Analysis and control strategy of bending force saturation for HC tandem cold mill

-

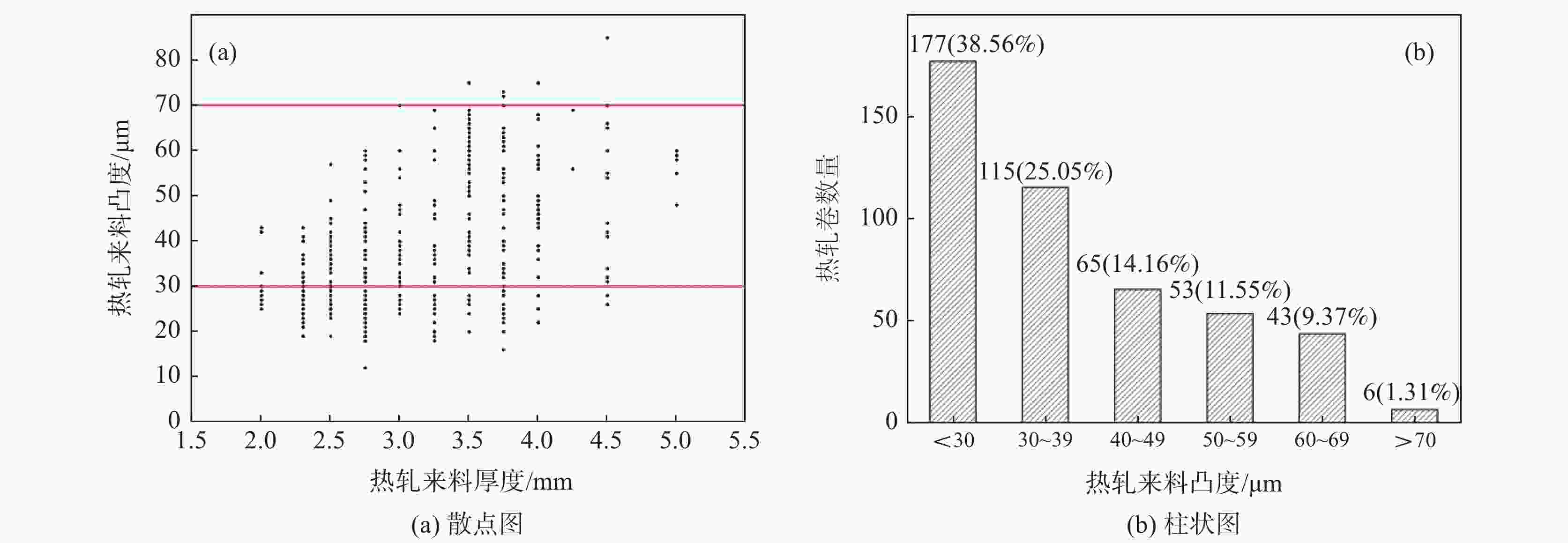

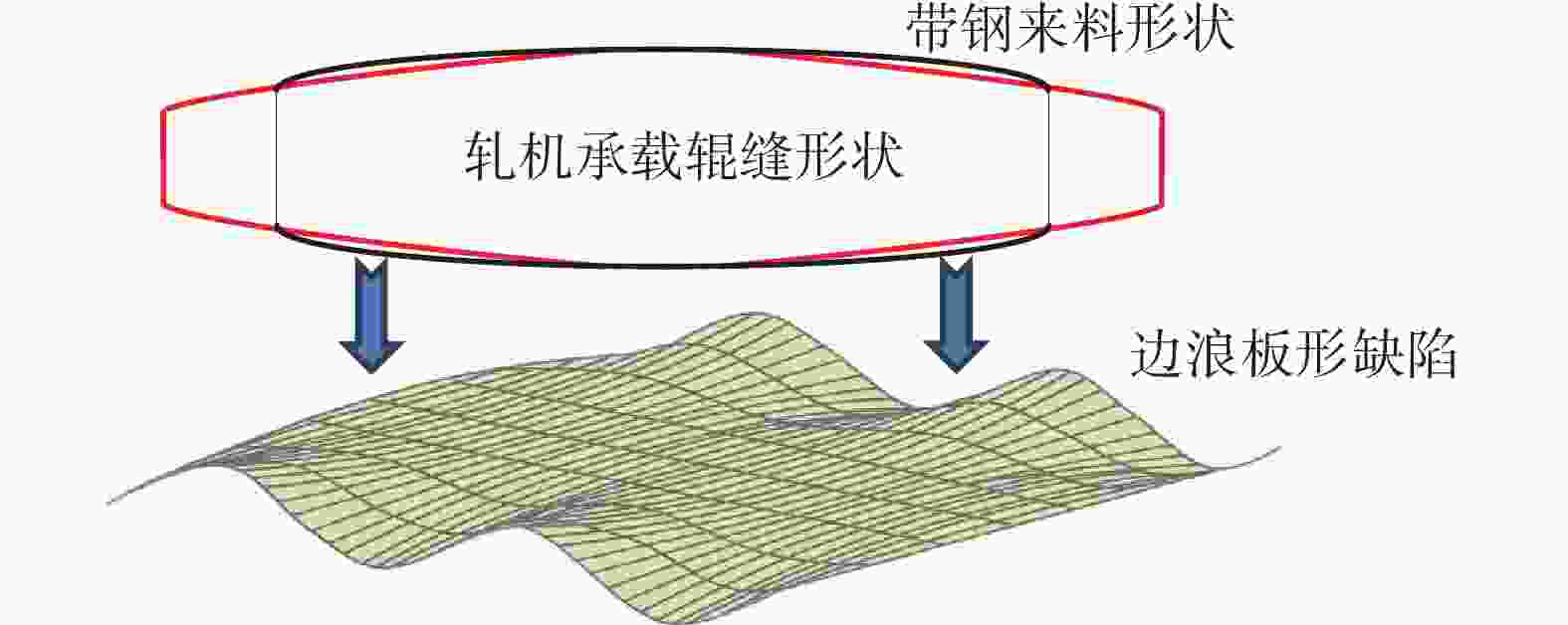

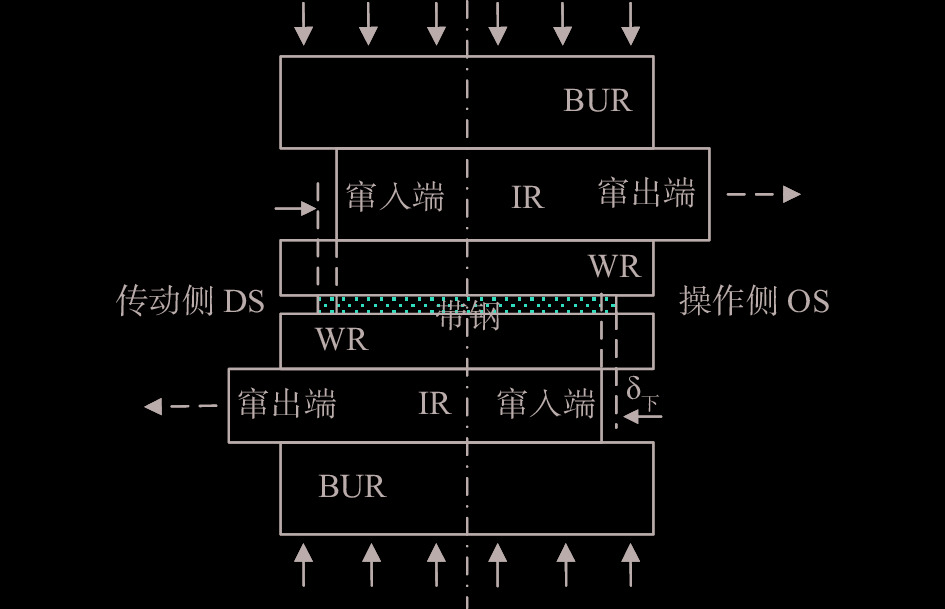

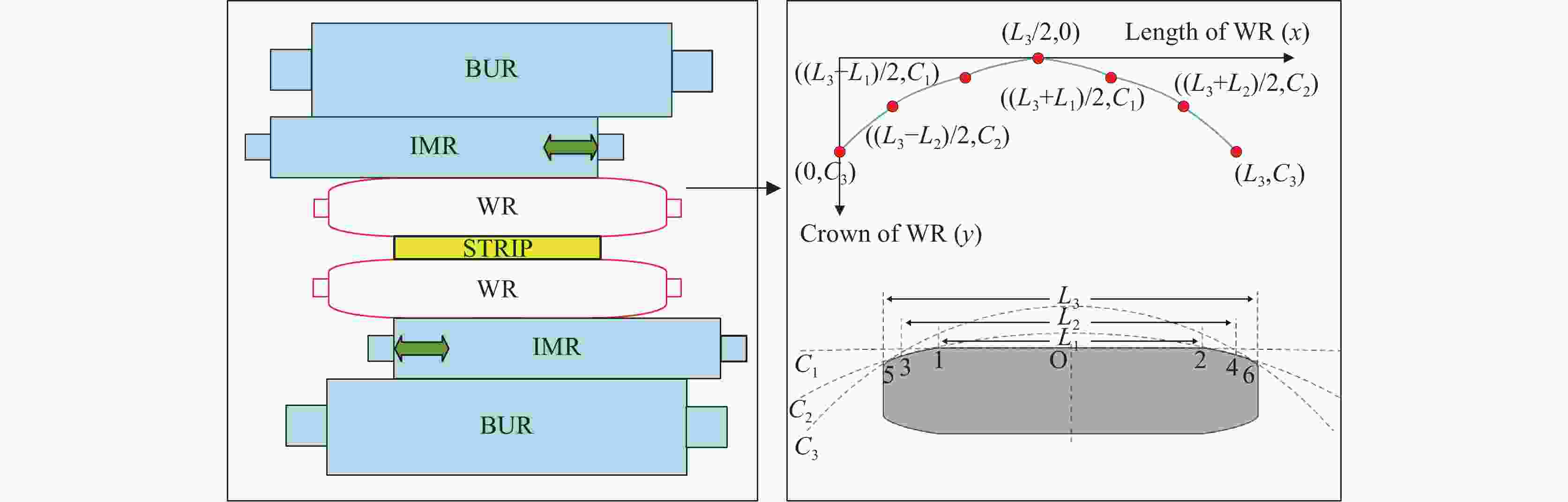

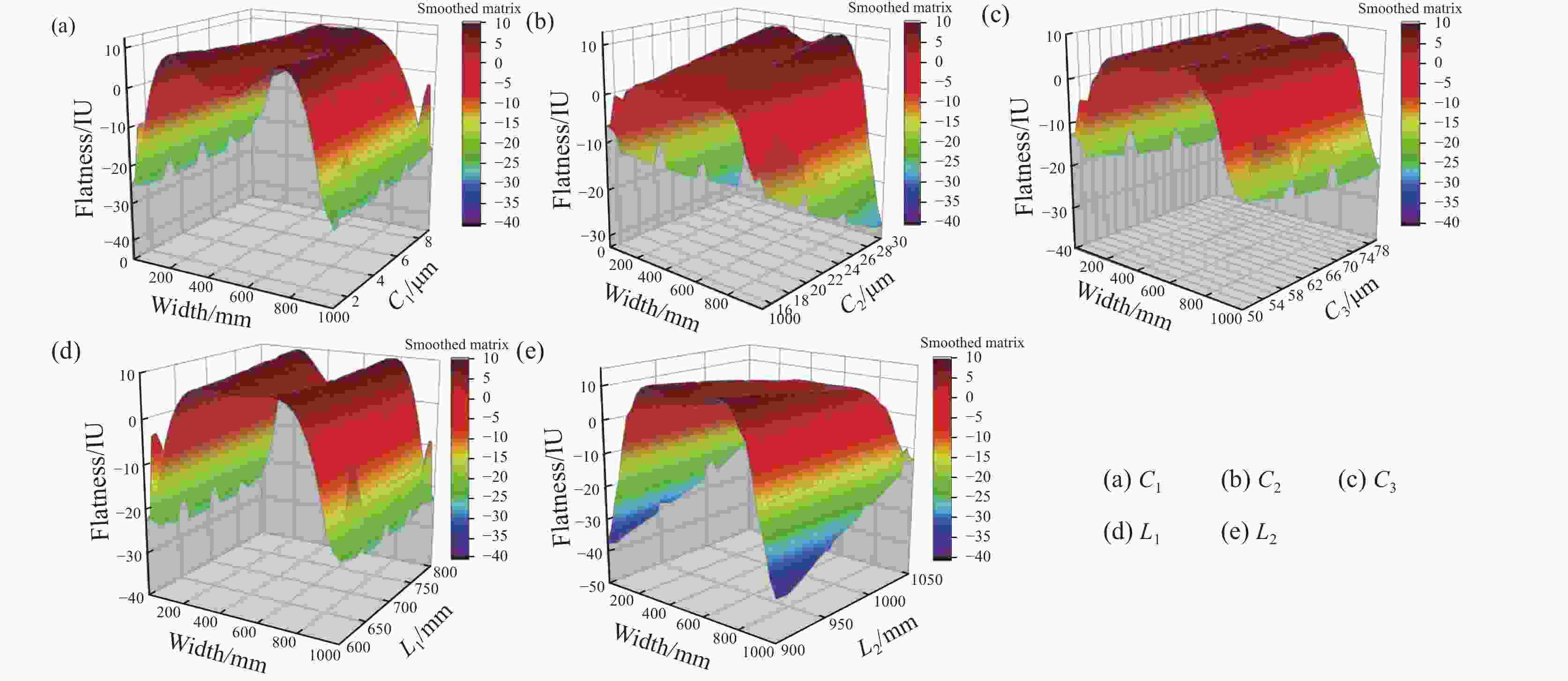

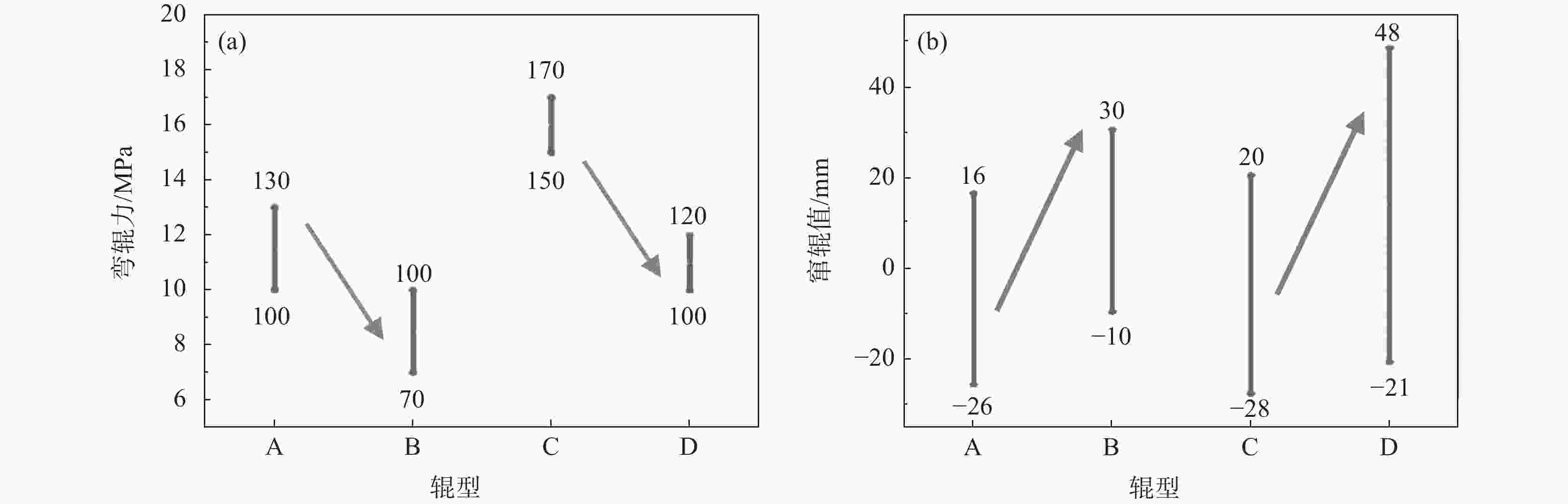

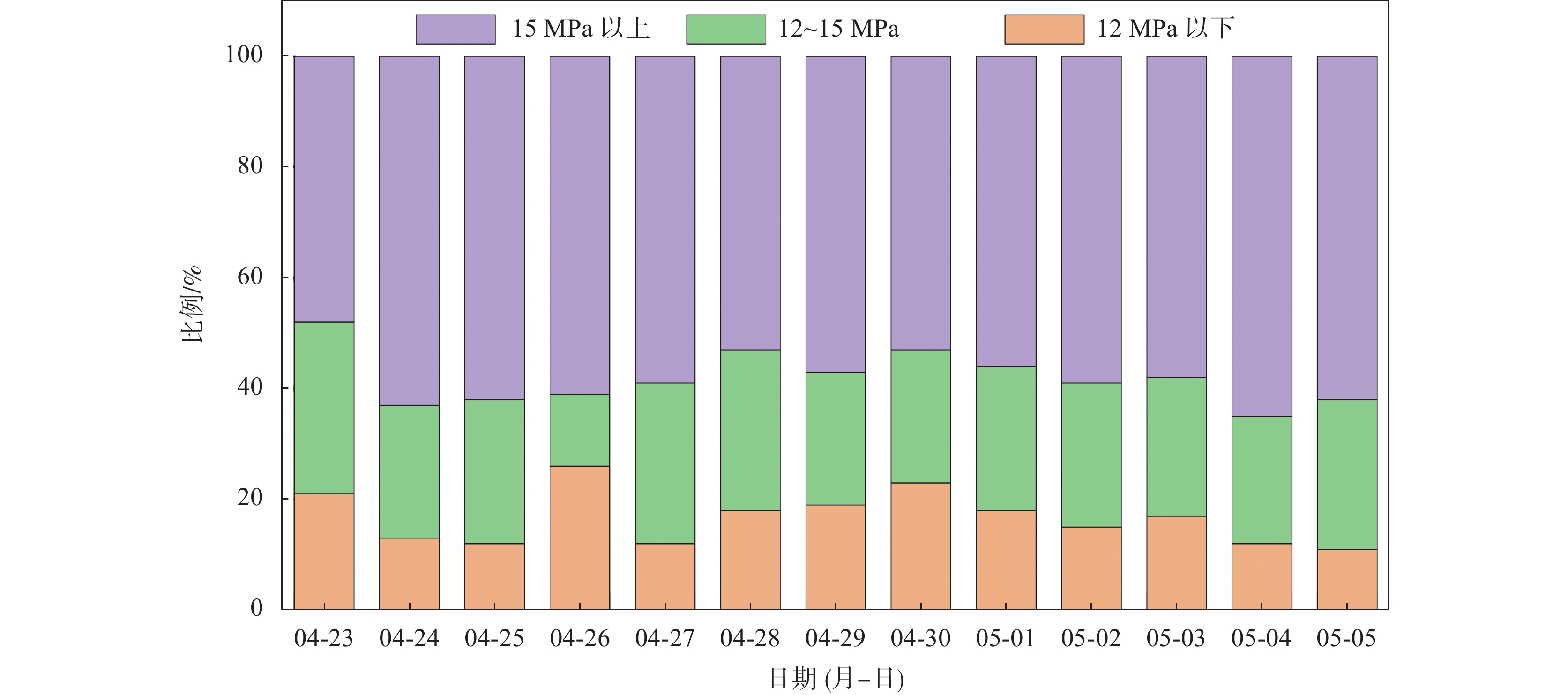

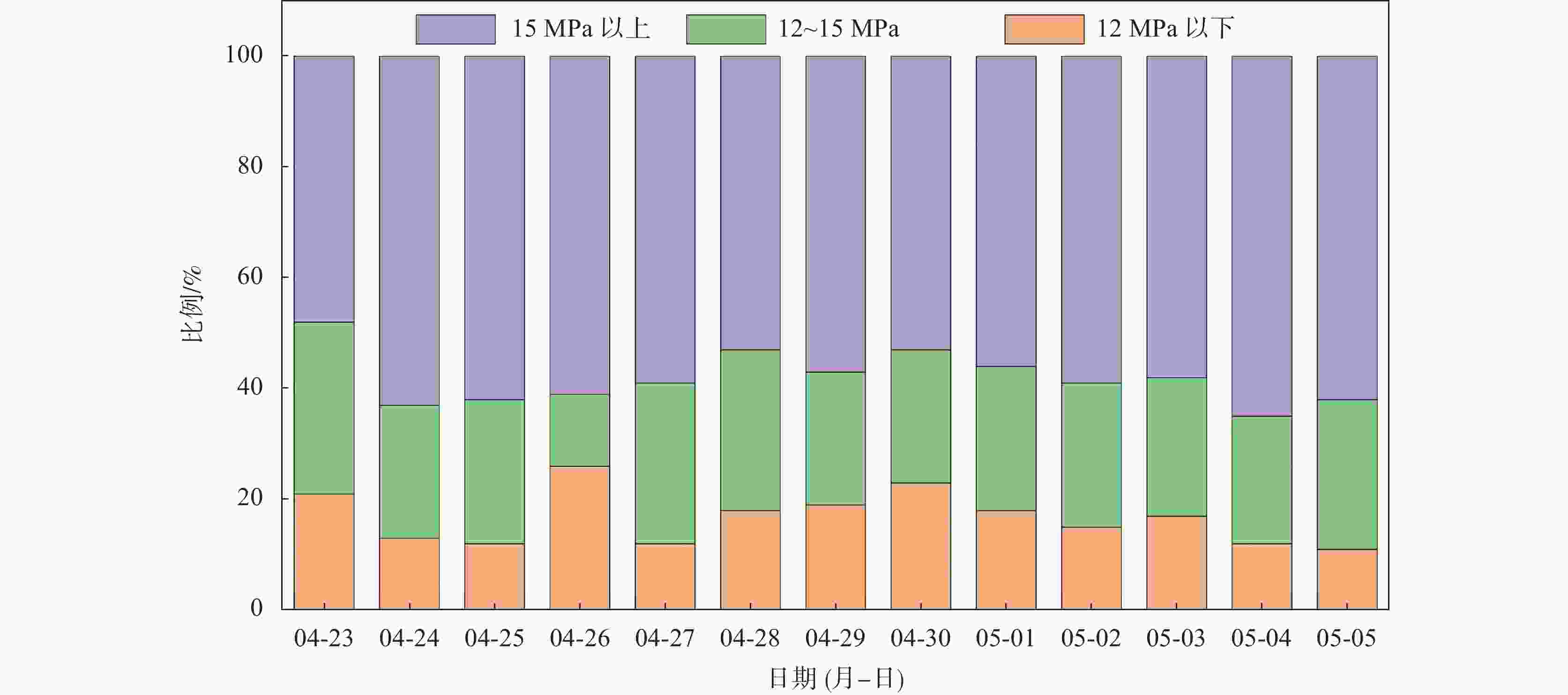

摘要: 四机架六辊HC冷连轧机组末机架在采用光辊轧制时,工作辊弯辊力常处于饱和状态,致使板形调控能力不足,板形缺陷很难消除或进一步降低,影响了板形质量的持续提升。为此,收集并统计了部分热轧卷的板凸度及其分布,结合前三机架弯辊力的分布特点,分析了热轧来料凸度与冷轧末机架承载辊缝形状的匹配关系及对弯辊力的影响。同时分析了利用中间辊负窜来降低弯辊力的在线调整方法对带钢表面质量的影响。在此基础上,提出了采用多段式凸度辊辊型来解决末机架弯辊力饱和的调控策略。在分析辊型参数对板形影响的基础上,通过多次凸度工作辊轧制试验,获得了较优的六次多项式辊型参数。辊型试验结果也表明,在末机架采用五段式正凸度工作辊可增大弯辊的调节能力,减小中间辊负窜量,能有效地解决末机架弯辊力饱和的问题,可进一步提升带钢板形质量。Abstract: The work roll bending force of the last stand of the four stands 6-Hi HC tandem cold rolling mill is usually in saturation state when the brightwork roll is used in the last stand. This production phenomenon leads to the lack of the ability to control the strip shape, and then the shape defects are difficult to eliminate or further reduce. In the meantime, these restrict the continuous improvement of the shape quality of the cold-rolled strip. Therefore, the crown data of some hot-rolled coils were collected, and then its distribution was computed. Combined with the distribution characteristics of the work roll bending force of the first three stands, the relationship between the hot-rolled strip crown and the shape of the loaded roll gap and its impact on the work roll bending force was analyzed. Meanwhile, the influence of the online adjustment method to reduce the work roll bending force by using the negative displacement of intermediate roll on the surface quality of strip was also analyzed. On these bases, a control strategy of using a multi-section positive crown work roll was proposed to solve the saturation of the work roll bending force of the last stand. With the help of analyzing the influence of work roll profile parameters on the strip shape, the optimized parameters of sixth-order polynomial work roll were finally obtained through several online crown work roll rolling tests. In addition, the test results also showed that using five sections of positive crown work roll in the last stand can increase the adjustment ability of the work roll bending and reduce the negative displacement of the intermediate roll. This phenomenon can effectively solve the problem of the saturation of the work roll bending force of the last stand and improve the quality of the strip shape’s quality.

-

Key words:

- HC mill /

- roll bending /

- roll shifting /

- hot-rolled strip crown /

- work roll contour

-

表 1 辊型参数变化范围

Table 1. Variation range of roll contour parameters

中部凸度

$ {C_1} $/μm边部凸度

$ {C_2} $/μm端部凸度

$ {C_3} $/μm长度

$ {L_1} $/mm长度

$ {L_2} $/mm1~9 10~30 40~80 600~850 900~1100 表 2 板形计算用轧制参数示例

Table 2. Rolling parameters for flatness calculation

轧制速度/(m·min−1) 摩擦

系数前张力/kN 后张力/kN 入口厚度/mm 出口厚度/mm 宽度/mm 工作辊

弯辊力/MPa中间辊

窜辊/mm850 0.05 21 120 0.65 0.52 1010 5 20 -

[1] Zhou Jun, Dai Jianhua. The cold rolling mill of Pan steel and vanadium increases new product development[J]. Sichuan Metallurgy, 2011,33(2):38. (周军, 代建华. 攀钢钒冷轧厂加大新产品开发力度[J]. 四川冶金, 2011,33(2):38. [2] Yin Hongguo. The analysis and cptimization of the flatness control system of HC cold tandem mill in pan steel[J]. Sichuan Metallurgy, 2011,33(6):32−36. (尹红国. 攀钢HC冷连轧机板形控制现状分析及优化[J]. 四川冶金, 2011,33(6):32−36. doi: 10.3969/j.issn.1001-5108.2011.06.008 [3] 王国栋. 板形与板凸度控制[M]. 北京: 化学工业出版社, 2016: 12−17Wang Guodong. Flatness and strip crown control [M]. Beijing: Chemical Industry Press, 2016: 12−17. [4] Li Junhong, Deng Han, Zhou Sanbao, et al. Optimization for roll profiles of HC-Mill[J]. Iron and Steel, 2009,44(11):64−66. (李俊洪, 邓菡, 周三保, 等. HC轧机辊型曲线优化[J]. 钢铁, 2009,44(11):64−66. [5] Sun Lifeng. Design optimization on roll shape for 1250 mm cold strip mills[J]. Cfhi Technology, 2013,1(1):1−3. (孙立峰. 1250 mm冷连轧机辊型优化设计[J]. 一重技术, 2013,1(1):1−3. [6] Li Hongbo, Bao Renren, Zhang Jie, et al. Cluster analysis of strip flatness characteristics for ultra-wide cold rolling mills[J]. Chinese Journal of Engineering, 2016,38(11):1569−1575. (李洪波, 包仁人, 张杰, 等. 超宽冷轧机带钢板形特征聚类分析[J]. 工程科学学报, 2016,38(11):1569−1575. [7] Li Junchen, Huang Xutao, Ma Guocai, et al. Optimization and research of loaded roll gap model of complex rollsystem based on influence function method[J]. Journal of Lanzhou University of Technology, 2020,46(6):22−27. (李俊琛, 黄旭涛, 马国才, 等. 基于影响函数法的复杂辊系有载辊缝模型优化[J]. 兰州理工大学学报, 2020,46(6):22−27. doi: 10.3969/j.issn.1673-5196.2020.06.004 [8] Jin Xin, Li Changsheng, Wang Yu. Multi-objective optimization of intermediate roll profile for a 6-high cold rolling mill[J]. Metals-Open Access Metallurgy Journal, 2020,10(2):287. -

下载:

下载: