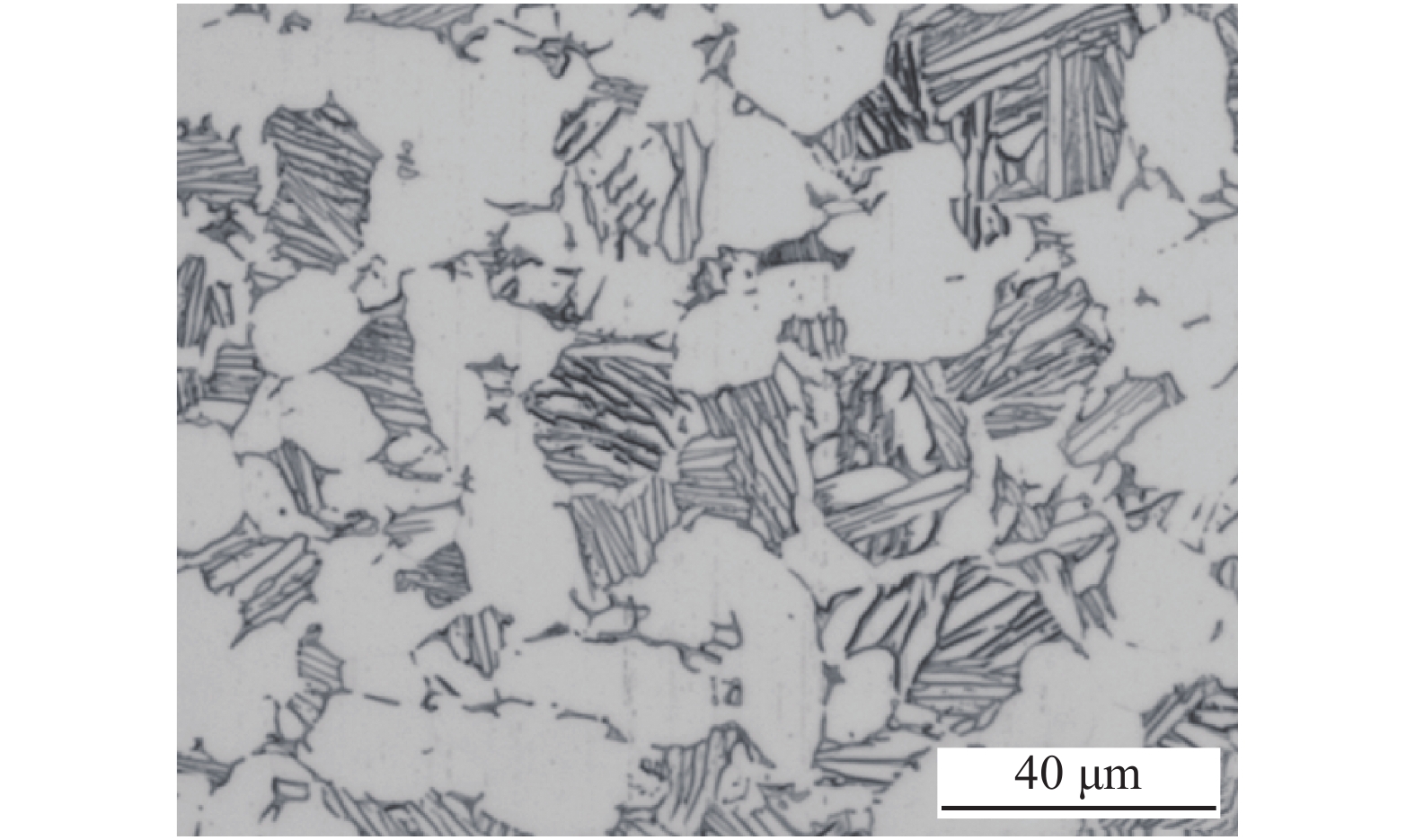

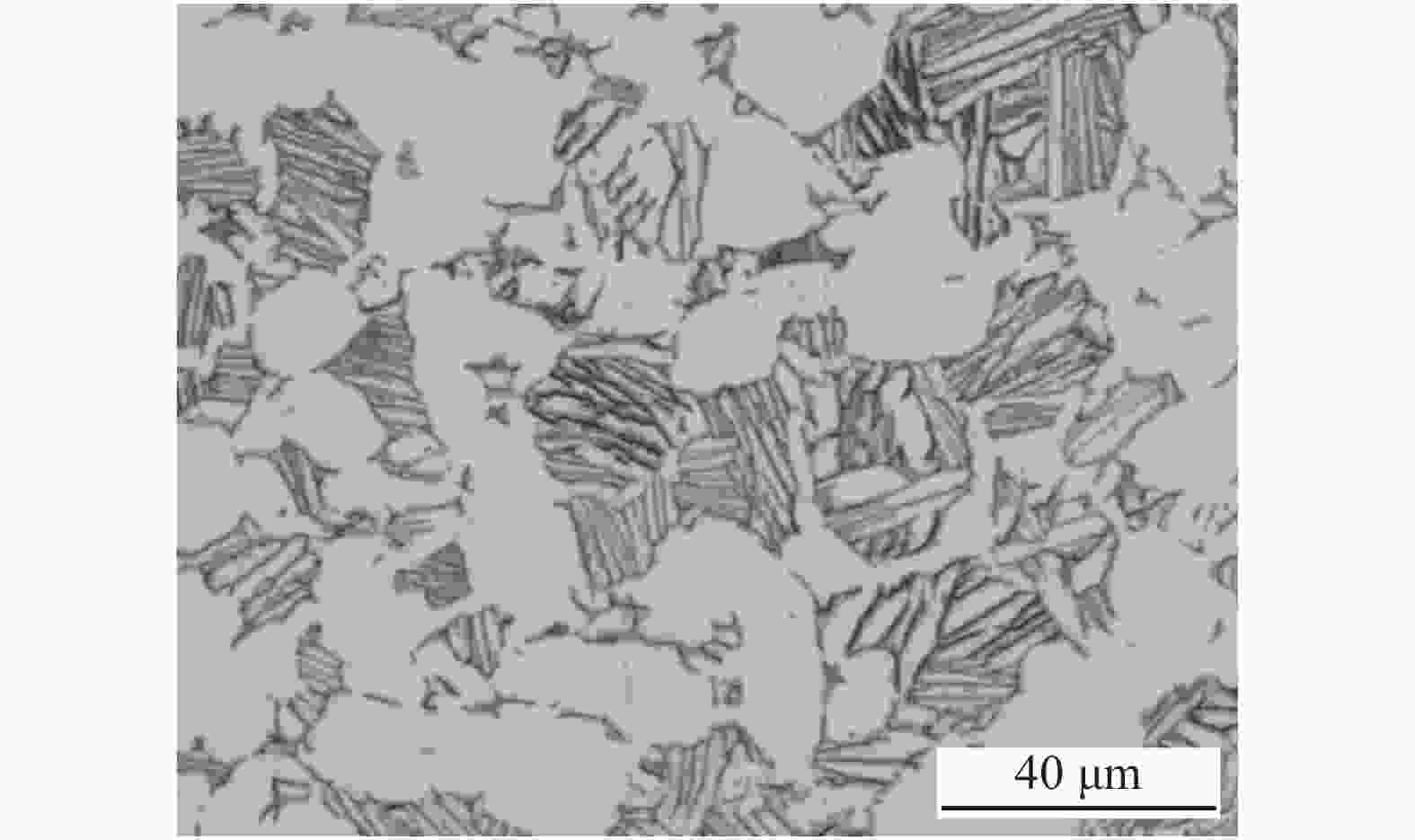

摘要: 以热轧态Ti80合金作为基材,在Gleeble-3500热模拟测试机上进行高温压缩测试,变形温度为800~1000 ℃,应变速率为0.01~10 s−1,总变形比例为75%。结果表明:Ti80钛合金在800~950 ℃时处于α+β两相区,其流变行为受变形温度和应变速率的显著影响。Ti80钛合金的加工硬化主要来自于初始α相中位错密度的提高,变形温度的提高会导致α相的减少,流变峰值应力不断降低,过高的应变速率会导致α相内位错运动受阻。Ti80钛合金中的初始α相更容易发生动态回复和动态再结晶,随着变形温度的提高,初始α相不断减少,动态软化程度逐渐减小直至接近0。为保证钛管热轧的稳定性,应适当提高变形温度,保证Ti80钛合金热变形组织具有较高的β相体积分数,同时避免应变速率过高造成轧制载荷过大。Abstract: Hot-rolled Ti80 alloy was used as the substrate, and the high temperature compression test was carried out on the Gleeble-3500 thermal simulation tester. The deformation temperature was 800~1 000 ℃, the strain rate was 0.01~10 s−1, and the total deformation ratio was 75%. The results show that the phase of Ti80 titanium alloy was in the α+β two-phase region at 800~950 ℃, and its rheological behavior was significantly affected by the deformation temperature and strain rate. The work hardening of Ti80 titanium alloy mainly came from the increase of the dislocation density in the initial α phase. The increase of the deformation temperature led to the decrease of the α phase, and the rheological peak stress continued to decrease. And the excessively high strain rate restrained the movement of the dislocations in the α phase. The initial α phase in Ti80 titanium alloy was more prone to dynamic recovery and dynamic recrystallization. As the deformation temperature increased, the initial α phase continued to decrease, and the dynamic softening degree gradually decreased until it approached zero. In order to ensure the stability of the hot rolling of the titanium tube, the deformation temperature should be appropriately increased for obtaining a higher β phase volume fraction of the hot deformed structure in the Ti80 titanium alloy, and avoiding the excessive rolling load caused by the excessively high strain rate.

-

Key words:

- titanium alloy tube /

- hot rolling /

- deformation temperature /

- strain rate /

- two-phase region /

- rheological behavior

-

表 1 Ti80钛合金化学成分

Table 1. Chemical composition of Ti80 titanium alloy

% Al Mo Sn V Ti 5.5~6.5 1.5~2.5 0.5~1.0 3.0~3.5 余量 -

[1] Zhou Xiaofeng, Sun Yu, Zhang Chuanyou, et al. R & D of TP-Ti-110 TP-G2(Ti) titanium alloy oil tubing with premium connection[J]. Steel Pipe, 2019,48(1):20−23. (周晓锋, 孙宇, 张传友, 等. TP-Ti-110钢级TP-G2(Ti)特殊螺纹钛合金油管的研发[J]. 钢管, 2019,48(1):20−23. doi: 10.3969/j.issn.1001-2311.2019.01.003 [2] Zha Yongjin, Hu Shijie, Zhuo Lubin, et al. Study on application prospects of titanium-alloy petroleum tubulars[J]. Drilling and Production Technology, 2017,40(4):1−3. (查永进, 胡世杰, 卓鲁斌, 等. 钛合金石油管材应用前景研究[J]. 钻采技术, 2017,40(4):1−3. [3] Schutz R W, Watkins H B. Recent developments in titanium alloy application in the energy industry[J]. Materials Science and Engineering A, 1998,243(12):305−315. [4] Hu Xinhe. Titanium alloy drill pipe—the best choice for short-radius horizontal drilling platforms[J]. China Petroleum Machinery, 2000,28(6):61. (胡辛禾. 钛合金钻杆—短半径水平钻井平台最佳选择[J]. 石油机械, 2000,28(6):61. doi: 10.3969/j.issn.1001-4578.2000.06.024 [5] Shi Xuezhi, Zhou Xiaohu, Qiao Zhiguo. Optimization of well completion string for ultra-deep gas reservoir with high sulfur content[J]. China Petroleum Machinery, 2016,44(8):11−14. (史雪枝, 周小虎, 乔智国. 超高深含硫气藏完井管材优化与实践[J]. 石油机械, 2016,44(8):11−14. [6] Banerjee D, Williams J C. Perspectives on titanium science and technology[J]. Acta Materialia, 2013,61:844−879. doi: 10.1016/j.actamat.2012.10.043 [7] Wang M, Zhou J X, Yin Y J, et al. Hot deformation behavior of the Ti6Al4V alloy prepared by powder hot isostatic pressing[J]. Journal of Alloys and Compounds, 2017,721:320−332. doi: 10.1016/j.jallcom.2017.06.003 [8] Chen W, Cao S, Kou W J, et al. Origin of the ductile-to-brittle transition of metastable β-titanium alloys: Self-hardening of ω-precipitates[J]. Acta Materialia, 2019,170(11):187−204. [9] Shang Guoqiang, Zhu Zhishou, Kou Hongchao, et al. Influence of hot rolling deformation on microstructure and properties of Ti-10V-2Fe-3Al alloy[J]. Transactions of Materials and Heat Treatment, 2013,34(3):108−113. (商国强, 朱知寿, 寇宏超, 等. 热轧变形对Ti-10V-2Fe-3Al合金组织和性能的影响[J]. 材料热处理学报, 2013,34(3):108−113. [10] Tang B, Li J S, Zhang F S, et al. Modeling the high temperature deformation constitutive relationship of TC4-DT alloy based on fuzzy-neural network[J]. Rare Metal Materials and Engineering, 2013,42(7):1347−1351. doi: 10.1016/S1875-5372(13)60083-1 [11] Wu Lin, Wang Kelu, Lu Shiqiang. Study on constitutive relationship of TB6 alloy based on stepwise regression method[J]. Material and Heat Treatment, 2010,39(8):29−31. (吴琳, 王克鲁, 鲁世强. 基于逐步回归法的TB6钛合金本构关系研究[J]. 热加工工艺, 2010,39(8):29−31. doi: 10.3969/j.issn.1001-3814.2010.08.010 [12] Yang Tao, Song Dandan. Thermal compression deformation behavior of as-cast Ti-5.5Al alloy for vehicle[J]. Ordnance Material Science and Engineering, 2021,44(2):103−106. (杨涛, 宋丹丹. 车用铸态Ti-5.5Al合金热压缩变形行为研究[J]. 兵器材料科学与工程, 2021,44(2):103−106. [13] Dong Hongbo, Yu Xinping, Zhang Wei. Dynamic softening and strain hardening behavior of Q550D steel based on the dislocation density theory[J]. Journal of Plasticity Engineering, 2015,22(3):98−102. (董洪波, 余新平, 章威. 基于位错密度理论的Q550D钢动态软化及加工硬化行为[J]. 塑性工程学报, 2015,22(3):98−102. -

下载:

下载: