Study on the effect of electromagnetic stirring of mold on the removal of non-metallic inclusions in billet

-

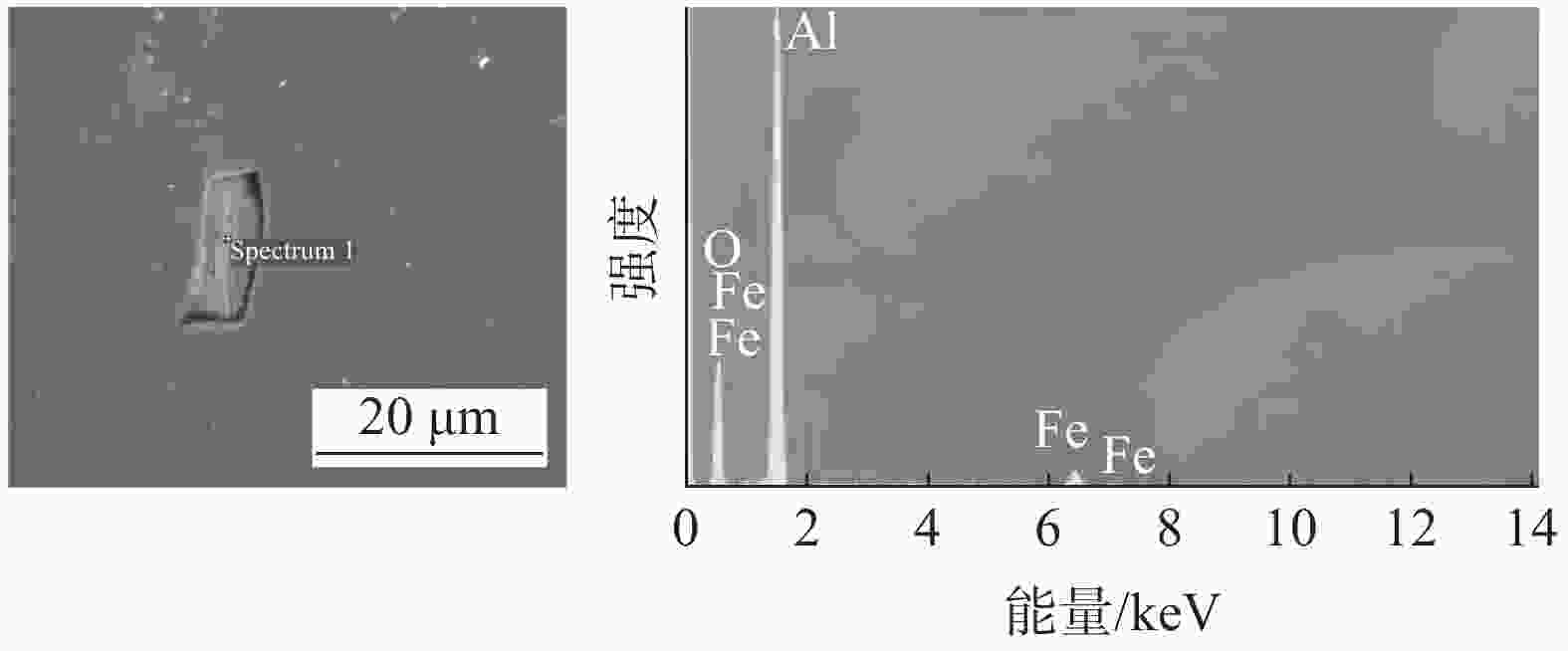

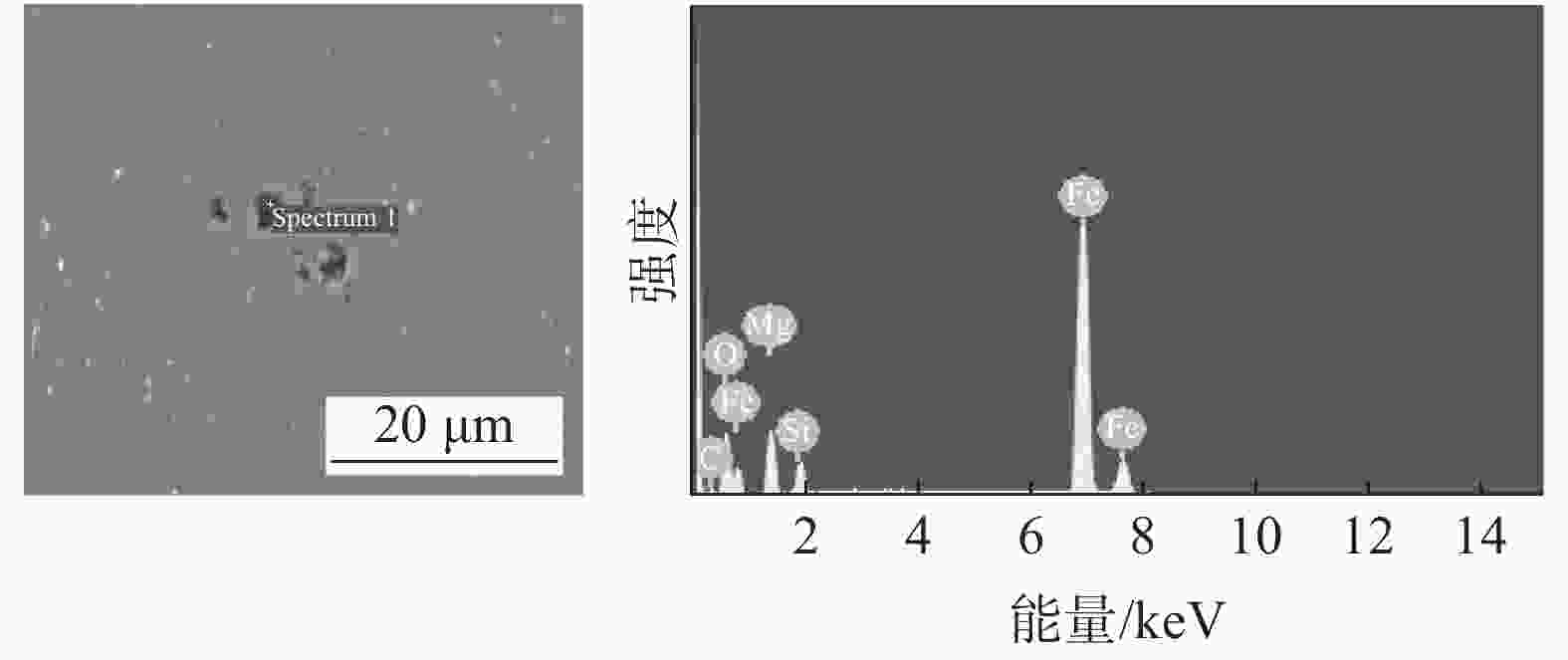

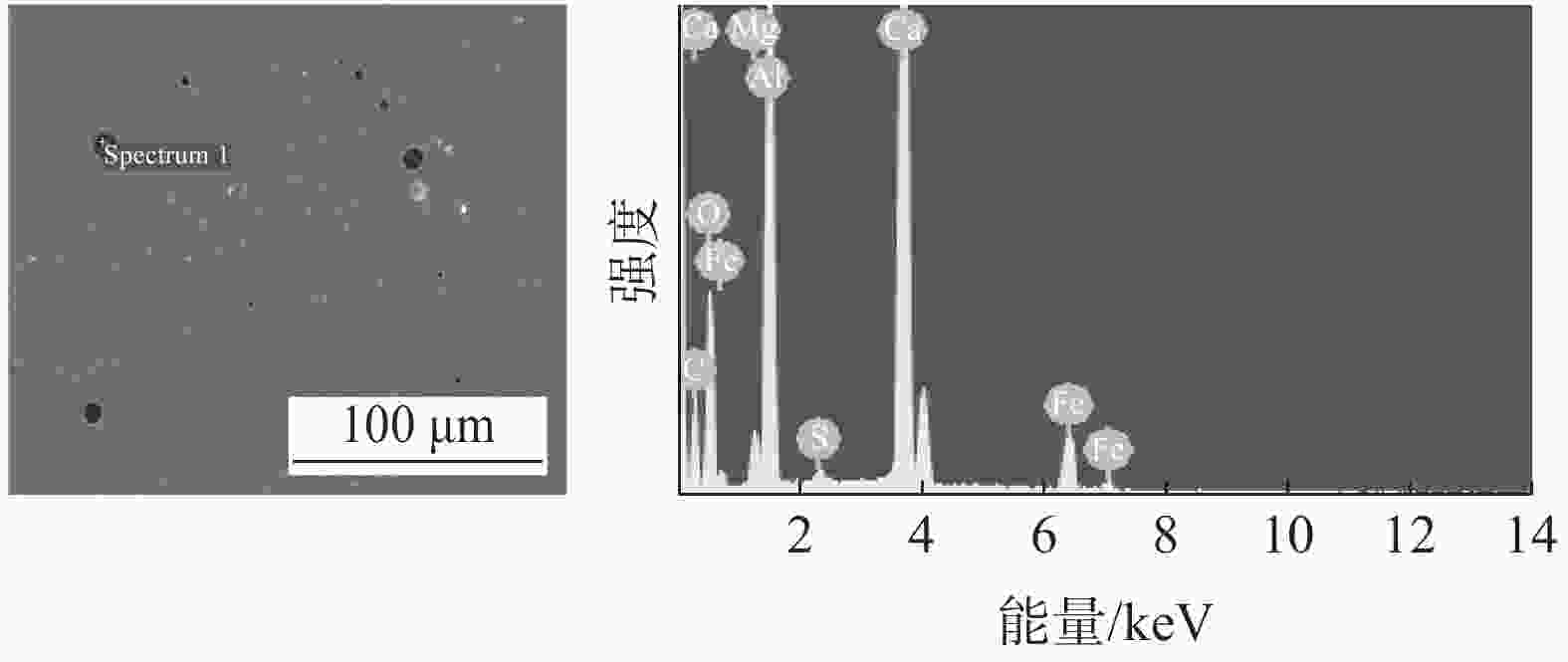

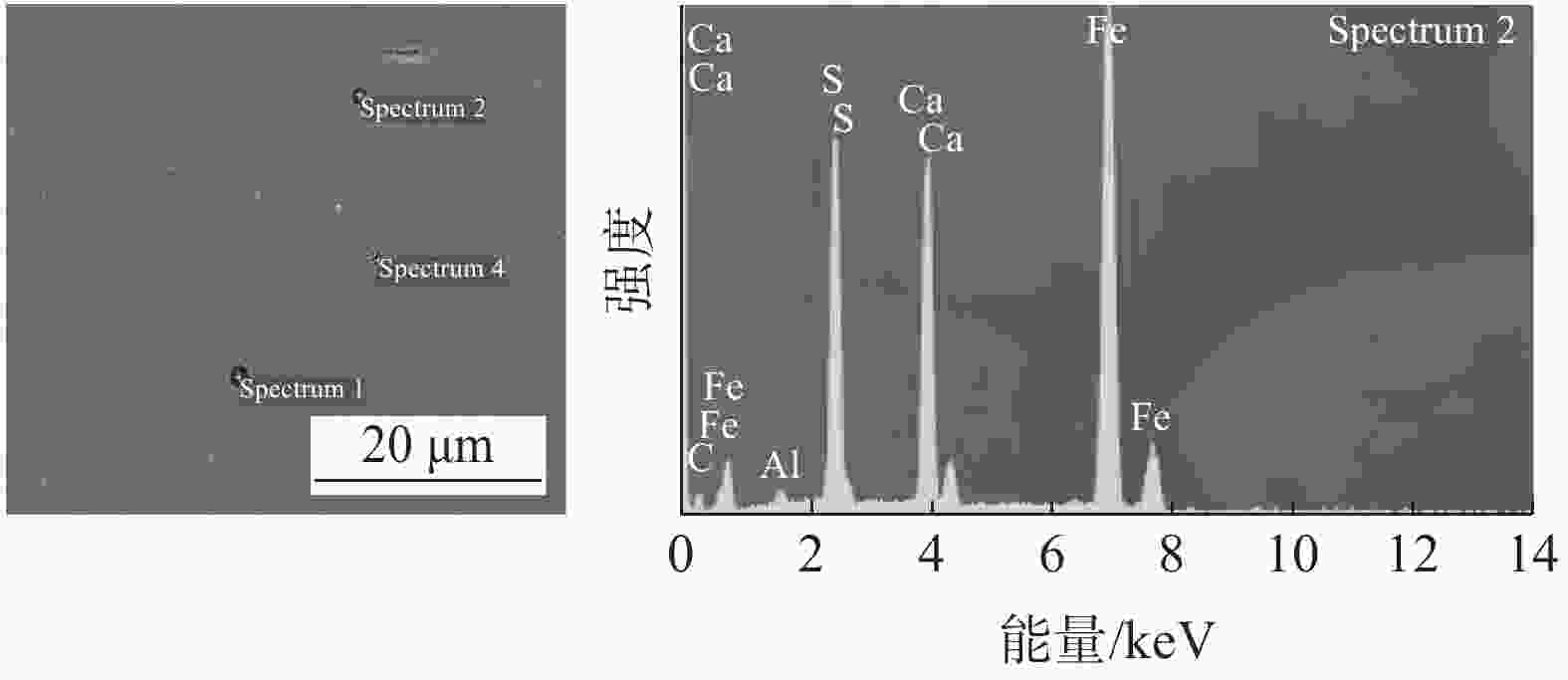

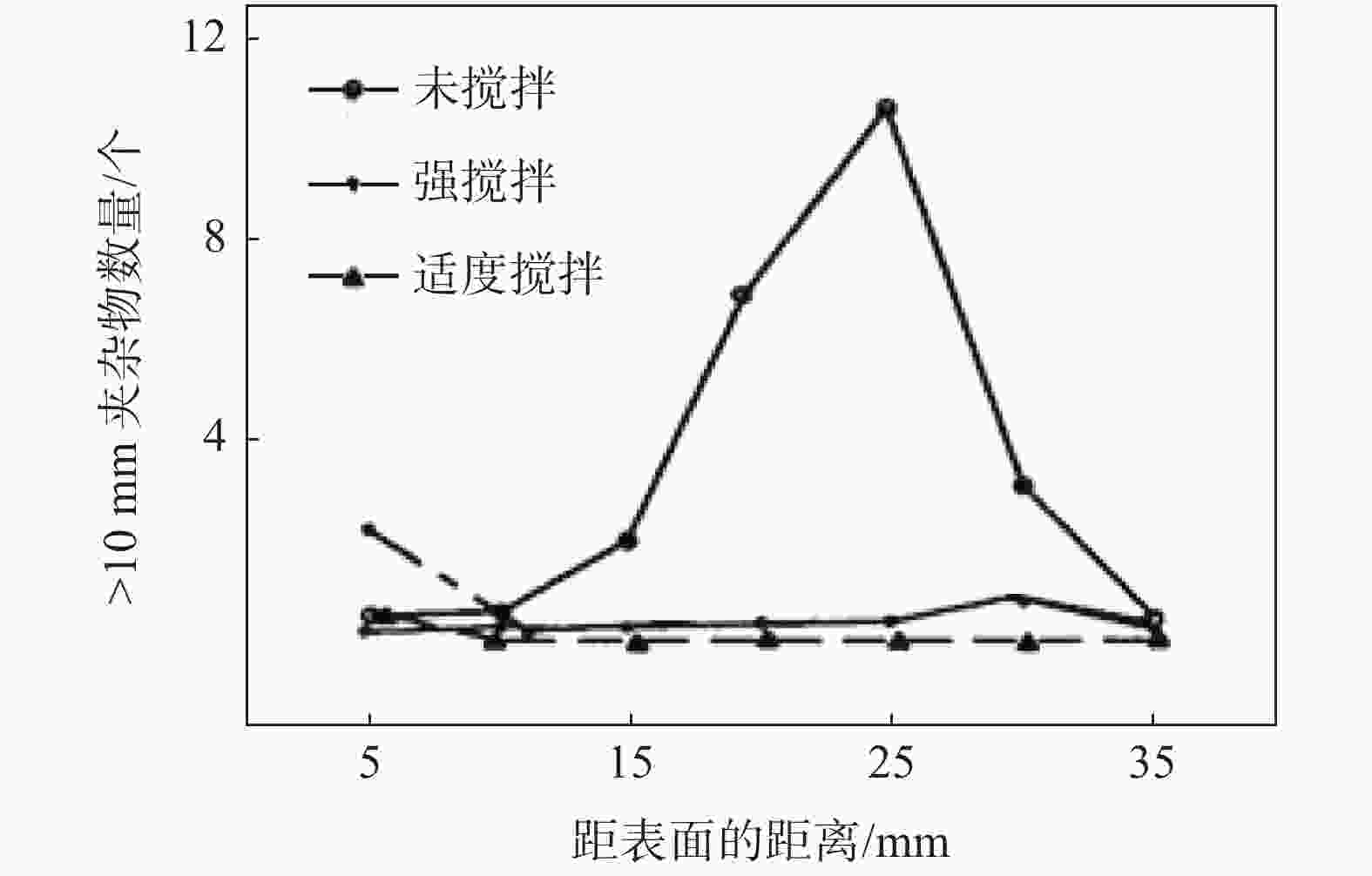

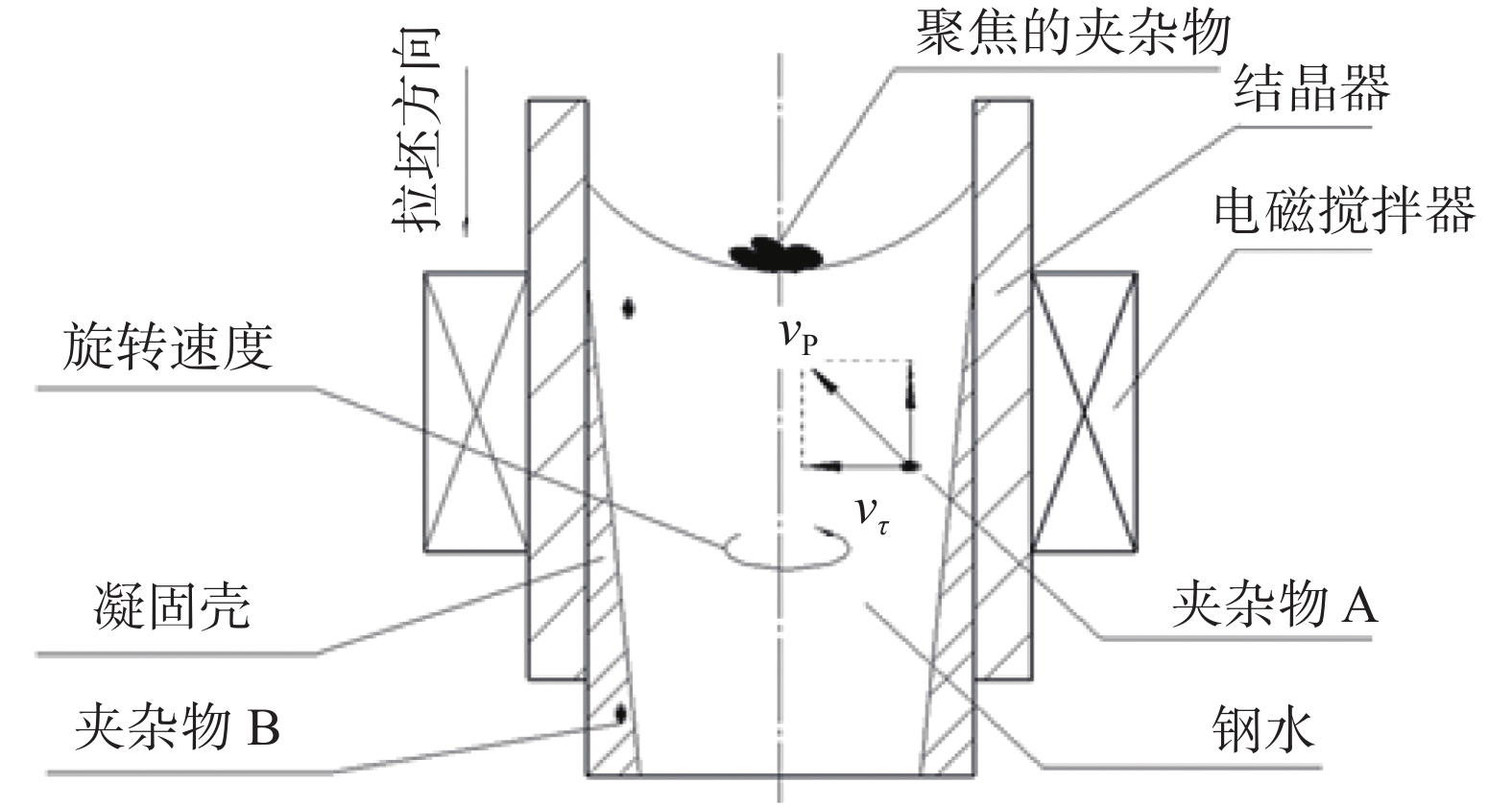

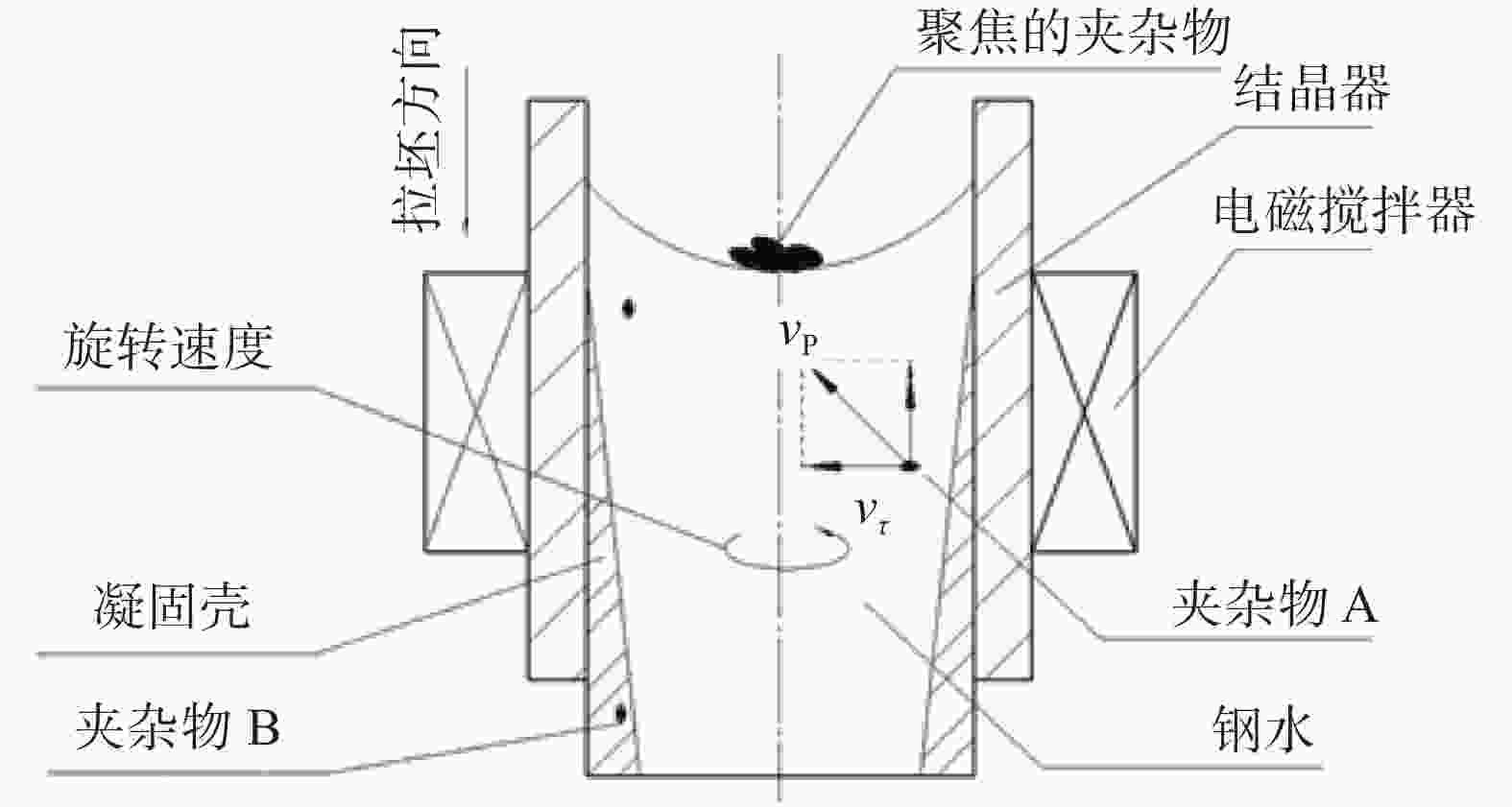

摘要: 电磁力影响金属熔体中非金属夹杂物的分布及颗粒的传输速度,根据这一原理,进行了结晶器电磁搅拌对方坯中非金属夹杂物去除影响的试验研究。采用200、250 A和300 A这3种不同的EMS电流对方坯坯料进行了夹杂物分离和去除的试验,并采集样品进行能谱分析。结果表明,当结晶器的电磁搅拌参数为300 A电流和3 Hz频率时,铸坯中的非金属夹杂物控制效果最佳,比不采用电磁搅拌减少了35%。Abstract: Based on the principle that electromagnetic force affects the distribution of non-metallic inclusions and the velocity of particles in molten metal, the effect of electromagnetic stirring in mold on the removal of non-metallic inclusions in billet was studied. The inclusion separation and removal experiments were carried out by using EMS current of 200, 250 and 300 A, and the samples were collected for energy spectrum analysis. The results show that the best control effect of non-metallic inclusion in the billet is obtained when the electromagnetic stirring parameters of the mold are 300 A current and 3 Hz frequency, which is 35% less than that without electromagnetic stirring.

-

Key words:

- continuous casting /

- crystallizer /

- electromagnetic stirring /

- non-metallic inclusion

-

表 1 连铸浇注工艺参数

Table 1. Process parameters for the continuous casting

炉批号 平台温度/℃ 中包温度1/℃ 中包温度2/℃ 中包温度3/℃ 中包平均温度/℃ 过热度/℃ 拉速/(m·min−1) 1 1569 1545 1540 1535 1540 29 1.95 2 1565 1540 1535 1531 1535 24 1.95 3 1570 1545 1540 1536 1540 29 1.95 4 1567 1541 1535 1529 1535 24 1.95 5 1566 1540 1535 1530 1535 24 1.95 6 1569 1545 1540 1534 1539.7 28.7 1.95 7 1567 1542 1536 1529 1535.7 24.7 1.95 8 1560 1538 1530 1525 1531 20 1.95 9 1562 1539 1533 1528 1533.3 22.3 1.95 -

[1] 韩志成. 电磁冶金技术及装备[M]. 北京: 冶金工业出版社, 2012.Han Zhicheng. Em metallurgy technology and equipment [M] . Beijing: Metallurgical Industry Press, 2012. [2] 毛斌, 张桂芳, 李爱武. 连铸铸钢用电磁搅拌的理论与技术[M]. 北京: 冶金工业出版社, 2012.Mao Bin, Zhang Guifang, Li Aiwu. Theory and technology of electromagnetic stirring for continuous casting steel[M]. Beijing: Metallurgical Industry Press, 2012. [3] Chung S, Yoon J. Numerical analysis of effects of electromagnetic stirring on solidification phenomena in continuous casting[J]. Ironmaking and Steelmaking, 1996,23(5):425-432. [4] Luo Bogang, Wang Guorui, Zhou Deguang, et al. EMS parameter optimization of continuous caster[J]. Iron and Steel, 2005,40(10):32−34,79. (罗伯钢 , 王国瑞 , 周德光 , 等. 连铸机电磁搅拌参数的优化[J]. 钢铁, 2005,40(10):32−34,79. [5] Gong Zhixiang, Chen Gang, Jiao Xingli, et al. Effect of mould-electromagnetic stirring on structure and inclusion in 450 mm concasting round billet[J]. Special Steel, 2004,25(4):35−37. (龚志翔, 陈刚, 焦兴利, 等. 结晶器电磁搅拌对Φ450 mm连铸圆坯组织和夹杂物的影响[J]. 特殊钢, 2004,25(4):35−37. [6] 纪振双, 沈雁臣. 利用电磁搅拌改善铸坯的中心偏析[J]. 钢铁研究学报, 1992, 4(3): 17-21.Ji Zhenshuang,Shen Yanchen. Improvement of central segregation of billet by electromagnetic stirring[J]. Journal of Iron and Steel Studies, 1992, 4(3) : 17-21. [7] Li Guozhong, Chen Feng, Chen Weiqing, et al. Effect of mould electromagnetic stirring on carbon segregation of medium carbon continuous casting bloom[J]. Steelmaking, 2008,24(1):43−46. (李国忠, 陈峰, 陈伟庆, 等. M-EMS对中碳钢连铸方坯碳偏析的影响[J]. 炼钢, 2008,24(1):43−46. [8] 薄开涛, 成国光, 吴洁, 等. 双条型磁极作用下结晶器内液态金属流动的数学模型[J].北京科技大学学报, 1999, 21(4) : 334-337.Bo Kaitao, Cheng Guoguang, Wu Jie, et al. Mathematical model of molten alloy flow in mold with two pairs of magnetic poles[J] .Journal of University of Science and Technology Beijing, 1997, 21(4) : 334-337. [9] 杨晓枝. 电磁搅拌对连铸小方坯质量的影响[J]. 连铸, 2000(4): 41-42.Yang Xiaozhi. Effect of electromagnetic stirring on continuous casting billet quality[J]. Continuous Casting, 2000(4) : 41-42. [10] He Jicheng. Improving steel quality by electromagnetic field[J]. Iron and Steel, 2005,1(40):24−30. (赫冀成. 电磁场对改善钢材质量的作用[J]. 钢铁, 2005,1(40):24−30. [11] Thomas B G, Quan Y, Sivaramakrishnan S, et al. Comparison of four methods to evaluate fluid velocities in a continuous slab casting mold[J]. ISIJ International, 2007,41(10):1262−1271. -

下载:

下载: