Research progress of weld formation and performance control of thin plate TC4 titanium alloy by laser welding

-

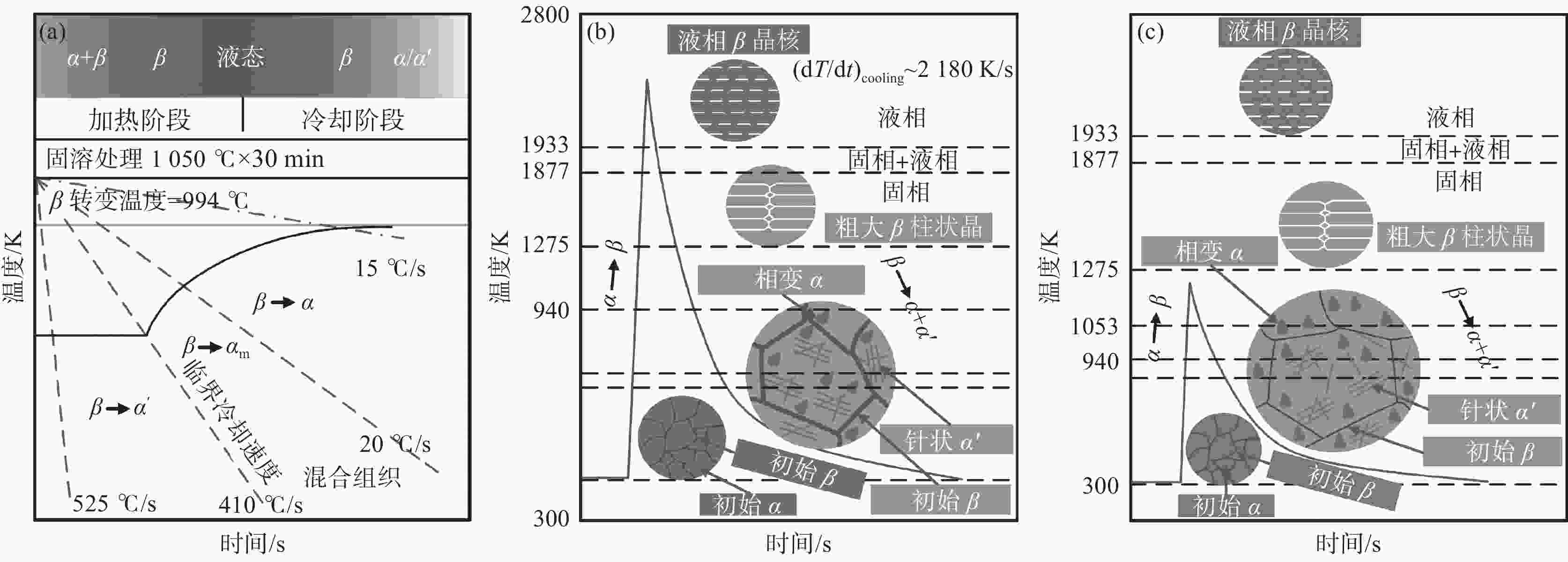

摘要: TC4钛合金的焊接工艺及焊接性研究一直受到国内外的广泛关注,主要综述了目前激光焊工艺对薄壁TC4钛合金焊缝几何形状、显微组织及力学性能影响的研究进展。简要分析了激光焊接工艺对焊缝几何形状及焊缝显微组织转变的规律,并对焊缝几何形状和显微组织的转变机理进行了探讨。研究发现,激光焊焊缝几何形状的变化主要原因在于焊接热输入的变化导致焊接过程中激光焊匙孔形状及模式发生了改变;焊接热输入的增加会引起显微组织的转变,焊缝金属中针状马氏体α'相是主要的强化相,块状αm和魏氏α相是主要的韧性相;应对激光能量进行严格的控制,以便在实际生产应用中提高焊接质量。Abstract: The research on welding process and weldability of TC4 titanium alloy has been widely concerned at home and abroad. Therefore, this paper mainly reviewed the current research progress of the effect of laser welding process on the geometrical dimensions, microstructure and mechanical properties of thin plate TC4 alloy. The weld geometrical dimension and microstructure transformation as well as the related mechanism were analyzed and discussed. It is found that the change of weld geometrical dimension is mainly due to the variation of welding heat input, which leads to the change of laser welding keyhole shape and mode. The increase of welding heat input causes the transformation of the microstructure. The acicular martensite α' phase is the main strengthening phase, with the blocky αm and Widmanstatten α phase as the main malleable phases. The laser energy should be strictly controlled to improve the welding quality in actual production applications.

-

Key words:

- TC4 /

- laser welding /

- weld geometrical dimension /

- microstructure /

- mechanical properties

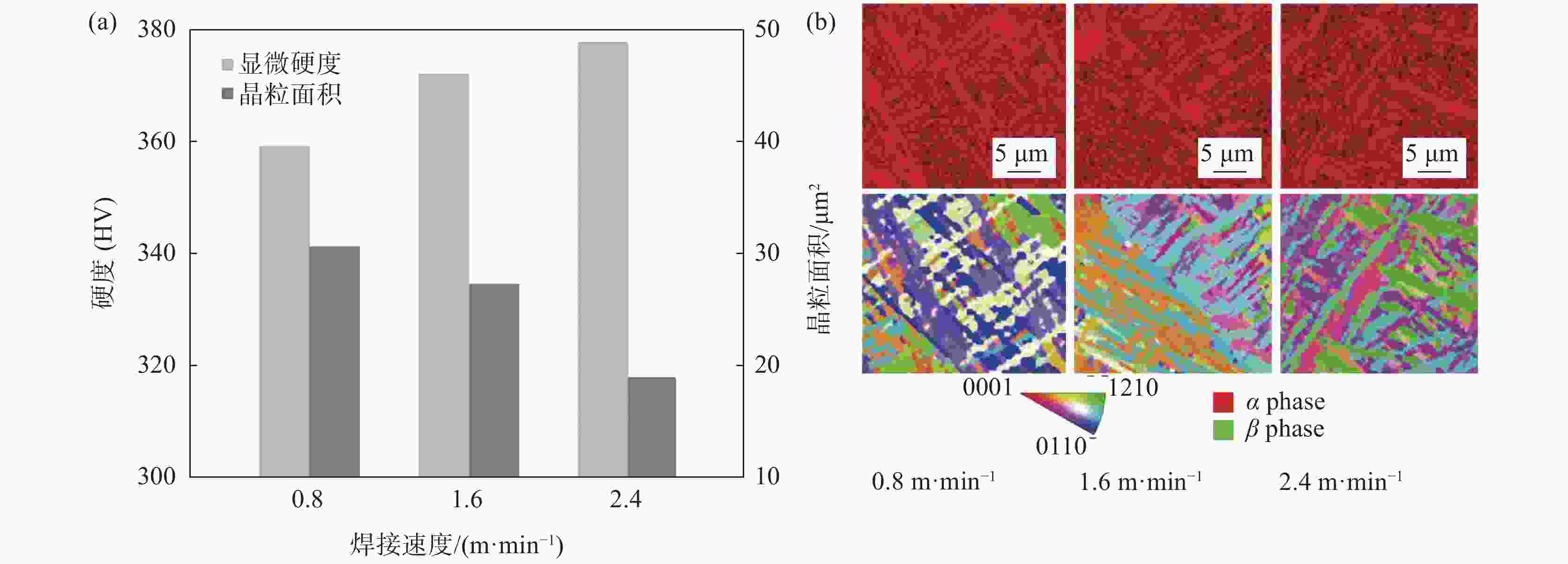

-

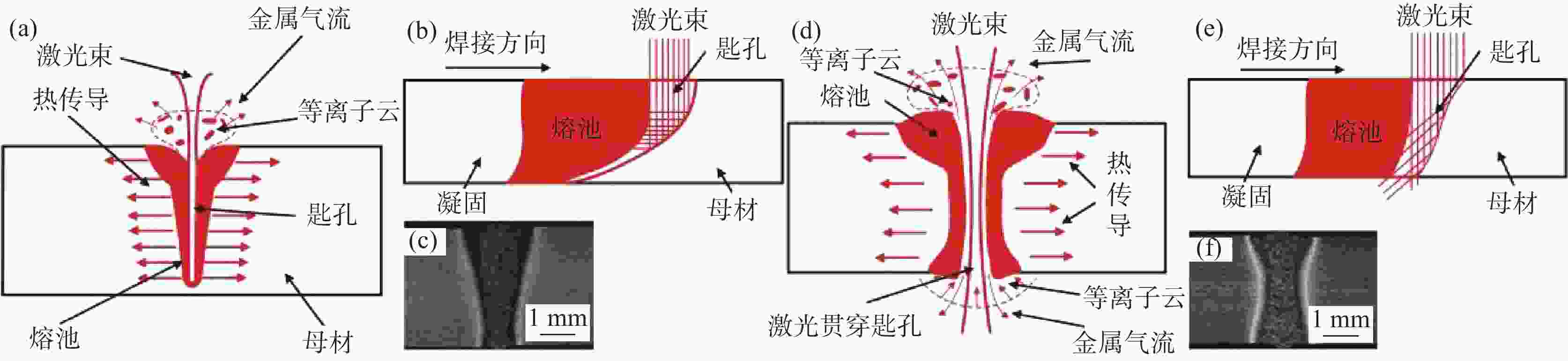

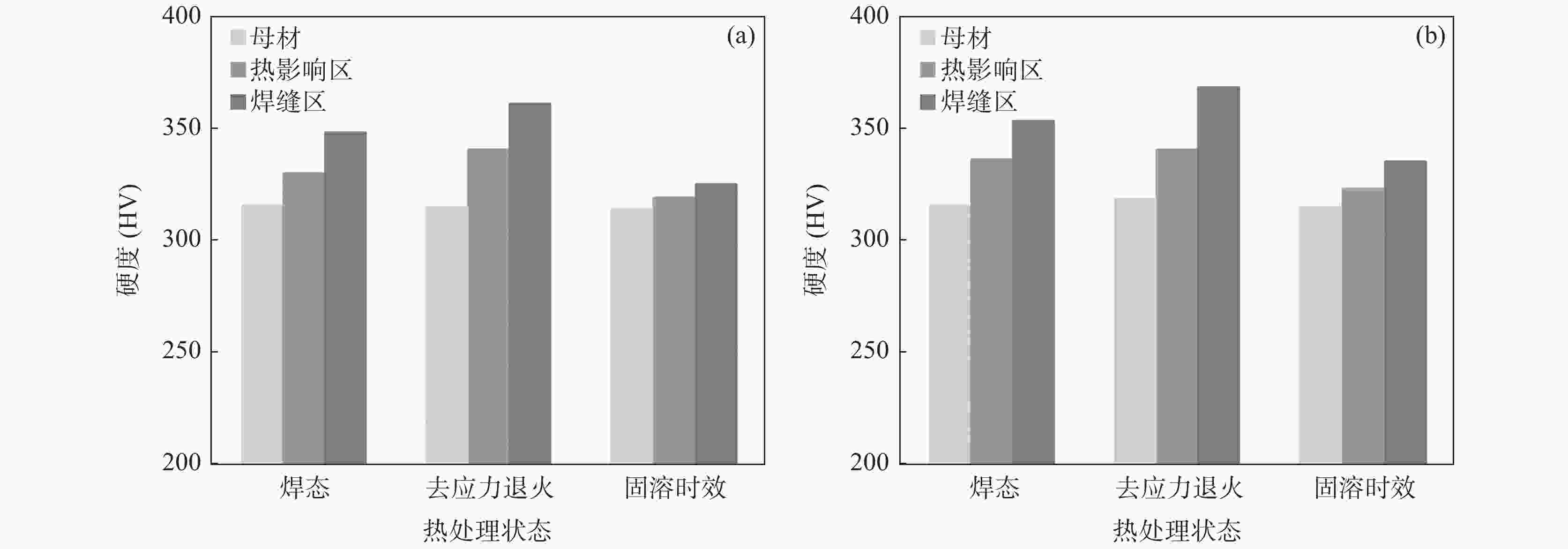

图 1 不同强度激光作用于金属表面的物理过程[36]

(a) 固态加热; (b) 表面熔化; (c) 匙孔效应; (d) 等离子体屏蔽

Figure 1. Physical processes of laser of different intensities acting on metal surface

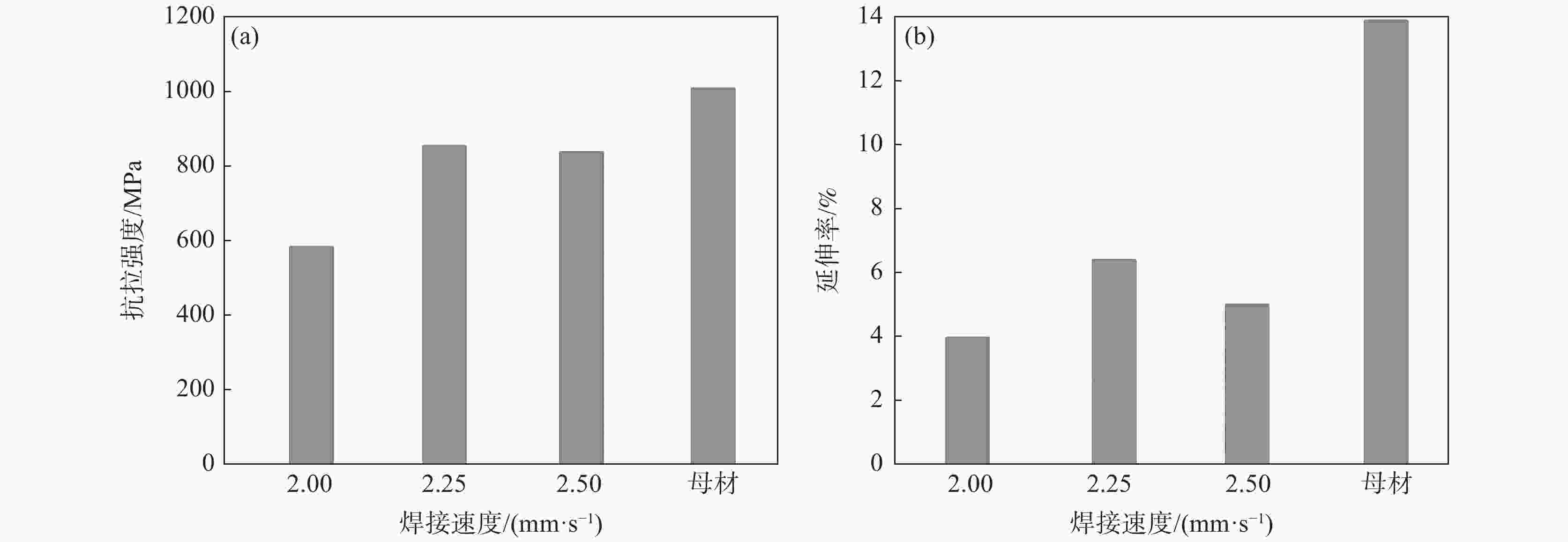

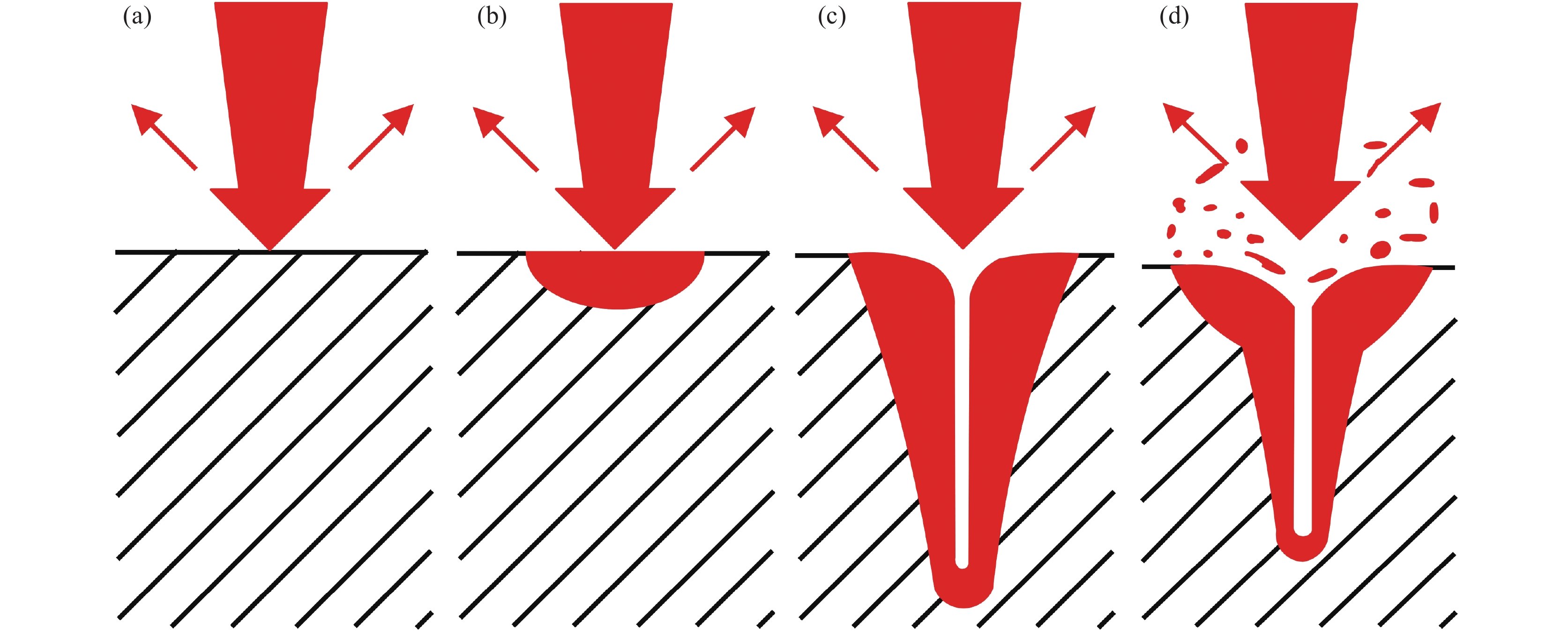

图 6 不同焊接速度下焊缝金属力学性能[63]

(a) 抗拉强度; (b) 延伸率

Figure 6. Mechanical properties of weld metal with different welding speeds

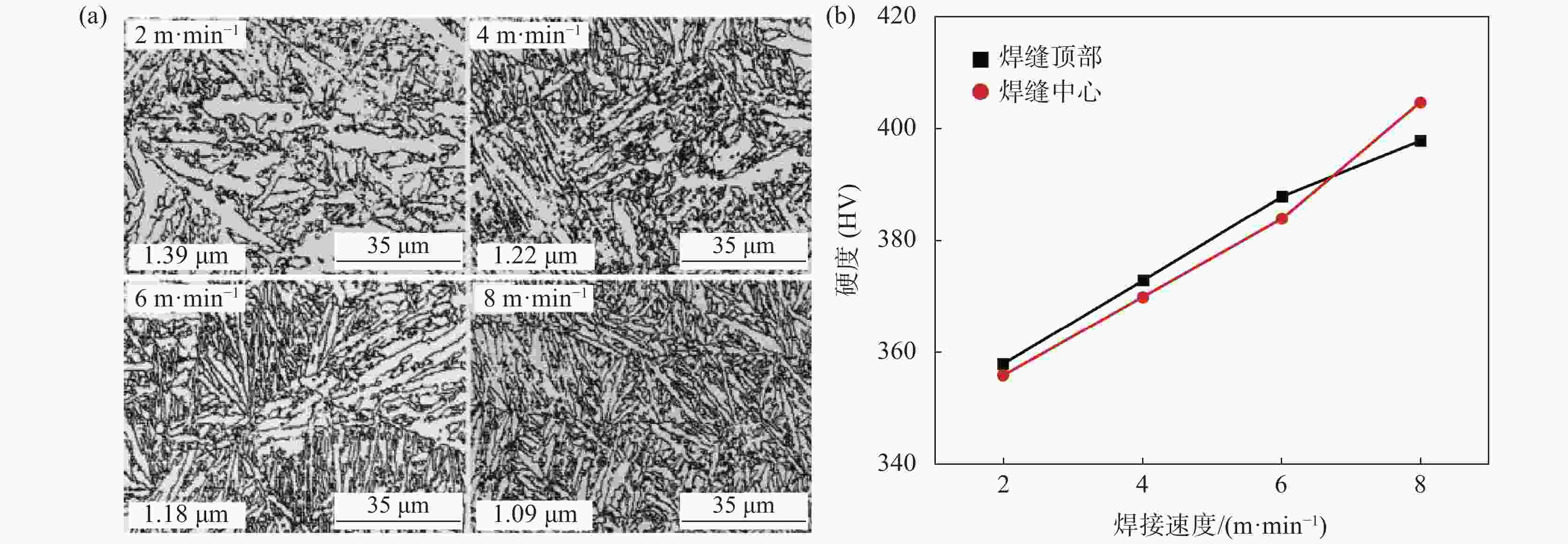

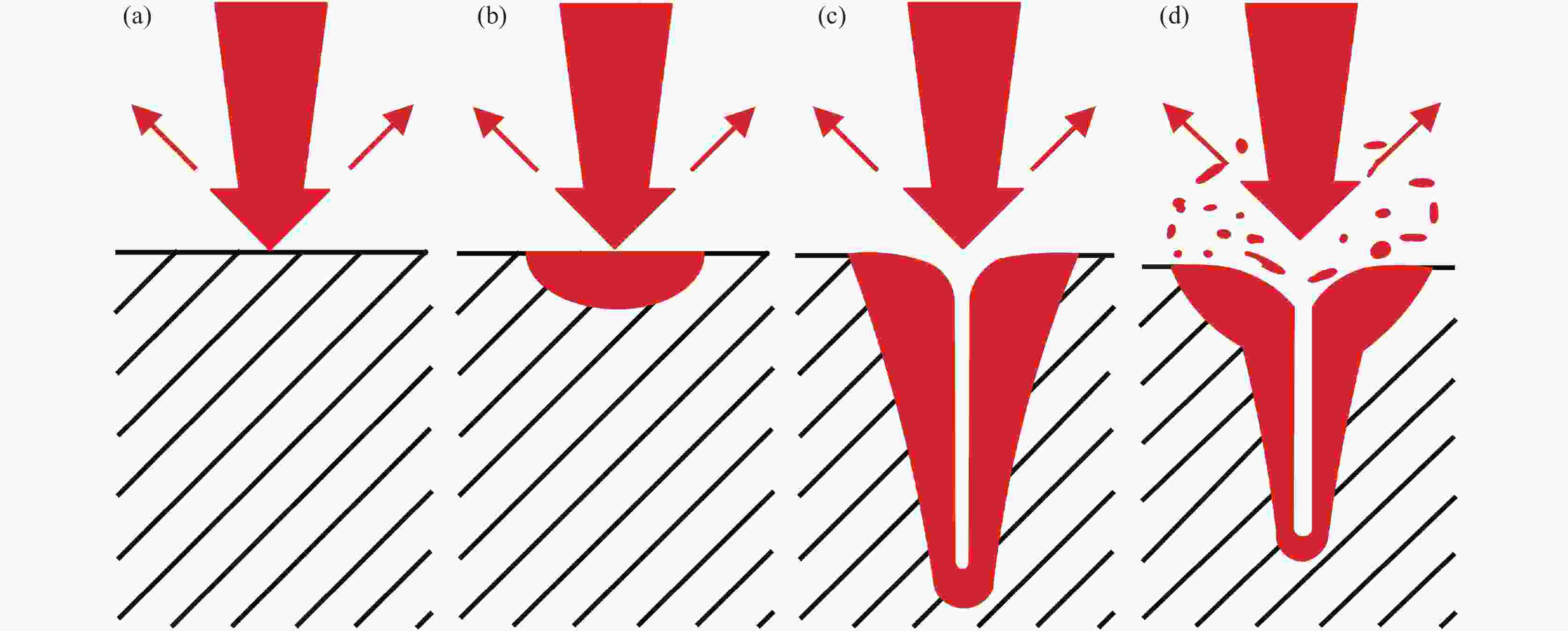

图 11 焊态、SRA和STA条件下三个不同区域的平均硬度

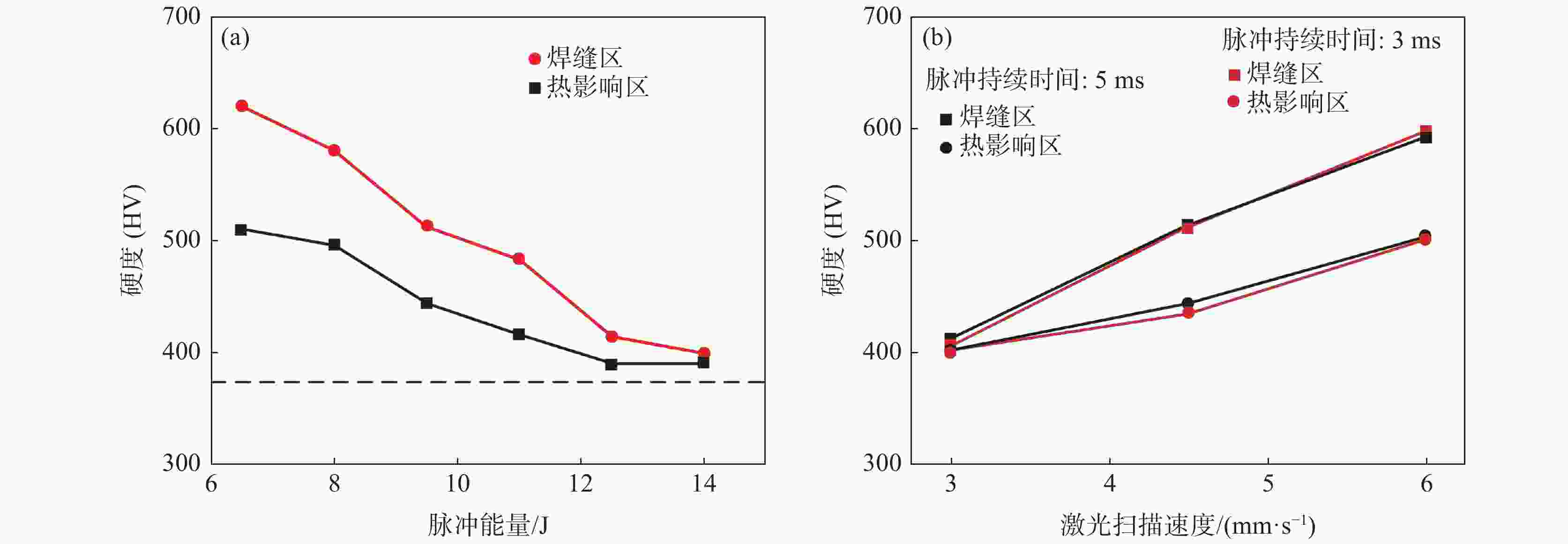

Figure 11. Average hardness of the three different zones in as-welded, SRA, and STA conditions[75]

(a) 3.2 mm; (b) 5.1 mm

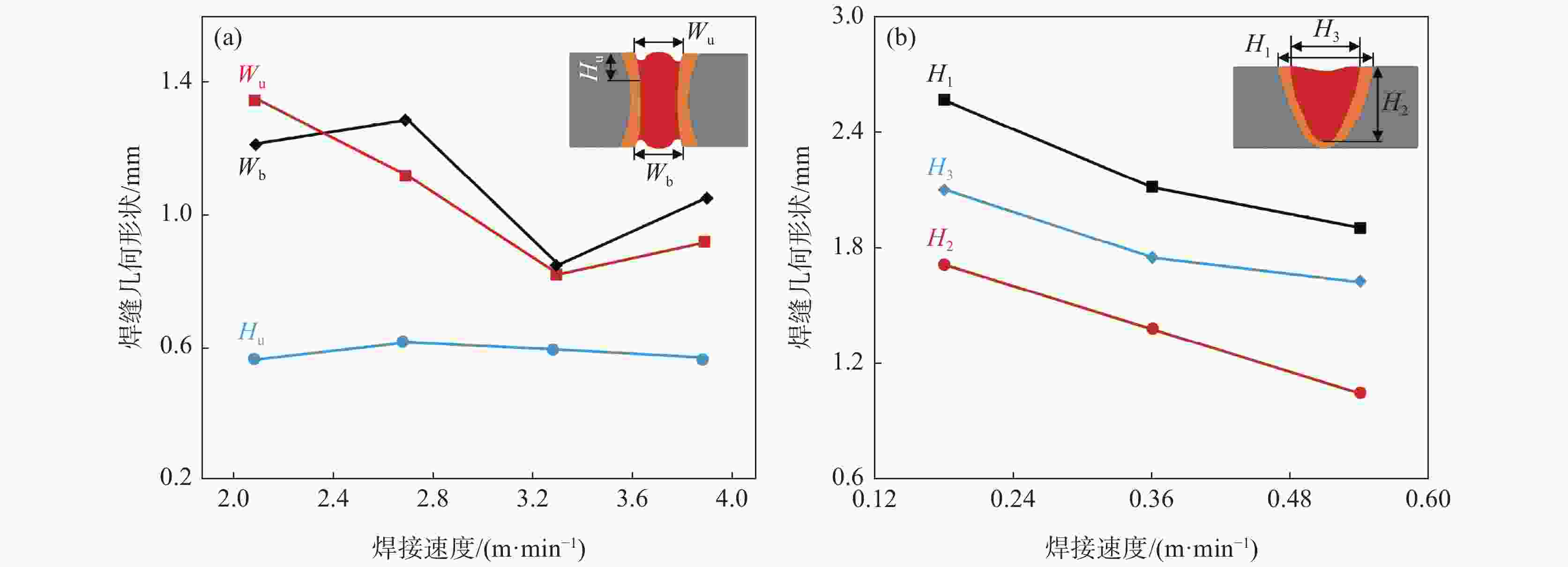

表 1 不同焊接速度下熔池几何形状的比较[43]

Table 1. Comparison of the geometry of the molten pool for various welding speeds

编号 焊接速度/(m·min−1) 焊缝宽度/mm 焊缝深度/mm 热影响区宽度 (板厚=1 mm)/mm 热影响区厚度(板厚=1.5 mm)/mm 1 2 1.51 完全焊透 0.86 0.79 2 4.3 1.26 完全焊透 0.74 0.7 3 6.2 0.93 0.89 0.59 0.48 表 3 不同厚度下TC4钛合金的激光焊接工艺参数

Table 3. Laser welding process parameters of TC4 titanium alloy with different thicknesses

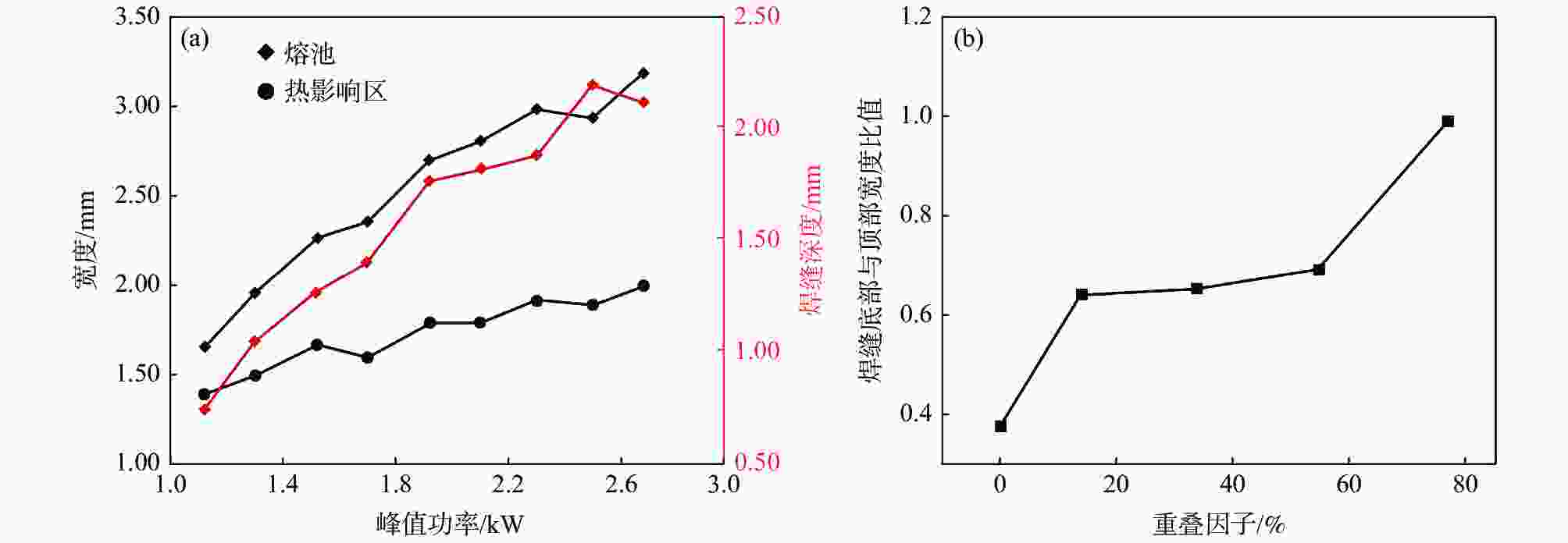

编号 厚度/mm 学者 年份 焊接参数 参考文献 激光功率/W 焊接速度/(m·min−1) 离焦量/mm 焊接保护气 1 0.5 杨烁等人 2019 430 1.5 3 Ar [15] 2 0.8 杨静等人 2007 1300 3 0.5 [60] 3 1.2 张颖云等人 2019 1200 1.5 3 Ar [70] 4 1.2 姜毅等人 2020 1200 1.4 1 Ar [8] 5 2.0 徐洁洁 2009 2500 6 He [54] 6 2.0 Campanelli .et al 2015 1200 2.25 Ar+He [63] 7 2.1 李仲树等人 2017 1550 1.5 0 Ar [64] 8 3.0 张启良 2014 2300 0.4 0 Ar [1] 9 3.0 李明军等人 2017 2300 3.3 0 Ar [12] 10 3.0 李海刚等人 2017 2100 1.2 0 Ar [14] 11 3.5 黄炜等人 2019 4000 3 0 Ar [11] 12 4.0 Köse .et al 2017 1500 0.36 He [51] 13 4.0 陈波等人 2021 4000 1.2 0 [16] 表 4 激光焊接接头及多次热处理后的力学性能[74]

Table 4. Mechanical properties of laser welded joints after multiple heat treatment

多次热处理 抗拉强度/MPa 屈服强度/MPa 延伸率/% 焊态 1139 1080 10.9 1 1124 1056 9.6 2 1133 1086 10.1 3 1123 1023 10.4 4 1144 1084 9.6 -

[1] 张启良. TC4钛合金激光焊接工艺优化及接头组织性能研究[D]. 呼和浩特: 内蒙古工业大学, 2014: 12−40.Zhang Qiliang. Welding process optimization and research on microstructure and properties for laser weld joints of TC4 titanium alloy[D]. Huhhot: Inner Mongolia University of Technology, 2014: 12−40. [2] Wu Yanpei, Liu Jinhe, Xu Weifeng. Study on welding temperature and joints microstructure of TC4 titanium alloy thin plate in laser weld[J]. Hot Working Technology, 2010,39(15):145−147. (吴言沛, 刘金合, 徐韦锋. TC4薄板激光焊接温度和接头微观组织分析[J]. 热加工工艺, 2010,39(15):145−147. doi: 10.3969/j.issn.1001-3814.2010.15.046 [3] Ma Shihui, Li Jiyuan. Influence of shaft shoulder diameter on microstructure and properties of Ti-6Al-4V friction stir welding joint[J]. Iron Steel Vanadiun Titanium, 2021,42(3):82−87. (马世辉, 李积元. 轴肩直径对Ti-6Al-4V钛合金搅拌摩擦焊接头组织和性能的影响[J]. 钢铁钒钛, 2021,42(3):82−87. doi: 10.7513/j.issn.1004-7638.2021.03.012 [4] Liu Bili, Xie Songjing, Yao Jianhua. Application and development trend of laser welding[J]. Laser and Optoelectronics Progress, 2006,42(5):43−47. (刘必利, 谢颂京, 姚建华. 激光焊接技术应用及其发展趋势[J]. 激光与光电子学进展, 2006,42(5):43−47. [5] Hou Jijun, Dong Junhui, Zhang Qiliang. Analysis on microstructure and fracture of TC4 titanium alloy laser welded joints[J]. Hot Working Technology, 2016,45(3):35−37,41. (侯继军, 董俊慧, 张启良. TC4钛合金激光焊接头显微组织及断口分析[J]. 热加工工艺, 2016,45(3):35−37,41. [6] Zhao Xingwang, Liu Yanmei, Fu Heguo, et al. Research on microstructure and mechanical properties of laser butt welding of thin TC4 titanium alloy[J]. Vacuum, 2020,57(4):89−94. (赵兴旺, 刘艳梅, 付和国, 等. TC4薄壁钛合金激光对接接头组织及力学性能研究[J]. 真空, 2020,57(4):89−94. [7] 涂世豪. 钛合金脉冲激光焊接工艺的研究[D]. 武汉: 华中科技大学, 2015: 1−14.Tu Shihao. Research on pulsed laser welding procedure of titanium alloy[D]. Wuhan: Huazhong University of Science and Technology, 2015: 1−14. [8] Jiang Yi, Zhang Yingyun, Zhu Shengli, et al. Effect of laser power on butt weld morphology of TC4 titanium alloy sheet[J]. Hot Working Technology, 2020,49(15):16−18,24. (姜毅, 张颖云, 朱胜利, 等. 激光功率对TC4钛合金薄板对接焊缝形貌的影响[J]. 热加工工艺, 2020,49(15):16−18,24. [9] Xu Aiping, Dong Junhui, Zhen Shaoyang, et al. Orthogonal experiment was used to optimize the microstructure of TC4 titanium alloy laser welded joint[J]. World Nonferrous Metals, 2020,(8):170−171. (许爱平, 董俊慧, 甄邵杨, 等. 焊接功率对TC4钛合金激光焊接头成形与组织性能研究[J]. 世界有色金属, 2020,(8):170−171. doi: 10.3969/j.issn.1002-5065.2020.08.078 [10] Xu Z Z, Dong Z Q, Yu Z H, et al. Relationships between microhardness, microstructure, and grain orientation in laser-welded joints with different welding speeds for Ti6Al4V titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2020,30(5):1277−1289. doi: 10.1016/S1003-6326(20)65295-5 [11] Huang Wei, Wang Shaogang, Li Lize, et al. Laser beam welding of titanium alloy and microstructure and mechanical properties of welded joint[J]. Development and Application of Materials, 2019,34(2):20−27. (黄炜, 王少刚, 李立泽, 等. 钛合金激光焊及其接头的显微组织与力学性能[J]. 材料开发与应用, 2019,34(2):20−27. [12] Li Mingjun, Chen Hexing, Chen Yongcheng, et al. Effect of welding speed on laser welding formation and microstructure of TC4 titanium alloy[J]. Welding Technology, 2017,46(12):30−32,33. (李明军, 陈和兴, 陈永城, 等. 焊接速度对TC4钛合金激光焊接成形及组织的影响[J]. 焊接技术, 2017,46(12):30−32,33. [13] Xu Aiping, Dong Junhui, Zhen Shaoyang, et al. Research on optimization of microstructure and properties of laser welded joints of TC4 titanium alloy based on orthogonal experiment[J]. Mechanical Electrical Information, 2020,9:49−52. (许爱平, 董俊慧, 甄邵杨, 等. 基于正交实验的TC4钛合金激光焊接头组织性能优化研究[J]. 机电信息, 2020,9:49−52. doi: 10.3969/j.issn.1671-0797.2020.05.029 [14] Li Haigang, Yuan Zhang, Cheng Hao, et al. Influence of welding parameters on porosity in welding of TC4 titanium alloy in two positions[J]. Aerospace Materials and Technology, 2017,47(6):43−46. (李海刚, 原璋, 程昊, 等. TC4钛合金激光焊中工艺参数对气孔生成量的影响[J]. 宇航材料工艺, 2017,47(6):43−46. doi: 10.12044/j.issn.1007-2330.2017.06.008 [15] Yang Shuo, Song Wenqing, Qu Shen, et al. Experimental research on laser welding of thin-walled TC4 titanium alloy[J]. Welding Joining, 2019,(1):5−11. (杨烁, 宋文清, 曲伸, 等. 薄壁TC4钛合金激光焊缝成形试验研究[J]. 焊接, 2019,(1):5−11. [16] Chen Bo, Meng Zheng, Ma Chengyuan, et al. Study on welding properties and molten pool flow behavior of TC4 titanium alloy by oscillating galvanometer laser[J]. Acta Aeronautica et Astronautica Sinica, 2021,42(12):1−13. (陈波, 孟正, 马程远, 等. 扫描振镜激光TC4钛合金焊接性能及熔池流动行为研究[J]. 航空学报, 2021,42(12):1−13. [17] Kumar B, Bag S, Paul C P, et al. Influence of the mode of laser welding parameters on microstructural morphology in thin sheet Ti6Al4V alloy[J]. Optics and Laser Technology, 2020,131:106456. doi: 10.1016/j.optlastec.2020.106456 [18] Liu Jing, Gao Xiaolong. Study of high temperature mechanical performance on Ti6Al4V LBW welding joint[J]. Journal of Hebei University of Science and Technology, 2018,39(4):299−305. (刘晶, 高晓龙. Ti6Al4V脉冲激光焊接头高温力学性能研究[J]. 河北科技大学学报, 2018,39(4):299−305. doi: 10.7535/hbkd.2018yx04002 [19] Liu J, Gao X L, Zhang L J, et al. A study of fatigue damage evolution on pulsed Nd: YAG Ti6Al4V laser welded joints[J]. Engineering Fracture Mechanics, 2014,117:84−93. doi: 10.1016/j.engfracmech.2014.01.005 [20] Cui Li, Li Xaoyan, He Dingyong, et al. Laser-arc hybrid welding of titanium alloy[J]. Welding Joining, 2009,(7):60−64. (崔丽, 李晓延, 贺定勇, 等. 钛合金的激光-电弧复合焊接[J]. 焊接, 2009,(7):60−64. doi: 10.3969/j.issn.1001-1382.2009.07.010 [21] Mou Gang, Hua Xueming, Xu Xiaobo, et al. Comparative study on TIG and MIG welding process and performance of 8 mm thick TC4 titanium alloy[J]. Electric Welding Machine, 2020,50(4):70−74. (牟刚, 华学明, 徐小波, 等. 8 mm厚TC4钛合金TIG, MIG焊接工艺及性能对比研究[J]. 电焊机, 2020,50(4):70−74. [22] Zhang Long, Chen Donggao, Wang Dafeng, et al. Laser-MIG hybrid welding of TC4 titanium alloy[J]. Ordnance Material Science and Engineering, 2019,42(2):73−77. (张龙, 陈东高, 王大锋, 等. TC4钛合金激光-MIG复合焊接研究[J]. 兵器材料科学与工程, 2019,42(2):73−77. [23] Zhao An,an, Zhang Yingyun, Hou Lin, et al. Dual beam laser welding of TC4T-shape joint by using auxiliary step as filler metal[J]. Applied Laser, 2021,41(2):276−283. (赵安安, 张颖云, 侯琳, 等. 含工艺台阶TC4钛合金T形接头的双光束激光焊接[J]. 应用激光, 2021,41(2):276−283. [24] Gao X L, Liu J, Zhang L J, et al. Effect of the overlapping factor on the microstructure and mechanical properties of pulsed Nd: YAG laser welded Ti6Al4V sheets[J]. Materials Characterization, 2014,93(7):136−149. [25] Heydari H, Akbari M. Investigating the effect of process parameters on the temperature field and mechanical properties in pulsed laser welding of Ti6Al4V alloy sheet using response surface methodology[J]. Infrared Physics and Technology, 2020,106:103267. doi: 10.1016/j.infrared.2020.103267 [26] Jiang D Z, Alsagri A S, Akbari M, et al. Numerical and experimental studies on the effect of varied beam diameter, average power and pulse energy in Nd: YAG laser welding of Ti6Al4V[J]. Infrared Physics and Technology, 2019,101:180−188. doi: 10.1016/j.infrared.2019.06.006 [27] Chang B H, Yuan Z, Pu H T, et al. A Comparative study on the laser welding of Ti6Al4V alloy sheets in flat and horizontal positions[J]. Applied Sciences, 2017,7:376. doi: 10.3390/app7040376 [28] Janasekaran S, Tan A W, Yusof F, et al. Influence of the overlapping factor and welding speed on T-joint welding of Ti6Al4V and inconel 600 using low-power fiber laser[J]. Metals, 2016,6:134. doi: 10.3390/met6060134 [29] Kandaoui M E, Scandella F, Germain L, et al. Microstructure and mechanical properties of Ti-6Al-4V laser welds for airplane floor manufacturing application[C]//Proceedings of the 13th World Conference on Titanium.Wiley, 2016:1551−1556. [30] Chang B H, Yuan Z, Cheng H, et al. A study on the influences of welding position on the keyhole and molten pool behavior in laser welding of a titanium alloy[J]. Metals, 2019,9:1082. doi: 10.3390/met9101082 [31] Li C, Li B, Wu Z F, et al. Stitch welding of Ti−6Al−4V titanium alloy by fiber laser[J]. Transactions of Nonferrous Metals Society of China, 2017,27:91−101. doi: 10.1016/S1003-6326(17)60010-4 [32] Cheng Donghai, Huang Jihua, Yang Jing, et al. Laser welding forming and microstructure of TC4 titanium alloy[J]. Rare Metal Materials and Engineering, 2009,38(2):255−258. (程东海, 黄继华, 杨静, 等. TC4钛合金激光叠焊成形及显微组织[J]. 稀有金属材料与工程, 2009,38(2):255−258. doi: 10.3321/j.issn:1002-185X.2009.02.015 [33] Zhang Yingyun, Zhao An,an, Chen Suming. Study on microstructure and mechanical properties of laser locking surface butt welding of TC4 titanium alloy[J]. Hot Working Technology, 2019,48(13):46−49. (张颖云, 赵安安, 陈素明. TC4 钛合金激光锁面对接焊的微观组织及力学性能研究[J]. 热加工工艺, 2019,48(13):46−49. [34] 施项中. TC4钛合金水下激光焊接工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2018: 6-11.Shi Xiangzhong. Welding procedure research in underwater laser welding of TC4 titanium alloy[D]. Harbin: Harbin Institute of Technology, 2018: 6-11. [35] 黄潞. TC4钛合金水下激光填丝焊接控形控性工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2019: 10-11.Huang Lu. Research on controllability technology of TC4 titanium alloy underwater laser wire filling welding[D]. Harbin: Harbin Institute of Technology, 2019: 10-11. [36] Gong S L, Pang S Y, Wang H, et al. Weld pool dynamics in deep penetration laser welding[M]. Beijing: China Aviation Publishing, 2021: 12-14. [37] Dowden J, Postacioglu N, Davis M, et al. A keyhole model in penetration welding with a laser[J]. Journal of Physics D Applied Physics, 1987,20:36−44. doi: 10.1088/0022-3727/20/1/006 [38] Dowden J, Kapadia P, Postacioglu N, et al. An analysis of the laser-plasma interaction in laser key hole welding[J]. Journal of Physics D Applied Physics, 1989,22:741−749. doi: 10.1088/0022-3727/22/6/004 [39] Lambrakos S G. Inverse thermal analysis of Ti-6Al-4V laser welds using solidification and heat-affected zone boundaries[J]. Journal of Materials Engineering and Performance, 2017,26:1195−1208. doi: 10.1007/s11665-017-2546-5 [40] Hong K M, Shin Y C. Analysis of microstructure and mechanical properties change in laser welding of Ti6Al4V with a multiphysics prediction model[J]. Journal of Materials Processing Technology, 2016,237:420−429. doi: 10.1016/j.jmatprotec.2016.06.034 [41] Mashinini P M, Hattingh D G. Influence of laser power and traverse speed on weld characteristics of laser beam welded Ti-6Al-4V sheet[J]. Materials Research Proceedings, 2018,4:59−64. [42] Akbari M, Saedodin S, Toghraie D, et al. Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy[J]. Optics and Laser Technology, 2014,59:52−59. doi: 10.1016/j.optlastec.2013.12.009 [43] Li Z X, Rostam K, Panjehpour A, et al. Experimental and numerical study of temperature field and molten pool dimensions in dissimilar thickness laser welding of Ti6Al4V alloy[J]. Journal of Manufacturing Processes, 2020,49:438−446. doi: 10.1016/j.jmapro.2019.11.024 [44] Cheepu M, Venkateswarlu D, Rao P N, et al. Effect of process parameters and heat input on weld bead geometry of laser welded titanium Ti-6Al-4V alloy[J]. Materials Science Forum, 2019,969:613−618. doi: 10.4028/www.scientific.net/MSF.969.613 [45] Kurmi J S, P A A, Mahidhara V, et al. Experimental investigations on the effect of heat input on CO2 laser welded Ti-6Al-4V plates[J]. IOP Conference Series:Materials Science and Engineering, 2020,912:032007. doi: 10.1088/1757-899X/912/3/032007 [46] Gao X L, Zhang L J, Liu J, et al. Effects of weld cross-section profiles and microstructure on properties of pulsed Nd: YAG laser welding of Ti6Al4V sheet[J]. International Journal of Advanced Manufacturing Technology, 2014,72:895−903. doi: 10.1007/s00170-014-5722-x [47] Liu J, Gao X L, Zhang L J, et al. On the use of infrared thermography for analysis of fatigue damage in Ti6Al4V-welded joints[J]. Journal of Materials Engineering and Performance, 2014,23:2965−2972. doi: 10.1007/s11665-014-1031-7 [48] 杨东旭. TC4钛合金激光焊接接头溶质元素分布及不均匀性的研究[D]. 武汉: 华中科技大学, 2015: 20-28.Yang Dongxu. Study on solute elements distribution and heterogeneity of microstructure and mechanical properties of TC4 alloy joints welded by fiber laser beam[D]. Wuhan: Huazhong University of Science and Technology, 2015: 20-28. [49] Akbari M, Saedodin S, Panjehpour A, et al. Numerical simulation and designing artificial neural network for estimating melt pool geometry and temperature distribution in laser welding of Ti6Al4V alloy[J]. Optik-International Journal for Light and Electron Optics, 2016:11161−11172. [50] Akman E, Demir A, Canel T, et al. Laser welding of Ti6Al4V titanium alloys[J]. Journal of Materials Processing Technology, 2009,209:3705−3713. doi: 10.1016/j.jmatprotec.2008.08.026 [51] Köse C, Karaca E. Robotic Nd: YAG fiber laser welding of Ti-6Al-4V alloy[J]. Metals, 2017,7:221. doi: 10.3390/met7060221 [52] Qiao Liang, Su Xuan, Tao Wang, et al. Comparison of microstructure and properties of TC4 alloy under different welding processes[J]. Hot Working Technology, 2016,45(3):19−22. (乔亮, 苏轩, 陶汪, 等. TC4钛合金不同焊接工艺下组织性能对比[J]. 热加工工艺, 2016,45(3):19−22. [53] Ahmed T, Rack H J. Phase transformations during cooling in α+β titanium alloys[J]. Materials Science and Engineering:A, 1998,243:206−211. doi: 10.1016/S0921-5093(97)00802-2 [54] 徐洁洁. TC4钛合金激光焊接接头组织性能研究[D]. 北京: 北京工业大学, 2009: 17-26.Xu Jiejie. Research on microstructure and properties of laser welding joints of TC4 titanium alloy[D]. Beijing: Beijing University of Technology, 2009: 17-26. [55] Chen Suming, Zhao An,an, Jiang Yi, et al. Effect of TC4 titanium alloy laser filler wire welding process parameters on weld macro formation[J]. Chinese Journal of Lasers, 2021,48(4):140200. (陈素明, 赵安安, 姜毅, 等. TC4钛合金激光填丝焊工艺参数对焊缝宏观成形的影响[J]. 中国激光, 2021,48(4):140200. [56] Yang Xiaohua, Yang Wulin, Dui Weizhen, et al. Microstructure and microhardness of laser welding joints in TC4 alloy[J]. Transactions of Materials and Heat Treatment, 2014,35(10):70−74. (杨晓华, 杨武林, 兑卫真, 等. TC4钛合金激光焊接头微观组织和硬度[J]. 材料热处理学报, 2014,35(10):70−74. [57] Dong Zhijun, Lv Tao, Lei Zhenglong, et al. Microstructure and mechanical properties of laser welded TC4 alloys[J]. Aerospace Manufacturing Technology, 2013,(1):27−30. (董智军, 吕涛, 雷正龙, 等. 激光焊接TC4钛合金组织性能研究[J]. 航天制造技术, 2013,(1):27−30. [58] 田德勇. 中厚板 TC4 钛合金激光焊接微观组织与缺陷研究[D]. 南京: 南京航空航天大学, 2020: 57-58.Tian Deyong. Study on the microstructure and defect in the laser welded joint of medium thickness TC4 alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020: 57-58. [59] Baruah M, Bag S. Influence of pulsation in thermo-mechanical analysis on laser micro-welding of Ti6Al4V alloy[J]. Optics and Laser Technology, 2017,90:40−51. doi: 10.1016/j.optlastec.2016.11.006 [60] Yang Jing, Cheng Donghai, Huang Jihua. Effect of laser welding parameters on microstructure and mechanical proper ties of TC4 welded joints[J]. Hot Working Technology, 2007,36(23):15−18. (杨静, 程东海, 黄继华. TC4合金激光焊接工艺参数与接头组织性能研究[J]. 热加工工艺, 2007,36(23):15−18. doi: 10.3969/j.issn.1001-3814.2007.23.006 [61] Yang Jing, Cheng Donghai, Huang Jihua, et al. Microstructure and properties of laser welding joint of TC4 titanium alloy[J]. Rare Metal Materials and Engineering, 2009,38(2):259−262. (杨静, 程东海, 黄继华, 等. TC4钛合金激光焊接接头组织与性能[J]. 稀有金属材料与工程, 2009,38(2):259−262. doi: 10.3321/j.issn:1002-185X.2009.02.016 [62] Zhao Xiaolong, Wang Bin, Gong Shuili, et al. Study on microstructure and mechanical properties of laser welded joint of 2 mm thick TC4 titanium alloy[J]. Hot Working Technology, 2017,46(9):209−211. (赵晓龙, 王彬, 巩水利, 等. 2.0 mm厚TC4钛合金激光焊接接头组织与力学性能研究[J]. 热加工工艺, 2017,46(9):209−211. [63] Campanelli S L, Casalino G, Mortello M, et al. Microstructural characteristics and mechanical properties of Ti6Al4V alloy fiber laser welds[J]. Procedia Cirp, 2015,33:428−433. doi: 10.1016/j.procir.2015.06.098 [64] Li Zhongshu, Zhou Jinyu. Effects of laser welding power on microstructure and fatigue life of TC4 titanium alloy[J]. Hot Working Technology, 2017,46(5):45−47,51. (李仲树, 周金宇. 激光焊接功率对TC4钛合金微观组织和疲劳寿命的影响[J]. 热加工工艺, 2017,46(5):45−47,51. [65] Aravind A P, Kurmi J S, Swamy P M, et al. Optimization of welding parameters in laser welding of Ti6Al4V using VIKOR optimization method[J]. Materials Today:Proceedings, 2021,45:592−596. doi: 10.1016/j.matpr.2020.02.388 [66] Xu P Q, Li L J, Zhang C B. Microstructure characterization of laser welded Ti-6Al-4V fusion zones[J]. Materials Characterization, 2014,87:179−185. doi: 10.1016/j.matchar.2013.11.005 [67] Liu H, Nakata K, Yamamoto N, et al. Microstructural characteristics and mechanical properties in laser beam welds of Ti6Al4V alloy[J]. Journal of Materials Science, 2012,47:1460−1470. doi: 10.1007/s10853-011-5931-8 [68] Levine E, Greenhut I, Margolin H. Grain size and grain growth in an equiaxed alpha-beta titanium alloy[J]. Metallurgical Transactions, 1973,4:2519−2525. doi: 10.1007/BF02644253 [69] Li Zheng, Zhao Wei, Zhang Hui. Study on microstructure and mechanical properties of laser welded joint of TC4 titanium alloy[J]. Journal of Qilu University of Technology, 2021,35(4):48−52. (李镇, 赵伟, 张辉. TC4钛合金激光焊接接头组织及力学性能研究[J]. 齐鲁工业大学学报, 2021,35(4):48−52. [70] Zhang Yingyun, Zhu Zenghui, Liu Jiangzhe, et al. Research on laser welding of 1.2 mm thick TC4 titanium alloy[J]. Applied Laser, 2019,39(4):596−601. (张颖云, 朱增辉, 刘江哲, 等. 1.2 mm厚TC4钛合金薄板激光焊工艺研究[J]. 应用激光, 2019,39(4):596−601. [71] Ohmori Y, Nakai K, Ohtsubo H, et al. Formation of widmansttten alpha structure in a Ti–6Al–4V alloy[J]. Materials Transactions, 1994,35(4):238−246. doi: 10.2320/matertrans1989.35.238 [72] Peters M, Williams J C. Microstructure and mechanical properties of a welded (α+β) Ti alloy[J]. Metallurgical and Materials Transactions A, 1984,15A:1589−1596. [73] Xu P Q. Microstructure characterization of Ti–6Al–4V titanium laser weld and its deformation[J]. Transactions of Nonferrous Metals Society of China, 2012,22(9):2118−2123. doi: 10.1016/S1003-6326(11)61437-4 [74] Zhao Xiaolong, Wang Bin, He Enguang, et al. Effect of multiple heat treatments on the microstructure and properties of TC4 titanium alloy laser welding joint[J]. Applied Laser, 2020,40(5):831−835. (赵晓龙, 王彬, 何恩光, 等. 多次热处理对TC4钛合金激光焊接头组织和性能的影响[J]. 应用激光, 2020,40(5):831−835. [75] Kabir A S H, Cao X J, Gholipour J, et al. Effect of postweld heat treatment on microstructure, hardness, and tensile properties of laser-welded Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 2012,43A:4171−4184. [76] Du Yongqin, Zhu Xiaohui, Liu Min, et al. Study on the post-weld heat treatment process of Ti-6Al-4V alloy[J]. Machinist Metal Forming, 2021,6:47−50. (杜永勤, 祝晓辉, 刘敏, 等. Ti-6Al-4V合金焊后热处理工艺研究[J]. 金属加工:热加工, 2021,6:47−50. [77] Cheng Gaopeng, Xu Jialei, Luo Hao, et al. Effect of post-weld stress relief process on bending property of TC4 welded joints[J]. Hot Working Technology, 2021,50(13):155−158. (陈高澎, 徐家磊, 罗皓, 等. 焊后消应力工艺对TC4焊接接头弯曲性能的影响[J]. 热加工工艺, 2021,50(13):155−158. [78] 史超. Ti-6Al-4V合金不同热处理工艺组织和性能的研究[D]. 西安: 西安工业大学, 2016: 48.Shi Chao. Effect of heat treatment process on microstructure and properties of Ti-6Al-4V titanium alloy[D]. Xi, an: Xi, an Technological University, 2016: 48. -

下载:

下载: