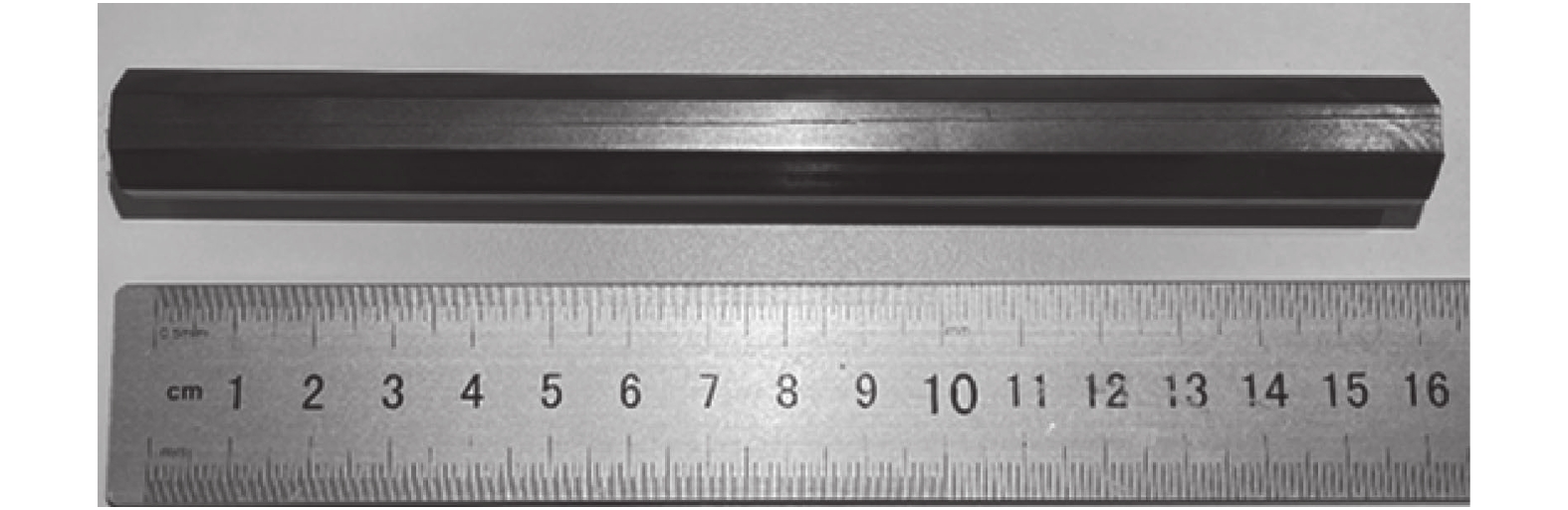

Analysis on surface crack defects of SAE1144 free-cutting octagonal steel bar

-

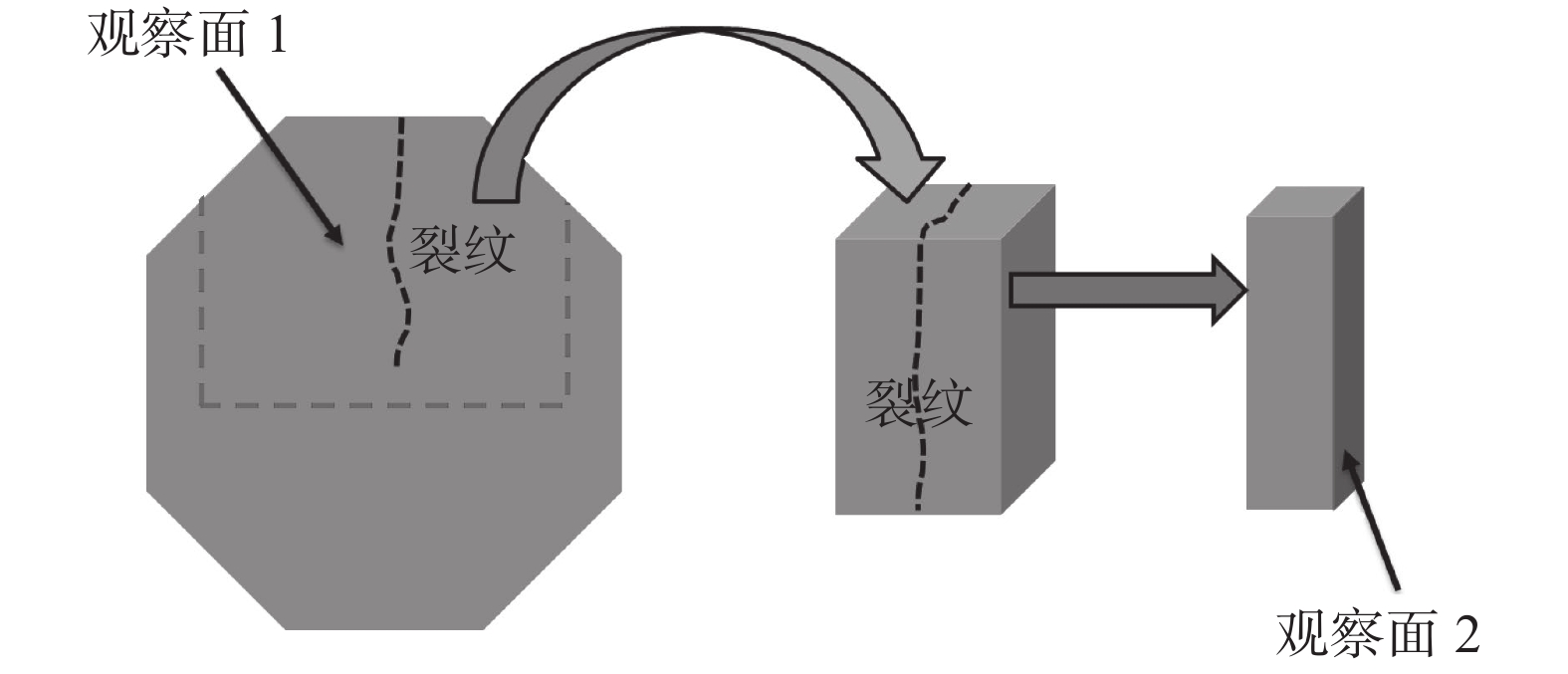

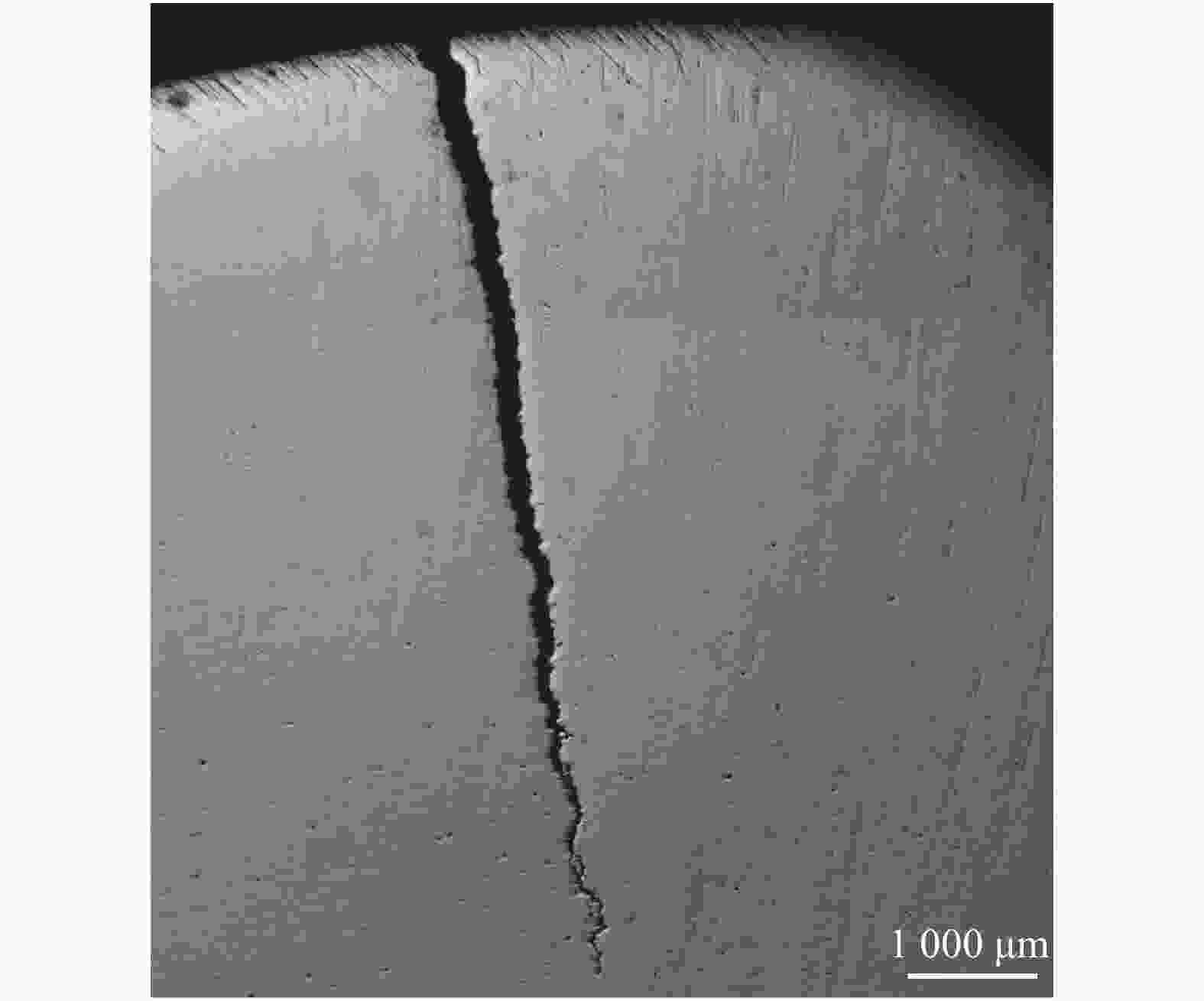

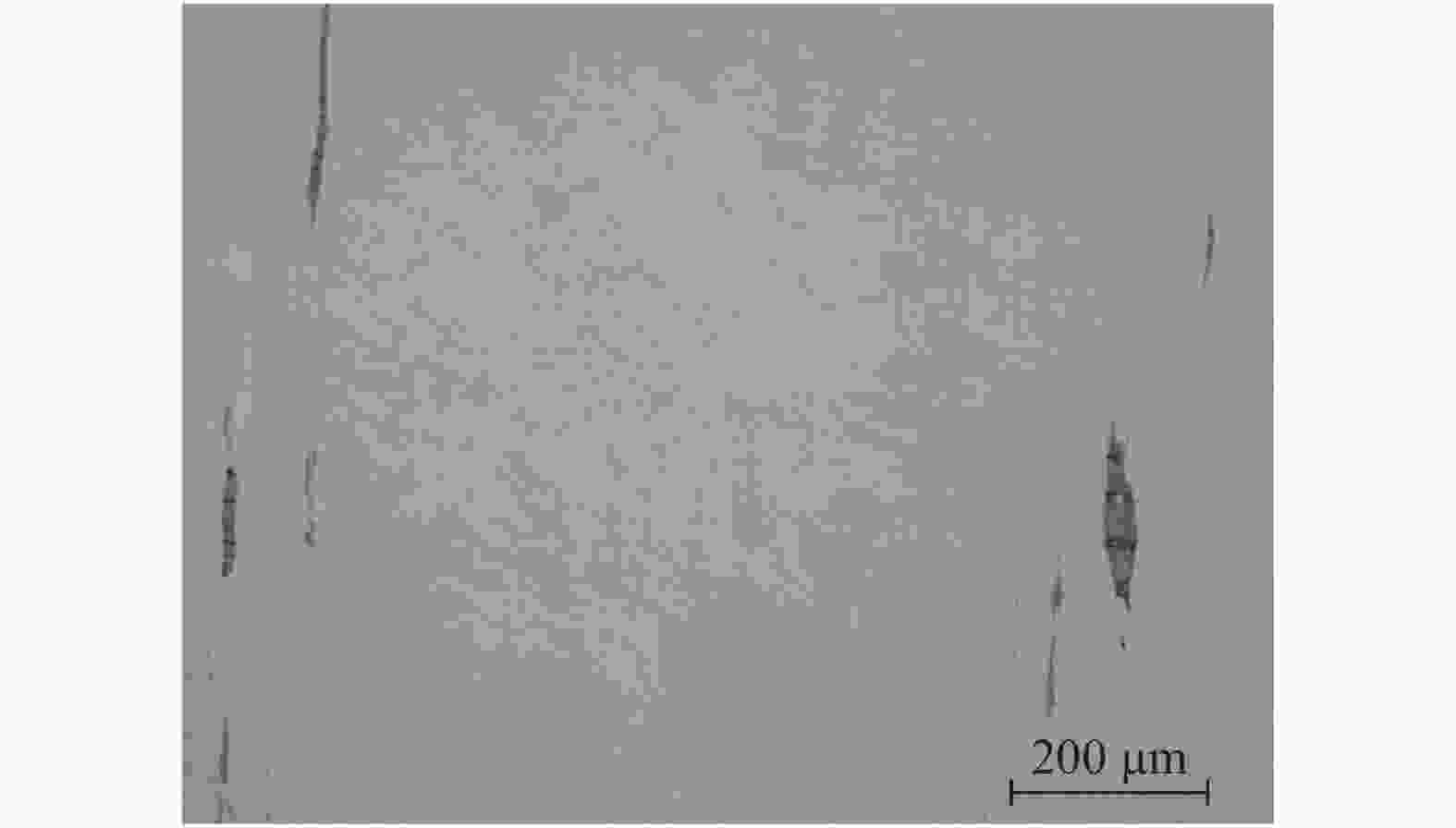

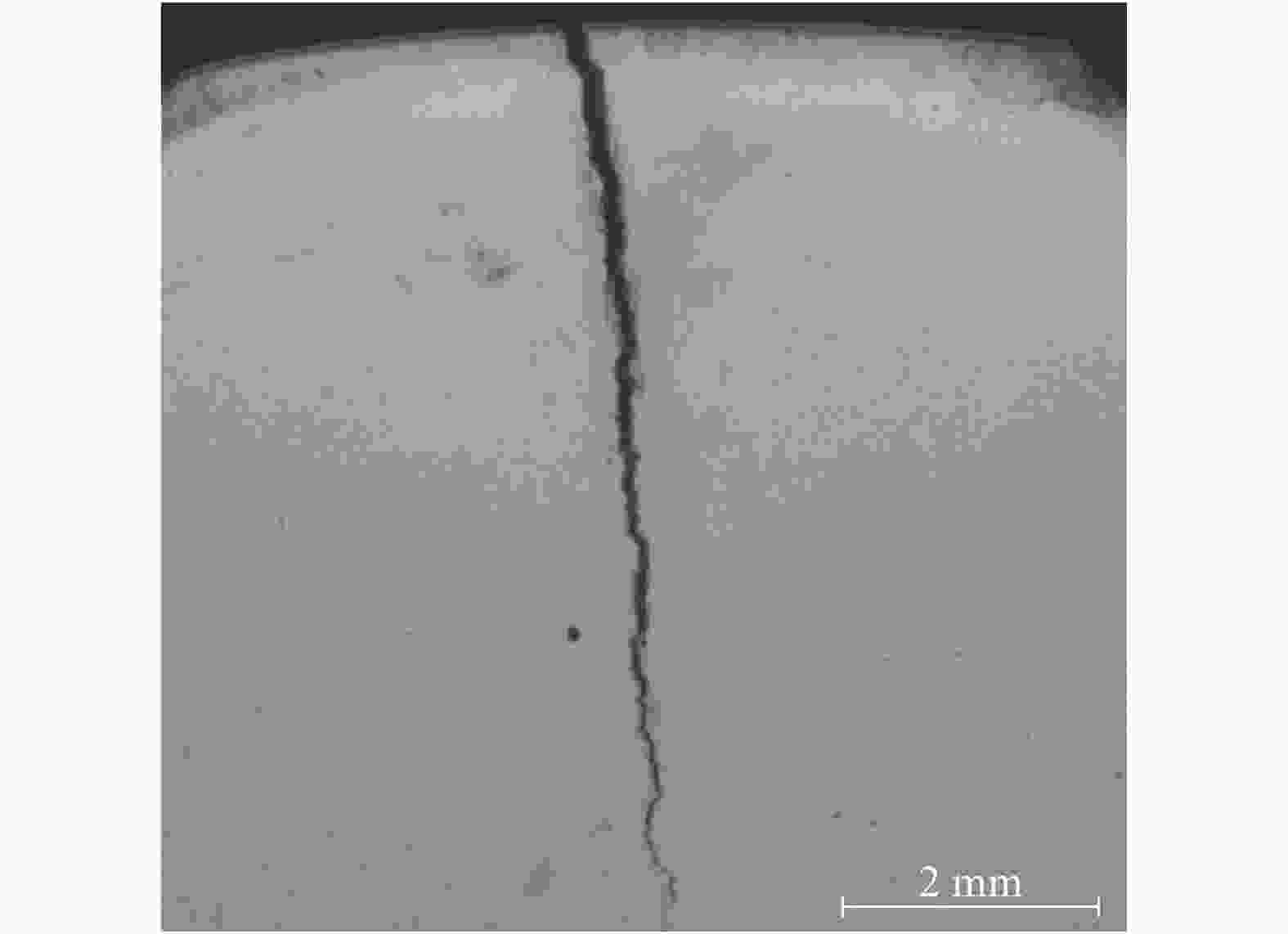

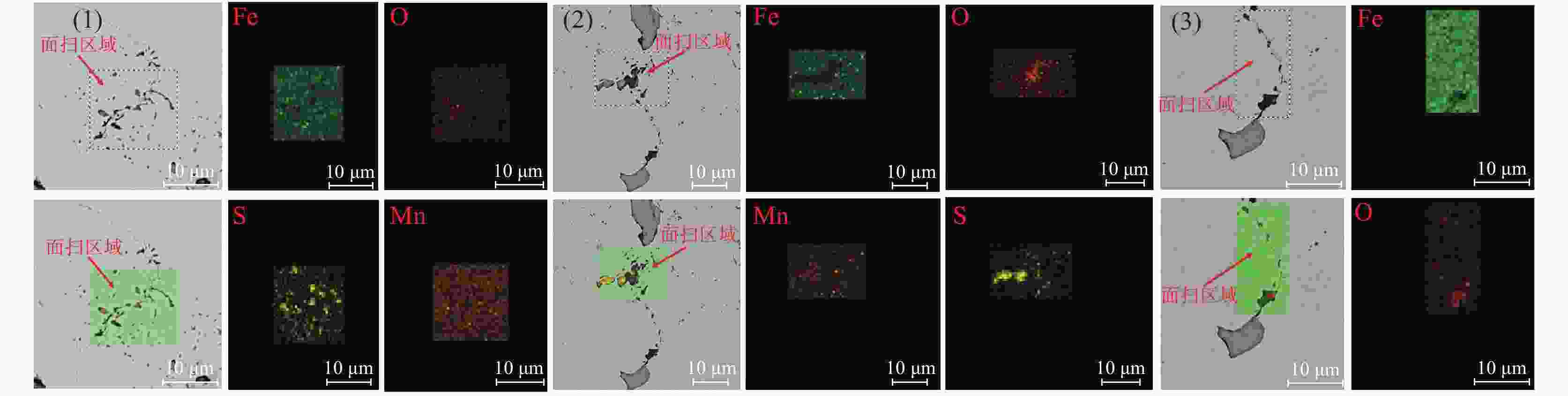

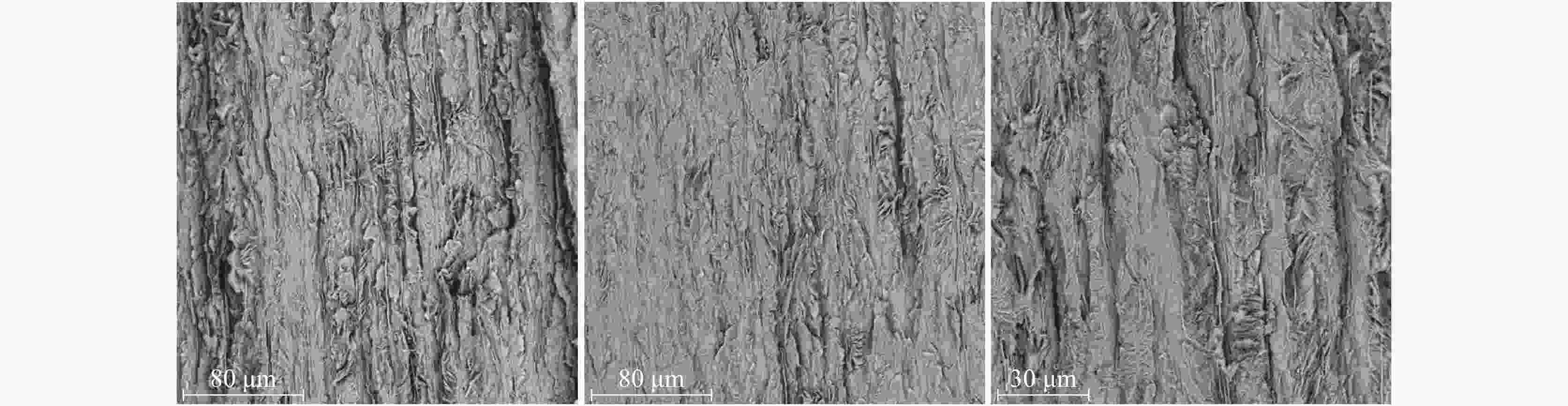

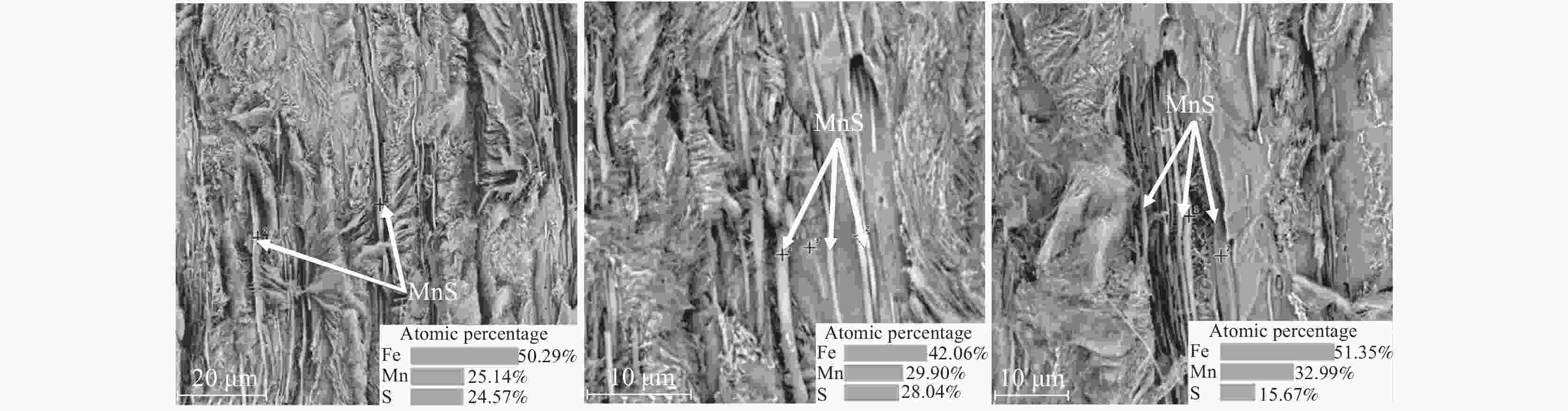

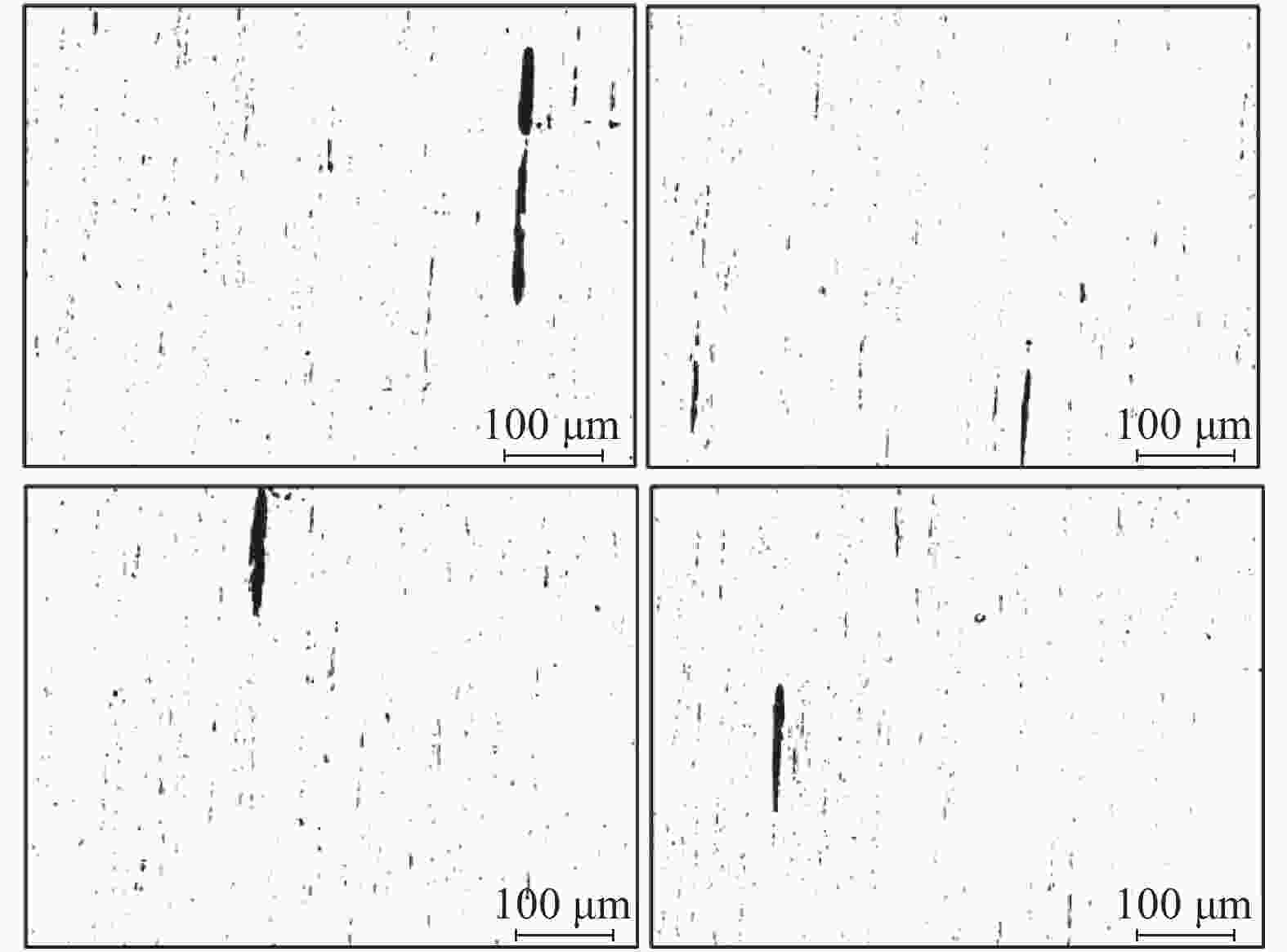

摘要: 采用光学显微镜、小样电解、扫描电镜及能谱、ImageJ软件等分析检测方法,对SAE1144易切削钢由18 mm圆棒冷拉拔至15 mm八角棒过程中产生表面裂纹的区域进行研究。结果表明:八角棒裂纹扩展区有大颗粒状MnS夹杂、细长条形团簇状MnS夹杂以及大块的FeO夹杂,开裂面有大量密集的细长条状MnS;而大块的FeO夹杂是裂纹产生的微裂纹源,大颗粒状MnS夹杂、细长条形团簇状MnS夹杂是裂纹扩展的主要原因。Abstract: The surface crack area of SAE1144 free cutting steel during cold drawing from 18 mm round bar to 15 mm octagonal bar was studied by means of optical microscope, sample electrolysis, SEM+EDS and ImageJ software. The results show that there exist large granular MnS inclusions, elongated strip cluster MnS inclusions and massive FeO inclusions in the crack propagation zone of octagonal bar, and lots of dense elongated strip MnS present on the crack surface. The large FeO inclusions are the source of microcracks, and the large granular MnS inclusions and elongated strip cluster MnS inclusions are the main causes of crack propagation.

-

Key words:

- SAE1144 /

- free-cutting steel /

- octagonal bar /

- surface crack /

- manganese sulfide

-

表 1 SAE1144的化学成分

Table 1. Chemical compositions of SAE1144

% C Si Mn P S 内控上限 0.47 0.25 1.52 <0.025 0.300 内控下限 0.43 0.18 1.45 0.240 目标 0.45 0.22 1.47 ≤0.024 0.270 实测 0.46 0.23 1.47 0.023 0.256 表 2 图6中观察面1的能谱分析结果(原子分数)

Table 2. EDS analysis results of observation surface 1 in Fig. 6(atomic fraction)

% No. Mn S Fe O (1) 3.24 1.62 85.59 9.56 (2) 4.60 2.92 82.47 10.01 (3) 88.26 11.74 -

[1] Hu Juan, Liu Chunlin, Zhang Zhiming, et al. Quality analysis and process improvement of free cutting steel 1215MS products[J]. Southern Metals, 2018,(3):15−18. (胡娟, 刘春林, 张志明, 等. 1215MS易切削钢产品质量分析及工艺改进[J]. 南方金属, 2018,(3):15−18. doi: 10.3969/j.issn.1009-9700.2018.03.005 [2] Zheng Lu. Free-cutting steel and its application[J]. Metal World, 1996,(2):7. (郑鲁. 易切削钢及其应用[J]. 金属世界, 1996,(2):7. [3] Wang Wei, Zhao Sixin, Gao Jiaqiang. Hole analysis of Y15 free-cutting steel and its precautions[J]. Physics Examination and Testing, 2021,39(2):50−55. (王维, 赵四新, 高加强. Y15易切削钢孔洞分析及其预防[J]. 物理测试, 2021,39(2):50−55. [4] Zhang Panpan, Hu Shaohui, Ai Kenan, et al. Comparison of sulfide in 1215MS steel bars[J]. Shanghai Metals, 2021,43(2):92−98. (张盼盼, 胡绍晖, 艾克南, 等. 1215MS钢棒材中硫化物对比分析[J]. 上海金属, 2021,43(2):92−98. doi: 10.3969/j.issn.1001-7208.2021.02.015 [5] Martinez Krahmer D, Urbicain G, Sánchez Egea A J. Dry machinability analyses between free cutting resulfurized, and carbon steels[J]. Materials and Manufacturing Processes, 2020,35(4):460−468. doi: 10.1080/10426914.2020.1734615 [6] Tian Qi, Zhuang Ying, Wang Huimian, et al. Analysis of blowhole defects in Y12Cr13 free-cutting stainless steel and process improvement measures[J]. Physics Examination and Testing, 2020,38(5):18−22. (田奇, 庄迎, 王辉绵, 等. Y12Cr13易切削不锈钢气孔缺陷分析及工艺改进措施[J]. 物理测试, 2020,38(5):18−22. [7] Wang Gaofeng, Li Chengliang, Zhang Zhiming, et al. Analysis on structure and sulfide in 1215MS free-cutting steel[J]. Special Steel, 2020,41(4):64−67. (王高峰, 李成良, 张志明, 等. 1215MS易切削钢中组织与硫化物分析[J]. 特殊钢, 2020,41(4):64−67. doi: 10.3969/j.issn.1003-8620.2020.04.016 [8] Ryabov A V. Comparative characteristics of free-machining steels of Cr-Mo type[J]. Solid State Phenomena, 2020,4857:670−675. [9] Cao Chenwei, Zhang Panpan, Hu Shaohui, et al. Structure and sulfide comparative analysis of sulfide, tellurium and lead free-cutting fteels[J]. Metallurgical Analysis, 2020,40(7):8−15. (曹晨巍, 张盼盼, 胡绍晖, 等. 硫系、碲系、铅系易切削钢组织及硫化物对比分析[J]. 冶金分析, 2020,40(7):8−15. [10] Cui Jinzhong, Gao Tianzuo. Analysis on forming reasons and improvement measures of crack defects on bars[J]. Iron Steel Vanadium Titanium, 2016,37(3):158−162. (崔进忠, 高天佐. 棒材裂纹缺陷成因分析及整改措施研究[J]. 钢铁钒钛, 2016,37(3):158−162. [11] Sung Kug Hwang, Shi Hyoung Ryu. Development of BN added free-machining steel based on AISI P20[J]. Journal of the Korean Society for Precision Engineering, 2020,37(3):175−180. doi: 10.7736/JKSPE.019.127 [12] Ai Kenan, Zhang Panpan, Zhao Menghao, et al. Analysis of formation mechanism of surface crack of 1215 free-cutting steel during drawing[J]. Iron and Steel, 2020,55(2):88−94. (艾克南, 张盼盼, 赵梦豪, 等. 1215易切削钢拉拔表面裂纹形成机制分析[J]. 钢铁, 2020,55(2):88−94. [13] Liu Chunlin, Zhou Nan, Lei Zhongyu, et al. Analysis of pinhole defects on surface of products made from 1215MS steel and relevant improvement measures[J]. Metal Materials and Metallurgy Engineering, 2017,45(Z1):37−42. (刘春林, 周楠, 雷中钰, 等. 1215MS加工成品表面针孔缺陷分析及改进措施[J]. 金属材料与冶金工程, 2017,45(Z1):37−42. [14] Cao Lei, Wang Guolian, Huang Weiqing, et al. Effect of selective crystallization on slab surface crack during continuous casting of peritectic steel[J]. Steelmaking, 2021,37(3):58−61. (曹磊, 王国连, 黄伟青, 等. 选分结晶对包晶钢连铸坯表面裂纹的影响[J]. 炼钢, 2021,37(3):58−61. [15] Wu Liangping, Sun Han, Xie Jianbo, et al. Analysis on split-head cracking of Y1Cr13 stainless rolled bar[J]. Iron Steel Vanadium Titanium, 2021,42(1):176−183. (吴良平, 孙晗, 谢剑波, 等. Y1Cr13不锈钢轧材劈头开裂原因分析[J]. 钢铁钒钛, 2021,42(1):176−183. [16] Ashby M F. Work hardening of dispersion-hardened crystals[J]. Philosophical Magazine, 1966,14(132):1157−1178. doi: 10.1080/14786436608224282 [17] Lin Tengchang, Zhu Rong, Yao LiuJie, et al. Influence of temperature, oxygen, and Bi on the morphology of MnS in free-cutting steel[J]. Chinese Journal of Engineering, 2018,40(S1):36−40. (林腾昌, 朱荣, 姚柳洁, 等. 氧含量、温度与铋对易切削钢中MnS形貌的影响[J]. 工程科学学报, 2018,40(S1):36−40. -

下载:

下载: