Source analysis and control technology of impurity Al in titanium sponge

-

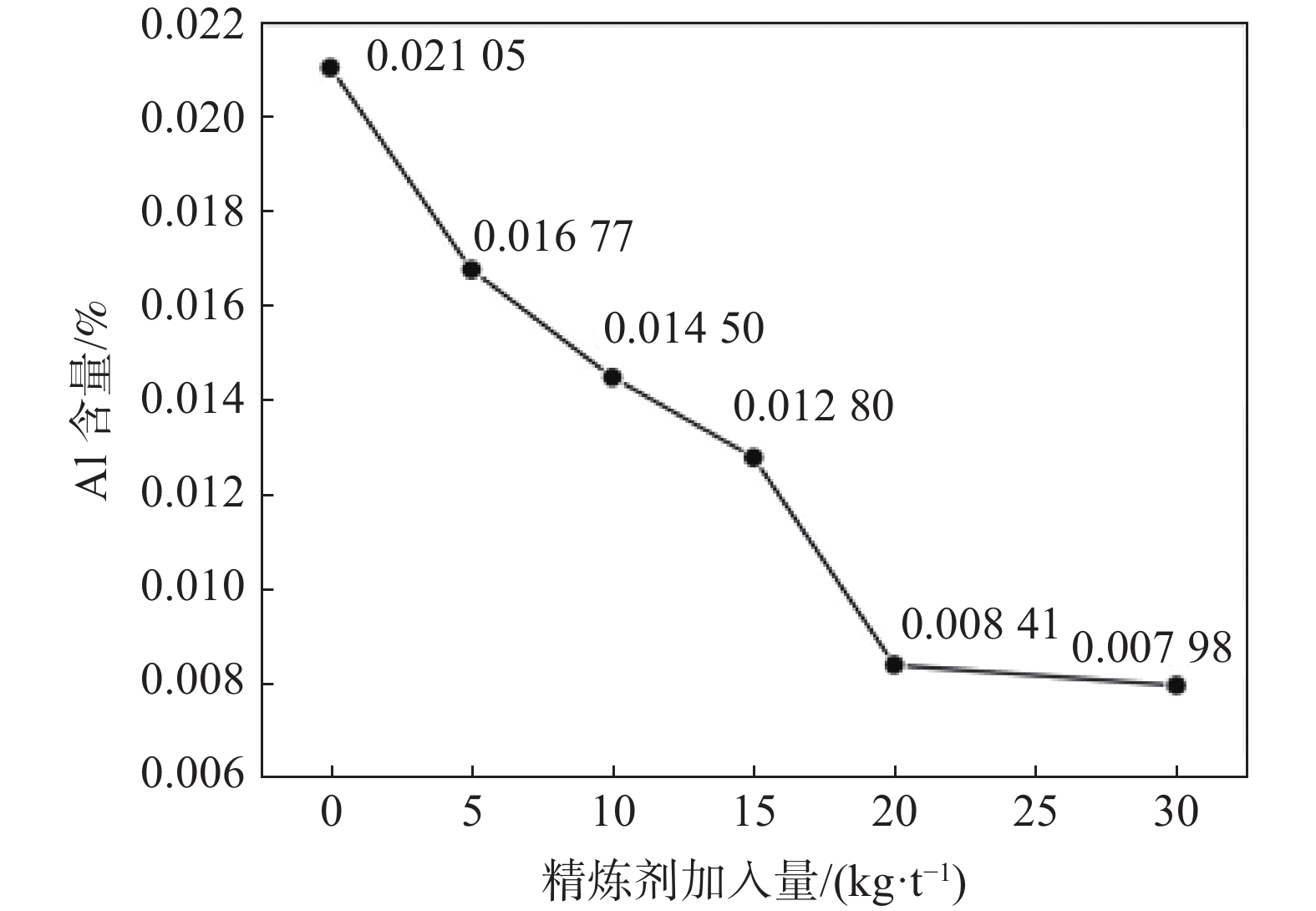

摘要: 对克劳尔法生产过程海绵钛中Al杂质的来源进行了分析,主要为原料四氯化钛以及原料镁所引入。随后主要对四氯化钛的Al杂质元素的来源进行分析,采取在氯化工序中通水蒸气的措施进行除铝,当通水量在10 kg/h时,就能达到84.22%的除铝效果;同时对原料镁中带入的Al的来源进行分析,并通过加入精炼剂来进行除杂,当精炼剂加入量达到20 kg/t时,除杂效果优异。又因为海绵钛钛坨在生成期间,受反应过程影响,杂质元素Al在海绵钛中分布并不均匀,因此要生产高质量海绵钛,需要从源头进行Al元素的除杂。Abstract: The sources of impurity Al in titanium sponge produced by the Kroll process were analyzed. The impurity Al is mainly derived from titanium tetrachloride and magnesium. Based on the source analysis of Al in titanium tetrachloride, water vapor was introduced for Al removal from titanium tetrachloride during the chlorination process, where 84.22% of Al removal ratio can be obtained at 10 kg/h of water dosage. At the same time, Al in magnesium was removed by adding refining agent, and a favorable effect can be obtained at 20 kg/t of refining agent amount. Influenced by the reaction process for titanium sponge formation, Al is not evenly distributed in titanium sponge. Therefore, it is necessary to carry out Al removal measures from the source materials to produce high-quality titanium sponge.

-

Key words:

- titanium sponge /

- aluminum /

- titanium tetrachloride /

- coarse magnesium /

- refining

-

表 1 不同通水量对四氯化钛中Al含量的影响

Table 1. Effect of water dosage on Al content in titanium tetrachloride

通水量/ (kg·h−1) 粗四氯化钛罐杂质元素含量/% Al Zr Nb 4 0.003823 0.00064 0.00299 8 0.001557 0.00021 0.00153 10 0.000603 0.00003 0.00080 12 0.000435 0.00001 0.00074 15 0.000366 0.00002 0.00065 表 2 常用的精炼剂(钙溶剂)成分

Table 2. Chemical compositions of the refining agent

% MgCl2 KCl NaCl CaCl2 BaCl2 MgO 38±3 37±3 8±3 8±3 9±3 ≤2 表 3 加入精炼剂前后精镁中其他杂质元素含量的变化

Table 3. Content of other impurities in crude magnesium before and after adding refining agent

% Fe Si V Ni Na Cr Sn 添加精炼剂前 0.00987 0.00368 0.00020 0.00174 0.000462 0.00102 0.000116 添加精炼剂后 0.00720 0.00238 0.00021 0.00147 0.000205 0.00104 0.000114 表 4 海绵钛坨不同位置Al含量

Table 4. Al content in different positions of titanium sponge

取样位置 Al含量/% 1#样 2#样 3#样 平均值 0.0093 0.0158 0.0122 PBT ① 0.0056 0.0114 0.0134 PBT ② 0.0054 0.0130 0.0318 顶部 0.0045 0.0238 0.0193 上左 0.0051 0.0143 0.0164 上中 0.0037 0.0069 0.0055 上右 0.0035 0.0158 0.0101 上部均值 0.0041 0.0123 0.0107 中左 0.0035 0.0071 0.0126 中中 0.0015 0.0055 0.0097 中右 0.0056 0.0063 0.0124 中部均值 0.0035 0.0063 0.0116 下左 0.0057 0.1787 0.0065 下中 0.0063 0.028 0.0108 下右 0.0226 0.037 0.0203 下部均值 0.0115 0.0812 0.0125 底部1 0.011 0.0836 0.0615 底部2 0.0086 0.2412 0.0596 注:PBT表示爬壁钛。 -

[1] 邓国珠, 王武育. 钛冶金[M]. 北京: 冶金工业出版社, 2010.Deng Guozhu, Wang Wuyu. Titanium metallurgy[M]. Beijing: Metallurgical Industry Press, 2010. [2] 佟程程. 联合法海绵钛生产中杂质来源及控制办法[D]. 沈阳: 东北大学, 2016.Tong Chengcheng. The source of impurity and control measure in the combined process of sponge titanium production[D]. Shenyang: Northeastern University, 2016. [3] 宋光林. 精四氯化钛中主要杂质的分析及其工艺控制技术研究[D]. 北京: 北京理工大学, 2017.Song Guanglin. Analysis and control of main impurities in refined titanium tetrachloride[D]. Beijing: Beijing Institute of Technology, 2017. [4] Shi Yuying, Zhou Yunying, Chen Yinzhi, et al. Source and harm of aluminum trichloride in titanium tetrachloride[J]. Sichuan Metallurgy, 2015,37(2):20−23,40. (石玉英, 周云英, 陈映志, 等. 四氯化钛中三氯化铝的来源及其危害[J]. 四川冶金, 2015,37(2):20−23,40. doi: 10.3969/j.issn.1001-5108.2015.02.006 [5] Zhang Wencheng. Refining method of magnesium[J]. Light Metal, 1991,(2):47−49. (张文成. 镁的精炼方法[J]. 轻金属, 1991,(2):47−49. [6] 陈建立, 刘红斌, 石森森,等. 一种四氯化钛气相中去除三氯化铝的装置: 中国, CN202021182479.2[P].2021-03-16.Chen Jianli, Liu Hongbin, Shi Sensen, et al. A device for removing aluminum trichloride from titanium tetrachloride gas phase: China, 202021182479[P]. 2021-03-16. -

下载:

下载: