Microstructure and mechanical properties of TC4-DT produced by laser wire-feed additive manufacturing

-

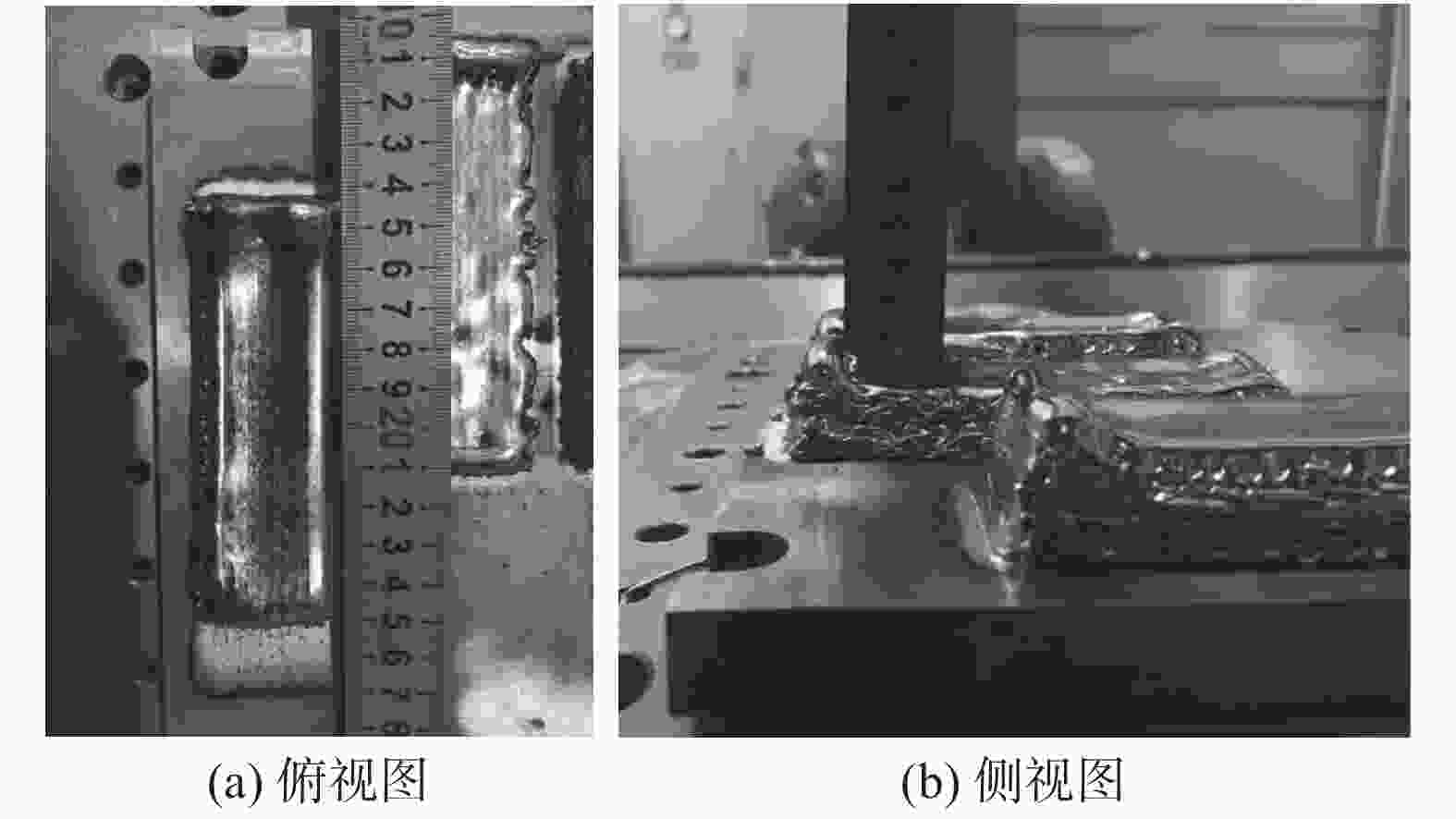

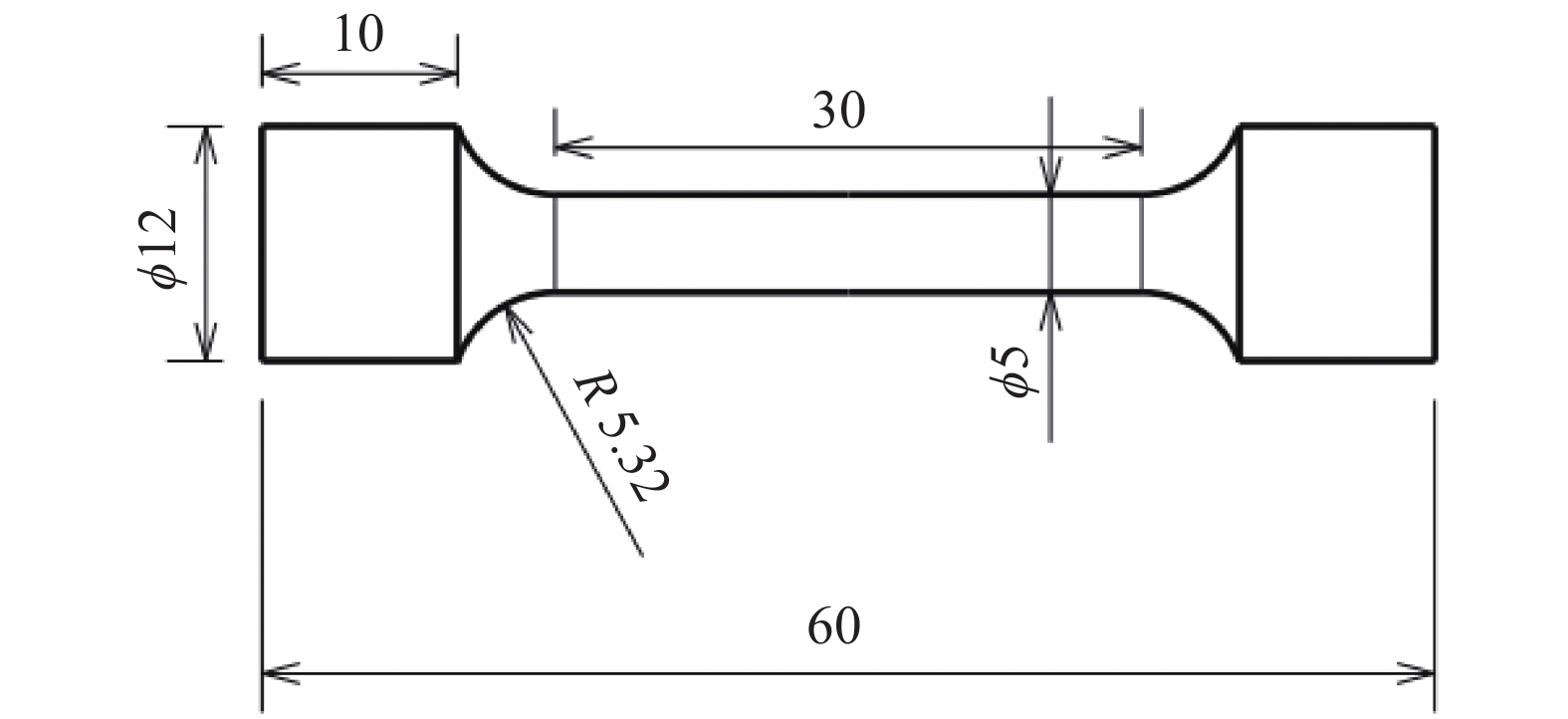

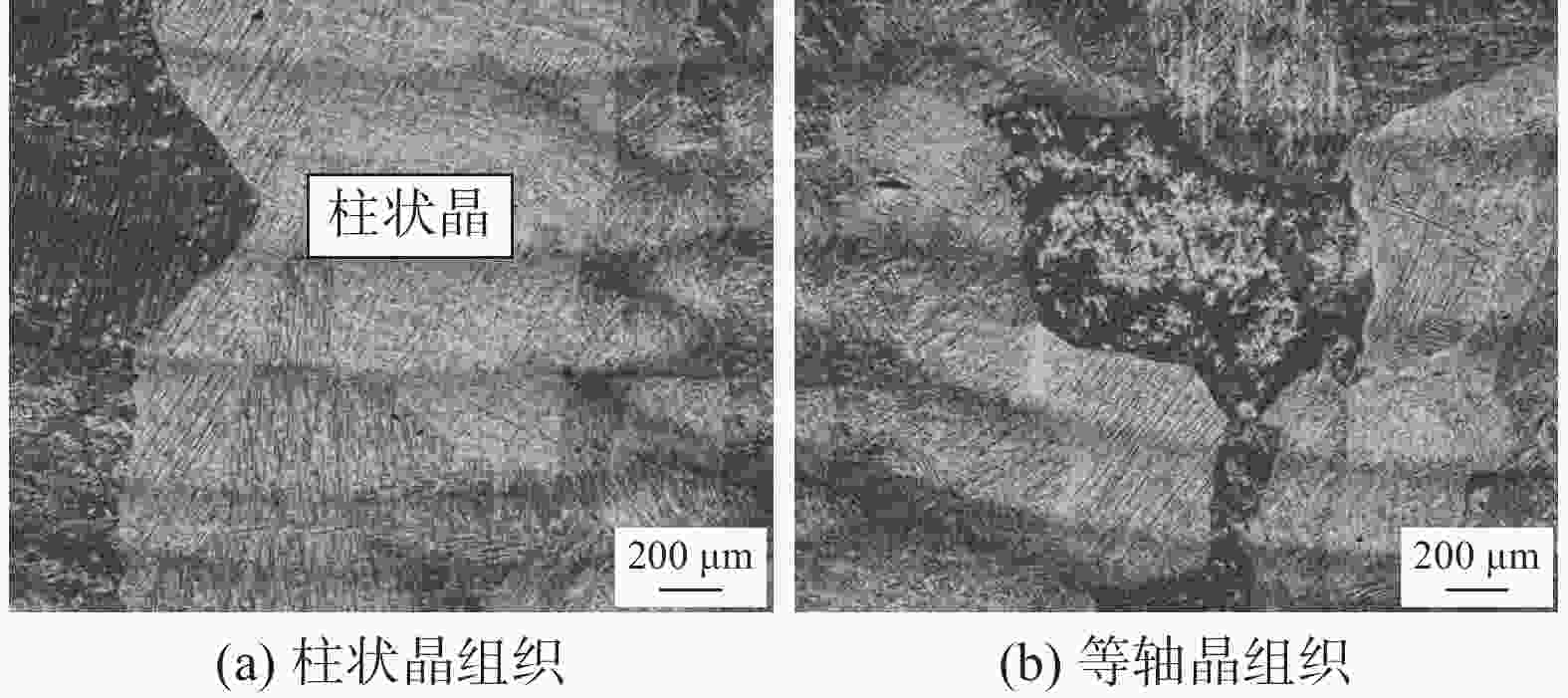

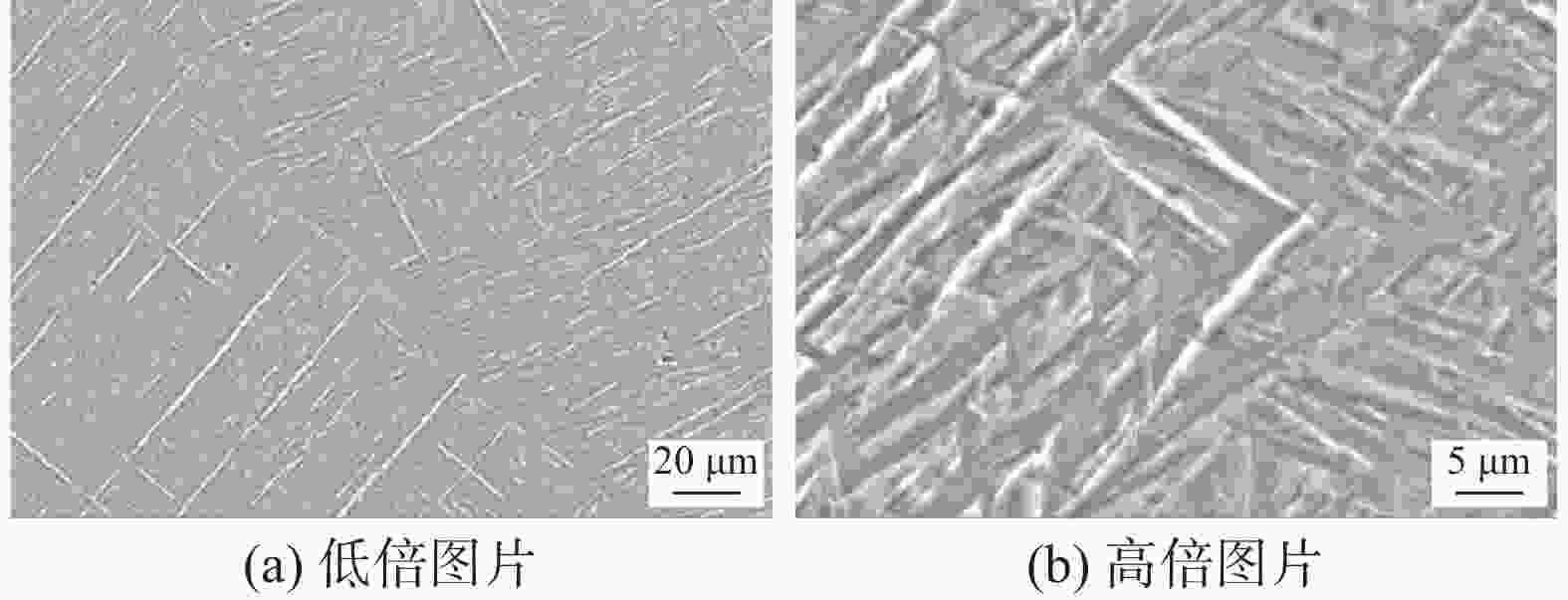

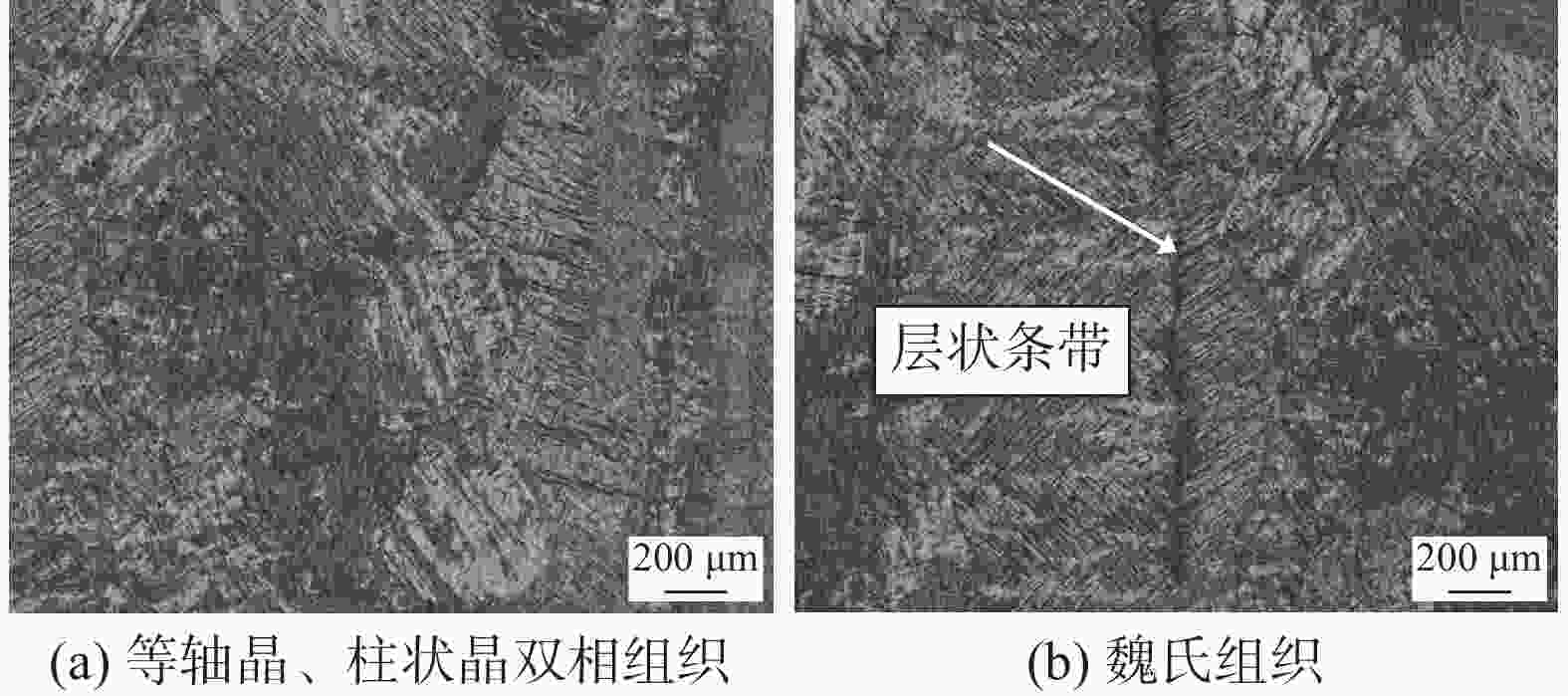

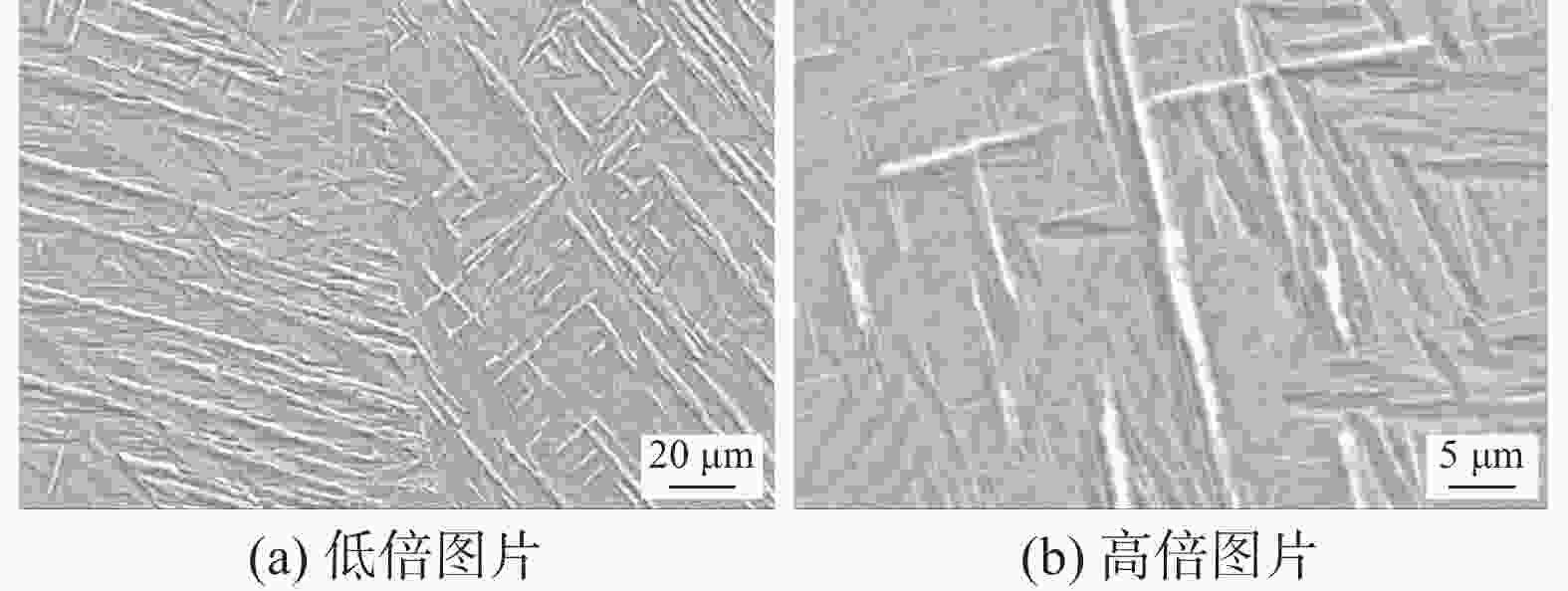

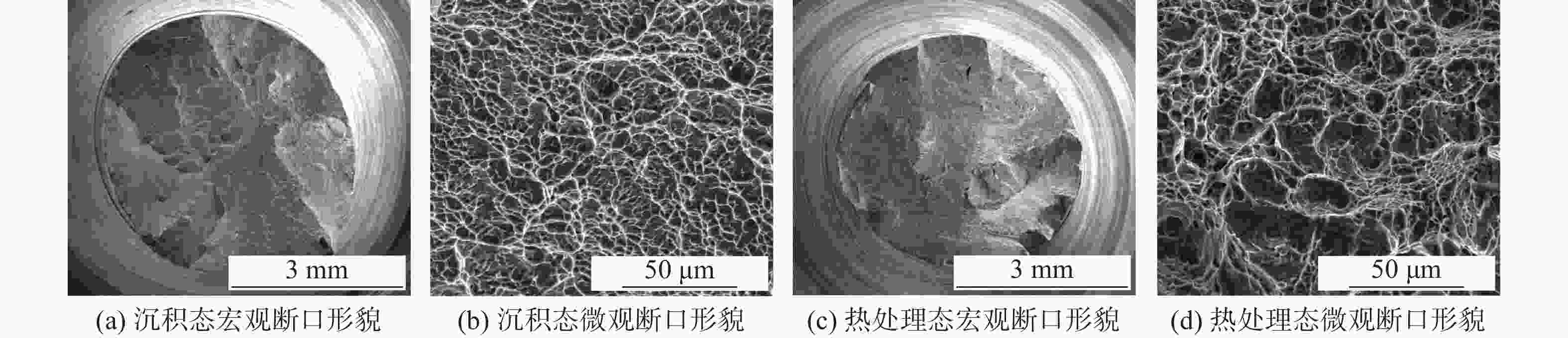

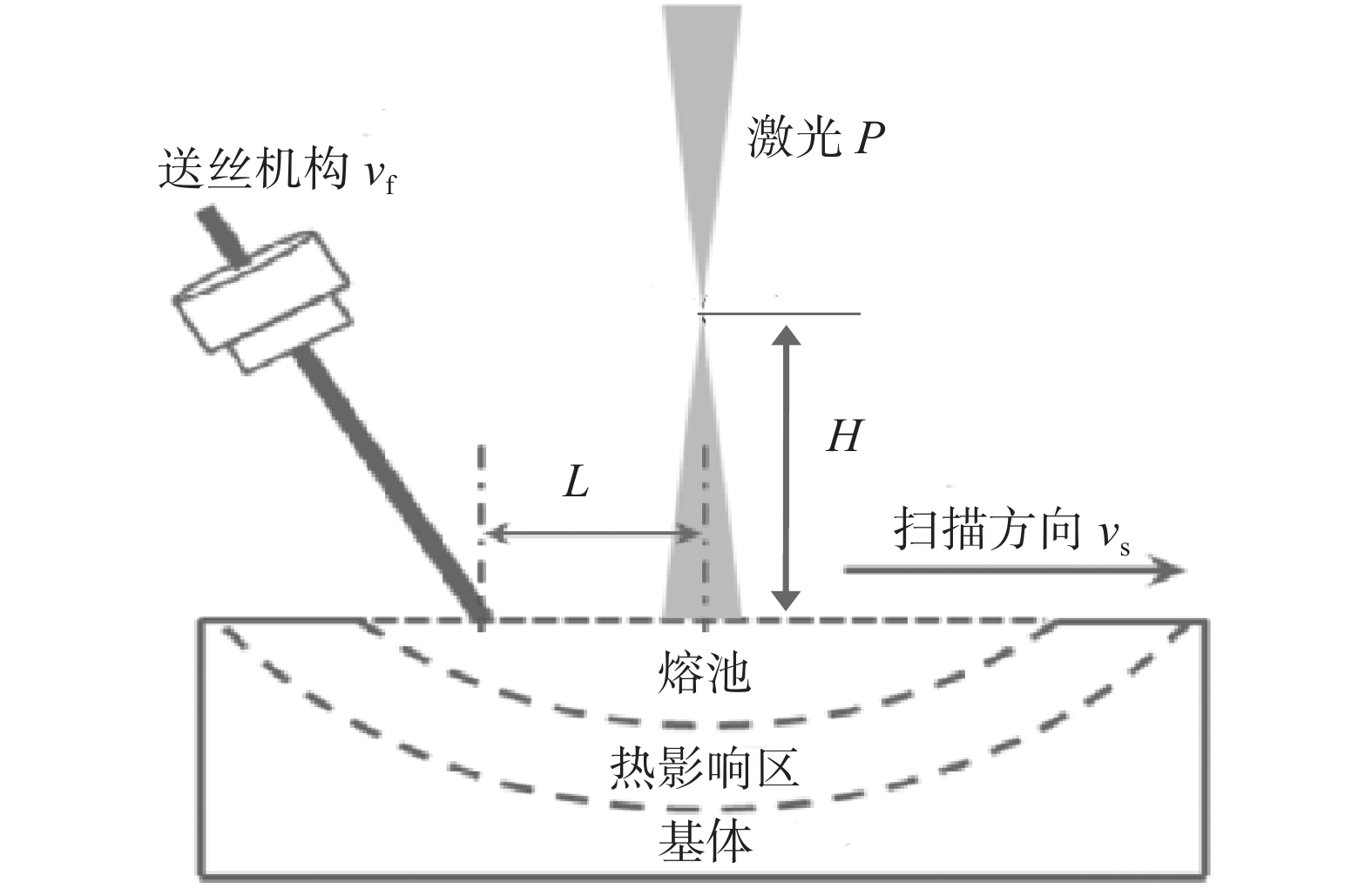

摘要: 激光熔丝增材制造技术在航空航天、海工船舶等领域应用前景广阔。针对TC4-DT材料,在初步优化的工艺参数下,通过激光熔丝增材制造技术制备金属试样,并对试样进行固溶-强化热处理,研究激光熔丝沉积态及热处理态的微观组织、缺陷及室温拉伸力学性能。研究发现,激光熔丝TC4-DT成形态组织为粗大的柱状晶及针状αʹ马氏体,热处理后转变为等轴晶与柱状晶的双相组织,马氏体分解为针状α+β双相组织,固溶-强化热处理后拉伸力学性能与锻件水平相当。Abstract: Laser wire-feed metal additive manufacturing technology has a wide application prospect in aerospace, marine engineering and shipbuilding. In this paper, TC4-DT samples were prepared by the laser wire-feed additive manufacturing technology combined with solution strengthening heat treatment method, based on the initial optimized process parameters. The microstructure, defects and room temperature tensile mechanical properties of the samples at as-deposited state and heat-treated state were respectively studied. It is found that the morphology of as-deposited TC4-DT is composed of columnar grains and acicular αʹ martensite. After solution strengthening heat treatment, equiaxed and columnar dual phase structure is formed, and αʹ martensite is decomposed into acicular structure of α+β. The tensile mechanical properties after heat treatment are equivalent to those of forgings.

-

表 1 TC4-DT丝材化学成分

Table 1. The chemical composition of TC4-DT wire

% C V Al Fe Ti H N O 0.013 4.03 6.33 0.049 90.14 0.0055 0.006 0.034 表 2 激光熔丝试验工艺参数

Table 2. Processing parameters of laser wire-feed additive manufacturing

扫描速度vs/(mm·s−1) 送丝速度vf/(mm·s−1) 功率P/kW 离焦量H/mm 光丝距L/mm 送丝角α/(°) 搭接率/% 10 20 3.0 50 0 30 50 表 3 TC4-DT钛合金激光熔丝沉积态、热处理态与(GB/T 25137—2010)标准中TC4 ELI退火态合金棒室温拉伸数据对比

Table 3. Comparison of tensile data at room temperature of as-deposited, heat-treated laser fusing additive manufactured TC4-DT titanium alloy and TC4 ELI annealed alloy in GB/T 25137—2010 standard

试样 Rm/MPa Rp0.2/MPa A/% 沉积态 976 901 6 热处理态 1 029 894 9.5 TC4 ELI锻件(GB/T 25137—2010) 828 759 10 -

[1] Jin Hexi, Wei Kexiang, Li Jianming, et al. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2015,25(2):280−292. (金和喜, 魏克湘, 李建明, 等. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015,25(2):280−292. [2] Zhao Yongqing, Ge Peng. Current situation and development of new titanium alloys invented in China[J]. Journal of Aeronautical Materials, 2014,34(4):51−61. (赵永庆, 葛鹏. 我国自主研发钛合金现状与进展[J]. 航空材料学报, 2014,34(4):51−61. doi: 10.11868/j.issn.1005-5053.2014.4.005 [3] Yang Chuan, Xu Wenchen, Wan Xingjie, et al. Research on near isothermal forging process of TC4 titanium alloy forgings with thin wall and high rib[J]. Journal of Plasticity Engineering, 2019,26(2):69−78. (杨川, 徐文臣, 万星杰, 等. TC4钛合金薄壁高筋构件近等温锻造技术研究[J]. 塑性工程学报, 2019,26(2):69−78. doi: 10.3969/j.issn.1007-2012.2019.02.009 [4] Liu Shunyu, Shin Yung C. Additive manufacturing of Ti6Al4V alloy: A review[J]. Materials & Design, 2019,164:107. [5] Gou Jian, Wang Zhijiang, Hu Shengsun, et al. Effects of CMT+P process and post heat treatment on microstructure and properties of TC4 component by additive manufacturing[J]. Transactions of the China Welding Institution, 2019,40(12):31−35, 46. (勾健, 王志江, 胡绳荪, 等. CMT+P过程及后热处理对TC4钛合金增材构件组织和性能影响[J]. 焊接学报, 2019,40(12):31−35, 46. [6] Brandl E, Baufeld B, Leyens C, et al. Additive manufactured Ti-6Al-4V using welding wire: comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications[J]. Physics Procedia, 2010,5:595−606. doi: 10.1016/j.phpro.2010.08.087 [7] Ahmed T, Rack H J. Phase transformations during cooling in α+β titanium alloys[J]. Materials Science and Engineering:A, 1998,243(1):206−211. [8] Ducato A, Fratini L, Cascia M L, et al. An automated visual inspection system for the classification of the phases of Ti-6Al-4V titanium alloy[C]//Computer Analysis of Images and Patterns. Springer, 2013. [9] Wang T, Zhu Y Y, Zhang S Q, et al. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing[J]. Journal of Alloys and Compounds, 2015,632:505−513. doi: 10.1016/j.jallcom.2015.01.256 [10] Wu Xinhua, Liang Jing, Mei Junfa, et al. Microstructures of laser-deposited Ti–6Al–4V[J]. Materials & Design, 2004,25(2):137−144. [11] Qian L, Mei J, Liang J, et al. Influence of position and laser power on thermal history and microstructure of direct laser fabricated Ti–6Al–4V samples[J]. Materials Science and Technology, 2005,21(5):597−605. doi: 10.1179/174328405X21003 [12] Yu Jun, Rombouts Marleen, Maes Gert, et al. Material properties of Ti6Al4V parts produced by laser metal deposition[J]. Physics Procedia, 2012,39:416−424. doi: 10.1016/j.phpro.2012.10.056 [13] Zhang Jinzhi, Zhang Anfeng, Wang Hong, et al. Microstructure and anisotropy of high performance TC4 obtained by micro forging laser cladding deposition[J]. Chinese Journal of Lasers, 2019,46(4):102−109. (张金智, 张安峰, 王宏, 等. 微锻造激光熔覆沉积高性能TC4组织与各向异性[J]. 中国激光, 2019,46(4):102−109. [14] Gil Mur F X, Rodríguez D, Planell J A. Influence of tempering temperature and time on the α′-Ti-6Al-4V martensite[J]. Journal of Alloys and Compounds, 1996,234(2):287−289. doi: 10.1016/0925-8388(95)02057-8 -

下载:

下载: