Failure mechanism and numerical simulation of High titanium heavy slag concrete

-

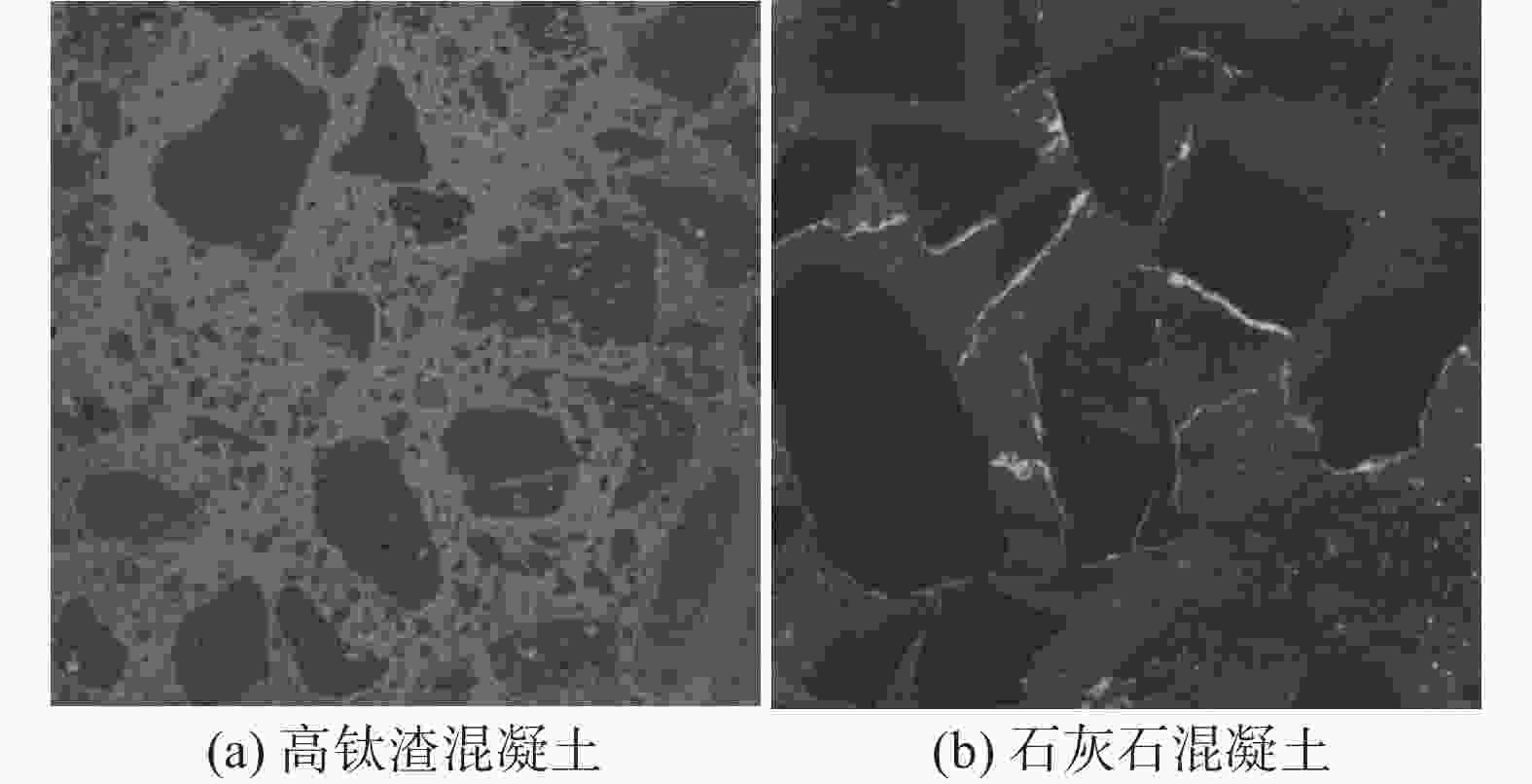

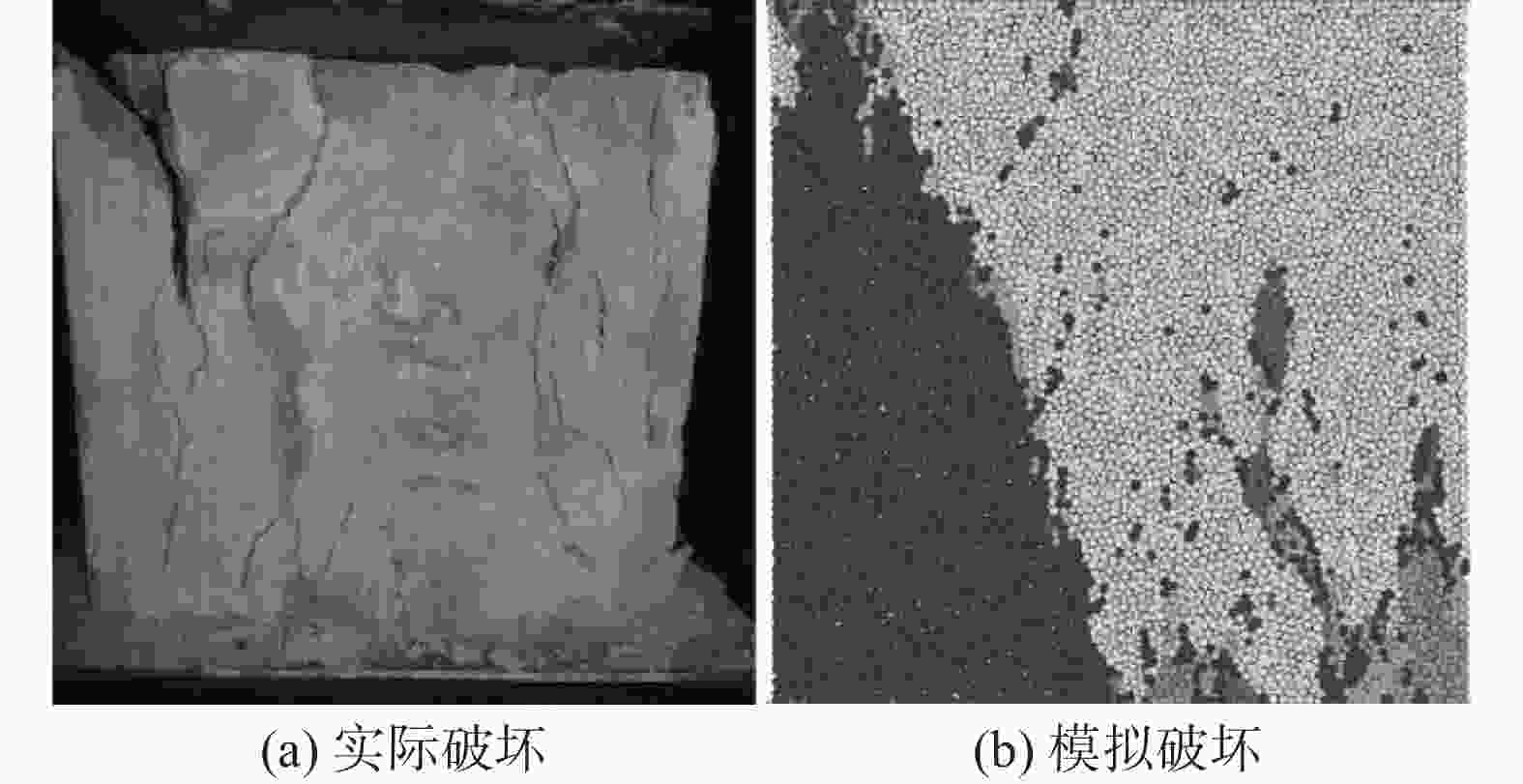

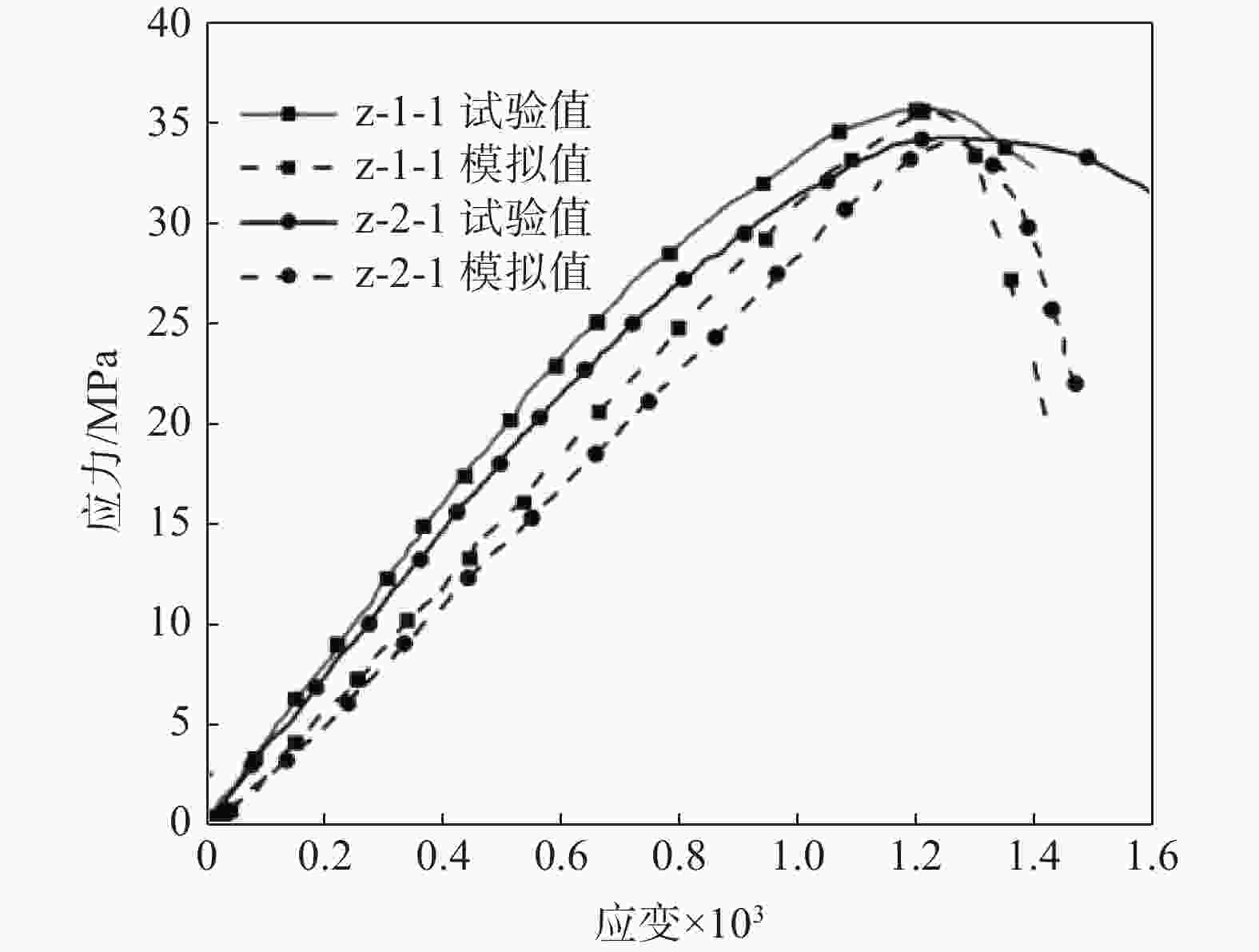

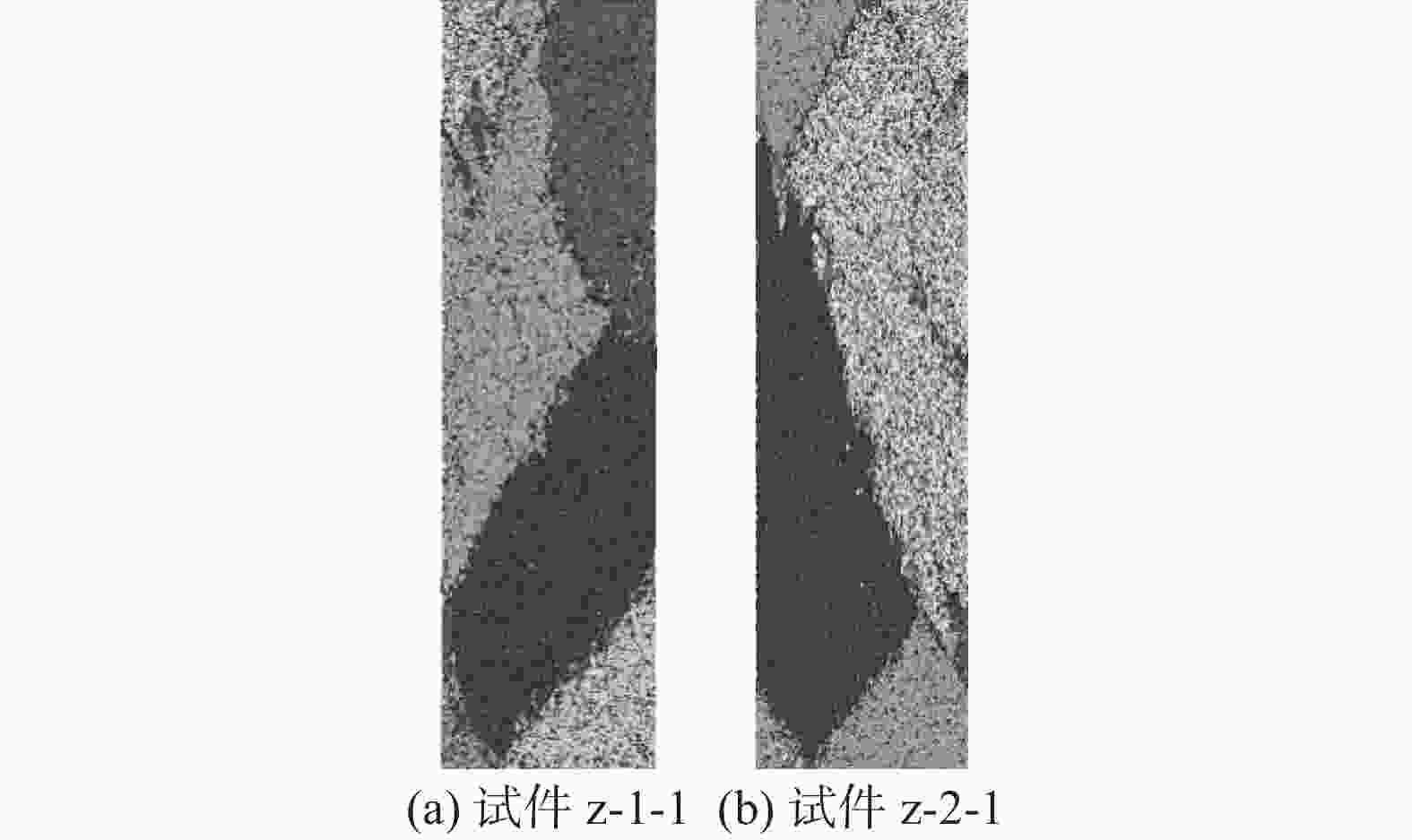

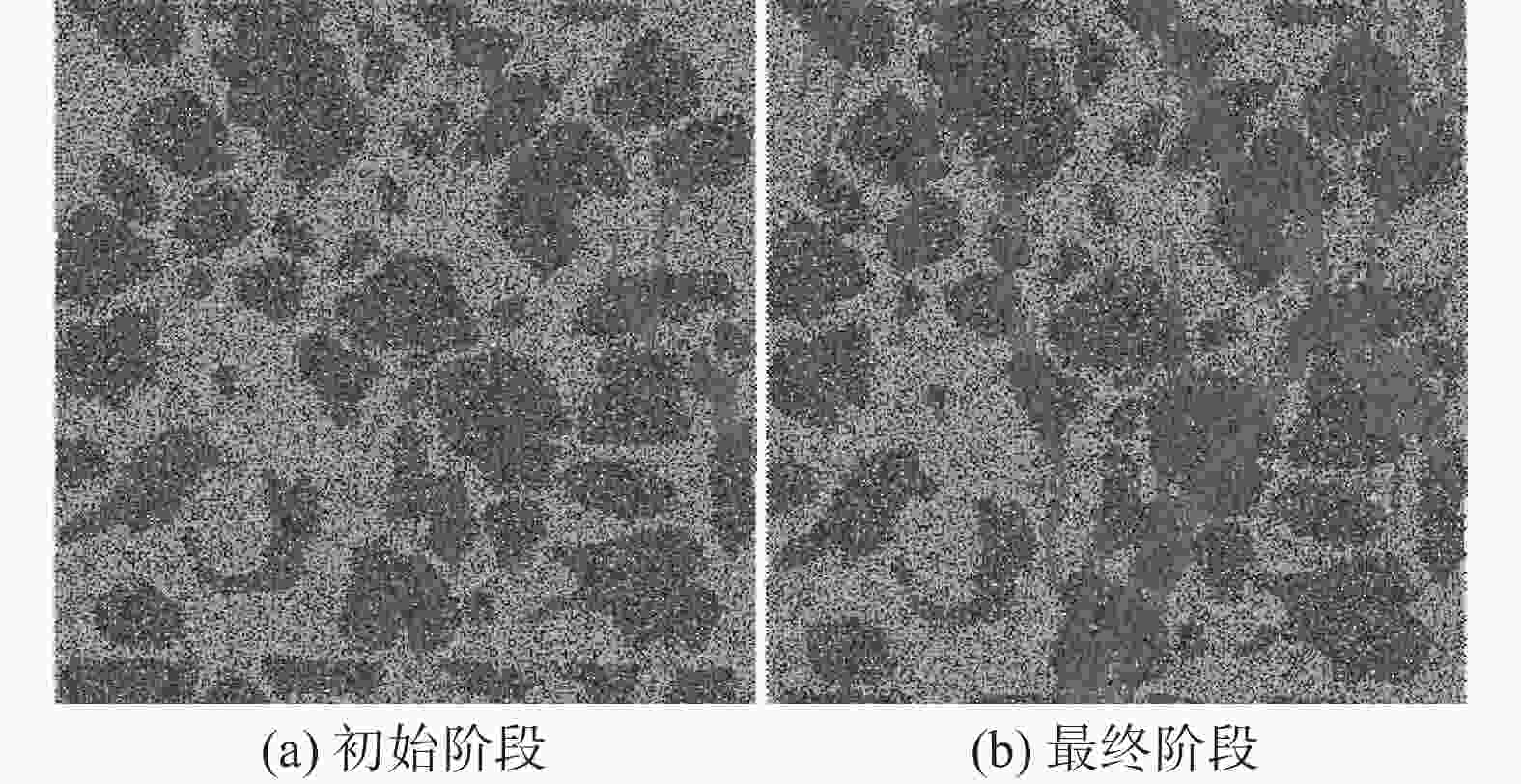

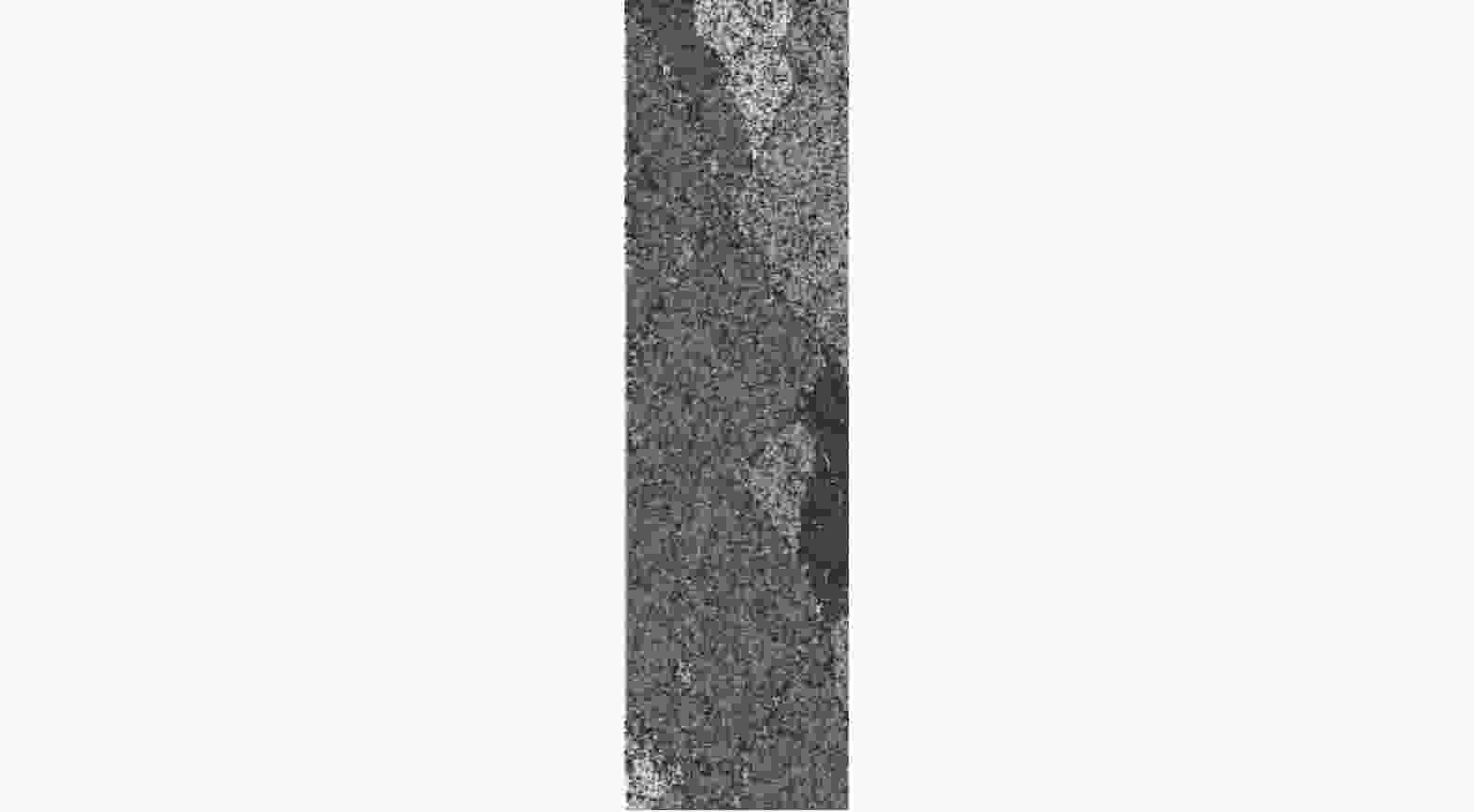

摘要: 进行了高钛重矿渣混凝土和普通混凝土配合比试验设计,分别制作了4组混凝土立方体试块和棱柱体试块并进行强度测试,通过PFC离散元软件标定了高钛重矿渣混凝土与普通混凝土试件的细观力学参数,模拟了高钛重矿渣混凝土和普通混凝土棱柱体试件受压破坏,分析了高钛重矿渣混凝土棱柱体试件破坏现象和破坏机理。研究结果表明,高钛重矿渣骨料内部的孔洞会削弱骨料的强度;高钛重矿渣骨料的粗糙表面会提高界面过渡区的粘结强度;高钛重矿渣混凝土破坏形态与普通混凝土破坏形态不一致,高钛重矿渣混凝土破坏时形成的破坏面会穿越骨料与硬化砂浆,而普通混凝土破坏时形成的破坏面会沿着界面过渡区穿越硬化砂浆。Abstract: The mix proportion of high titanium heavy slag concrete (HTHS) and normal concrete was designed. Four groups of concrete cubic and prism specimens were made and tested. Using the PFC discrete element software, the meso-structure mechanical parameters of HTHS and normal concrete specimen were calibrated. Uniaxial compressive tests of prism-shaped specimens made of HTHS and normal concrete were simulated. Furthermore, the failure phenomena and reasons of HTHS concrete prism specimens were analyzed. It is found that the strength of HTHS aggregate is decreased due to the holes within HTHS aggregate. The bonding strength of the interface transition zone between coarse aggregate and harden mortar is improved. In addition, the failure modes of HTHS and normal concrete are different. The failure surfaces of HTHS concrete pass through the coarse aggregate and hardened mortar, while the failure surfaces of normal concrete can only develop along the interface transition zone and pass through the harden mortar.

-

表 1 试验基准配合比

Table 1. Experimental benchmark of mix proportion

标号 水胶比 水泥/kg 水/kg 渣石/kg 渣砂/kg 碎石/kg C35 z 0.56 480 267.8 955.1 913.7 C35 s 0.52 480 251.3 913.7 947 注:C35 z的粗骨料为高钛重矿渣,C35 s的粗骨料为石灰石。 表 2 强度对比

Table 2. Strength comparison

试件编号 立方体抗压强度/MPa 棱柱体抗压强度/MPa z-1 41.56 35.95 z-2 39.57 34.46 s-1 36.89 29.54 s-2 36.21 29.27 表 3 高钛重矿渣混凝土细观参数

Table 3. Meso-structure parameters of HTHS concrete

颗粒弹性刚度

模量/GPa抗拉强度/

MPa粘聚力/

MPa刚度比 水泥浆 14 9 19 1.0 高钛重矿渣骨料 12 6 15.5 1.0 界面过渡区 10 6 13 1.0 表 4 普通石灰石混凝土细观参数

Table 4. Meso-structure parameters of normal limestone concrete

颗粒弹性刚度

模量/GPa抗拉强度/

MPa粘聚力/

MPa刚度比 水泥浆 14 9 19 1.0 普通石灰石骨料 12 13.5 35 1.0 界面过渡区 10 4 10 1.0 -

[1] Jiang Jiafen. Application overview of granulated blast furnace slag in cement concrete[J]. China Concrete and Cement Products, 2002,(3):3−6. (蒋家奋. 矿渣微粉在水泥混凝土中应用的概述[J]. 混凝土与水泥制品, 2002,(3):3−6. doi: 10.3969/j.issn.1000-4637.2002.03.001 [2] 余颂国. 攀钢西渣场开发利用可行性研究[D]. 昆明: 昆明理工大学, 2002.Yu Songguo. Feasibility study on development and utilization of the west residue field of Panzhihua steel[D]. Kunming: Kunming University of Science and Technology, 2002. [3] 孙金坤. 全高钛重矿渣混凝土应用基础研究[D]. 重庆:重庆大学, 2006.Sun Jinkun. Fundamental research on application of complex high titanium heavy slag concrete[D]. Chongqing:Chongqing University, 2006. [4] 肖斐. 钛渣混凝土性能的研究[D]. 重庆:重庆大学, 2004.Xiao Fei. Performance research of tianium slag concrete[D]. Chongqing :Chongqing University, 2004. [5] Wu Zhongwei. Green high performance concrete—concrete development direction[J]. China Concrete and Cement Products, 1998,(1):3−6. (吴中伟. 绿色高性能混凝土—混凝土的发展方向[J]. 混凝土与水泥制品, 1998,(1):3−6. [6] Andreas Leemann, Roman Loser, Beat Münch. Influence of cement type on ITZ porosity and chloride resistance of self-compacting concrete[J]. Cement and Concrete Composites, 2009, 32(2):6. [7] Mehta P Kumar , Monteiro Paulo J M. Concrete: microstructure, properties and materials[M]. ACI: 2006. [8] Xu Chunsheng, Lou Yuantao, Deng Min, et al. Mechanical properties and autogenous volume deform ation of high titanium heavy slag concretes[J]. Concrete, 2015,(1):111−114. (徐春生, 娄元涛, 邓敏, 等. 高钛重矿渣混凝土的力学性能与自生体积变形[J]. 混凝土, 2015,(1):111−114. doi: 10.3969/j.issn.1002-3550.2015.01.028 [9] Zhou Xu, Li Jianglong, Luo Chongli. A resarch on high-Ti blast furnace slag crushed stone applied for concrete aggregate[J]. Iron Steel Vanadium Titanium, 2001,(4):43−46,68. (周旭, 李江龙, 罗崇理. 高钛高炉渣碎石用做砼骨料的研究[J]. 钢铁钒钛, 2001,(4):43−46,68. doi: 10.3969/j.issn.1004-7638.2001.04.008 [10] 王军, 王浩, 蒋中友, 等. 高钛高炉渣透水混凝土单轴压缩破坏试验及数值模拟[J]. 钢铁钒钛, 2020, 41(1): 82-87.Wang Jun, Wang Hao, Jiang Zhongyou, et al. Uniaxial compression failure test and numerical simulation of high titanium blast furnace slag pervious concrete[J]. Iron Steel Vanadium Titanium, 2020, 41(1): 82-87. [11] Li Haoyang, Yao Qiang, Hua Tianbo, et al. PFC3D-based study on strength and damage model of no-fines concerte[J]. Journal of Yangtze River Scientific Research Institute, 2019,36(6):127−132,138. (栗浩洋, 姚强, 华天波, 等. 基于PFC3D的无砂混凝土强度及损伤模式[J]. 长江科学院院报, 2019,36(6):127−132,138. [12] Su Hui, Tang Yang, Nie Hanjiang. The analysic of the macro failure for ecological concrete based on PFC2D different mesoscopic parameters[J]. Science Technology and Engineering, 2014,14(28):118−124. (宿辉, 唐阳, 聂汉江. 基于PFC2D不同细观参数对生态混凝土宏观破坏分析[J]. 科学技术与工程, 2014,14(28):118−124. doi: 10.3969/j.issn.1671-1815.2014.28.023 -

下载:

下载: