Effect of hot-pressing temperature on element diffusion behavior and microstructure of TC4/Ta layered composites

-

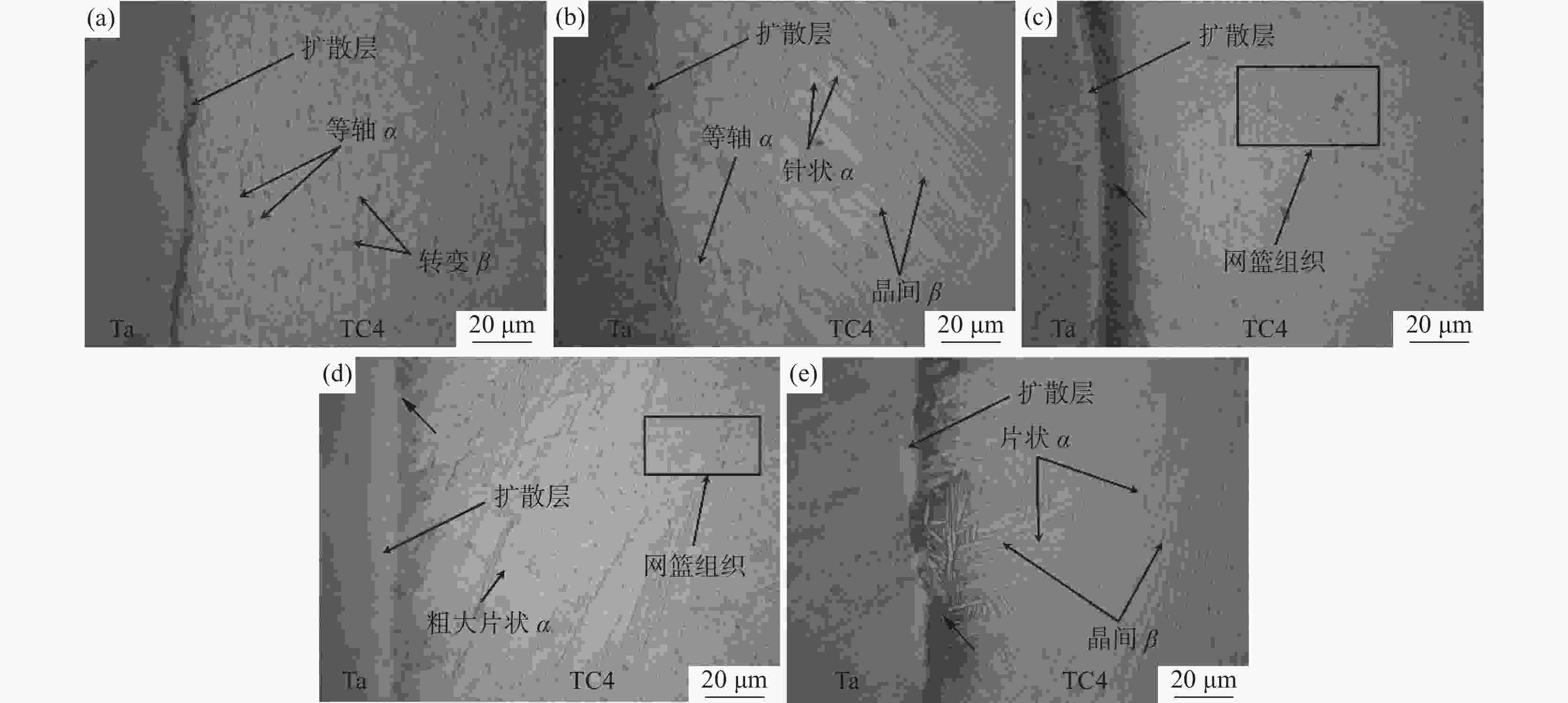

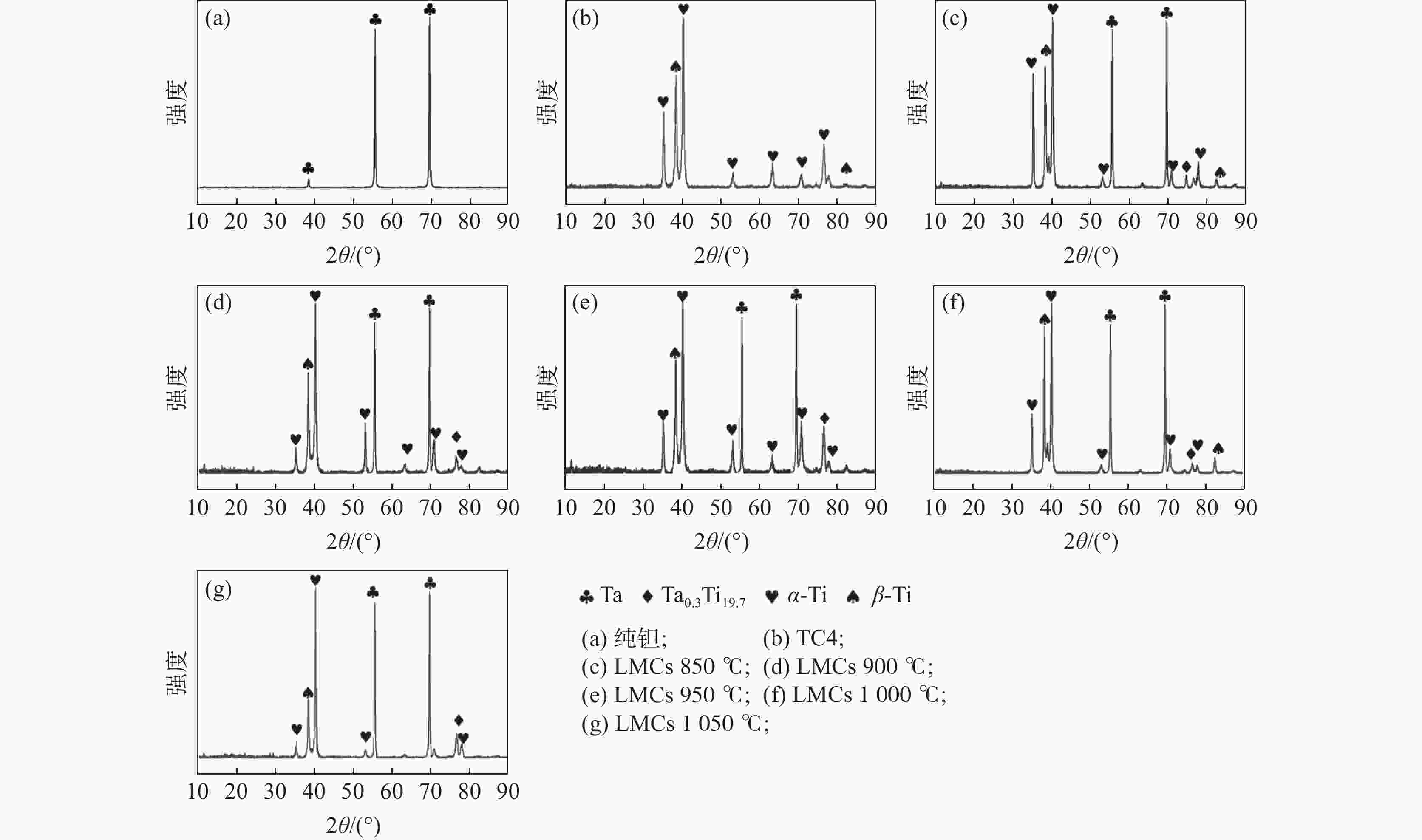

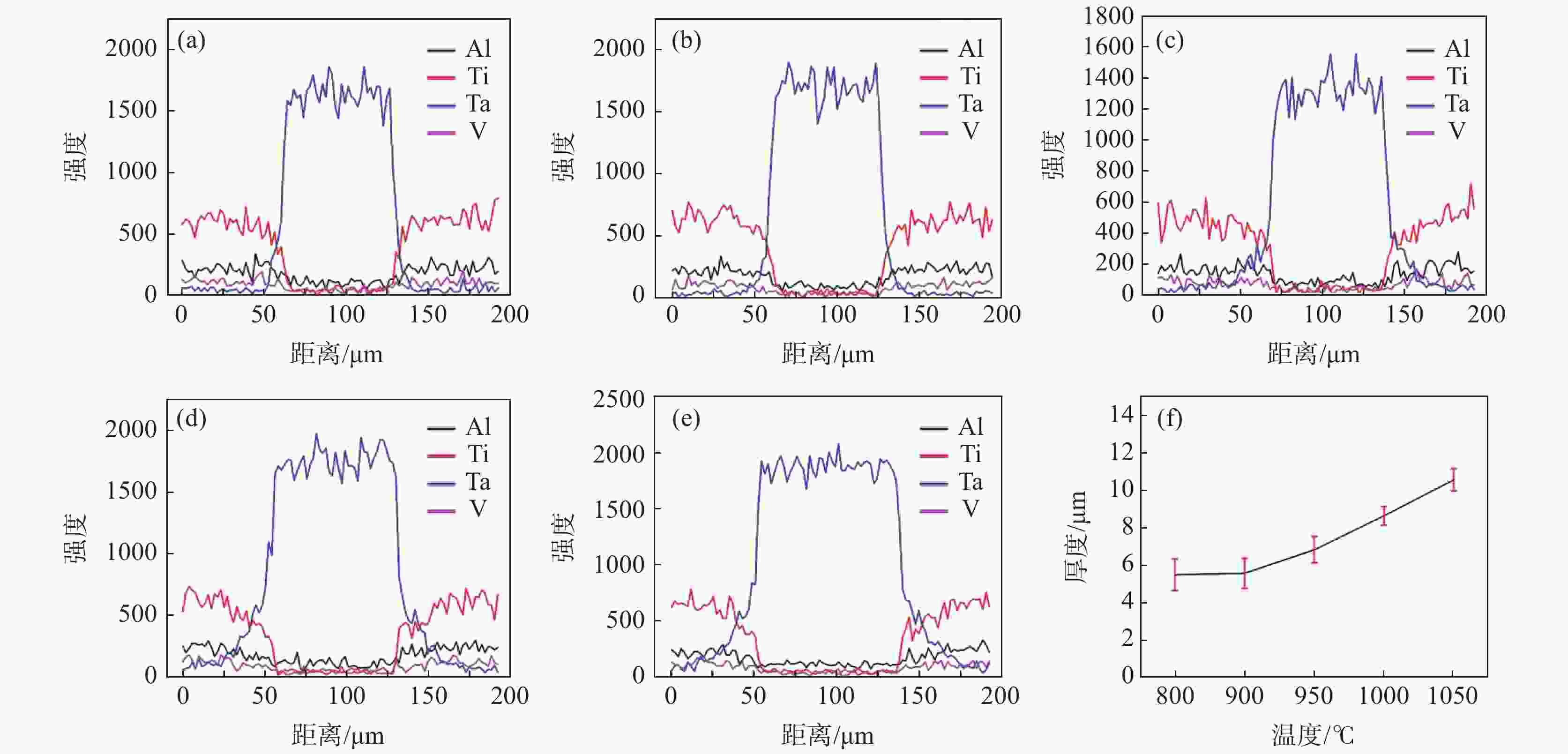

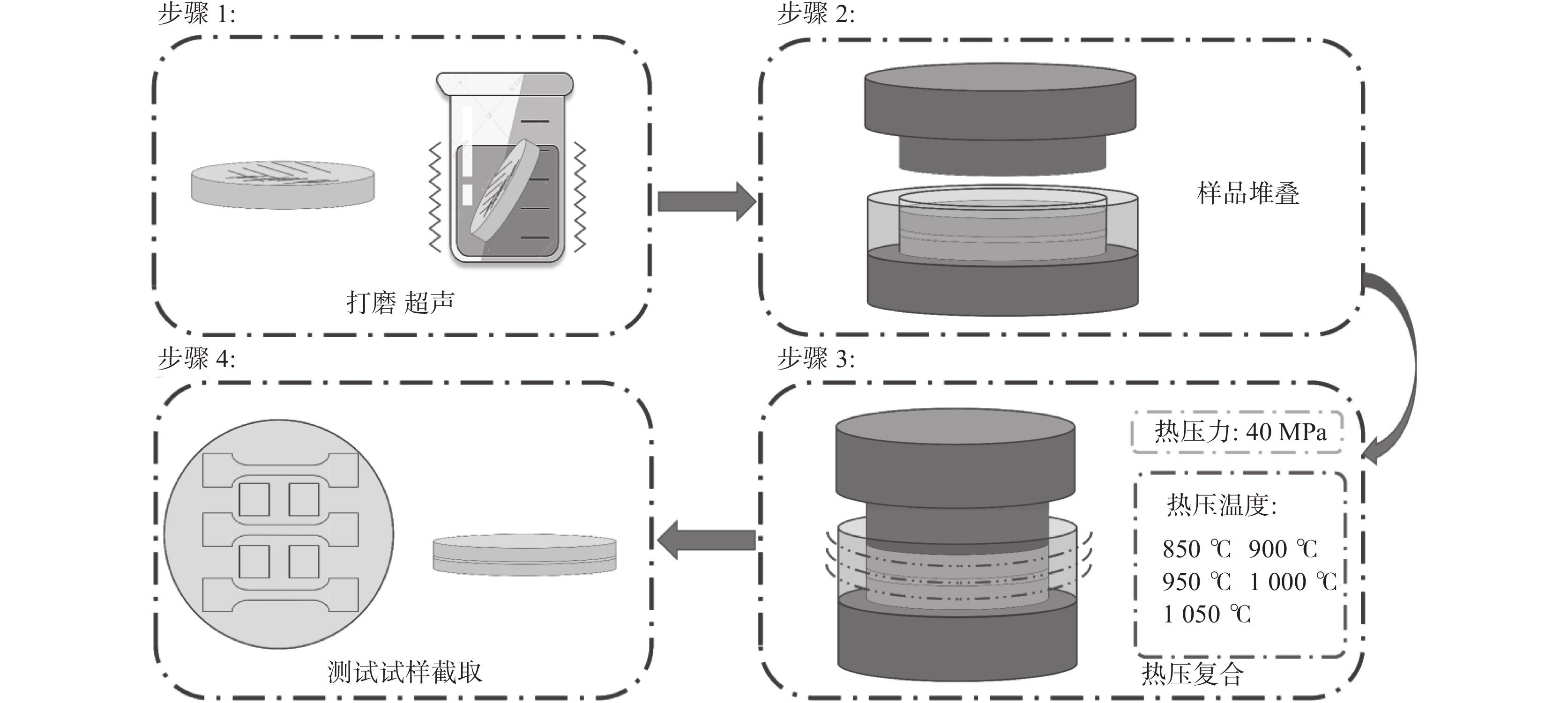

摘要: 在不同温度下通过高温热压复合制备了TC4/Ta/TC4层状金属复合材料(LMCs),并讨论了界面元素扩散行为、微观结构随热压温度的变化关系。结果表明,在热压和保温过程中两组元元素在界面处发生了明显的扩散行为,两组元实现了良好的冶金结合。高温热压促进了Al、V、Ti、Ta各元素在界面处的扩散,其扩散程度显著影响了界面附近的显微组织。每种元素的扩散深度与原子半径紧密相关,随着原子半径减小,扩散行为发生的更为强烈。元素扩散行为导致界面附近钛基体的相变温度降低,在低于TC4相变温度的950 ℃出现了网篮组织,随着与界面距离的变化呈现不同的微观组织形貌。Abstract: TC4/Ta/TC4 layered metal composites (LMCs) were prepared by hot-pressing at different temperatures, and the diffusion behavior of interfacial elements and the microstructure at different temperatures were discussed. The results show that obvious diffusion behavior occurs at the interface during the process of hot-pressing and holding, and the two groups achieve good metallurgical bonding. High temperature hot-pressing promotes the diffusion of Al, V, Ti and Ta, and the degree of diffusion significantly affects the microstructure near the interface. The diffusion depth of each element is closely related to the atomic radius. As the atomic radius decreases, the diffusion behavior occurs more intensely. The element diffusion behavior leads to the decrease in the phase transition temperature of the titanium matrix near the interface, and the basketweave structure appears at 950 ℃ below the phase transition temperature of TC4. The microstructure changes with the change of the interface distance.

-

Key words:

- laminated metal composites /

- TC4 /

- Ta /

- hot-pressing /

- element diffusion /

- microstructural evolution /

- interface /

- diffusion layer

-

表 1 商业级纯钽箔和Ti-6Al-4V化学成分

Table 1. Chemical compositions of the commercial purity Ta foil and Ti-6Al-4V

% 材料 Ti Al V Fe C N H O W Mo Nb Ta Ti-6Al-4V Bal. 5.7 3.8 0.28 0.07 0.04 0.01 0.15 Ta 箔 0.001 0.01 0.01 0.04 Bal. -

[1] Huang Lujun, An Qi, Geng Lin, et al. Multiscale architecture and superior high-temperature performance of discontinuously reinforced titanium matrix composites[J]. Advanced Materials, 2021,33(6):2000688. doi: 10.1002/adma.202000688 [2] Pan Deng, Zhang Xin, Hou Xiaodong, et al. TiB nano-whiskers reinforced titanium matrix composites with novel nano-reticulated microstructure and high performance via composite powder by selective laser melting[J]. Materials Science and Engineering:A, 2021,799:140137. doi: 10.1016/j.msea.2020.140137 [3] Wang Shuai, Huang Lujun, Geng Lin, et al. Microstructure evolution and damage mechanism of layered titanium matrix composites under tensile loading[J]. Materials Science and Engineering:A, 2020,777:139067. doi: 10.1016/j.msea.2020.139067 [4] Ma Z Y, Tjong S C, Gen L. In-situ Ti-TiB metal–matrix composite prepared by a reactive pressing process[J]. Scr Mater, 2000,42(4):367−373. doi: 10.1016/S1359-6462(99)00354-1 [5] Alman D E, Hawk J A. The abrasive wear of sintered titanium matrix–ceramic particle reinforced composites[J]. Wear, 1999,225-229:629−639. doi: 10.1016/S0043-1648(99)00065-4 [6] Huang L J, Geng L, Li A B, et al. In situ TiBw/Ti–6Al–4V composites with novel reinforcement architecture fabricated by reaction hot pressing[J]. Scr. Mater., 2009,60(11):996−999. doi: 10.1016/j.scriptamat.2009.02.032 [7] Tjong S C, Mai Yiu Wing. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites[J]. Composites Science and Technology, 2008,68(3):583−601. [8] Sen Indrani, Tamirisakandala S, Miracle D B, et al. Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys[J]. Acta Materialia, 2007,55(15):4983−4993. doi: 10.1016/j.actamat.2007.05.009 [9] Huang L J, Geng L, Peng H X, et al. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture[J]. Scr. Mater., 2011,64(9):844−847. doi: 10.1016/j.scriptamat.2011.01.011 [10] Liu B X, Huang L J, Geng L, et al. Microstructure and tensile behavior of novel laminated Ti–TiBw/Ti composites by reaction hot pressing[J]. Materials Science and Engineering:A, 2013,583:182−187. doi: 10.1016/j.msea.2013.06.058 [11] Liu B X, Huang L J, Geng L, et al. Gradient grain distribution and enhanced properties of novel laminated Ti–TiBw/Ti composites by reaction hot-pressing[J]. Materials Science and Engineering:A, 2014,595:257−265. doi: 10.1016/j.msea.2013.12.013 [12] Liu B X, Huang L J, Geng L, et al. Effects of reinforcement volume fraction on tensile behaviors of laminated Ti–TiBw/Ti composites[J]. Materials Science and Engineering:A, 2014,610:344−349. doi: 10.1016/j.msea.2014.05.057 [13] Liu B X, Huang L J, Rong X D, et al. Bending behaviors and fracture characteristics of laminated ductile-tough composites under different modes[J]. Composites Science and Technology, 2016,126:94−105. doi: 10.1016/j.compscitech.2016.02.011 [14] Huang L J, Wang S, Dong Y S, et al. Tailoring a novel network reinforcement architecture exploiting superior tensile properties of in situ TiBw/Ti composites[J]. Materials Science and Engineering:A, 2012,545:187−193. doi: 10.1016/j.msea.2012.03.019 [15] Li Pei, Sun Qiaoyan, Xiao Lin, et al. Tuning the morphology of Ti–5Al–5Mo–5V–3Cr–1Zr alloy: From brittle to ductile fracture[J]. Materials Science and Engineering:A, 2020,769:138487. doi: 10.1016/j.msea.2019.138487 [16] Meng Linglong, Wang Xiaojun, Hu Xiaoshi, et al. Role of structural parameters on strength-ductility combination of laminated carbon nanotubes/copper composites[J]. Composites Part A:Applied Science and Manufacturing, 2019,116:138−146. doi: 10.1016/j.compositesa.2018.10.021 [17] Xiang Yeyang, Wang Xiaojun, Hu Xiaoshi, et al. Achieving ultra-high strengthening and toughening efficiency in carbon nanotubes/magnesium composites via constructing micro-nano layered structure[J]. Composites Part A:Applied Science and Manufacturing, 2019,119:225−234. doi: 10.1016/j.compositesa.2019.02.006 [18] Lu Jinwen, Dong Longlong, Liu Yue, et al. Simultaneously enhancing the strength and ductility in titanium matrix composites via discontinuous network structure[J]. Composites Part A:Applied Science and Manufacturing, 2020,136:105971. doi: 10.1016/j.compositesa.2020.105971 [19] Wei Liangxiao, Liu Xuyang, Zheng Shoutao, et al. Micromechanical and tribological behavior of titanium matrix composites reinforced with graphene oxide[J]. Mater Chem Phys, 2021,269:124763. doi: 10.1016/j.matchemphys.2021.124763 [20] Dong L L, Lu J W, Fu Y Q, et al. Carbonaceous nanomaterial reinforced Ti-6Al-4V matrix composites: Properties, interfacial structures and strengthening mechanisms[J]. Carbon, 2020,164:272−286. doi: 10.1016/j.carbon.2020.04.009 [21] Xiao Lu, Lu Weijie, Yang Zhifeng, et al. Effect of reinforcements on high temperature mechanical properties of in situ synthesized titanium matrix composites[J]. Materials Science and Engineering:A, 2008,491(1):192−198. [22] Esmaeili Mohammad Mahdi, Mahmoodi Mahboobeh, Imani Rana. Tantalum carbide coating on Ti-6Al-4V by electron beam physical vapor deposition method: Study of corrosion and biocompatibility behavior[J]. International Journal of Applied Ceramic Technology, 2017,14(3):374−382. doi: 10.1111/ijac.12658 [23] Li Ren, Gu Yi, Zeng Fanhao, et al. High temperature diffusion behavior between Ta-10 W coating and CP-Ti and TC4 alloy[J]. Surface and Coatings Technology, 2021,406:126669. doi: 10.1016/j.surfcoat.2020.126669 [24] Mali V I, Bataev A A, Maliutina Iu N, et al. Microstructure and mechanical properties of Ti/Ta/Cu/Ni alloy laminate composite materials produced by explosive welding[J]. The International Journal of Advanced Manufacturing Technology, 2017,93(9):4285−4294. [25] Cao R, Ding Y, Yan Y J, et al. Effect of heat treatment on interface behavior of martensite/austenite multilayered composites by accumulative hot roll bonding[J]. Compos Interfaces, 2019,26(12):1069−1085. doi: 10.1080/09276440.2019.1583007 -

下载:

下载: