Effects of raw powder on NiTi parts fabricated by selective laser melting

-

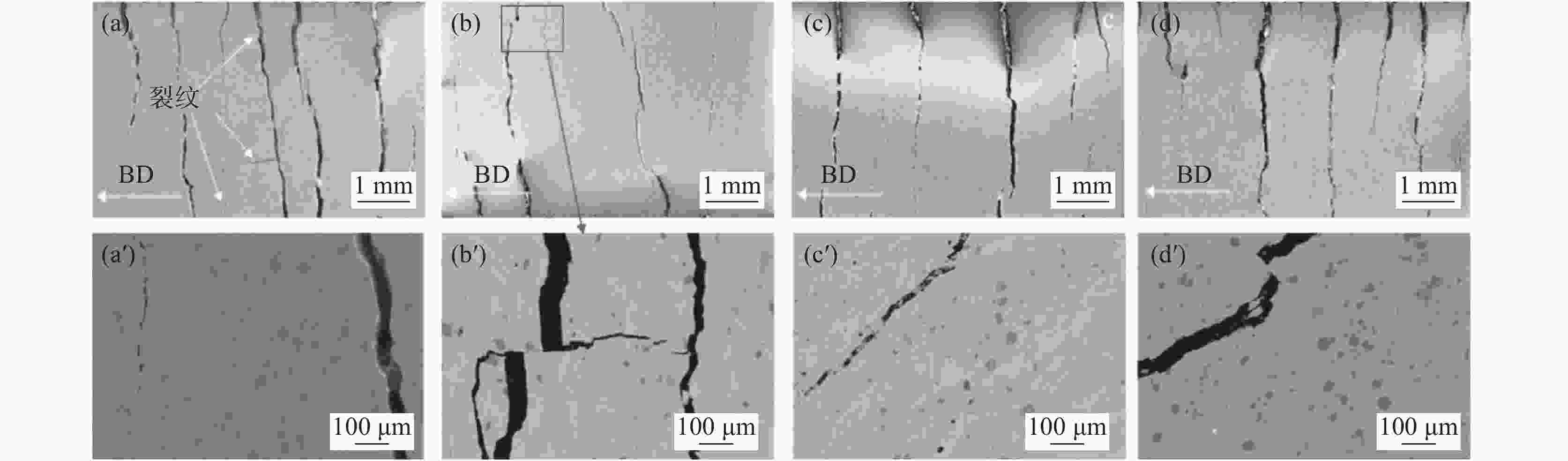

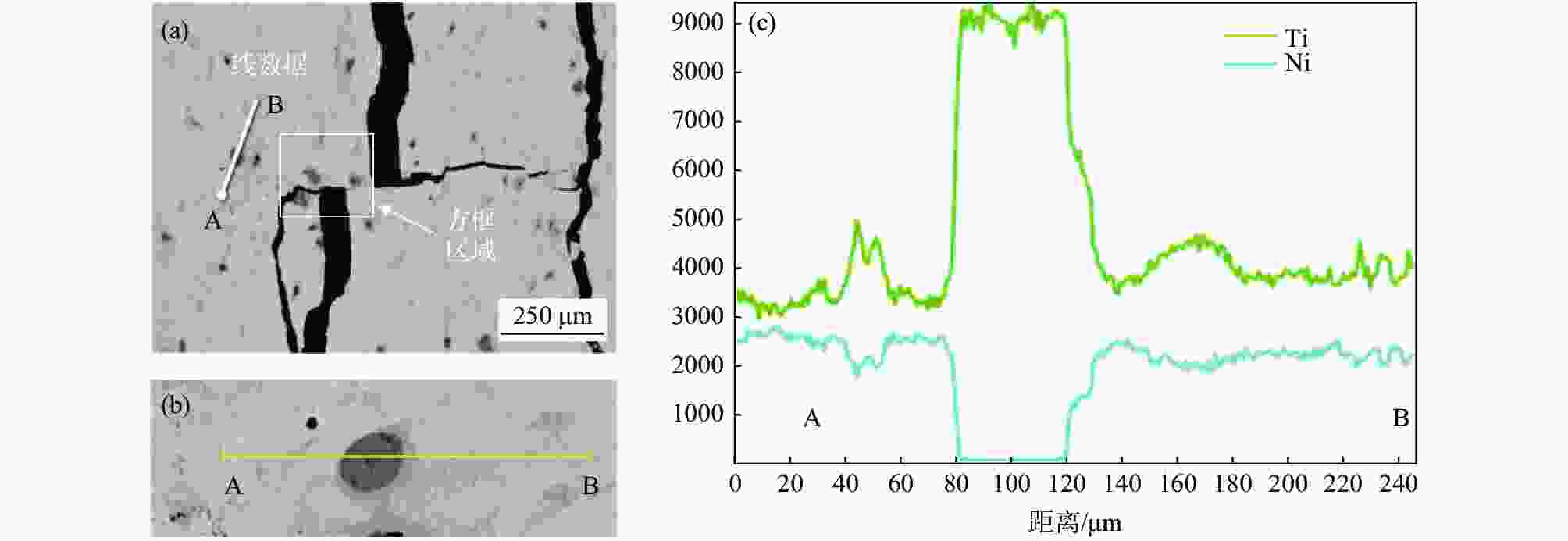

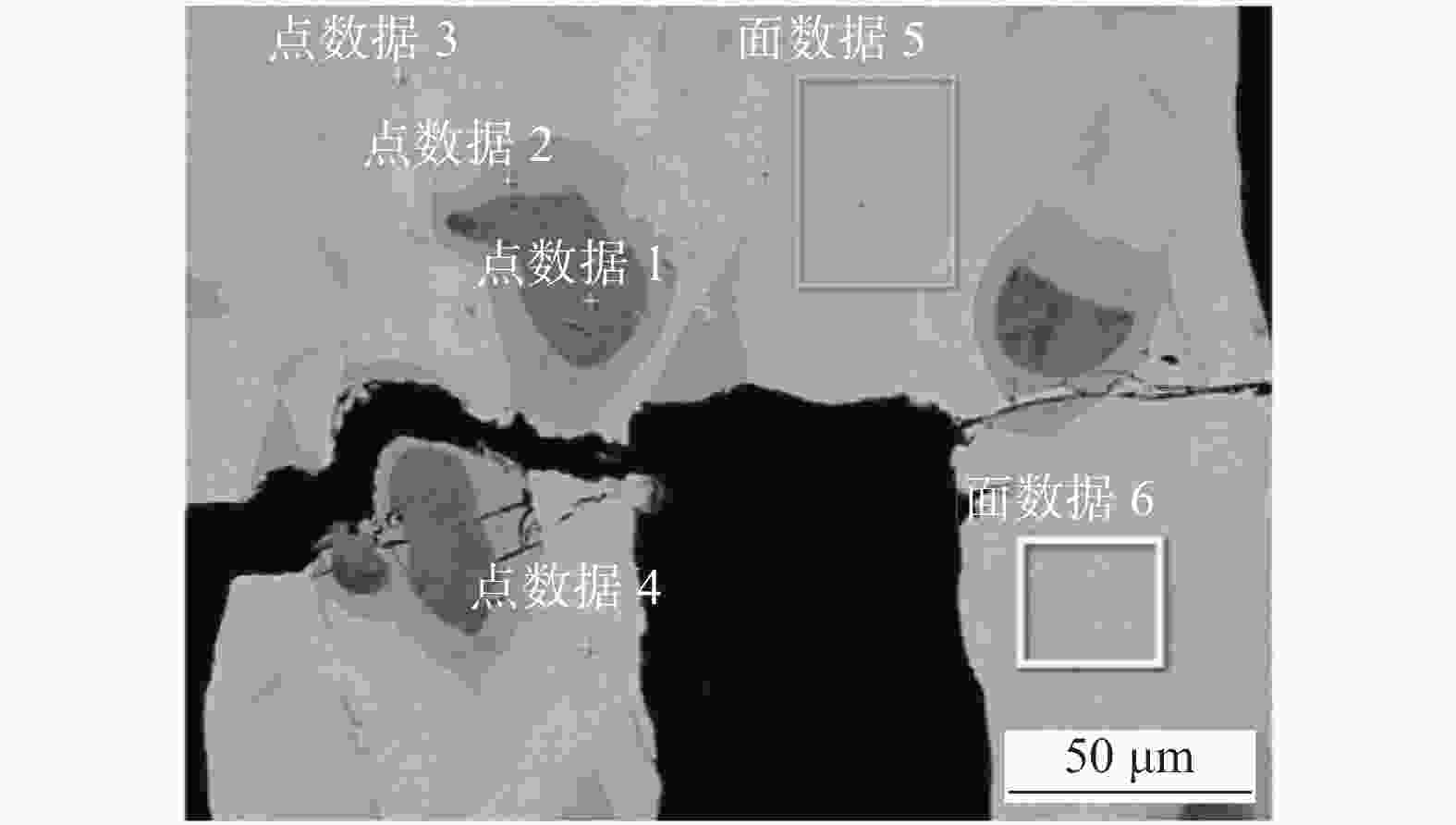

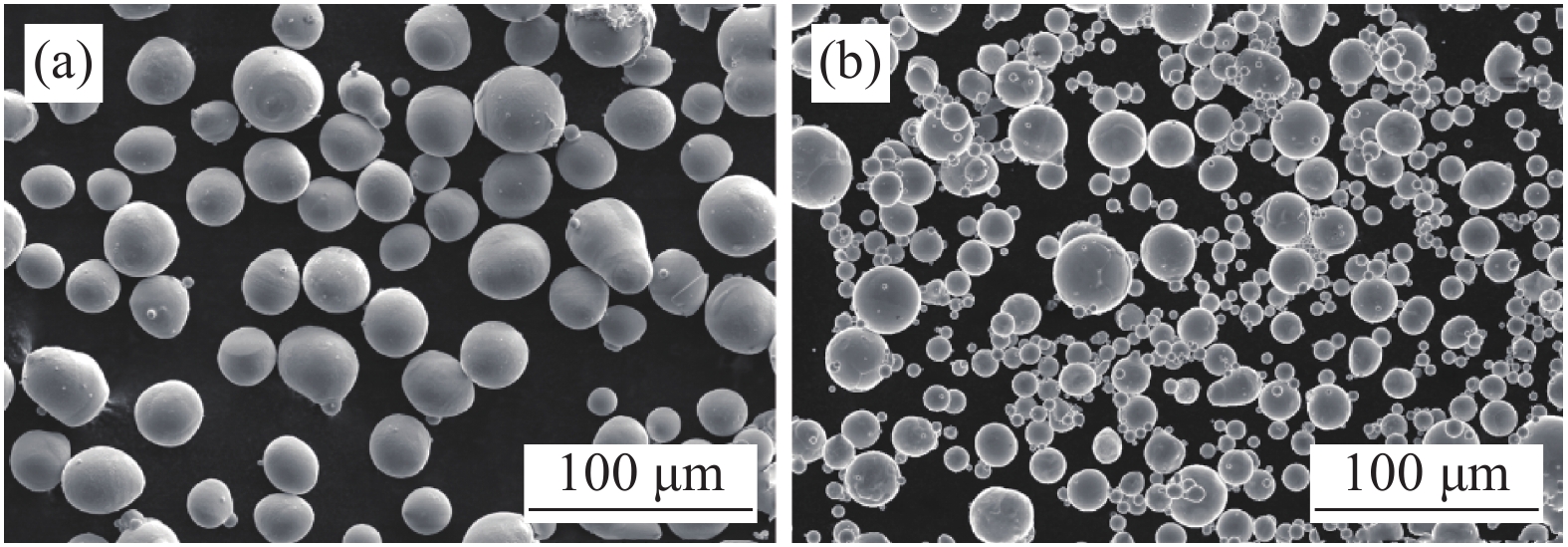

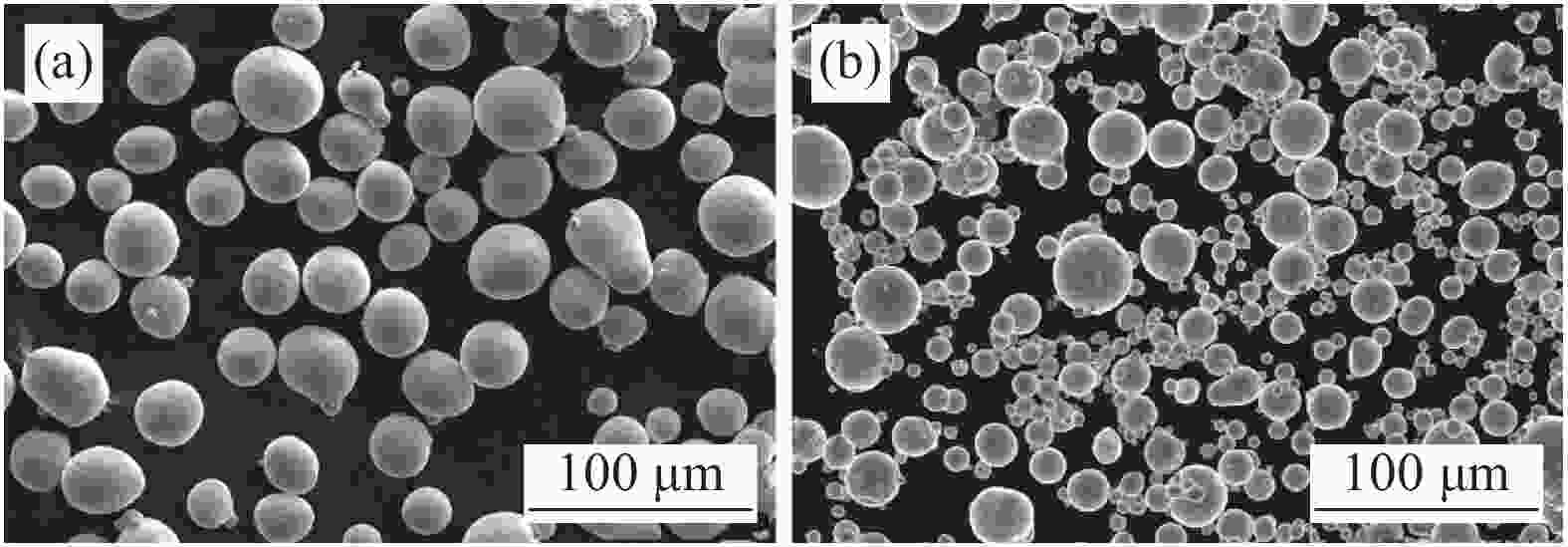

摘要: 分别以Ni+Ti元素混合粉末和NiTi预合金粉末为原料,采用选区激光熔化工艺打印成形。重点研究了在相同打印工艺参数下原料粉末对成形件致密度、物相组成、显微组织、显微硬度的影响,从而反馈说明所用打印粉末对成形件性能的影响。结果表明:在相同打印工艺参数下,整体上NiTi预合金粉末成形件的致密度较高,而Ni+Ti 混合粉末成形件的显微硬度较高。对于同一种粉末,随着能量密度的增大,成形件的致密度先增大后减小,而显微硬度先减小后增大。NiTi预合金粉末成形件有致密的微观结构且相分布均匀,但存在少量孔隙。Ni+Ti 混合粉末成形件的微观结构有和构建方向垂直的贯穿式裂纹以及不均匀的基体相,但几乎没有孔隙。Abstract: In this study, Ni + Ti mixed powder and NiTi pre-alloyed powder were used to print by selective laser melting process. The effects of raw material powder on the density, phase composition, microstructure and microhardness of formed parts under the identical processing parameters are studied, so as to feedback the effects of raw powder on the properties of formed parts. The results showed that under the identical processing parameters, the density of the formed parts fabricated by NiTi pre-alloyed powder was higher, while the microhardness of Ni + Ti mixed powder formed parts was higher. For the same powder, with increase of energy density, density of the formed parts first increased and then decreased, while microhardness first decreased and then increased. NiTi pre-alloyed powder formed parts had dense microstructure and uniform phase distribution, but there presented several pores. The microstructure of Ni + Ti mixed powder formed parts has through cracks perpendicular to the construction direction and uneven matrix phase, but there are almost no pores in the structure.

-

Key words:

- selective laser melting /

- Ni+Ti mixed powder /

- NiTi pre-alloyed powder /

- density /

- microhardness

-

表 1 原料粉末的杂质含量及粒度

Table 1. Impurity content and particle size of the raw material powders

原料粉末 w/% D10/µm D50/µm D90/µm C H O NiTi ~0.0015 ~0.0003 ~0.006 21.90 33.60 49.80 Ni ~0.0034 ~0.0006 ~0.0250 10.6 23.5 43.3 Ti ~0.0046 ~0.0014 ~0.0560 26.3 44.0 86.2 表 2 选区激光熔化工艺参数

Table 2. Experimental parameters of selective laser melting

层 P/W v/(mm·s−1) h/µm t/µm E/(J·mm−3) 1 50 350 120 30 39.68 2 50 300 120 30 46.29 3 50 250 120 30 55.55 4 50 166 120 30 83.66 表 3 Ni+Ti 混合粉末成形件微观结构的不同区域的Ni/Ti

Table 3. Ni/ Ti in different regions of microstructure of Ni + Ti mixed powder formed parts

区域 y/% Ti Ni 合计 点数据1 99.62 0.38 100.00 点数据 2 73.93 26.07 100.00 点数据 3 39.98 60.02 100.00 点数据 4 39.46 60.54 100.00 面数据 5 44.25 55.75 100.00 面数据 6 42.49 57.51 100.00 -

[1] Elahinia M H, Hashem M, Tabesh M, et al. Manufacturing and processing of NiTi implants: a review[J]. Progress in Materials Science, 2012,57(5):911−946. doi: 10.1016/j.pmatsci.2011.11.001 [2] Zhao X. Additive manufacturing NiTi shape memory alloy and its application in aeronautical manufacturing[J]. Aeronautical Manufacturing Technology, 2016,507(12):34−41. [3] Andani M T, Moghaddam N S, Haberland C, et al. Metals for bone implants. Part 1. Powder metallurgy and implant rendering[J]. Acta Biomaterialia, 2014,10(10):4058−4070. doi: 10.1016/j.actbio.2014.06.025 [4] Moghaddam N S, Skoracki R, Miller M, et al. Three dimensional printing of stiffness-tuned, nitinol skeletal fixation hardware with an example of mandibular segmental defect repair[J]. Procedia CIRP, 2016,49:45−50. doi: 10.1016/j.procir.2015.07.027 [5] Hutmacher D W, Sittinger M, Risbud M V. Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems[J]. Trends in Biotechnology, 2004,22(7):354−362. doi: 10.1016/j.tibtech.2004.05.005 [6] Thijs L, Montero Sistiaga M, Wauthle R, et al. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum[J]. Acta Materialia, 2013,61(12):4657−4668. doi: 10.1016/j.actamat.2013.04.036 [7] Ng C C, Savalani M M, Lau M L, et al. Microstructure and mechanical properties of selective laser melted magnesium[J]. Applied Surface Science, 2011,257(17):7447−7454. doi: 10.1016/j.apsusc.2011.03.004 [8] Zhang B, Chen J, Coddet C. Microstructure and transformation behavior of in-situ shape memory alloys by selective laser melting Ti-Ni mixed powder[J]. Journal of Materials Science & Technology, 2013,29(9):863−867. [9] Wang C, Tan X P, Du Z, et al. Additive manufacturing of NiTi shape memory alloys using pre-mixed powders[J]. Journal of Materials Processing Technology, 2019:152−161. [10] Yang Y, Zhan J B, Li B, et al. Laser beam energy dependence of martensitic transformation in SLM fabricated NiTi shape memory alloy[J]. Materialia, 2019,6:55−75. [11] Yang Y, Huang Y, Wu W. One-step shaping of NiTi biomaterial by selective laser melting [C]// Society of Photo-Optical Instrumentation Engineers (SPIE) Conference Series, 2007. [12] Li R, Liu J, Shi Y, et al. Balling behavior of stainless steel and nickel powder during selective laser melting process[J]. International Journal of Advanced Manufacturing Technology, 2012,59:1025−1035. doi: 10.1007/s00170-011-3566-1 [13] Haberland C, Elahinia M, Walker J M, et al. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing[J]. Smart Materials & Structures, 2014,23:55−67. [14] Li S, Hassanin H, Attallah M M, et al. The development of TiNi-based negative poisson's ratio structure using selective laser melting[J]. Acta Materialia, 2016,105:75−83. doi: 10.1016/j.actamat.2015.12.017 [15] Zhang L, Chen X, Xia T. Development of NiTi porous alloys prepared by SHS process[J]. Powder Metallurgy Industry, 2007,17(3):48−51. [16] Gu D, Ma C. In-situ formation of Ni4Ti3 precipitate and its effect on pseudoelasticity in selective laser melting additive manufactured NiTi-based composites[J]. Applied Surface Science, 2018:862−870. [17] Buehler W J, Gilfrich J V, Wiley R C. Effect of low temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics, 1963,34(5):1475−1477. doi: 10.1063/1.1729603 [18] Nishida M, Wayman C M, Honma T. Precipitation processes in near-equiatomic TiNi shape memory alloys[J]. Metallurgical Transactions A, 1986,17A:1505−1515. [19] Montero-Sistiaga M L, Miguel G M, Kurt B, et al. Microstructure evolution of 316 L produced by HP-SLM (high power selective laser melting)[J]. Additive Manufacturing, 2018,23:402−410. doi: 10.1016/j.addma.2018.08.028 [20] Jiang X, Xia W, Lou D, et al. Effect of scanning speed on internal defects and mechanical properties of Ti-6Al-4V alloy processed by selective laser melting[J]. Matertials for Mechanical Engineering, 2020,44(11):41−45. [21] Zhang B, Fenineche N E, Zhu L, et al. Studies of magnetic properties of permalloy (Fe–30%Ni) prepared by SLM technology[J]. Journal of Magnetism and Magnetic Materials, 2012,324(4):495−500. doi: 10.1016/j.jmmm.2011.08.030 [22] Elahinia M, Moghaddam N S, Andani M T, et al. Fabrication of NiTi through additive manufacturing: a review[J]. Progress in Materials Science, 2016,83(10):630−636. [23] Meier H, Haberland C. Experimental studies on selective laser melting of metallic parts[J]. Materialwissenschaft und Werkstofftechnik, 2008,39(9):665−70. doi: 10.1002/mawe.200800327 [24] Gao F, Wang H M. Dry sliding wear property of a laser melting/deposited Ti2Ni/TiNi intermetallic alloy[J]. Intermetallics, 2008,16:202−208. doi: 10.1016/j.intermet.2007.09.008 [25] Ma Y, Liu Y, Shi W, et al. Effect of scanning speed on forming defects and properties of selective laser melted 316 L stainless steel powder[J]. Laser & Optoelectronics Progress, 2019,56(10):55−64. -

下载:

下载: