Effect of Si on microstructure and mechanical properties of (Ti5Si3 + TiBw)/TC11

-

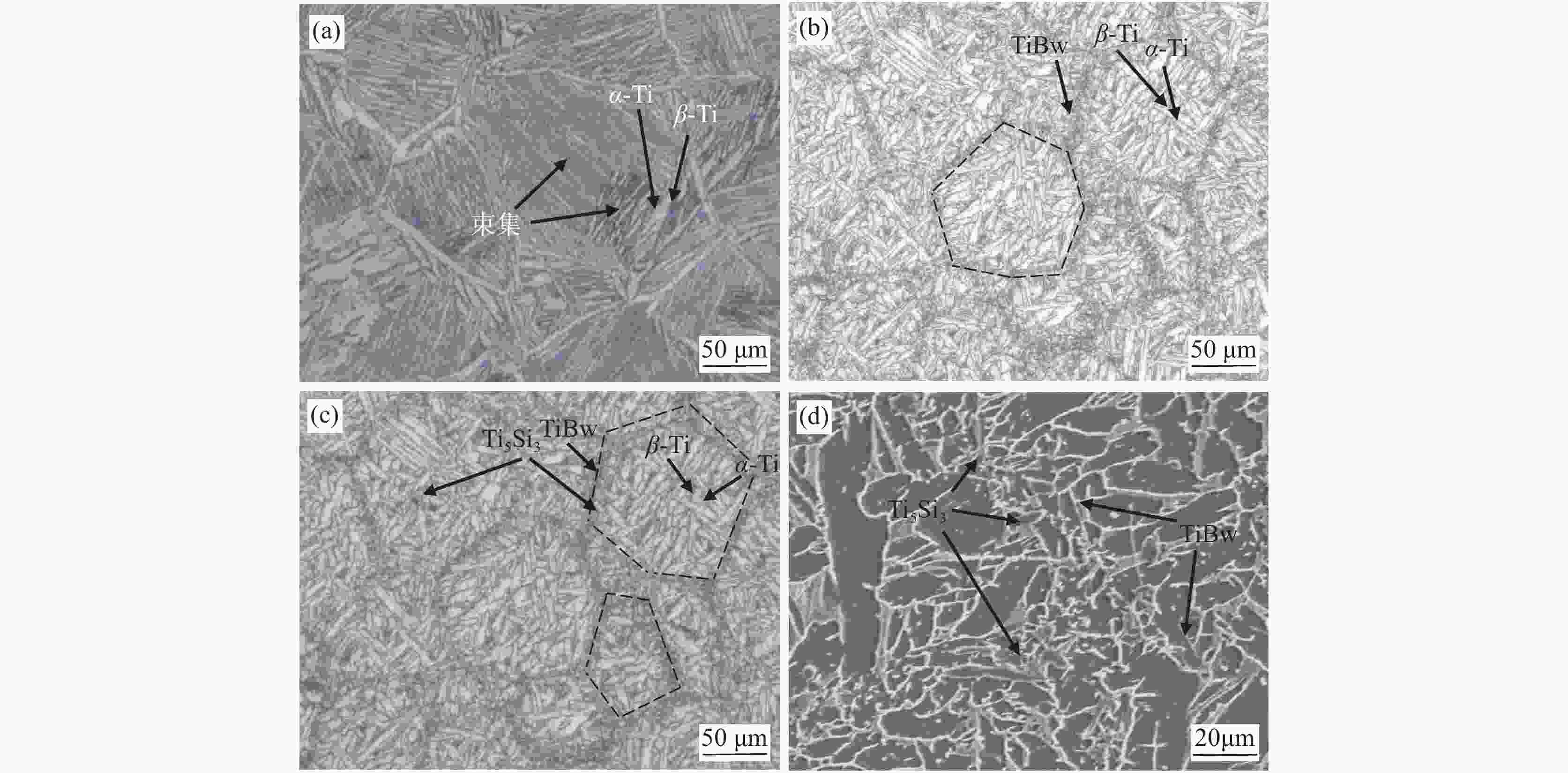

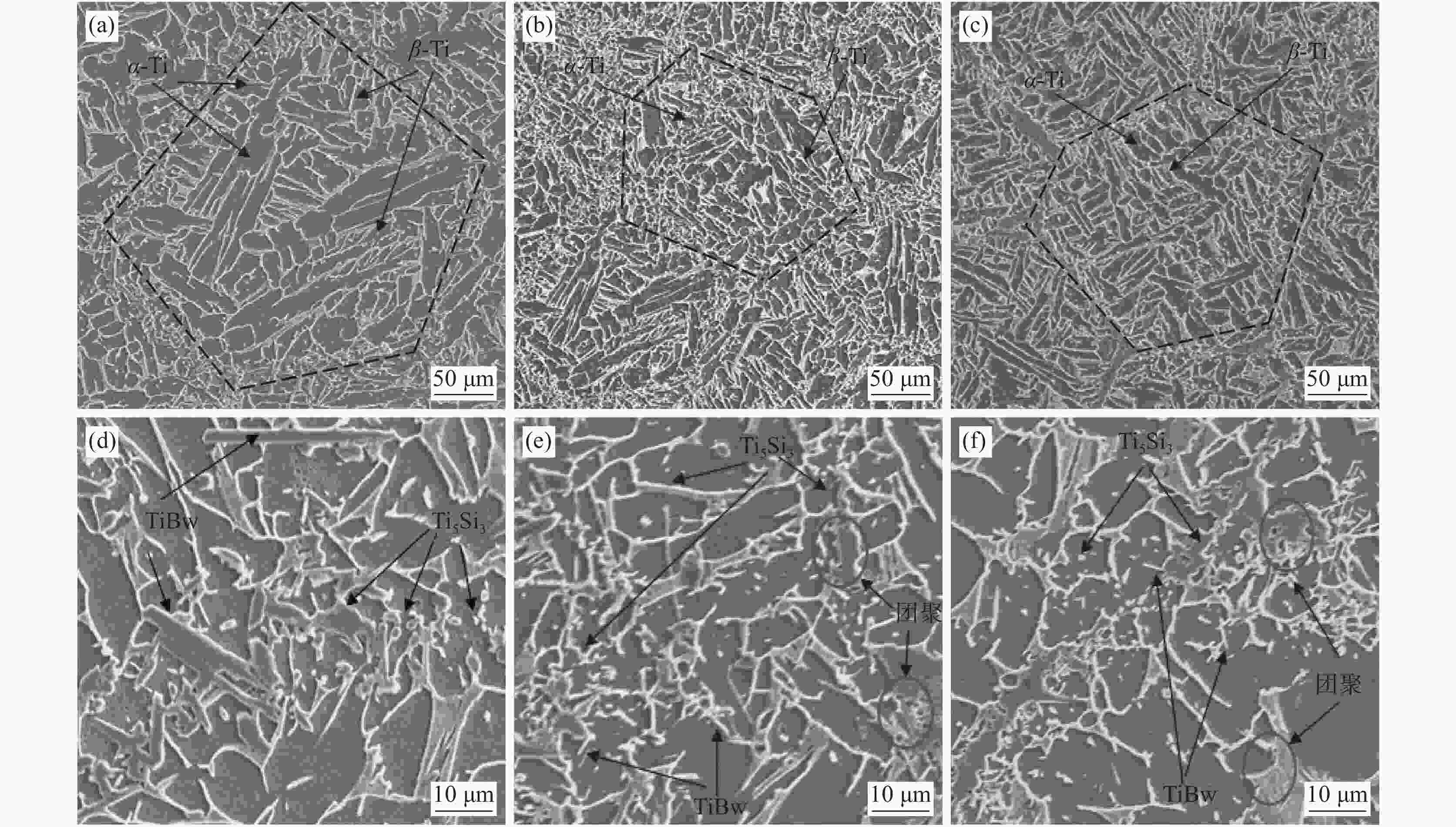

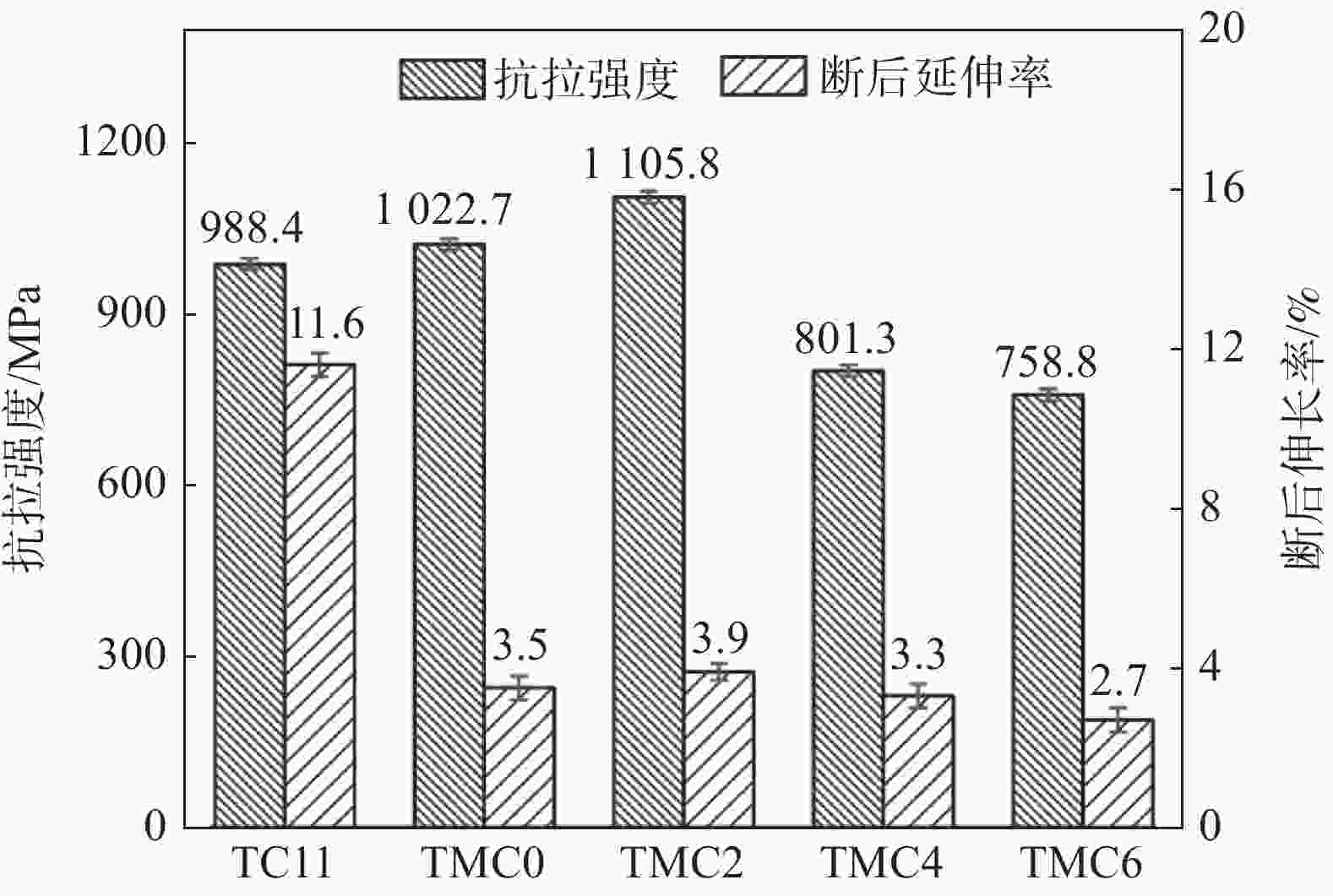

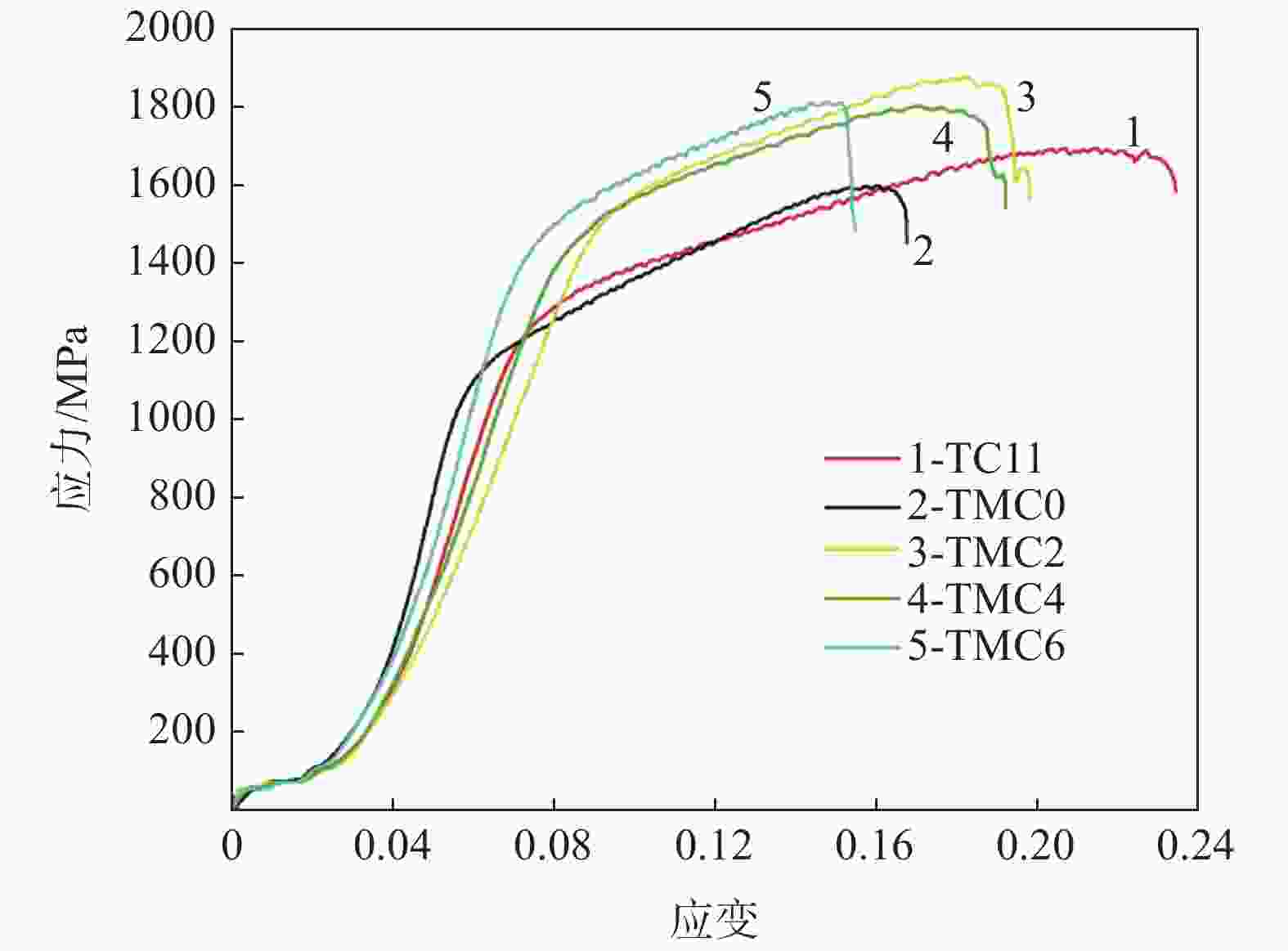

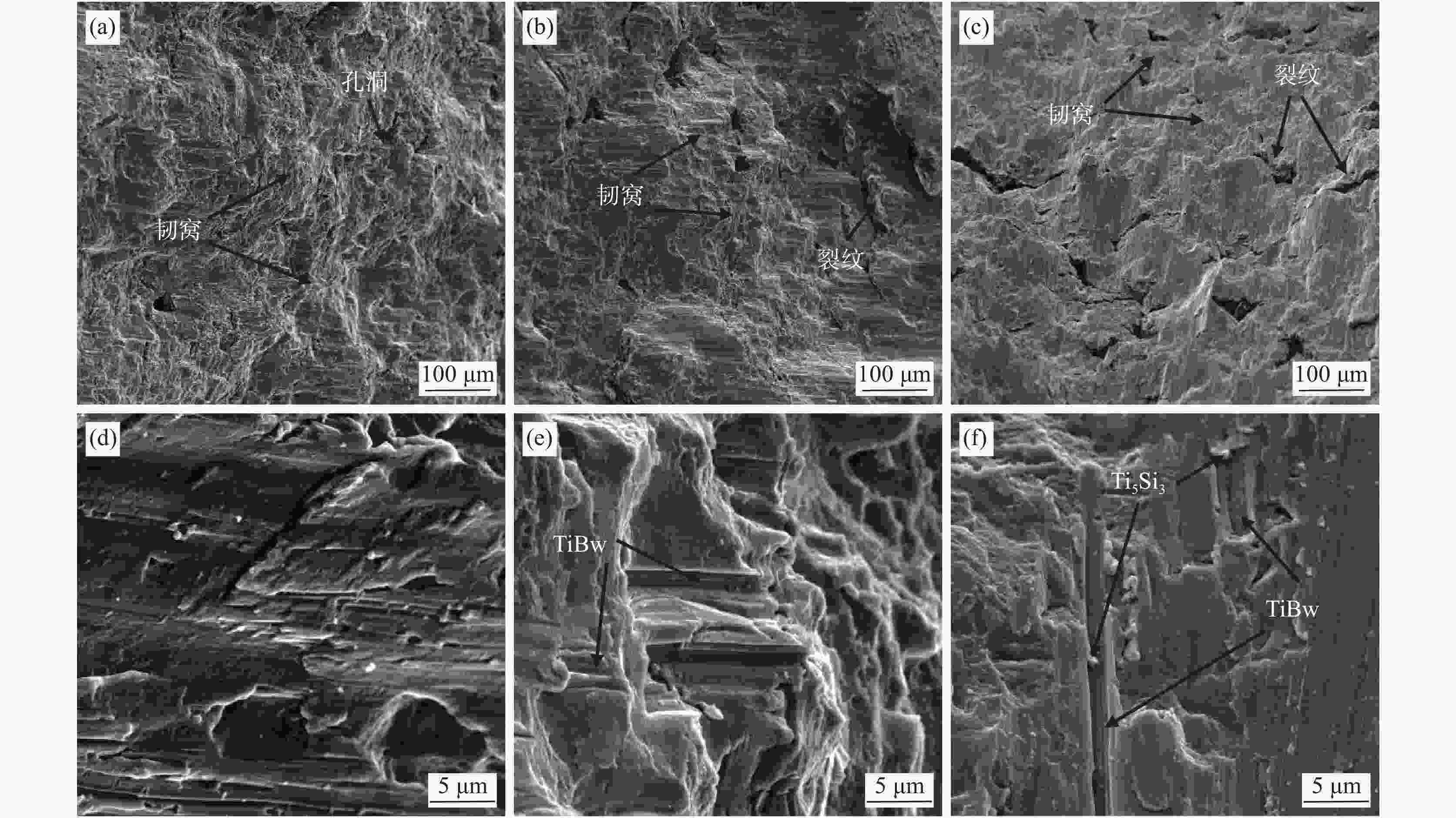

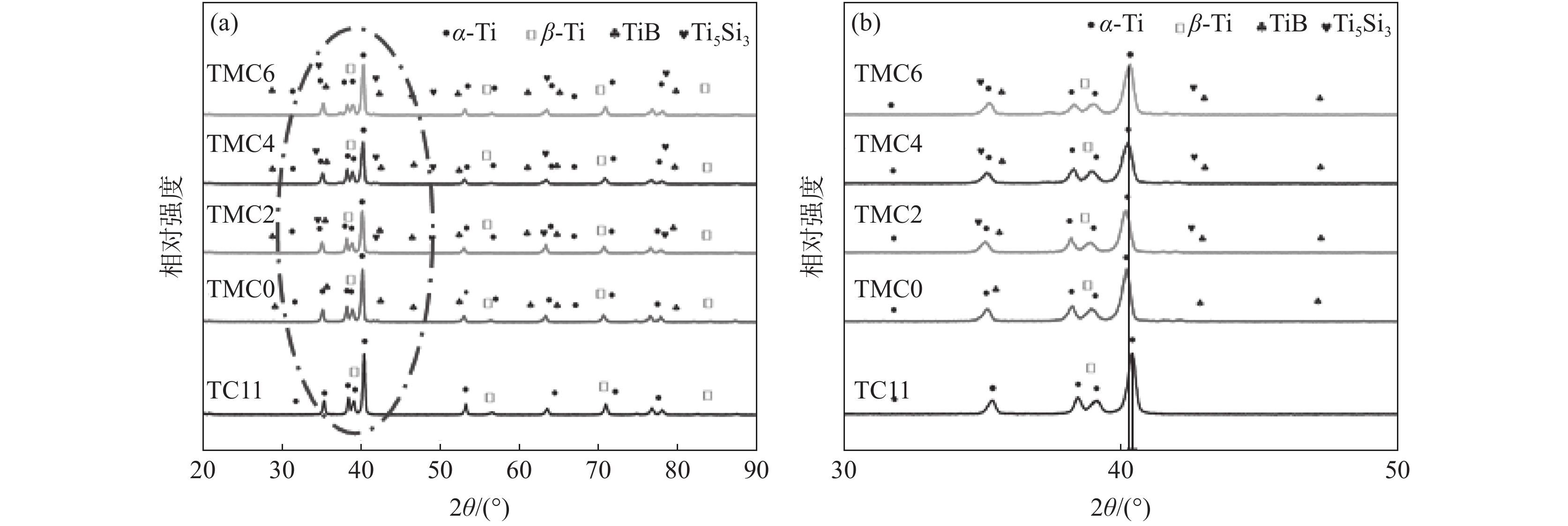

摘要: 采用粉末冶金法制备原位自生网状(Ti5Si3+TiBw)/TC11复合材料,对其金相组织、微观形貌、力学性能与断口进行研究分析。结果表明:TiBw 、部分Ti5Si3分布于基体颗粒周围,呈准连续网状分布;其余Ti5Si3分布于基体周围、β-Ti内、α-Ti与β-Ti相界处。随着Si元素的增加,原位生成Ti5Si3增多,α-Ti由长片状变为短棒状并趋向于等轴状,有明显细化组织作用。TiBw、Ti5Si3起到载荷传递、强化相界等作用,一方面Ti5Si3、TiBw 降低基体连通性,另一方面细化组织;复合材料强度提高的同时牺牲了部分塑性。 随着Si元素的增加,复合材料强度、塑性先增加后降低。(2vol.%Ti5Si3 + 5vol.%TiBw)/TC11具有最高的抗拉强度和抗压强度,分别为 1105.8 MPa和1870.6 MPa,具有优异的综合力学性能。 (Ti5Si3+TiBw)/TC11断口形貌以韧窝为主,在断裂过程中 (Ti5Si3+TiBw) 起到减缓裂纹扩展的作用。

-

关键词:

- 非连续增强钛基复合材料 /

- 粉末冶金 /

- Si /

- 微观组织 /

- 力学性能

Abstract: The in-situ formed (Ti5Si3 + TiBw)/TC11 composites with network structure were prepared by powder metallurgy. The metallographic structure, microstructure, mechanical properties and fracture surface of (Ti5Si3 + TiBw)/TC11 were analyzed. The results show that TiBw and partial Ti5Si3 distribute around the matrix particles in a quasi continuous network. The rest of Ti5Si3 distributes around the matrix, in β-Ti and at the boundary between α-Ti and β-Ti. With the increase of Si content, the in-situ reinforcement of Ti5Si3 increases, and α-Ti changes from long flake shape to short rod shape and tends to be equiaxed, which can refine the microstructure obviously. TiBw and Ti5Si3 play the role of load transfer and phase boundary strengthening, which can reduce the matrix connectivity and refine the matrix microstructure simultaneously. It is found that the strength of the composites is improved accompanying partial decrease of plasticity of the matrix. The strength and plasticity of the composites first increase and then decrease with increase of Si content. The composite of (2vol.%Ti5Si3+5vol.%TiBw)/TC11 has the highest tensile strength and compressive strength respectively at 1 105.8 MPa and 1 870.6 MPa, showing excellent mechanical properties. The fracture morphology of (Ti5Si3+TiBw)/TC11 composites is mainly dimple, and the reinforcements of Ti5Si3 and TiBw can slow down the crack propagation during the fracture process. -

表 1 TC11化学成分

Table 1. Chemical compositions of TC11

% Al Mo Zr Si Fe C O Ti 5.8~7.0 2.8~3.8 0.8~2.0 0.2~0.35 ≤0.25 ≤0.08 ≤0.15 余量 表 2 材料增强相名义体积分数及编号

Table 2. Nominal volume fraction of reinforcement and the number of TMCs

% 试样 Ti5Si3 TiB TC11 TMC0 5 TMC2 2 5 TMC4 4 5 TMC6 6 5 表 3 不同增强体含量的(Ti5Si3+TiBw)/TC11的室温压缩性能

Table 3. Compression properties of (Ti5Si3+TiBw)/TC11 with different reinforcement content at room temperature

试样编号 屈服强度/MPa 抗压强度/MPa 断后压缩率/% TC11 1409.2±9.4 1684.3±14.5 23.49±0.16 TMC0 1139.1±7.4 1601.1±8.7 16.76±0.13 TMC2 1582.1±10.2 1870.6±10.5 19.89±0.11 TMC4 1444.7±7.9 1800.4±7.4 19.18±0.14 TMC6 1516.6±6.7 1819.4±6.4 15.42±0.08 -

[1] Yang Yucheng, Pan Yu, Lu Xin, et al. Research progress of particle reinforced titanium matrix composites prepared by powder metallurgy[J]. Powder Metallurgy Technology, 2020,38(2):150−158. (杨宇承, 潘宇, 路新, 等. 粉末冶金法制备颗粒增强钛基复合材料的研究进展[J]. 粉末冶金技术, 2020,38(2):150−158. [2] Cai C, He S, Li L, et al. In-situ TiB/Ti-6Al-4V composites with a tailored architecture produced by hot isostatic pressing: microstructure evolution, enhanced tensile properties and strengthening mechanisms[J]. Composites Part B:Engineering, 2019,164:546−558. doi: 10.1016/j.compositesb.2019.01.080 [3] Tang Menghan, Lu Jie, Chu Shiyi, et al. Microstructure of (TiB + TiC)/TC18 titanium matrix composites undergoing heat treated[J]. Iron Steel Vanadium Titanium, 2017,38(5):64−67,72. (唐梦涵, 鲁婕, 褚诗意, 等. 热处理(TiB+TiC)/TC18钛基复合材料的微观组织[J]. 钢铁钒钛, 2017,38(5):64−67,72. doi: 10.7513/j.issn.1004-7638.2017.05.012 [4] Ammisetti D K, Kruthiventi S S H. Recent trends on titanium metal matrix composites: A review[J]. Materials Today:Proceedings, 2020,46:9730−9735. [5] 刘悦. (TiBw+(Ti, Zr)5Si3)/TA15复合材料组织与力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.Liu Yue. (TiBw+(Ti, Zr)5Si3)/TA15 composite structure and mechanical properties [D]. Harbin: Harbin Institute of Technology, 2018. [6] Huang Lujun, Sun Fengbo, An Qi, et al. Powder metallurgy fabrication and heat treatment modification of (TiBw + (TiZr)5Si3)/ TA15 composites[J]. China Science:Technology Science, 2020,50(7):935−946. (黄陆军, 孙枫泊, 安琦, 等. (TiBw+(TiZr)5Si3)/TA15钛基复合材料粉末冶金制备与热处理改性[J]. 中国科学:技术科学, 2020,50(7):935−946. [7] Zhang R, Huang L, An Q, et al. The hyperbolic constitutive equations and modified dynamic material model of TiBw/Ti-6.5Al-2.5Zr-lMo-lV-0.5Si composites[J]. Materials Science and Engineering, 2019,766(24):138329. [8] 姚尧. 石墨烯/CNTs混杂增强钛基复合材料设计制备与数值模拟[D]. 哈尔滨: 哈尔滨工业大学, 2020.Yao Yao. Design preparation and numerical simulation of graphene/CNTs hybrid reinforced titanium matrix composites [D]. Harbin: Harbin Institute of Technology, 2020. [9] Liu Shifeng, Song Xi, Xue Tong, et al. Application and development of titanium alloy and titanium matrix composites in aerospace fieid[J]. Journal of Aeronautical Materials, 2020,40(3):77−94. (刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展[J]. 航空材料学报, 2020,40(3):77−94. doi: 10.11868/j.issn.1005-5053.2020.000061 [10] Jianchao H, Lü Zhidan, Changjiang Z, et al. The Microstructural characterization and mechanical Properties of 5 vol.% (TiBw+TiCp)/Ti composite produced by open-die forging[J]. Metals-Open Access Metallurgy Journal, 2018,8(7):485. [11] Lu W J, Zhang D, Zhang X N, et al. Microstructure and tensile properties of in situ (TiB+TiC)/Ti6242 (TiB: TiC=1∶1) composites prepared by common casting technique[J]. Materials Science & Engineering A, 2001,311(1-2):142. [12] Zhou Zhiguang, Liu Yunzhong, Liu Xiaohui, et al. Microstructure evolution and mechanical properties of in-situ Ti6Al4V–TiB composites manufactured by selective laser melting[J]. Composites Part B:Engineering, 2020,207:108567. [13] Shi Chuan, Lei Jianbo, Zhou Shengfeng, et al. Research progress on continuous fiber-reinforced metal matrix composites and their laser cladding[J]. Progress in Laser and Optoelectronics, 2017,54(6):30−40. (石川, 雷剑波, 周圣丰, 等. 连续纤维增强金属基复合材料研究进展及其激光熔覆[J]. 激光与光电子学进展, 2017,54(6):30−40. [14] Feng Jiahao, Han Yuanfei, Huang Guangfa, et al. Crack propagation behavior of TiB+TiC+La2O3 ternary particle reinforced IMI834 titanium matrix composites[J]. Materials for Mechanical Engineering, 2018,42(2):8−12. (冯家浩, 韩远飞, 黄光法, 等. TiB+TiC+La2O3三元颗粒增强IMI834钛基复合材料的裂纹扩展行为[J]. 机械工程材料, 2018,42(2):8−12. doi: 10.11973/jxgccl201802002 [15] Xie H , Jin Y X , Niu M Y, et al. Effect of multilayer graphene/nano-Fe2O3 composite additions on dry sliding wear behavior of titanium matrix composites[J]. Journal of Iron and Steel Research International, 2020, 279(9): 10. [16] Huang Lujun, Geng Lin. Titanium matrix with network microstructure[J]. Progress of Materials in China, 2016,35(9):674. (黄陆军, 耿林. 网状结构钛基复合材料研究进展[J]. 中国材料进展, 2016,35(9):674. [17] Wang S, Huang L J, Geng L, et al. Microstructure evolution and damage mechanism of layered titanium matrix composites under tensile loading[J]. Materials Science and Engineering A, 2020,777:139067. doi: 10.1016/j.msea.2020.139067 [18] Hashin Z, Shtrikman S. A variational approach to the theory of the elastic behaviour of polycrystals[J]. Journal of the Mechanics & Physics of Solids, 1962,10(4):343. [19] 冯养巨. TiBw柱状网络增强钛基复合材料制备及强化机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.Feng Yangju. Preparation and strengthening mechanism of TiBw columnar network reinforced titanium matrix composites [D]. Harbin: Harbin Institute of Technology, 2018. [20] Liu Q, Zhang X C, Wang Q, et al. Microstructure evolution of Ti5Si3 in Cu-Ti-Si alloys[J]. China Foundry, 2020,17(4):286−292. doi: 10.1007/s41230-020-9140-4 [21] Hu Z, Zhan Y, She J. The role of Nd on the microstructural evolution and compressive behavior of Ti–Si alloys[J]. Materials Science & Engineering A, 2013,560(10):583. [22] Hsu H C, Wu S C, Hsu S K, et al. Structure and mechanical properties of as-cast Ti–Si alloys[J]. Intermetallics, 2014,47:11−16. doi: 10.1016/j.intermet.2013.12.004 [23] Jiao Y, Huang L J, Wei S L, et al. Constructing two-scale network microstructure with nano-Ti5Si3 for superhigh creep resistance[J]. Journal of Materials Science & Technology, 2019,35(8):1532. [24] 焦阳. 两级网状结构(Ti5Si3+TiBw)/Ti6Al4V复合材料研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.Jiao Yang. Research on (Ti5Si3+TiBw)/Ti6Al4V composites with two-scale network structure [D]. Harbin: Harbin Institute of technology, 2018. -

下载:

下载: