Study on temperature field of titanium slab heating process based on walking-beam-type furnace

-

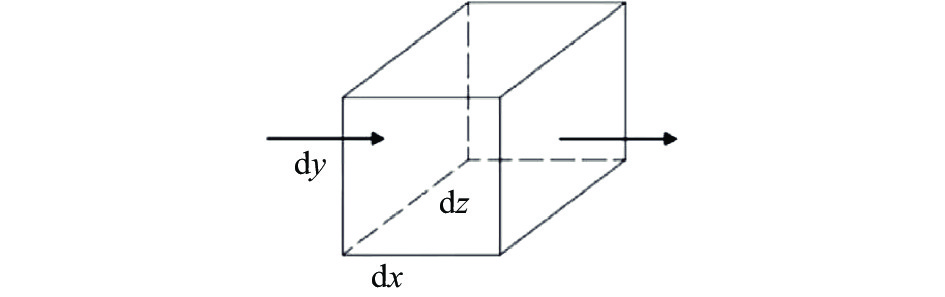

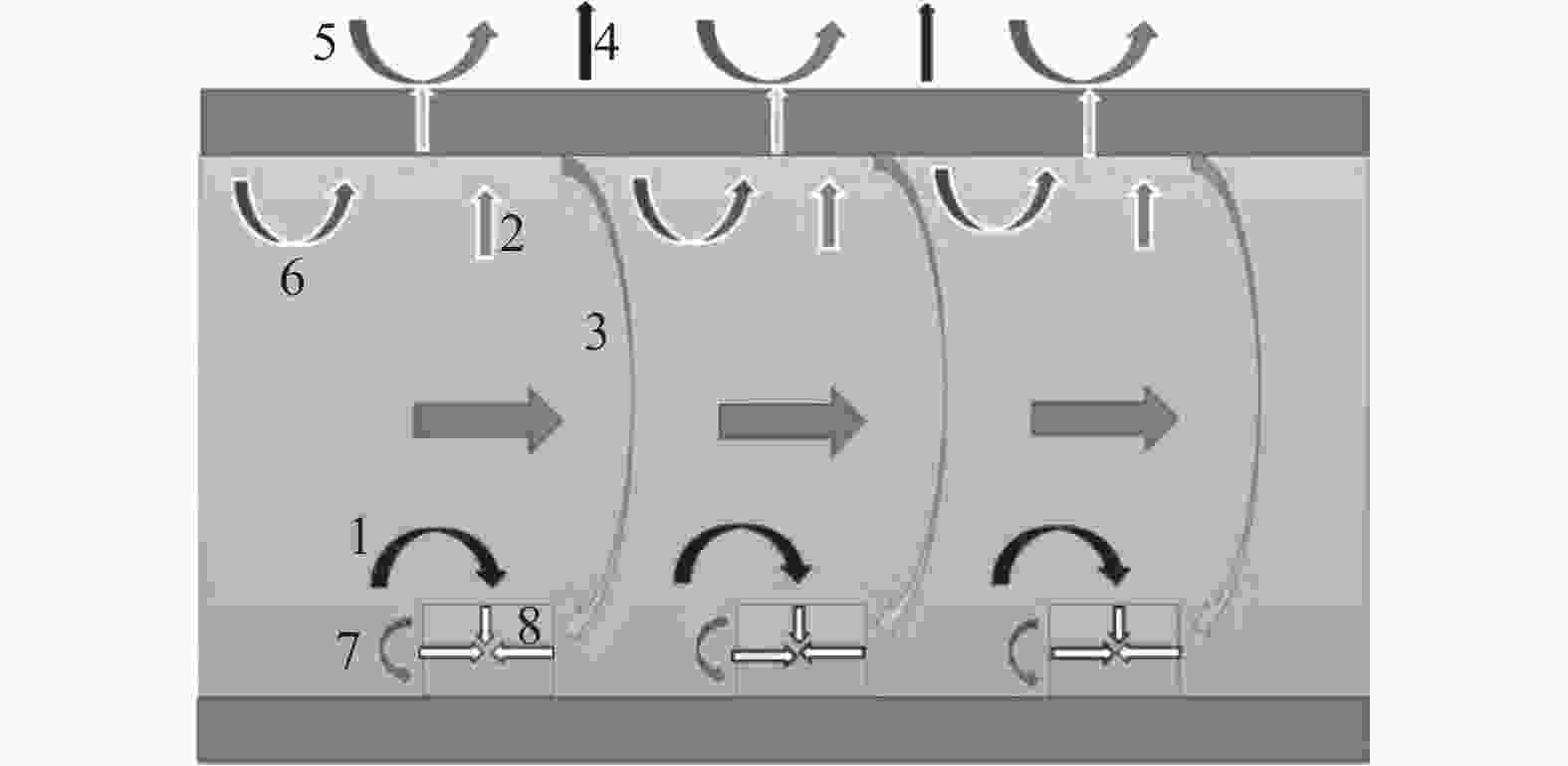

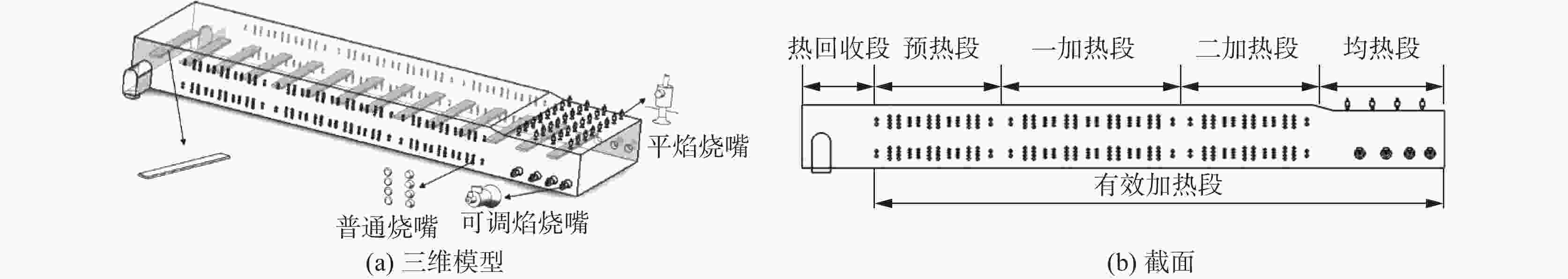

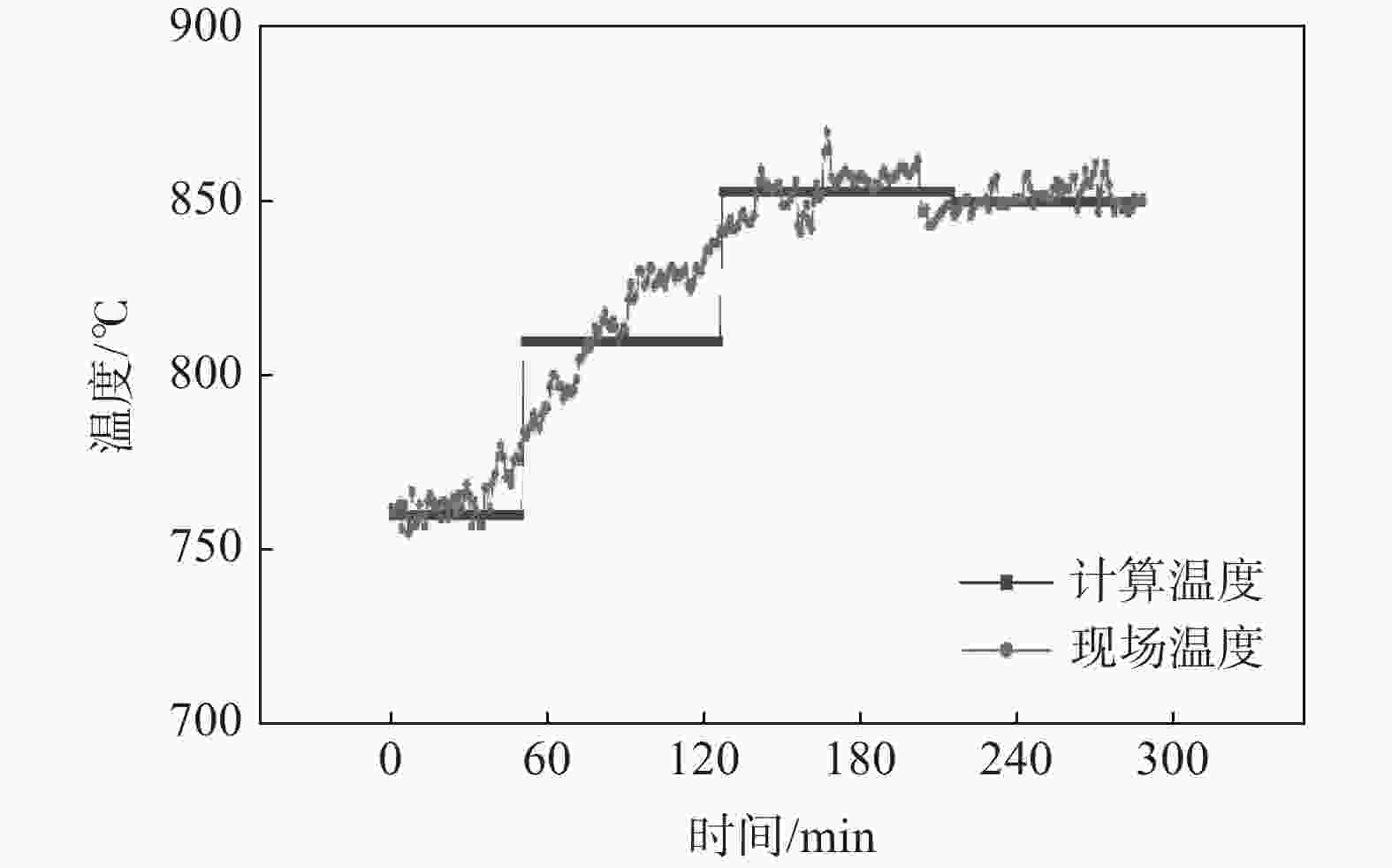

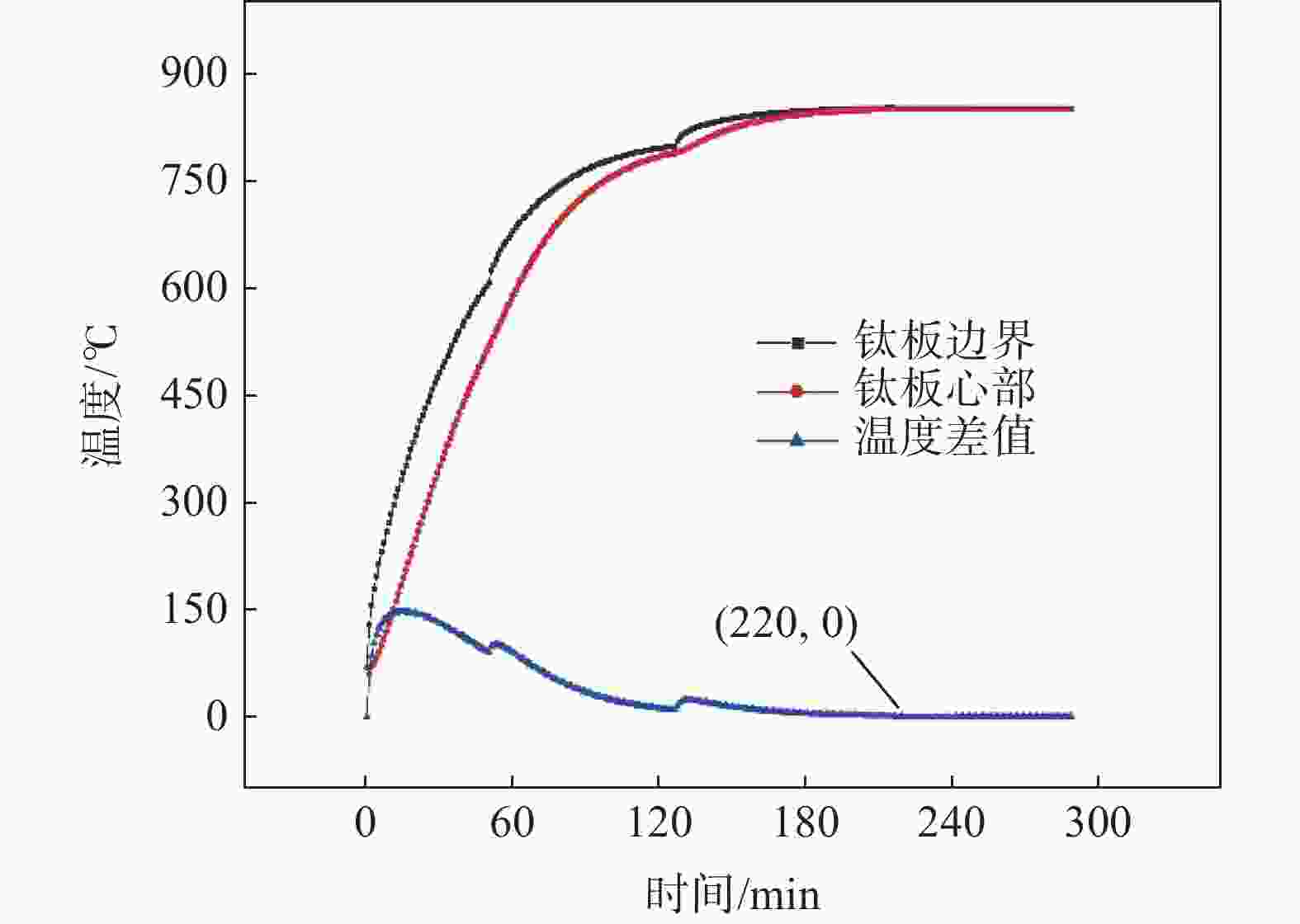

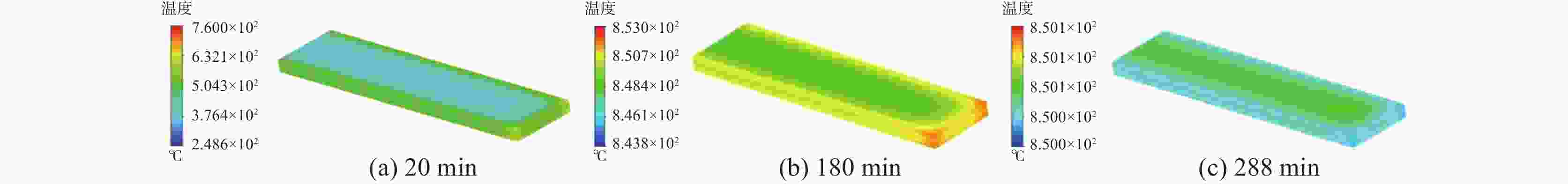

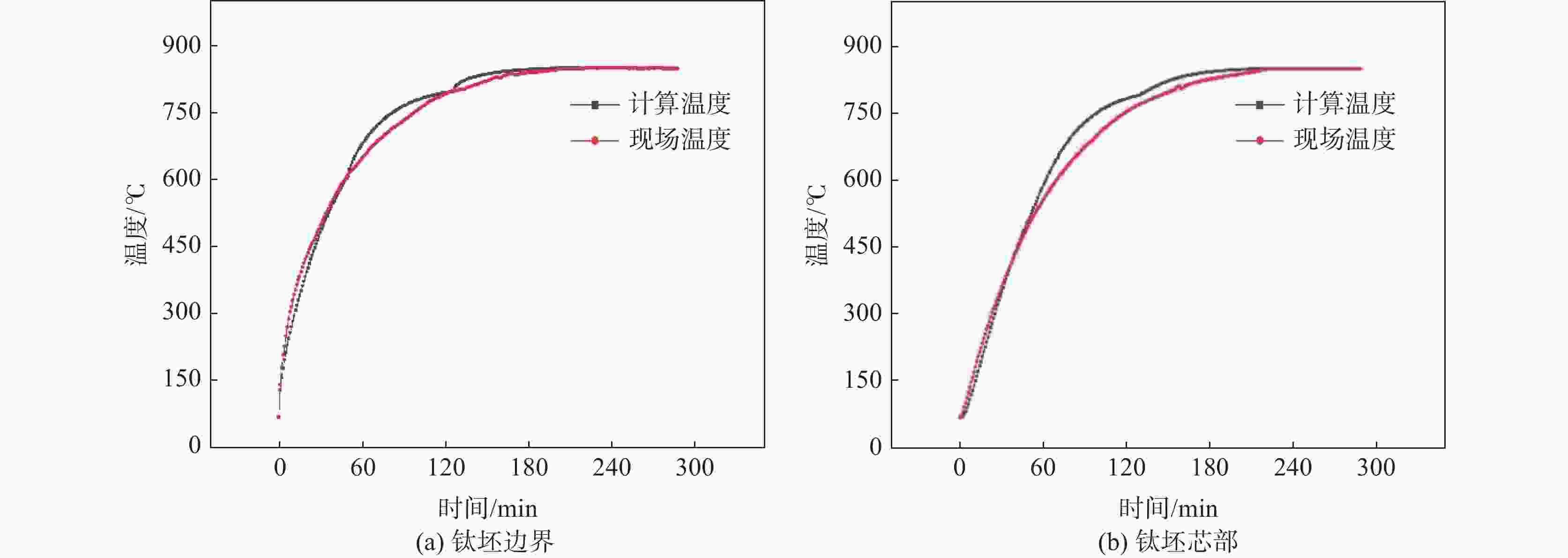

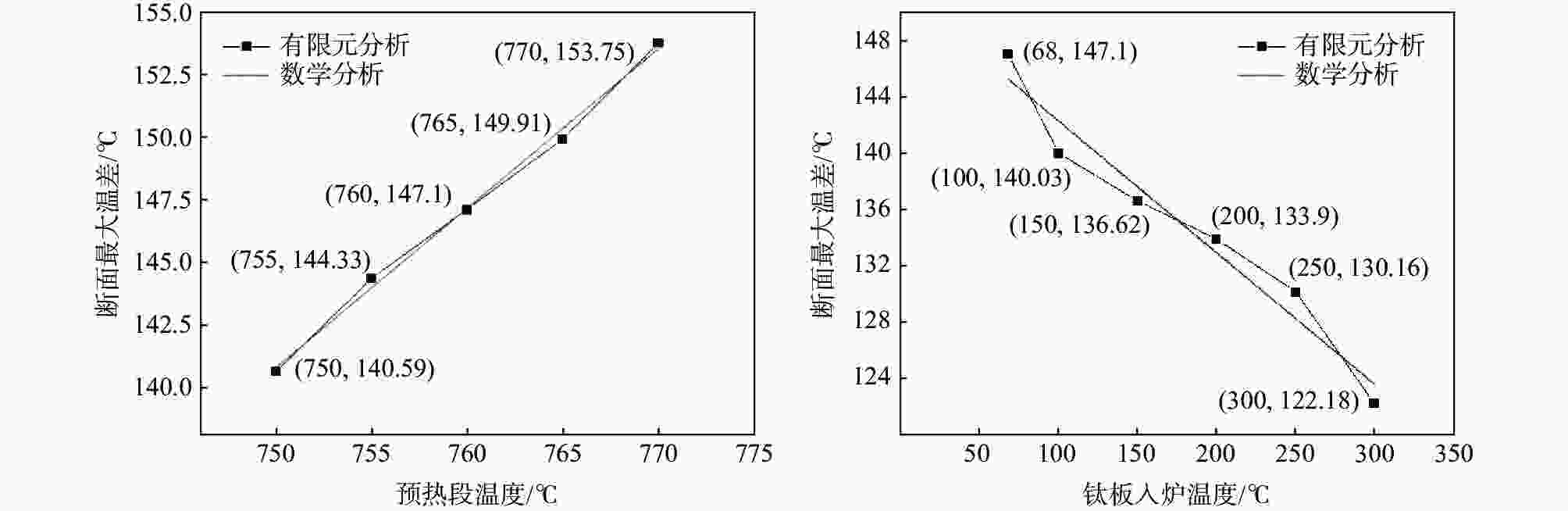

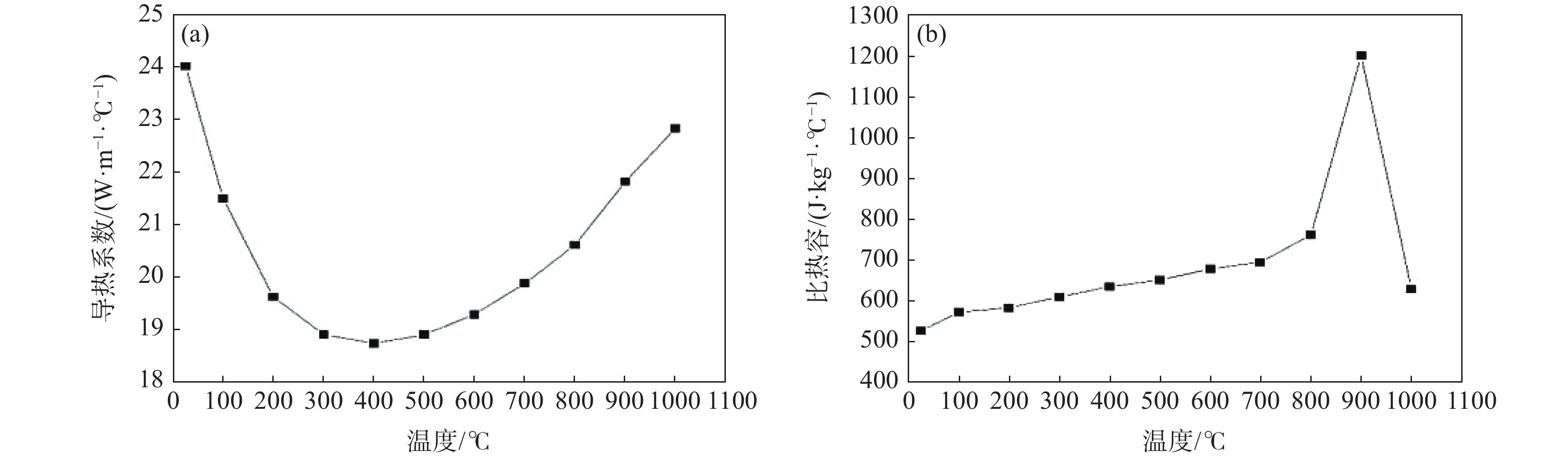

摘要: 基于某钢厂的蓄热室步进式加热炉,以炉内的TA1钛坯为研究对象,建立传热的数学模型和加热过程的有限元模型,开展钛坯在炉内加热过程中的温度分布研究。研究炉膛温度和钛坯入炉温度对钛坯加热过程中最大断面温差的影响,以及预热段温度和一加热段温度对满足出炉要求钛坯芯部温度的加热时间影响。结果表明:钛坯经过预热段和加热段加热时,其最高温度一直位于端面角部,最低温度位于钛坯芯部,而经过均热段后,角部温度最低。预热段温度每升高5 ℃,最大断面温差增加1~2 ℃,钛坯入炉温度每升高50 ℃,最大断面温差减小3~8 ℃;预热段温度每升高10 ℃,芯部温度满足出炉要求的时间减少1~2 min,一加热段温度每升高10 ℃,芯部温度满足出炉要求的时间减少4~6 min。Abstract: Based on the walking-beam-type reheating furnace in a certain steel plant, the TA1 titanium billet in the furnace was taken as the research object, and the mathematical model of heat transfer and the finite element model of heating process were established to study the temperature distribution of titanium billet in the heating process. The effects of furnace temperature and inlet temperature of titanium billet on the maximum temperature difference of cross section in the heating process of titanium billet were studied, and the effects of preheating zone temperature and heating zone (I) temperature on the heating time to meet the requirement of tapping temperature of titanium billet core were studied. The results show that the maximum temperature of the titanium billet is always at the corner of the end face and the minimum temperature is at the core of the titanium billet when the titanium billet is heated by the preheating zone and the heating zone (I), while the corner temperature is the lowest after the soaking zone. When the preheating temperature increases by 5 ℃, the maximum section temperature difference increases by 1~2 ℃, and when the titanium billet temperature increases by 50 ℃, the maximum section temperature difference decreases by 3~8 ℃. When the temperature of preheating zone increases by 10 ℃, the time for the core to meet the requirement of furnace discharge reduces by 1~2 min. When the temperature of heating zone (I) increases by 10 ℃, the time for the core to meet the requirement of furnace discharge reduces by 4~6 min.

-

表 1 钛坯加热制度

Table 1. Heating system of titanium slab

加热温度/℃ 加热时间/min 预热段 710~780 50±10 加热段一 800~830 70±10 加热段二 850~860 80±10 均热段 850±10 70±10 -

[1] Jin Ming, Ni Hongwei, Zhang Hua, et al. Simulation analysis of temperature field of slab in step heating furnace[J]. Journal of Wuhan University of Science and Technology, 2016,39(4):248−252. (金明, 倪红卫, 张华, 等. 步进式加热炉内板坯温度场模拟分析[J]. 武汉科技大学学报, 2016,39(4):248−252. [2] Guo Jingjin, Chen Jian. Effect of fuel ratio and slab trajectory on slab heating[J]. Shanxi Metallurgy, 2021,44(1):26−29,34. (果晶晶, 陈健. 燃料配比与钢坯运动轨迹对钢坯加热的影响[J]. 山西冶金, 2021,44(1):26−29,34. [3] Feng Guanghong, Zhang Hongliang. Temperature field analysis of cold and hot titanium slab heating process[J]. Special Steel Technology, 2015,21(3):27−31. (冯光宏, 张宏亮. 冷装和热送钛板加热过程的温度场分析[J]. 特钢技术, 2015,21(3):27−31. [4] Man Young Kim. A heat transfer model for the analysis of transient heating of the slab in a direct-fired walking beam type reheating furnace[J]. International Journal of Heat and Mass Transfer, 2007,50(19):3740−3748. [5] Tang Guangwu, Wu Bin, Bai Dengqi, et al. CFD modeling and validation of a dynamic slab heating process in an industrial walking beam reheating furnace[J]. Applied Thermal Engineering, 2018,132(5):779−789. [6] Wang Feilong, Zhang Yong, Long Gang, et al. TA1 industrial pure titanium thermophysical parameters measurement and application research[J]. Iron Steel Vanadium Titanium, 2021,42(2):48−52. (王飞龙, 张勇, 龙刚, 等. TA1工业纯钛热物性参数测量及应用研究[J]. 钢铁钒钛, 2021,42(2):48−52. [7] Wang Junhong, Huang Yuanfeng, Yang Qi, et al. Industrial pure titanium heating process and its practice in slab reheating furnace[J]. Industrial Furnace, 2010,32(2):17−20. (王钧洪, 黄远凤, 杨奇, 等. 工业纯钛加热工艺及其在板坯加热炉上的实践[J]. 工业炉, 2010,32(2):17−20. doi: 10.3969/j.issn.1001-6988.2010.02.006 [8] Sun Futao, Han Chen. Process and configuration characteristics of the first titanium strip coil hot rolling mill in China[J]. China Heavy Equipment, 2017,(1):14−16,19. (孙付涛, 韩晨. 国内首台钛板带炉卷热轧机的工艺及配置特点[J]. 中国重型装备, 2017,(1):14−16,19. [9] Du Lizhang. Industrial pure titanium slab production process research[J]. Special Steel Technology, 2008,14(4):19−21. (杜礼章. 工业纯钛板材生产工艺研究[J]. 特钢技术, 2008,14(4):19−21. [10] 刘肖波. 加热炉内钢坯温度场仿真研究[D]. 石家庄: 河北科技大学, 2019.Liu Xiaobo. Simulation of slab temperature field in reheating furnace [D]. Shijiazhuang: Hebei University of Science and Technology, 2019. [11] Chen Guang, Xie Qingju, Li Jiao, et al. Numerical simulation of temperature difference of titanium slab section in heating furnace[J]. Metallurgical Energy, 2011,30(2):24−27. (陈光, 谢庆举, 李娇, 等. 加热炉板坯断面温差数值模拟研究[J]. 冶金能源, 2011,30(2):24−27. doi: 10.3969/j.issn.1001-1617.2011.02.006 -

下载:

下载: